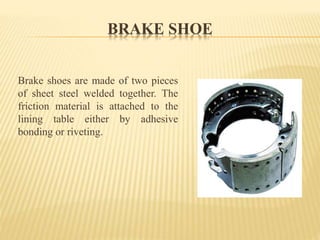

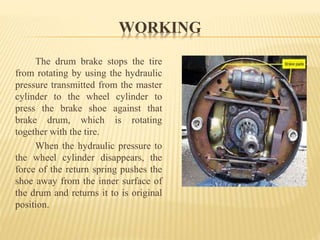

This document provides an overview of drum brakes. It discusses the history and invention of drum brakes in 1902 by Louis Renault. It describes the main components of drum brakes, including the back plate, brake drum, wheel cylinder, brake shoes, and return springs. It explains how drum brakes work by using hydraulic pressure from the master cylinder to push the brake shoes against the rotating brake drum, creating friction to slow the wheel. The document notes advantages like simpler construction but also disadvantages such as longer braking distances when wet. It concludes by discussing applications in trucks and cars.