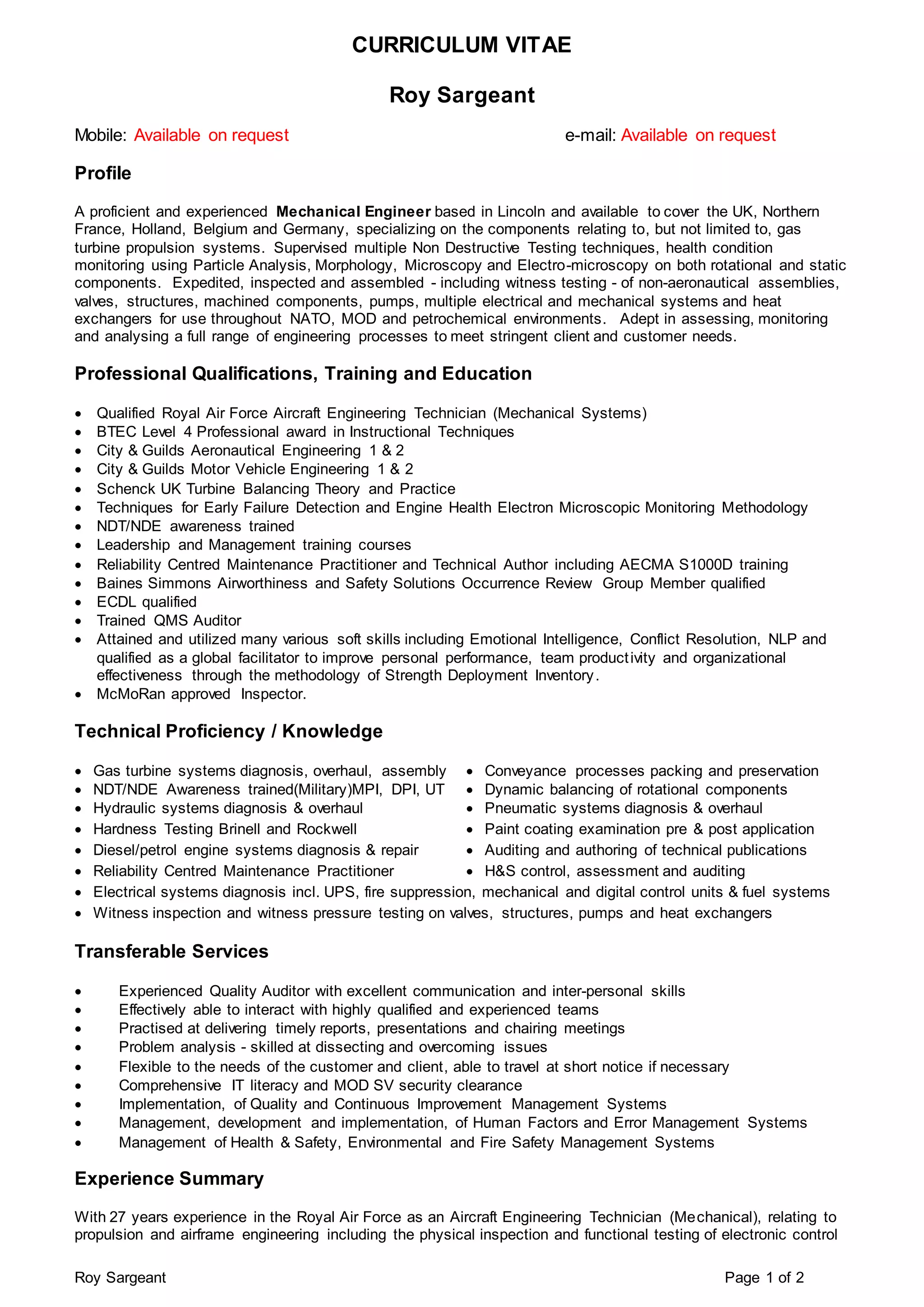

Roy Sargeant has over 27 years of experience as a mechanical engineer in the Royal Air Force and as a freelance inspector. He specializes in gas turbine propulsion systems and has expertise in non-destructive testing, component inspection, and engineering processes. Some of his qualifications include training in instructional techniques, aeronautical engineering, motor vehicle engineering, turbine balancing, electron microscopy, and auditing. He has comprehensive knowledge of systems like gas turbines, hydraulics, pneumatics, and diesels. Sargeant seeks to provide quality auditing, problem solving, and ensuring contractual obligations are met through effective communication and management skills.