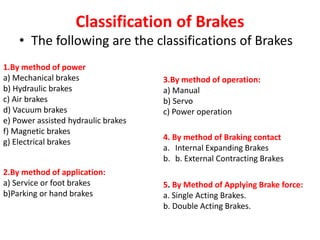

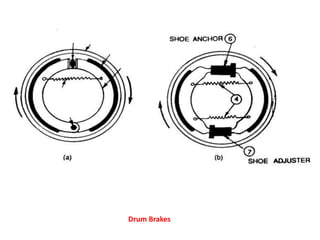

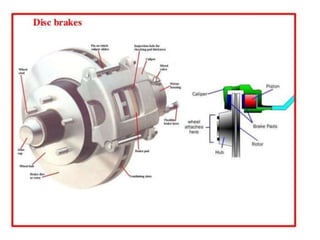

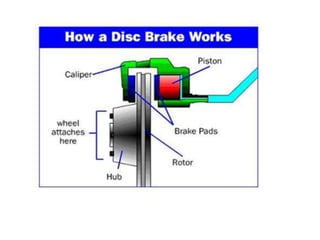

This document discusses different classifications and components of braking systems. It describes drum brakes, disc brakes, hydraulic braking systems, and their main components like the master cylinder, wheel cylinder, and tandem master cylinder. Drum brakes use shoes that contact a rotating drum to brake, while disc brakes use pads that squeeze a disc mounted to the wheel. Hydraulic systems use fluid pressure transferred through lines from the master cylinder to wheel cylinders to force brake shoes or pads against the drums or discs.