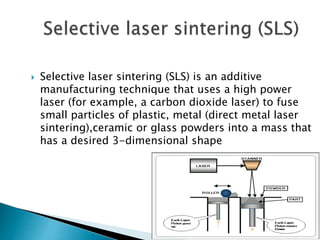

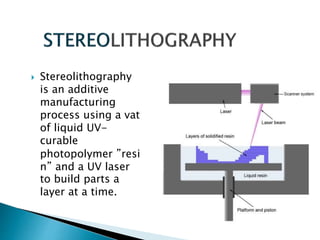

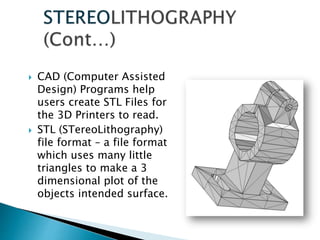

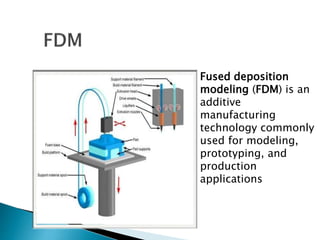

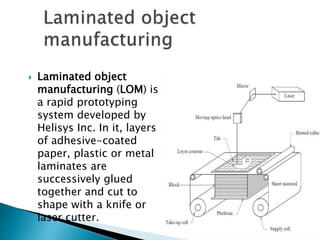

The document discusses 3D printing and additive manufacturing. It defines 3D printing as a process that uses additive manufacturing to create 3D objects from a digital file by laying down successive layers of material. The document outlines several 3D printing methods like selective laser sintering, stereolithography, and fused deposition modeling. It also discusses applications of 3D printing like prototyping and challenges like intellectual property issues.