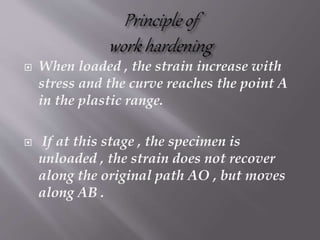

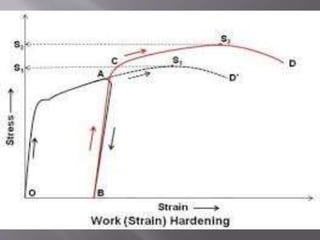

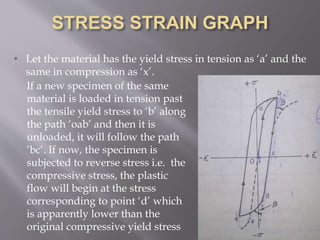

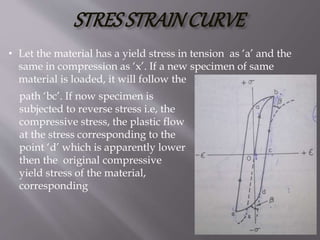

This presentation summarizes work hardening and the Bauschinger effect. Work hardening is the strengthening of metals through plastic deformation, which occurs due to dislocation movement and generation within the material. It increases strength and hardness but reduces ductility. The Bauschinger effect describes how plastic deformation in one direction increases yield strength in that direction but decreases it in the opposite direction. It is demonstrated through stress-strain curves, where yielding occurs at a lower stress level during reverse loading than the original yield stress. The effect is important for metal forming operations involving reversed stresses.