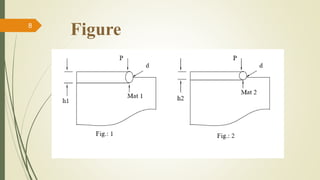

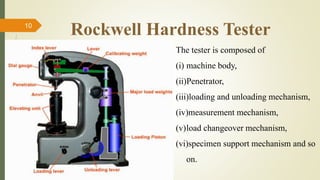

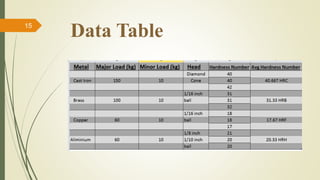

The document is a presentation on the Rockwell hardness test, detailing its objectives, apparatus, theory, and results obtained from testing various metal specimens including cast iron, brass, copper, and aluminum. It explains the working principle of the Rockwell hardness tester and outlines the average hardness numbers for the tested materials, along with discussions on limitations and potential errors in the testing process. The conclusion emphasizes the use of the Rockwell hardness scale for material selection in engineering applications.