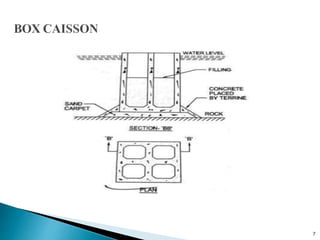

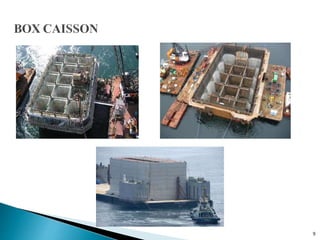

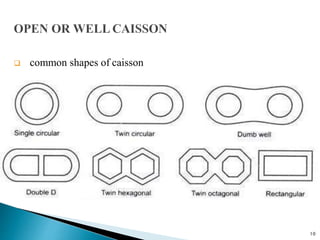

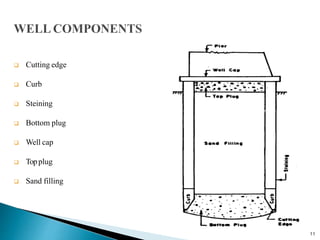

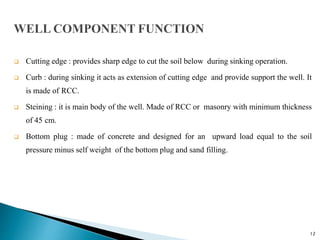

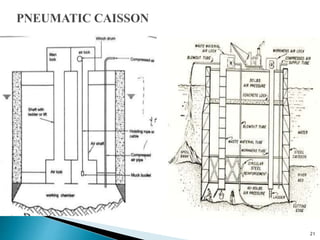

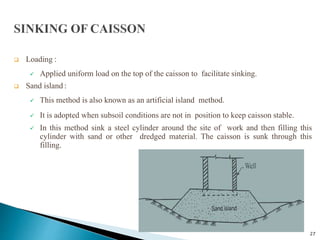

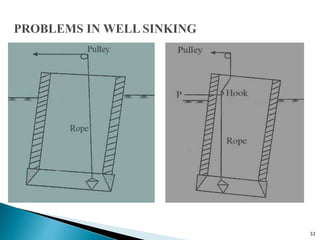

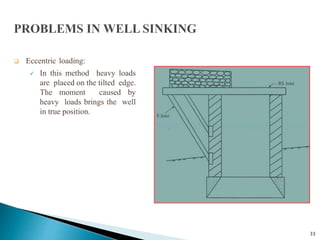

The document discusses caissons, which are large deep foundations used to transfer loads to hard strata, typically utilized for bridges and dams. It outlines different types of caissons, their construction methods, and challenges like sand blowing and tilting. Key construction techniques include pneumatic caissons for underwater applications, and the document emphasizes worker safety and prevention of caisson sickness during operations.