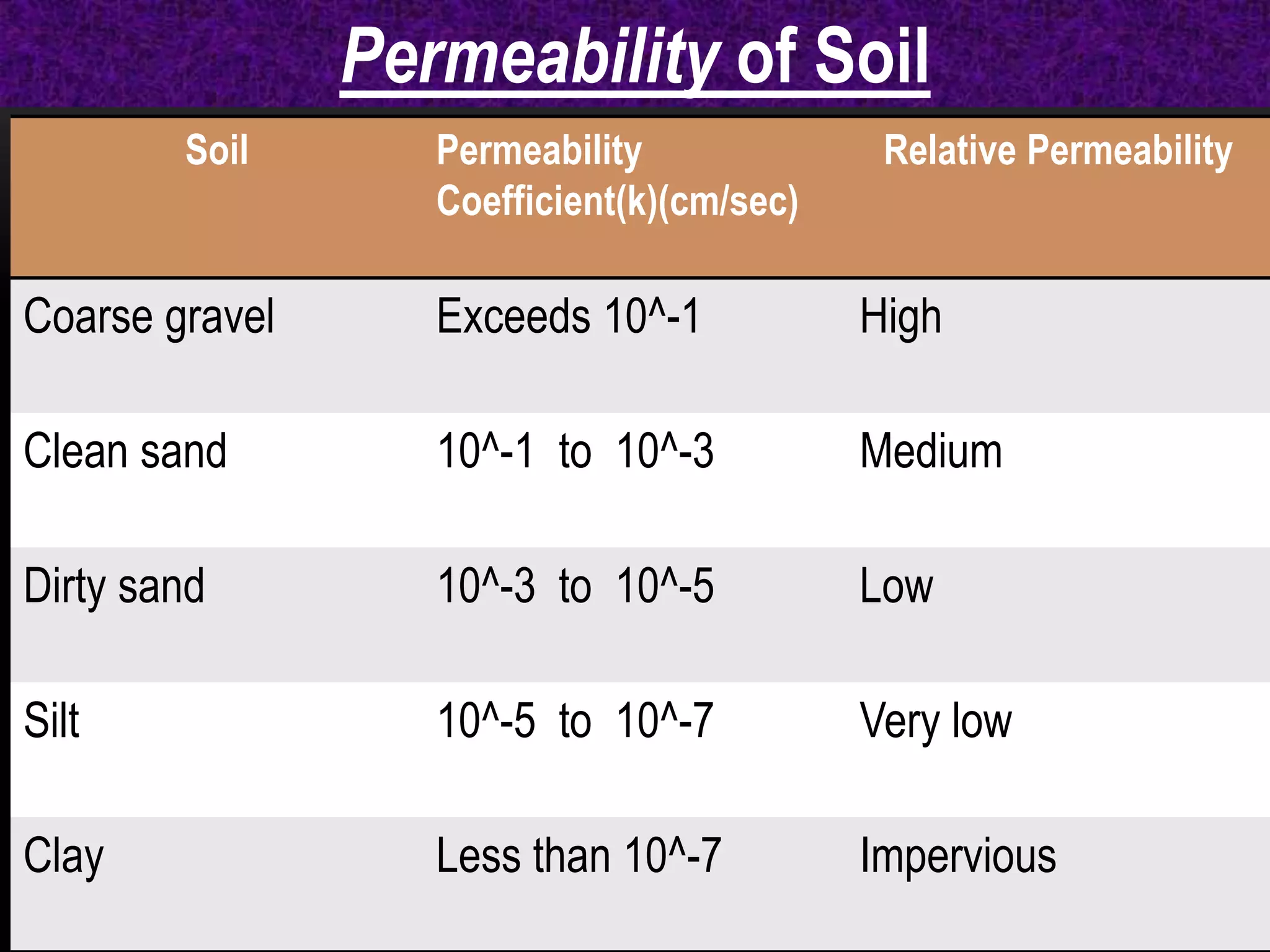

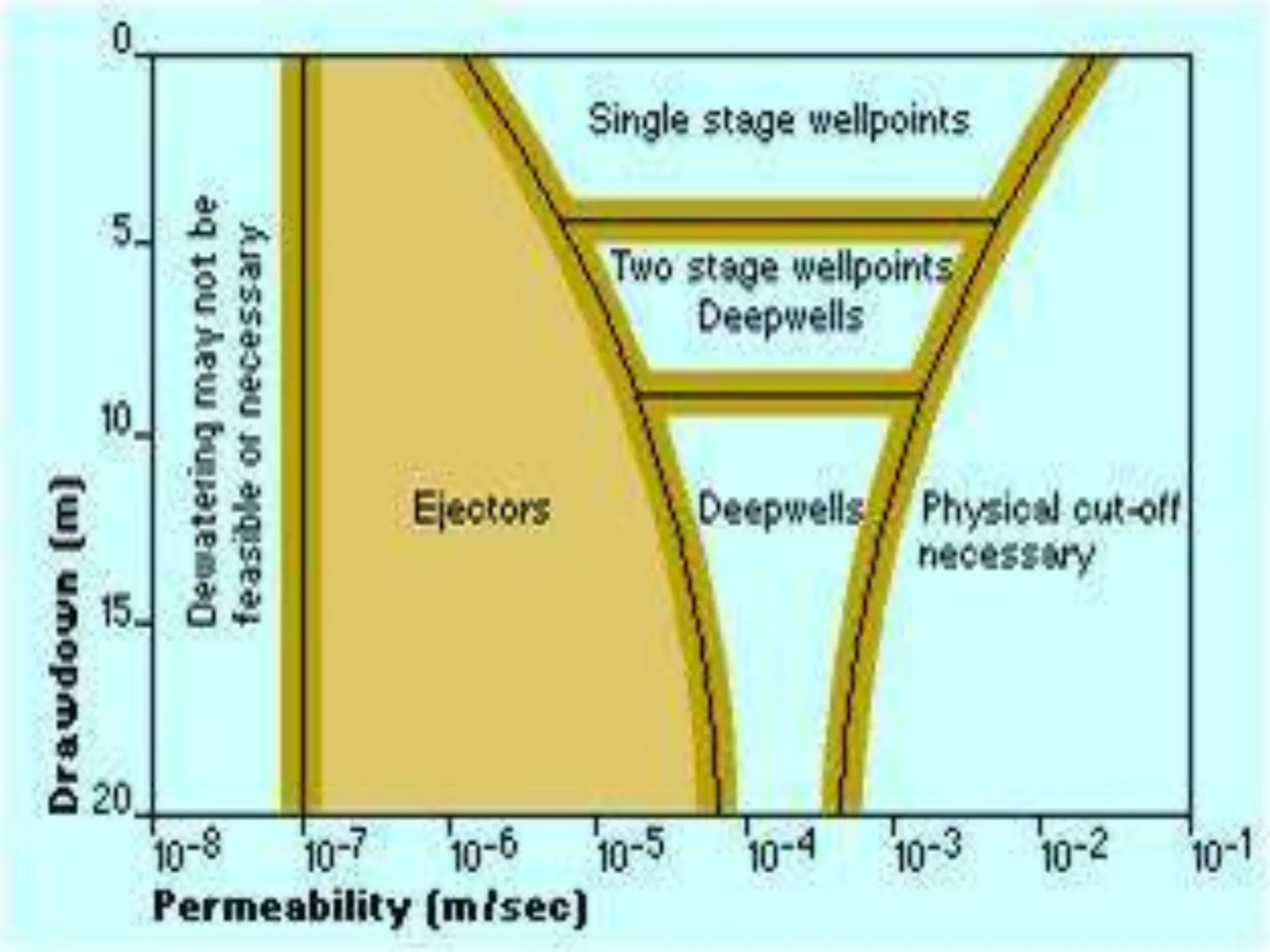

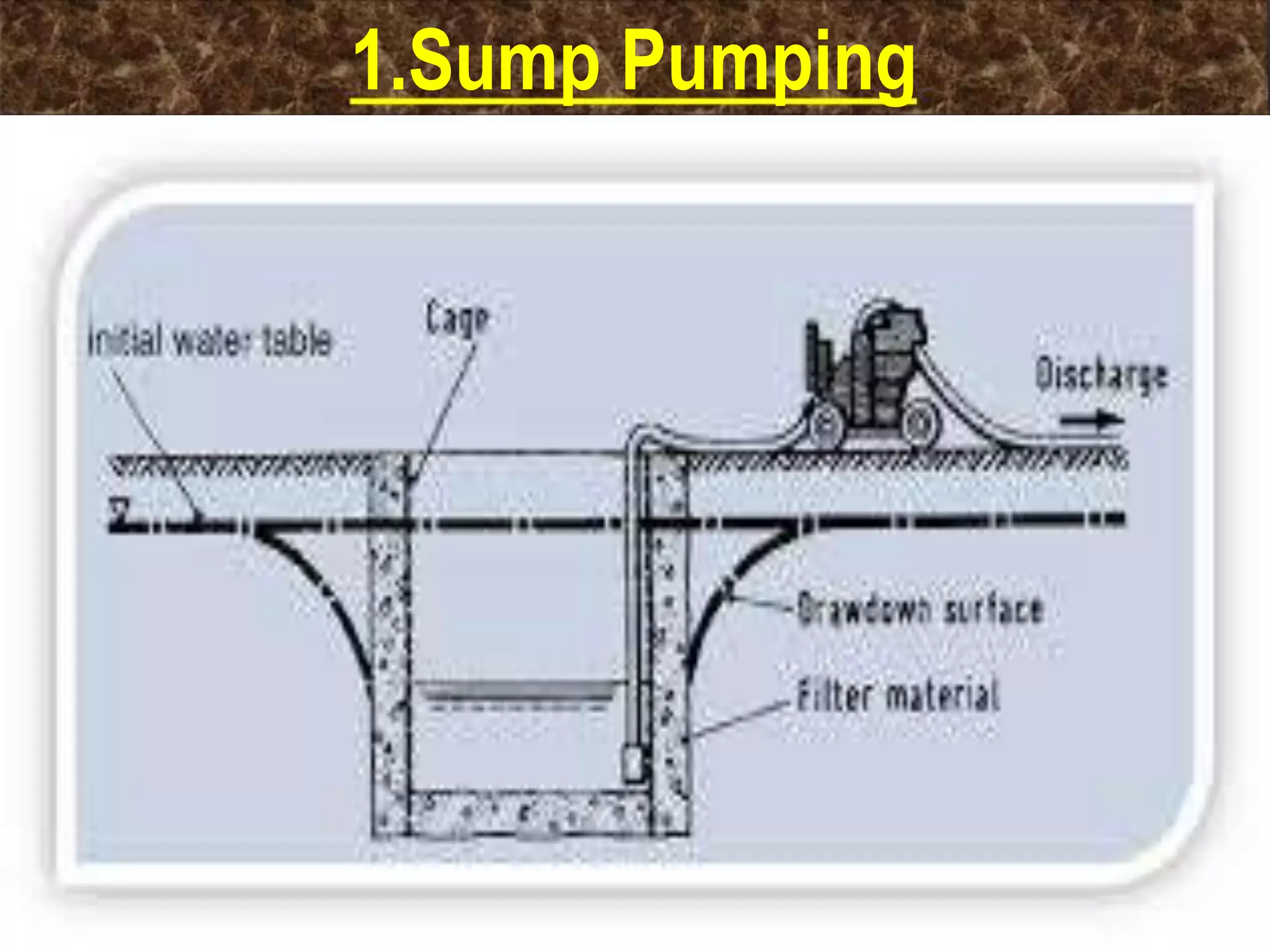

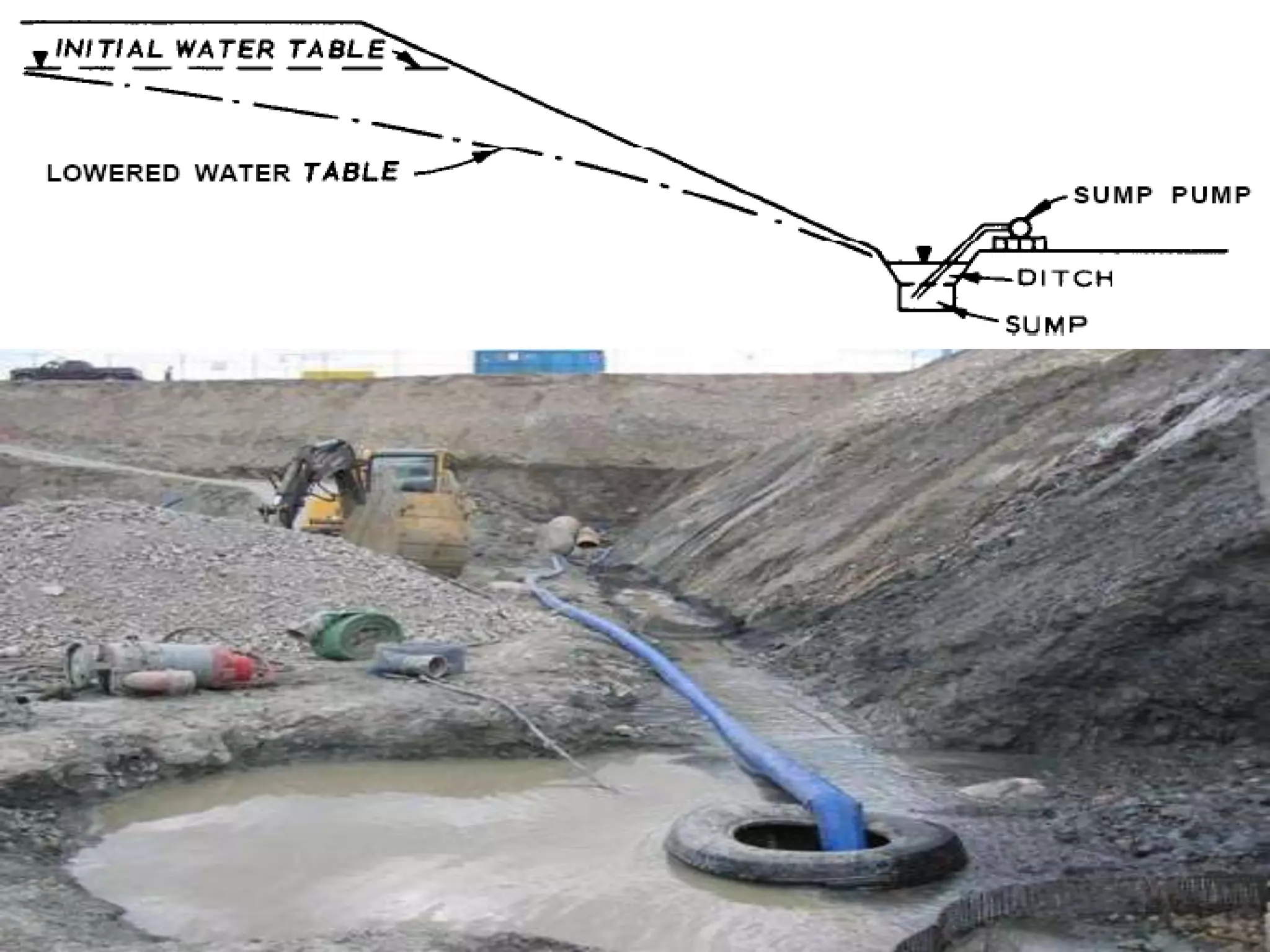

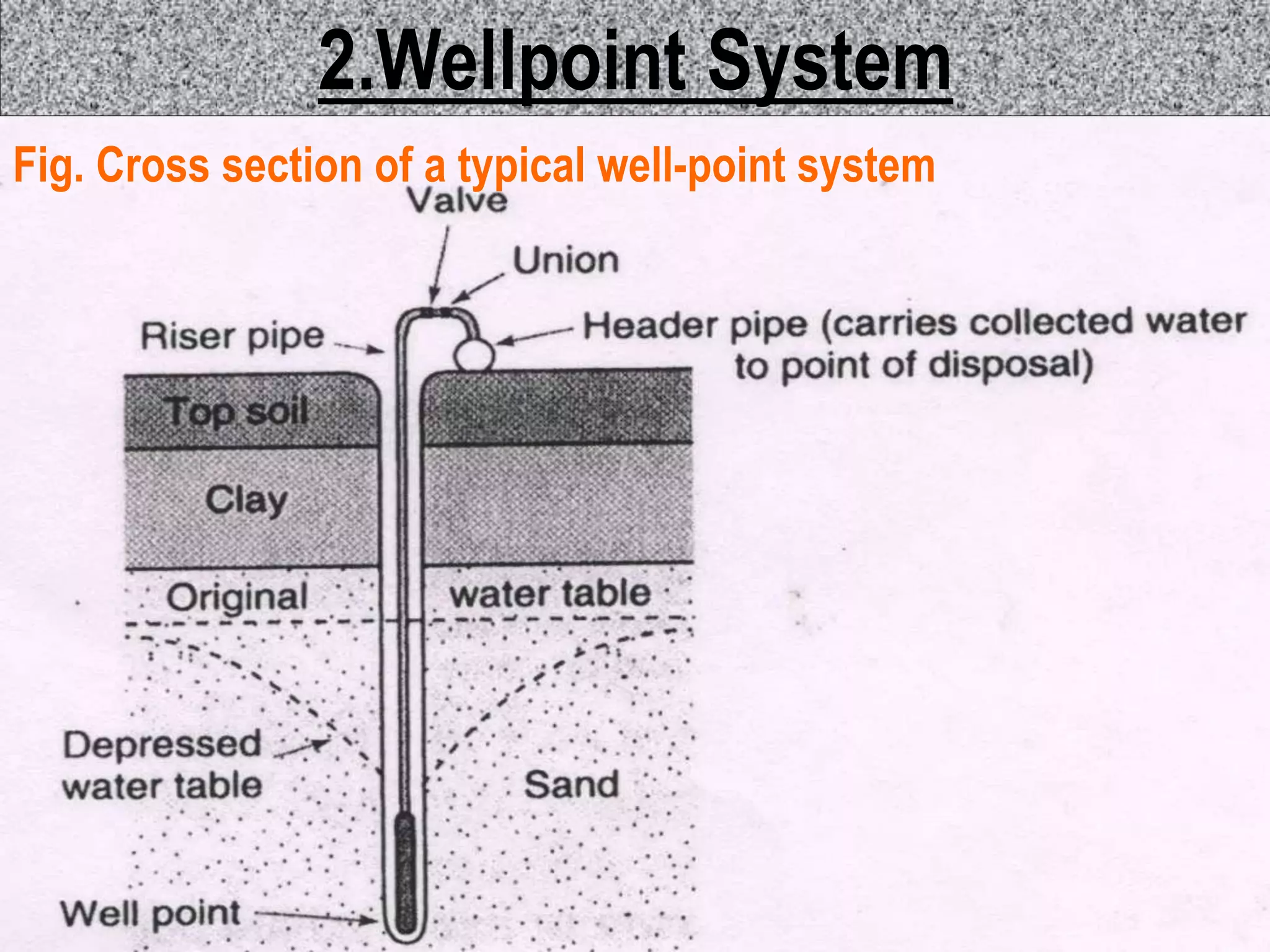

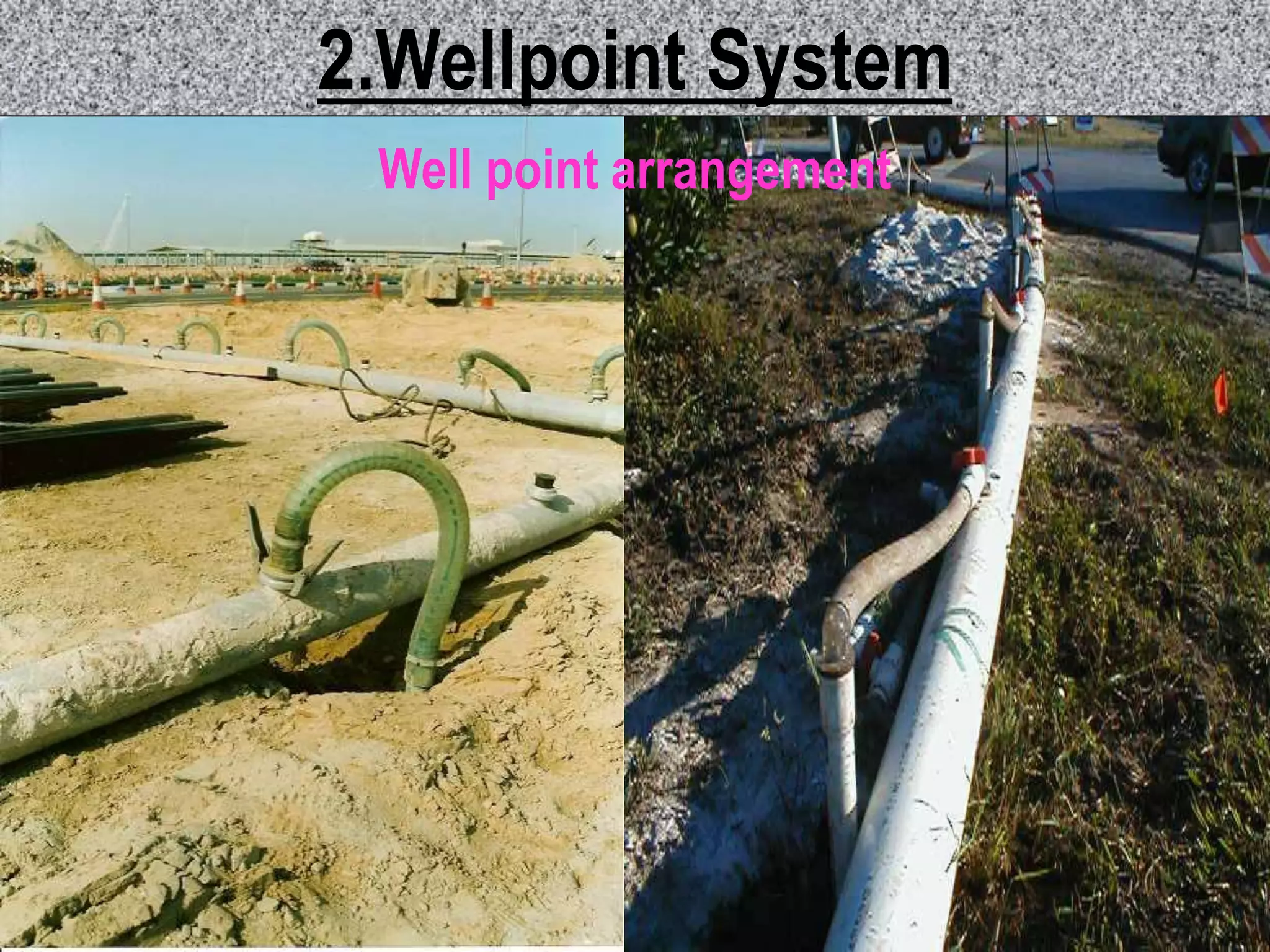

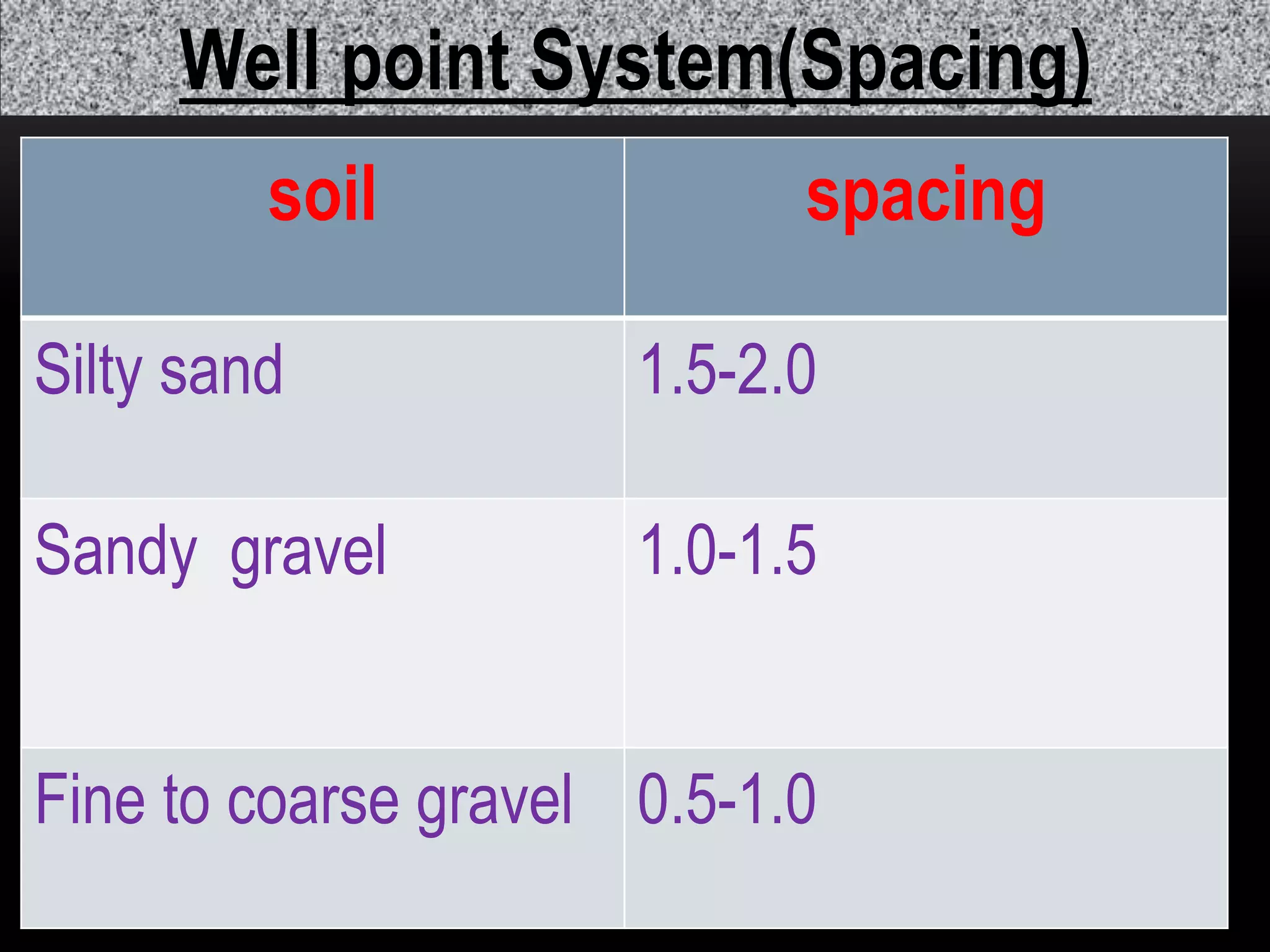

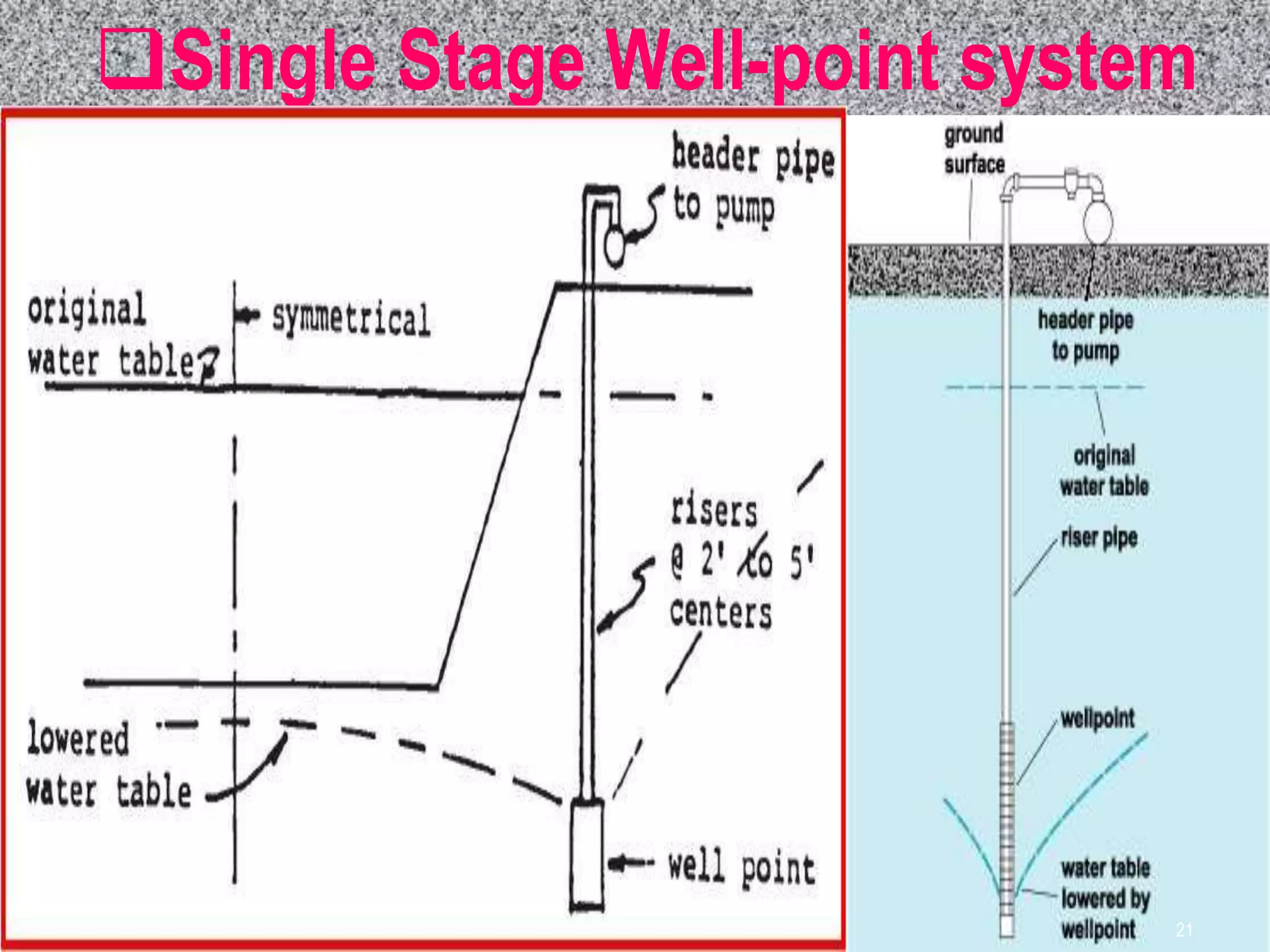

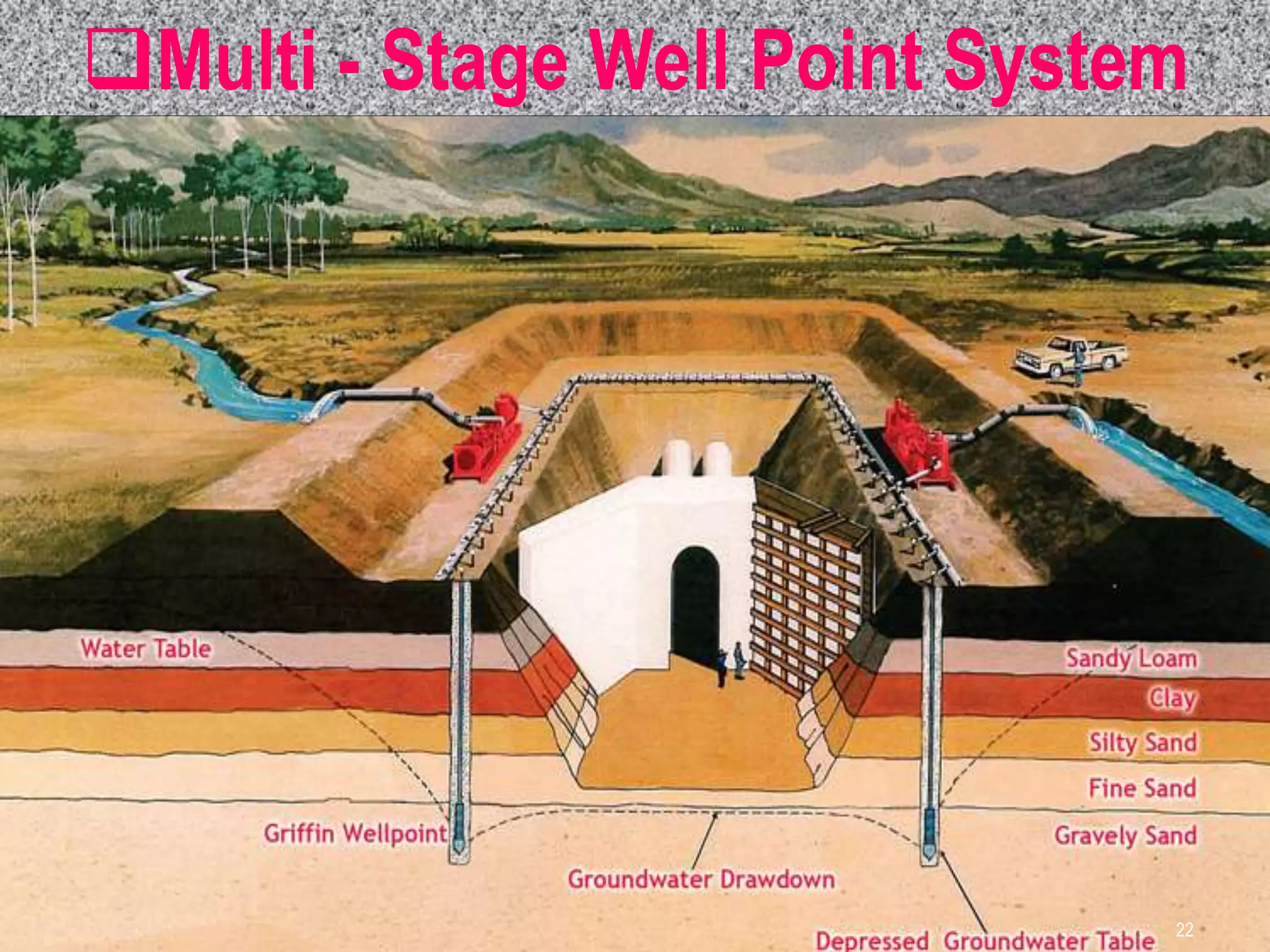

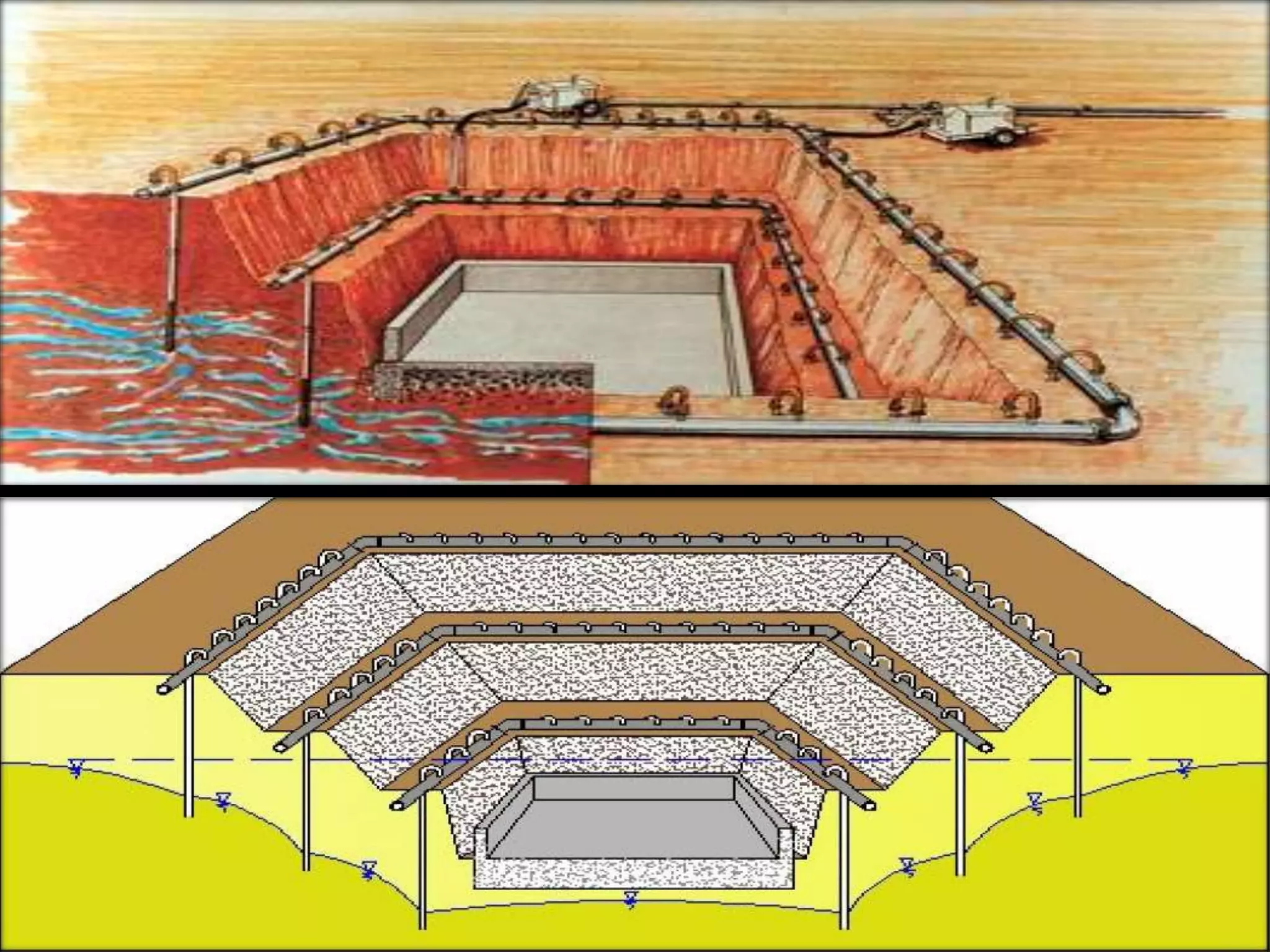

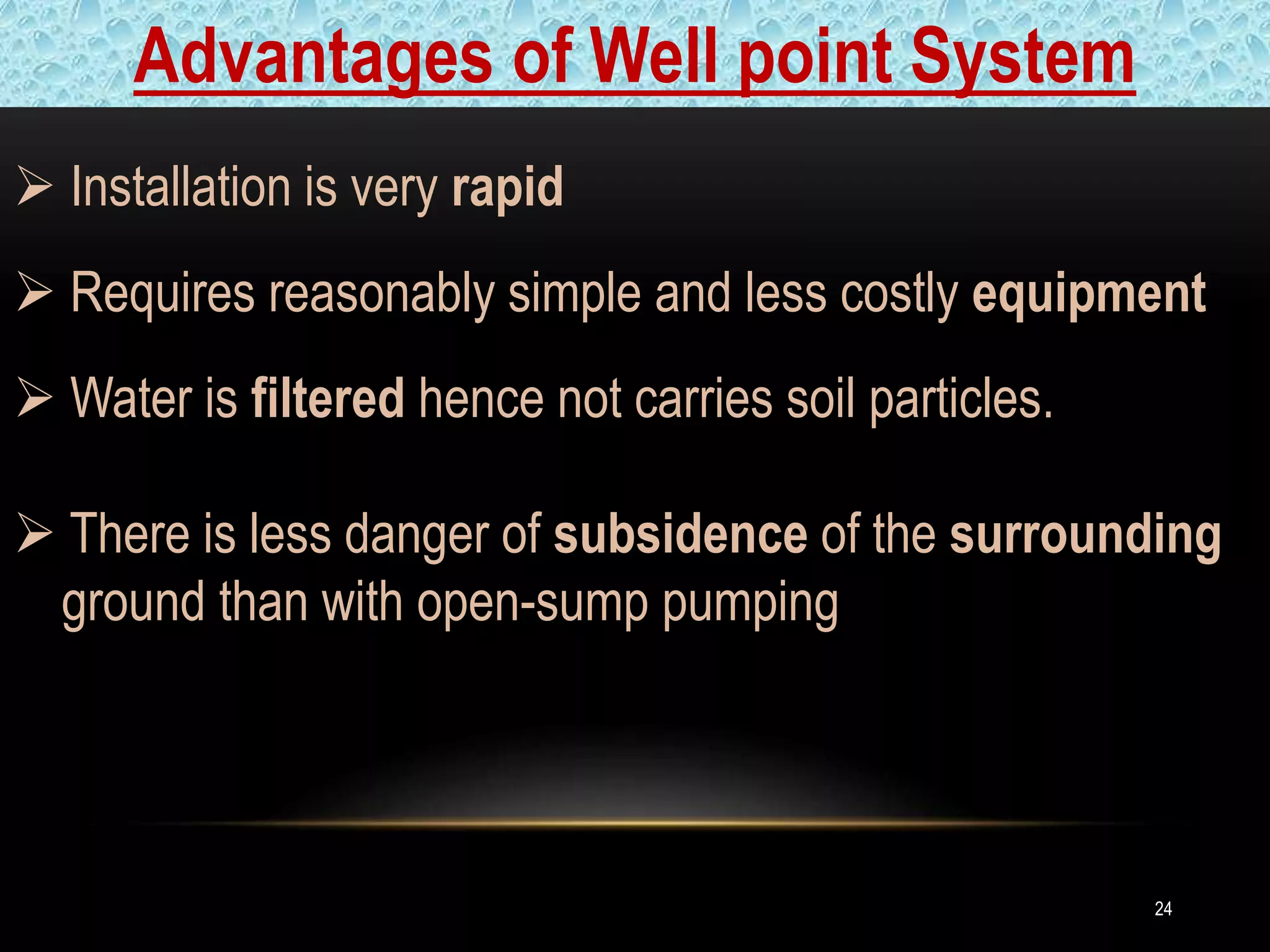

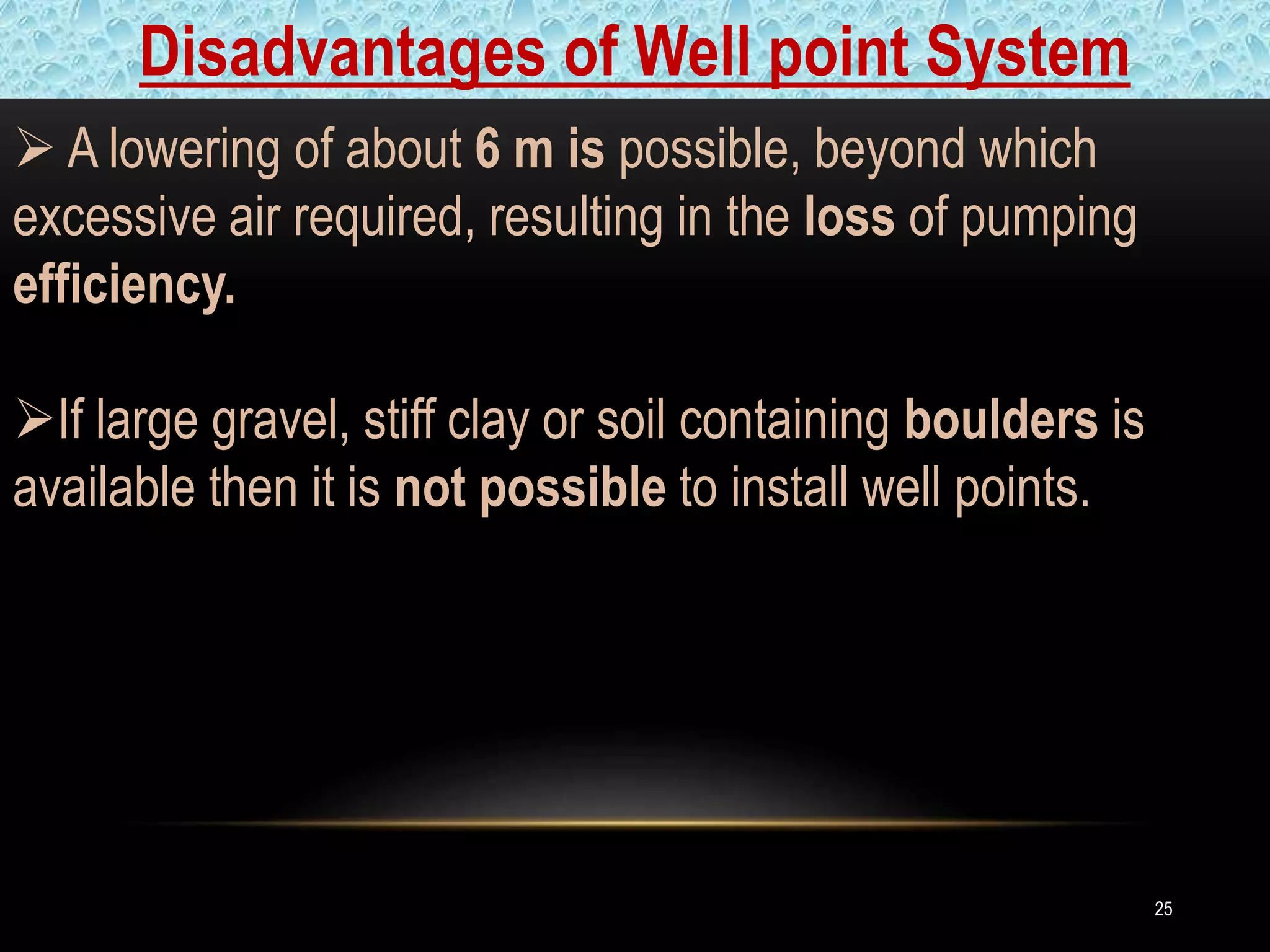

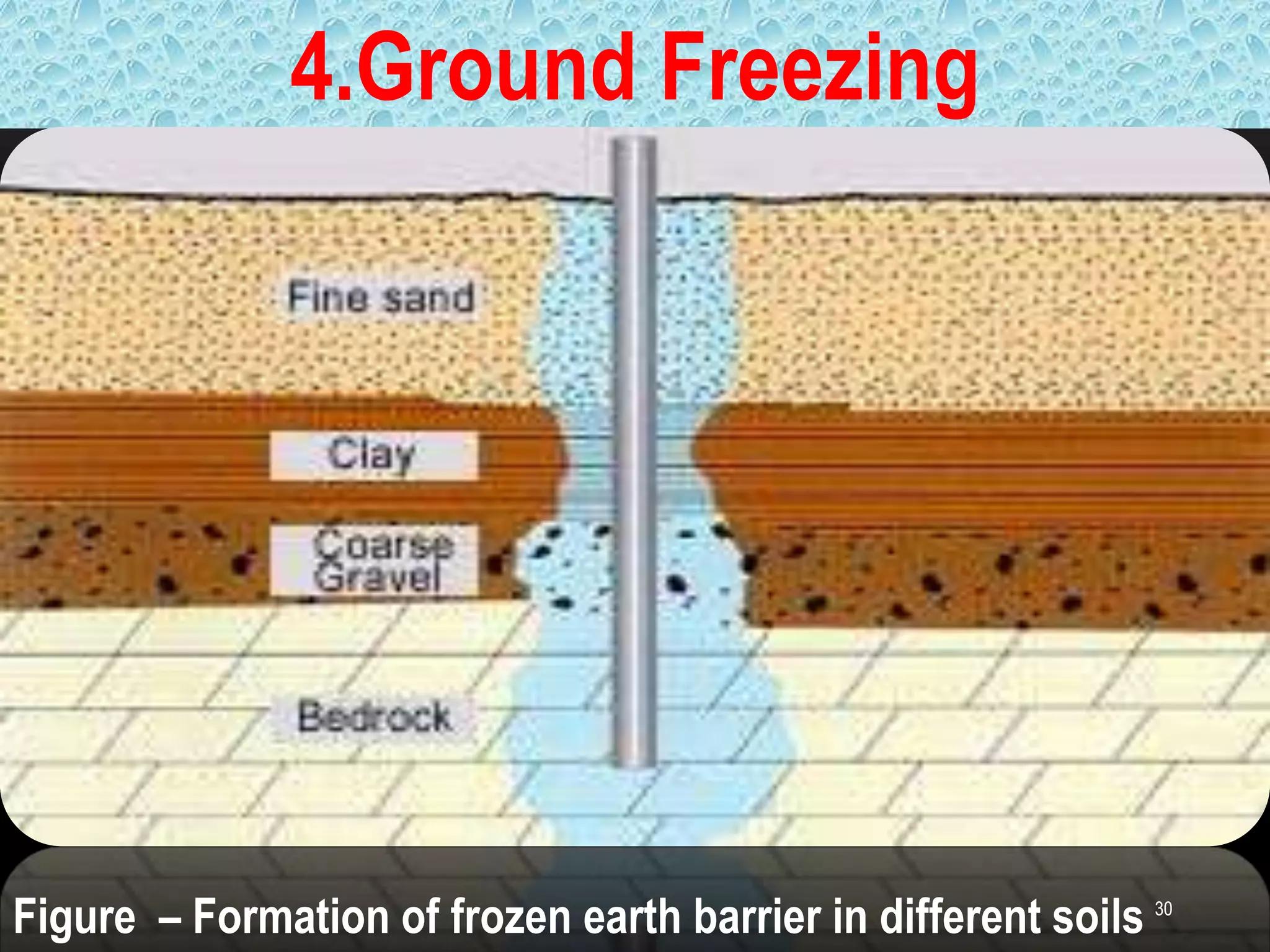

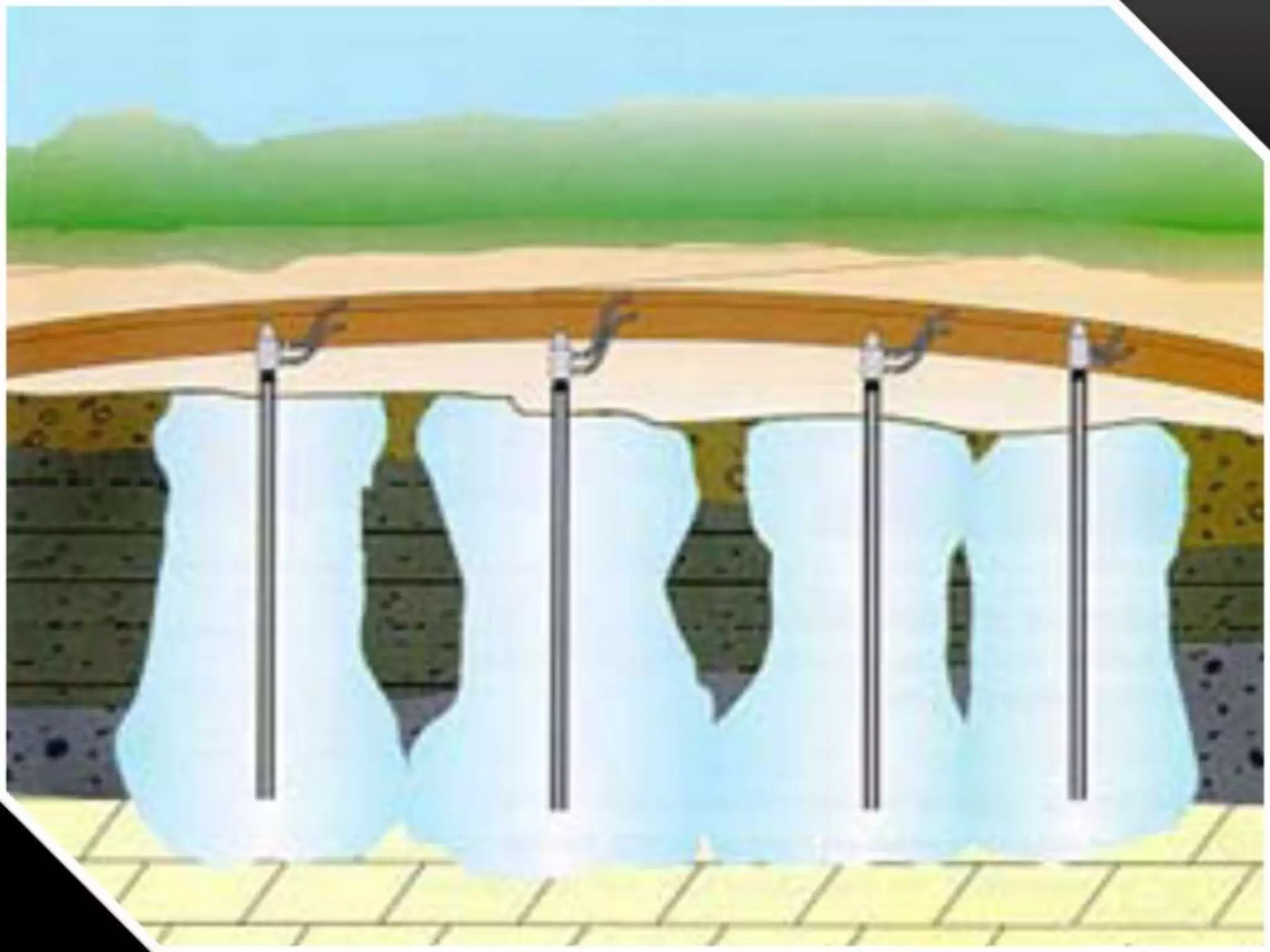

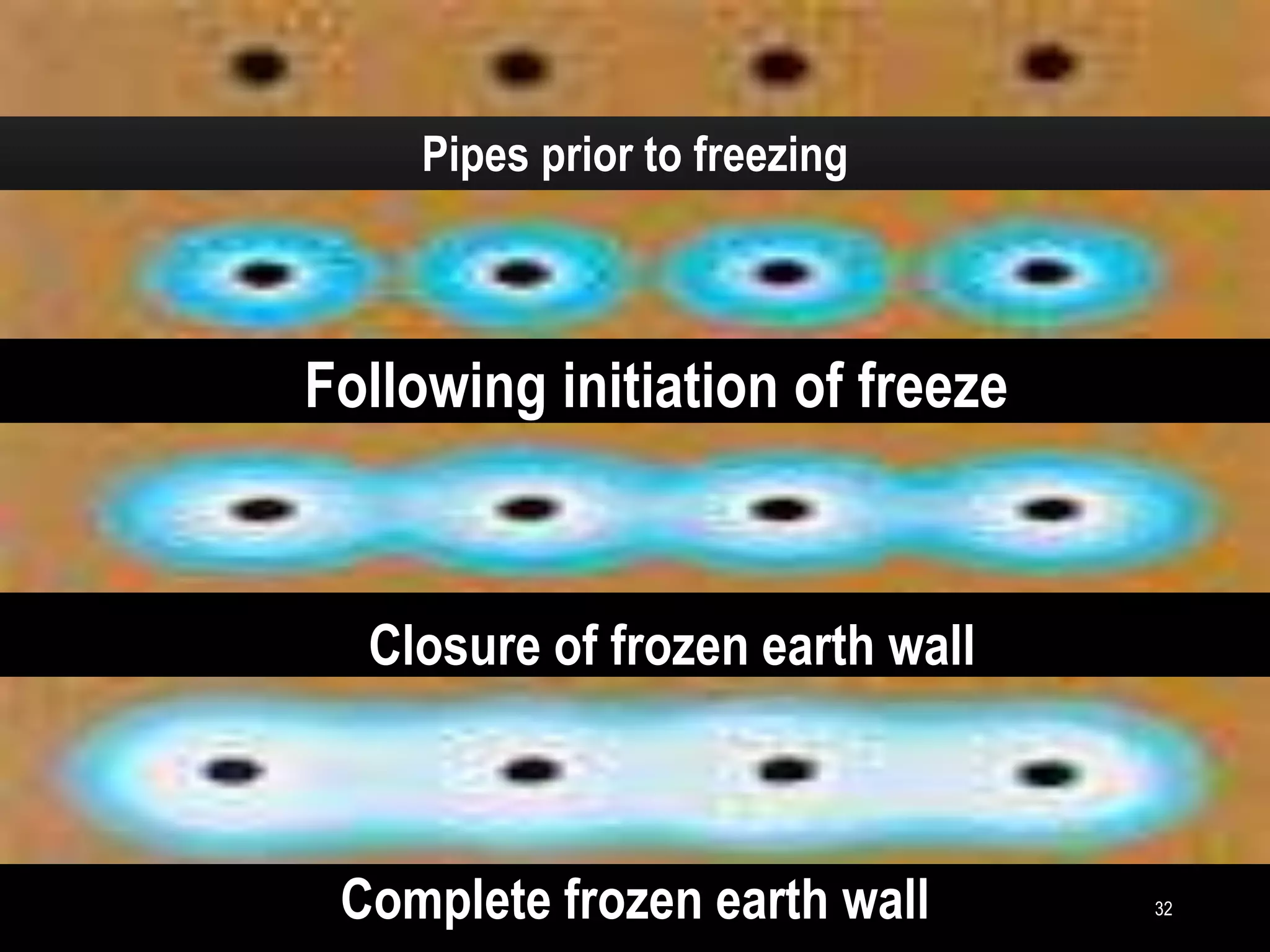

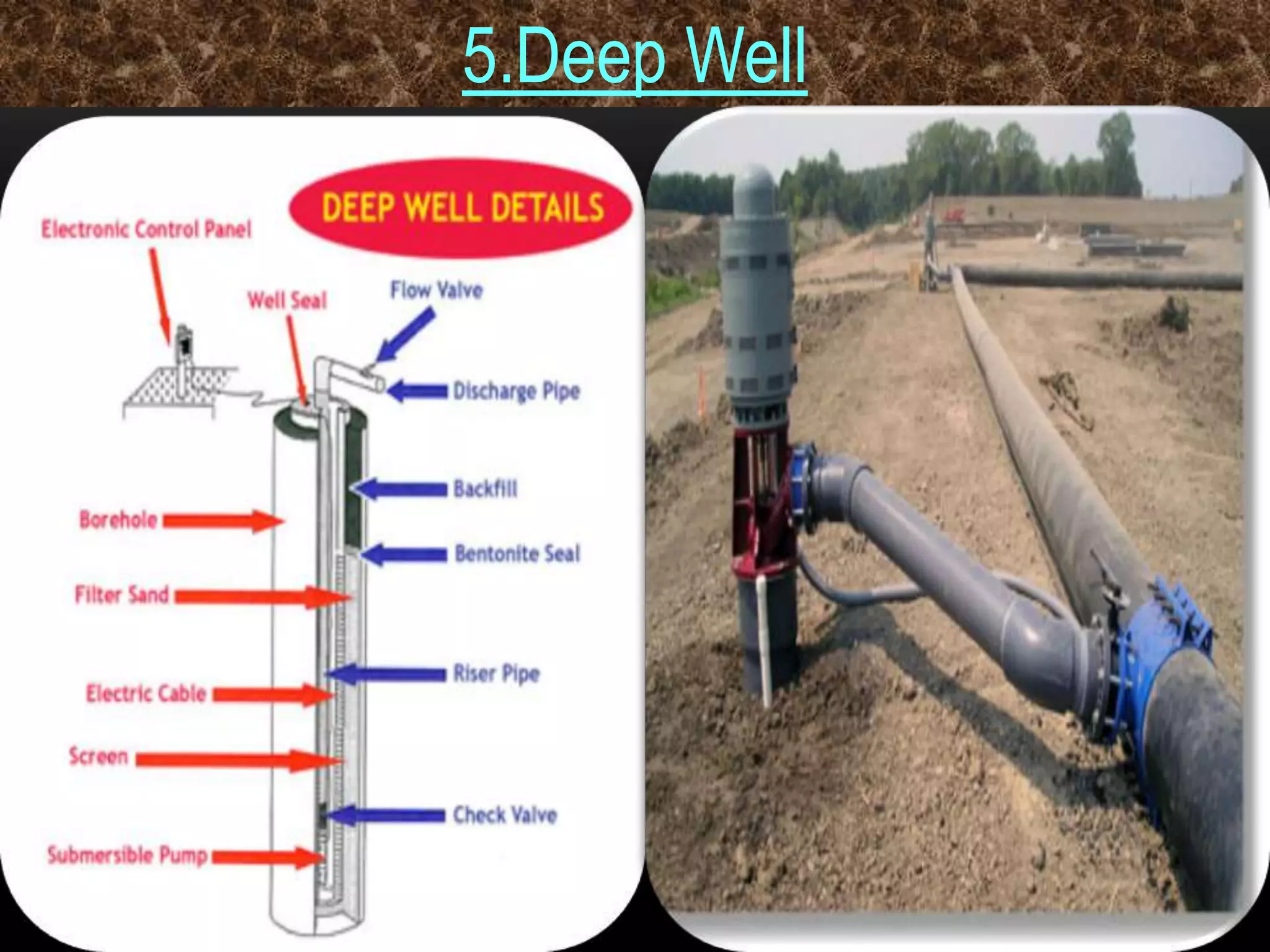

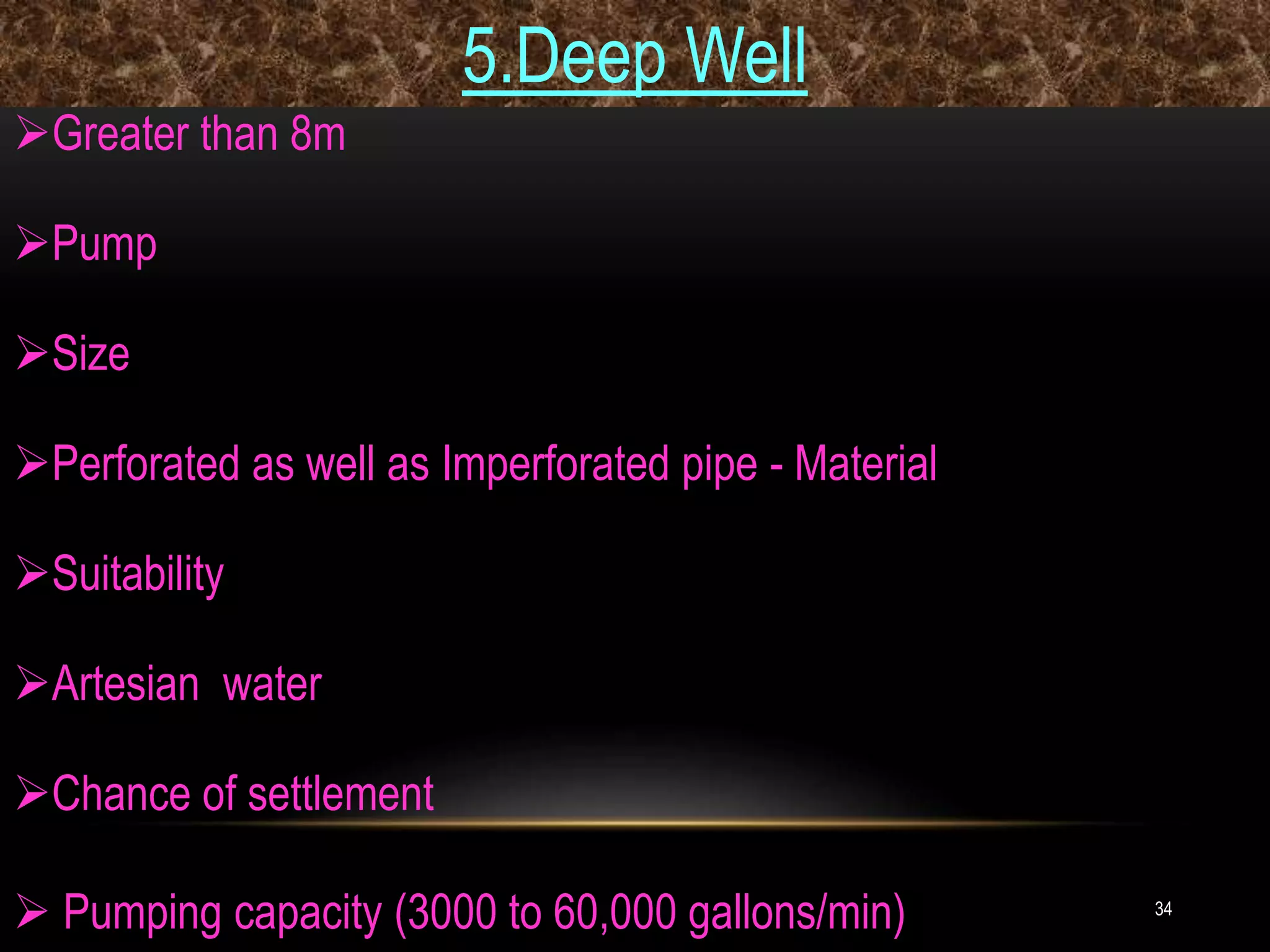

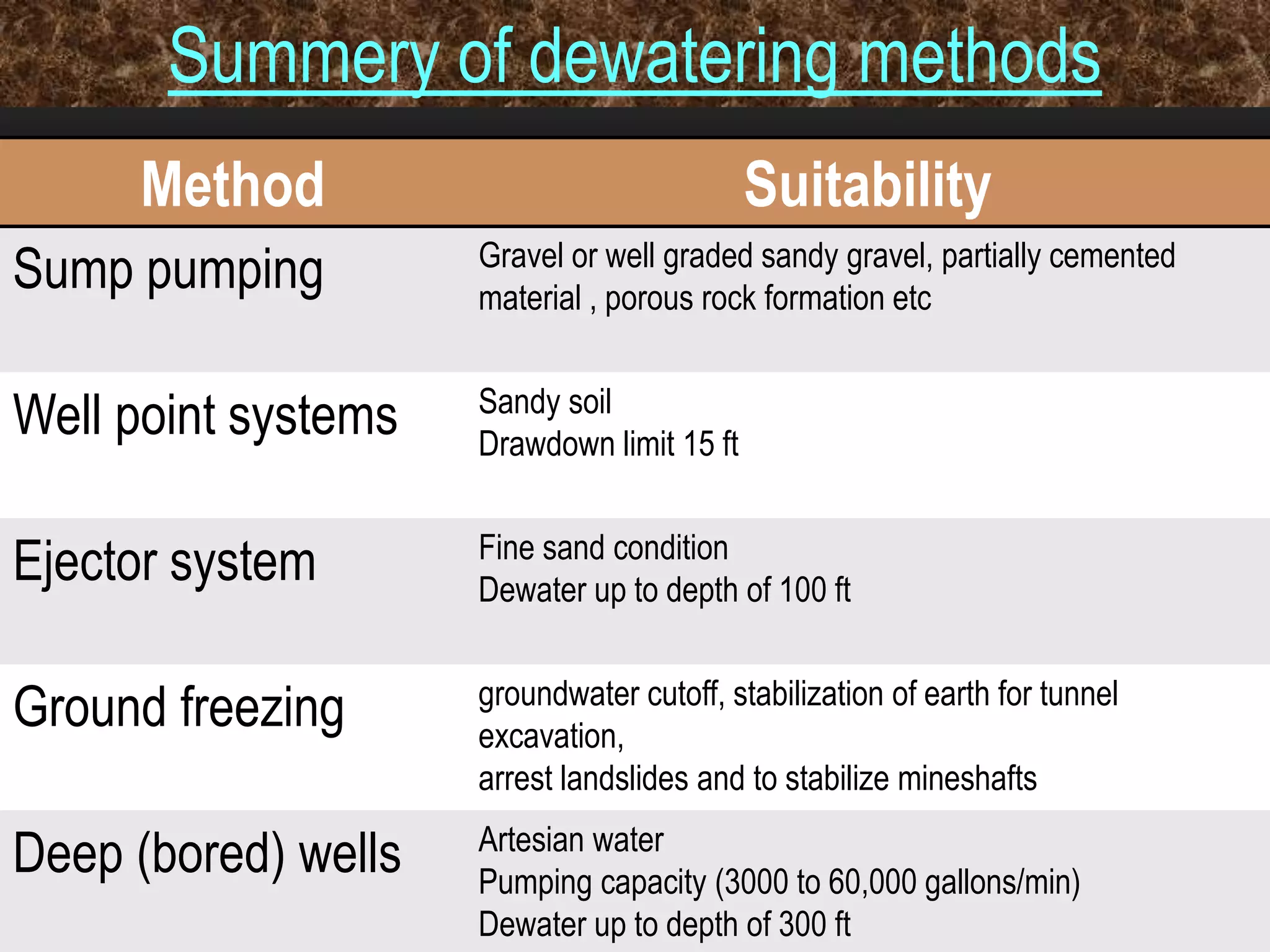

The presentation discussed various methods of dewatering on construction sites, including sump pumping, wellpoint systems, ejector wells, ground freezing, and deep wells. It described the purpose of dewatering, factors that influence selection of methods, and advantages and limitations of each approach. The methods vary in their suitability based on soil type, required depth of drawdown, and other site-specific factors. Proper dewatering is important for construction efficiency and stability.