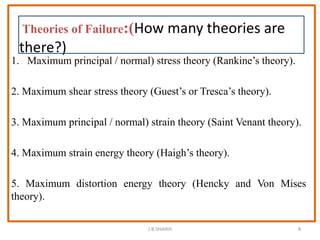

1. There are five main theories of failure used to predict failure of machine components under multi-axial stresses: Rankine, Tresca, Saint Venant, Haigh, and Hencky-Von Mises.

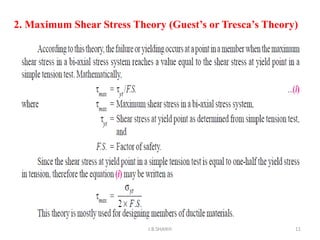

2. Theories of failure are required because material strengths are determined from uni-axial tests, while actual components experience multi-axial stresses, and the theories relate uni-axial strengths to multi-axial stresses.

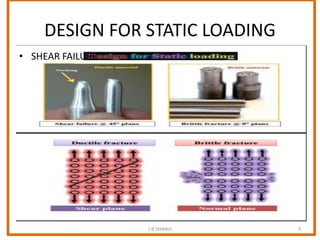

3. Rankine's theory applies to brittle materials and ductile materials under uniaxial or similar biaxial stresses, while Tresca's theory applies to ductile materials prone to shear failure.