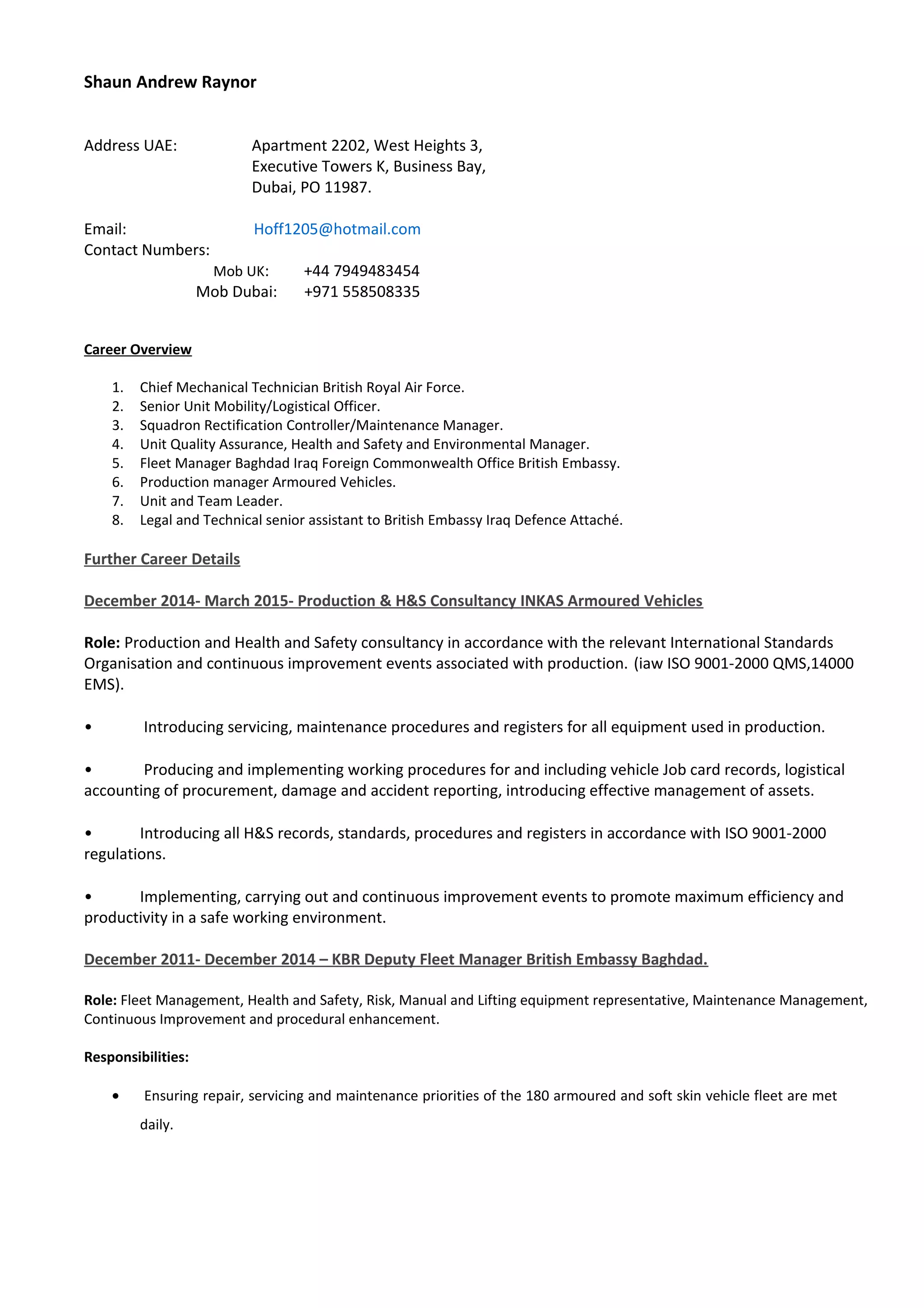

Shaun Raynor has over 30 years of experience in engineering, maintenance, and management roles in the British Royal Air Force and private sector. He has held positions such as Chief Mechanical Technician, Squadron Rectification Controller, Fleet Manager, Production Manager, and Legal Assistant. Raynor's expertise includes aircraft maintenance, quality assurance, health and safety, and project management. He holds qualifications in engineering, management, and safety.