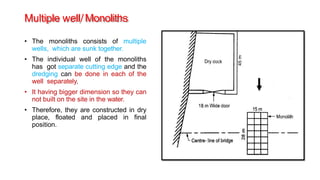

The document discusses caissons, which are watertight structures sunk into the ground or water to excavate foundations. There are several types, including box caissons (open top, closed bottom), open caissons (open top and bottom), and pneumatic caissons (closed top, open bottom). Materials used include steel, timber, concrete. Pneumatic caissons use compressed air to work in a dry environment underground. Challenges in sinking caissons include sand blowing, tilting, and shifting of wells. Precautions must be taken to avoid the bends disease from compressed air use.