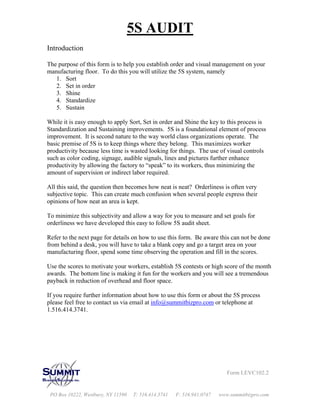

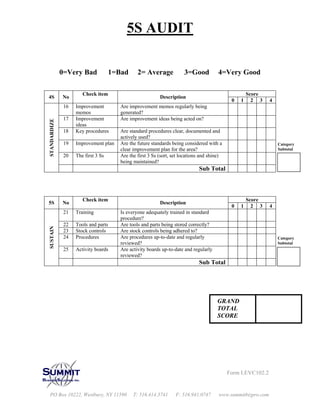

The document describes a 5S audit form that organizations can use to establish order and visual management on their manufacturing floors using the 5S methodology. The 5S methodology involves five steps: Sort, Set in Order, Shine, Standardize, and Sustain. The audit form provides a systematic way to score target areas on their implementation of each 5S step on a scale of 0 to 4. By completing the audit, organizations can identify areas for improvement, establish goals, and motivate workers to fully implement 5S practices to maximize productivity and efficiency.