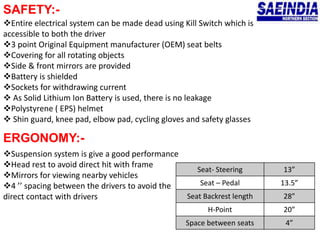

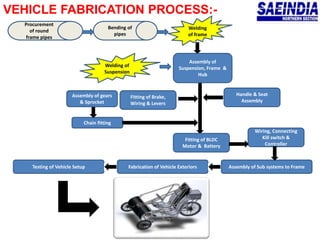

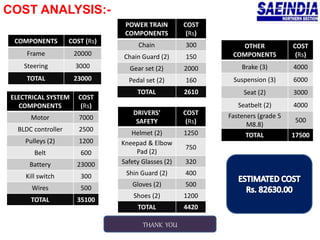

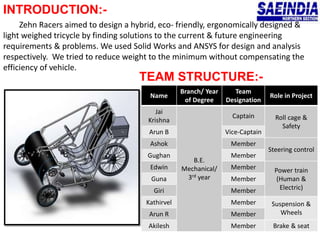

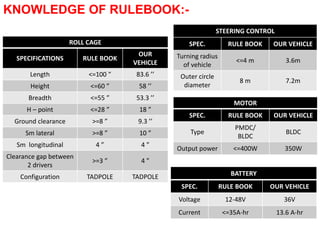

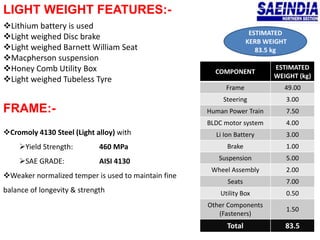

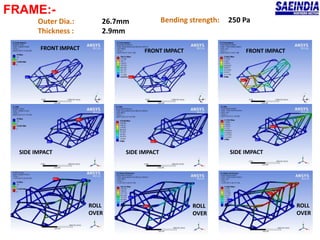

The document details the project of a hybrid, eco-friendly, and lightweight tricycle designed by a team from Sri Shakthi Institute of Engineering and Technology. It includes specifications, design methodologies, safety protocols, and the estimated costs of various components used in the construction of the vehicle. The project emphasizes the use of innovative materials and design techniques to meet engineering requirements while ensuring efficiency and safety.

![WHEELS & TYRES:-

SEATS:-

SPECIFICATIONS FRONT REAR

Outer Diameter 24” 26”

Rim size 11.25” 10.25”

Tyre size 2.125” 1.75”

Spoke thickness 3.2mm

Max. Load/ Tyre 150Kg

Tubeless tyres

Decrease in rolling resistance

Less vibration

Less heat generation

Sudden burst of tyres is avoided

SEAT SPECIFICATIONS

Type

Barnett William

Seat

Arrangement Adjacent

Material PUR[polyurethane]

Length*Breadth 18 ” * 22 ”

Tensile strength 4*10 7 N/m2

Mass density 1260kg/m3

Lightweight

High resilence

Low cost

Easily available

material is used](https://image.slidesharecdn.com/d6d11f8e-2bc0-4411-8e0e-444df9d9d34d-160220163058/85/15134-ZEHN-RACERS-12-320.jpg)