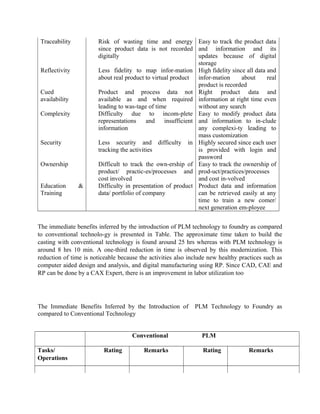

This document discusses the application of Product Lifecycle Management (PLM) strategies in a small foundry in India focused on improving efficiency in producing impeller castings. PLM tools were implemented to enhance collaboration, reduce lead times, and improve resource utilization, leading to a significant decrease in production time from approximately 25 hours to about 8 hours and 10 minutes. The study emphasizes the advantages of adopting PLM technology, such as improved quality, reduced errors, and better customer interactions, arguing for its essential role in modern manufacturing environments.