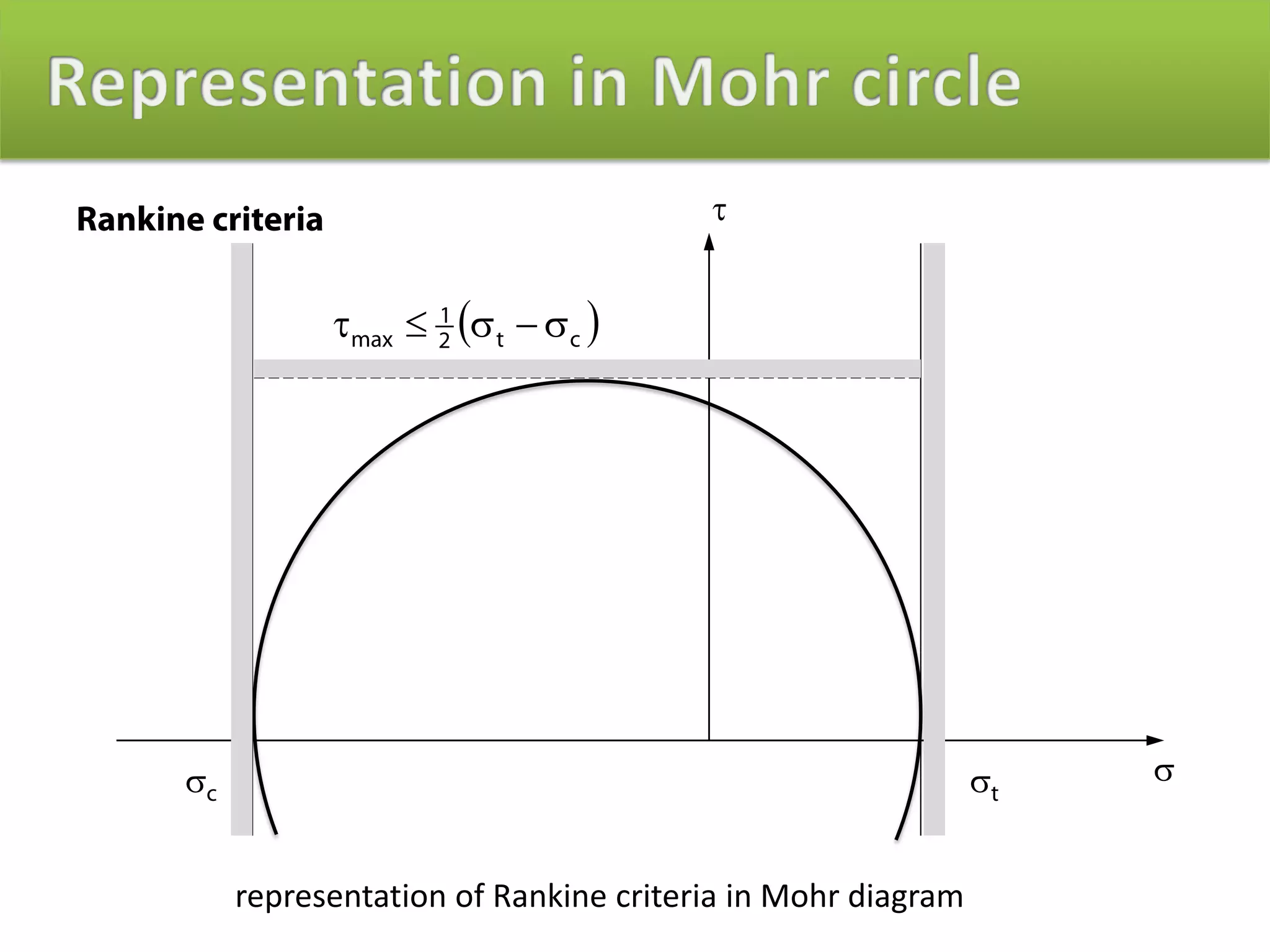

The document discusses different stress and failure criteria used to analyze materials. It describes the Tresca, Von Mises, and Rankine criteria, which use maximum shear stress, equivalent deviatoric strain energy, and limits on principal stresses respectively to determine failure. The Von Mises criterion applies best to isotropic ductile metals, while Tresca and Rankine criteria can also be used for such materials. Rankine is more suitable for low-cohesion materials like ceramics. The appropriate criterion depends on the material properties.