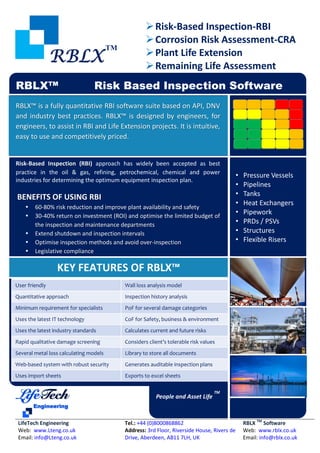

RBLXTM is a risk-based inspection software that helps engineers conduct risk-based inspection and life extension projects for assets like pressure vessels, pipelines, tanks, and heat exchangers. It uses quantitative models and industry standards to calculate current and future corrosion and other risks. The software generates customized inspection plans to reduce risks by 60-80% while optimizing budgets and inspection intervals. It provides features like wall loss analysis, inspection history review, and risk calculations for different damage categories.