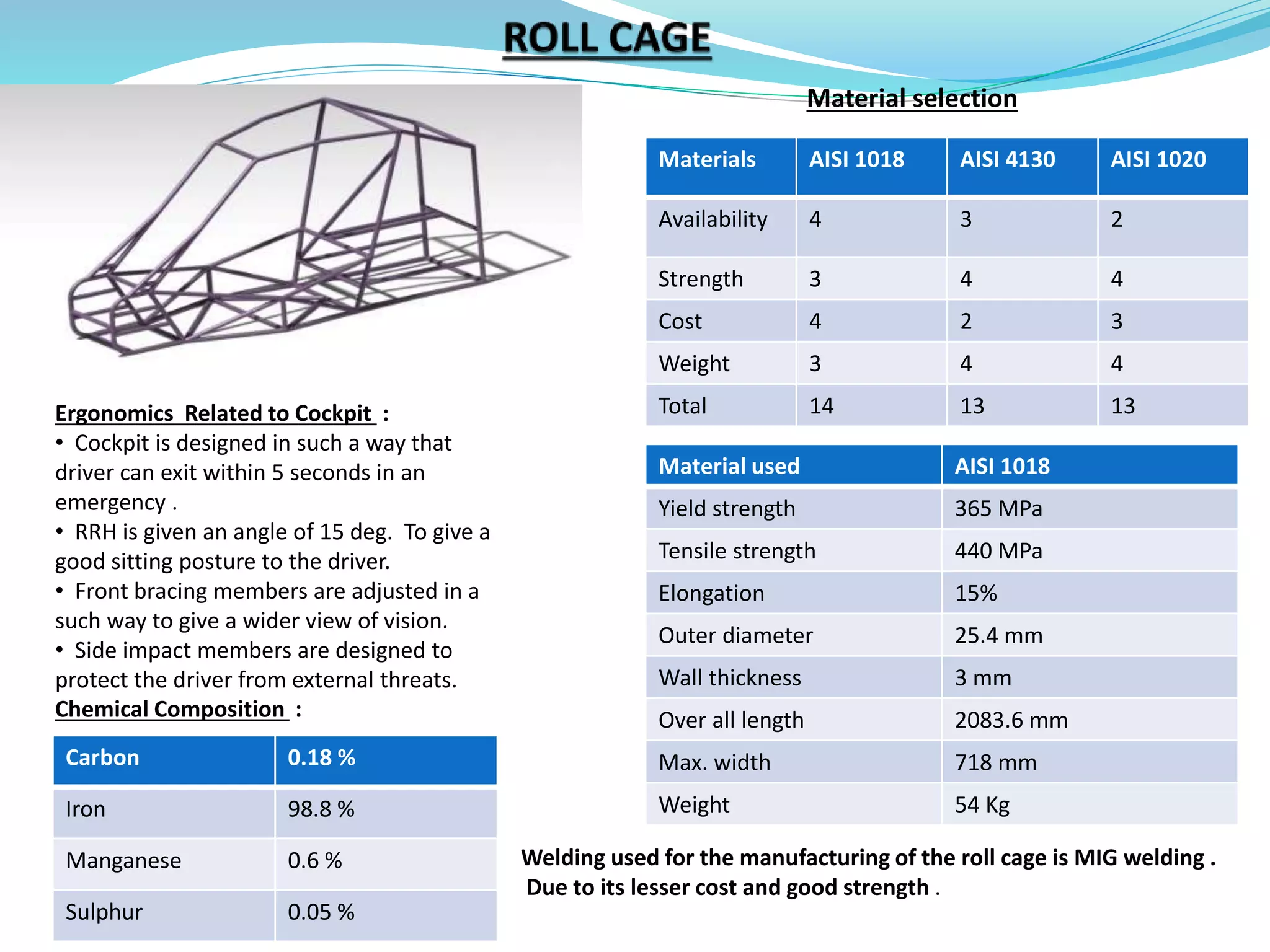

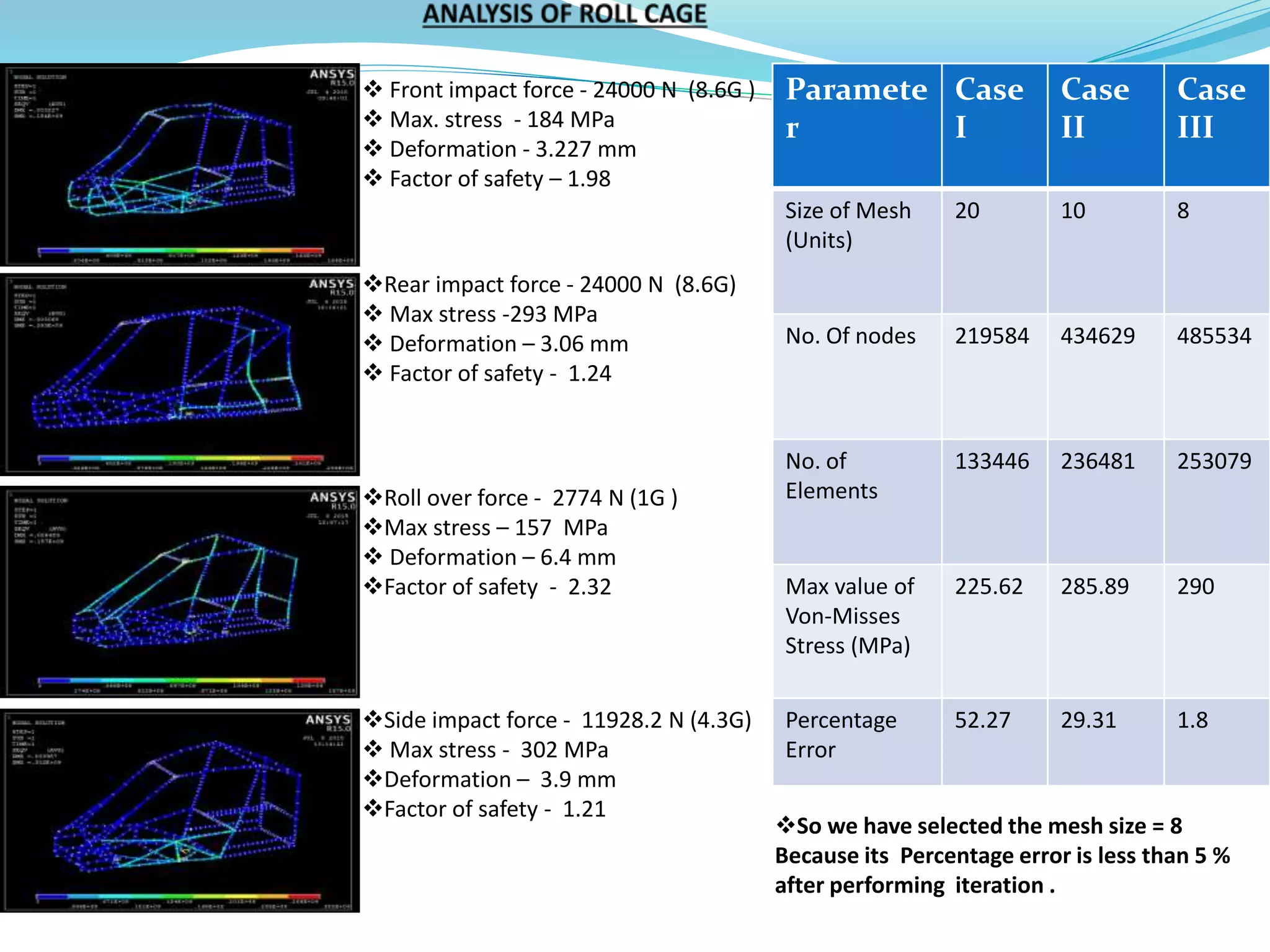

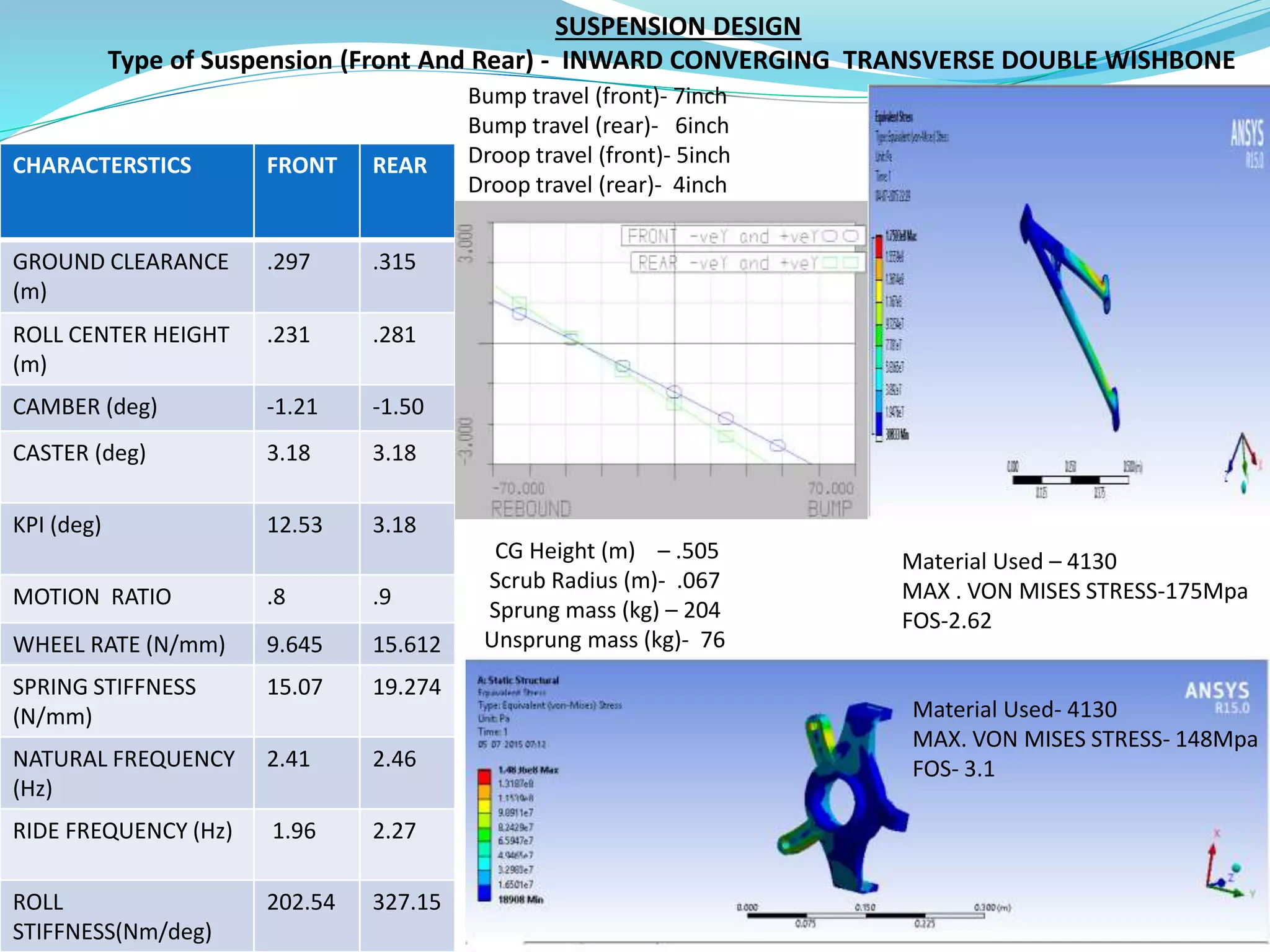

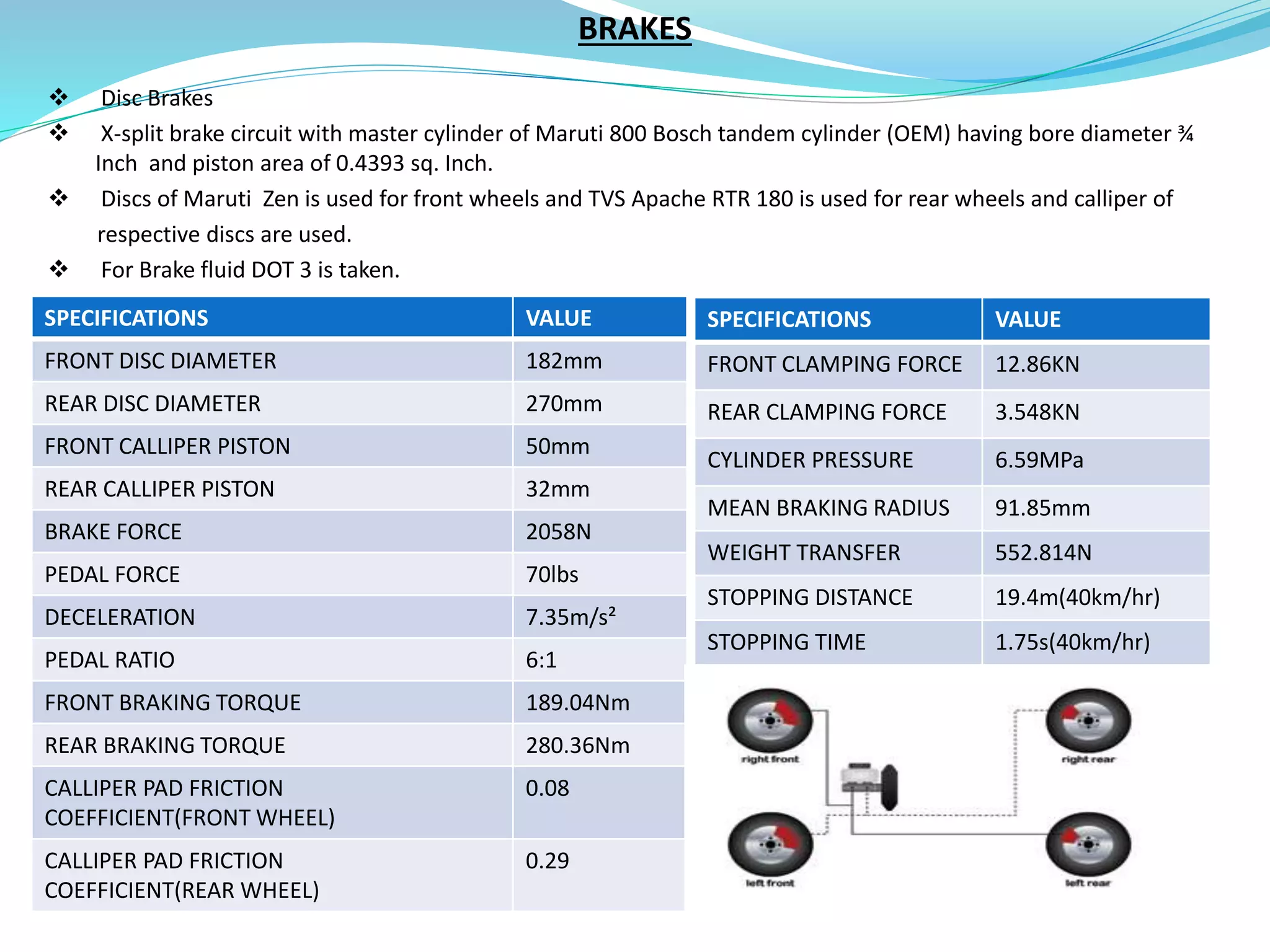

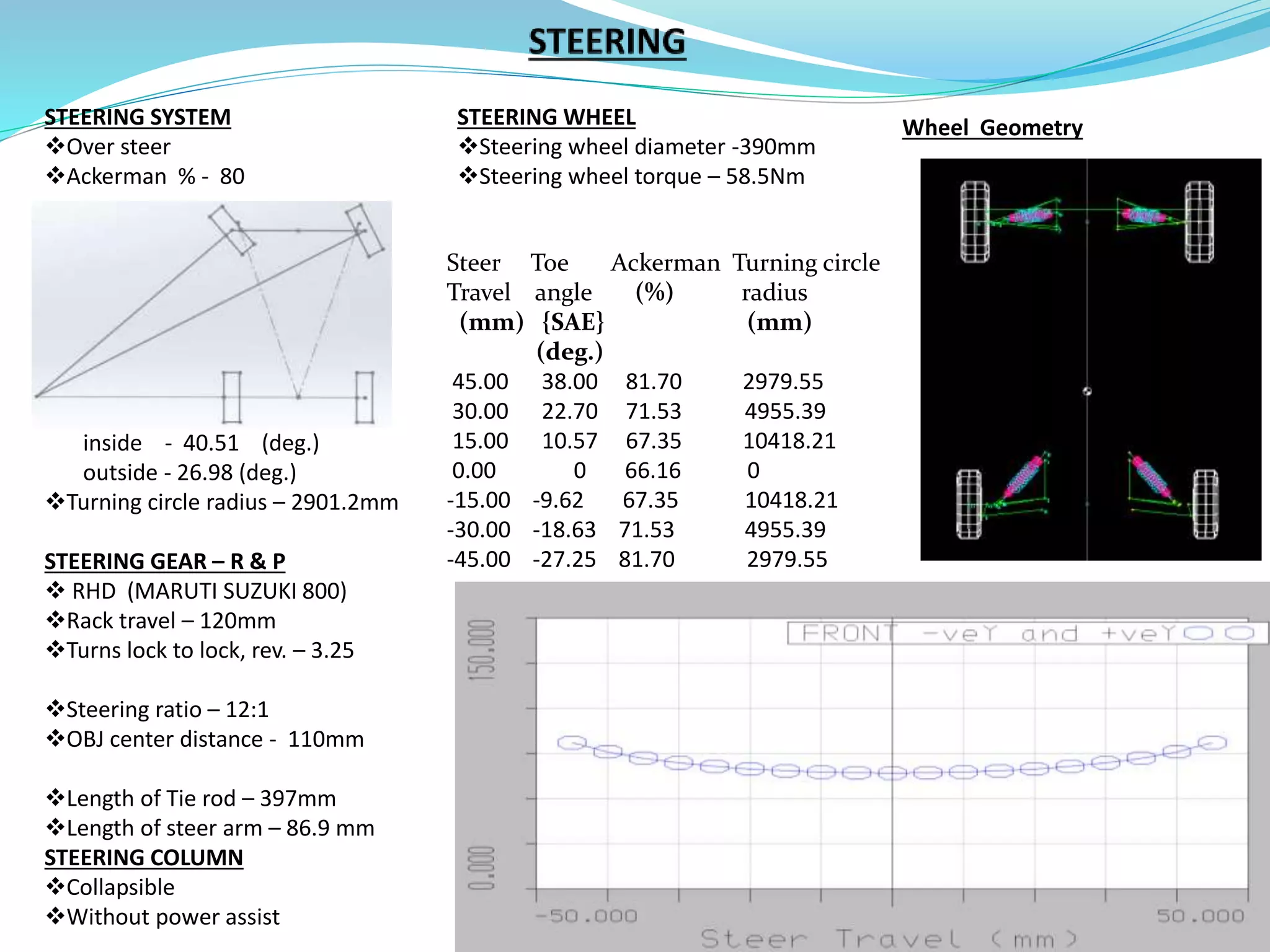

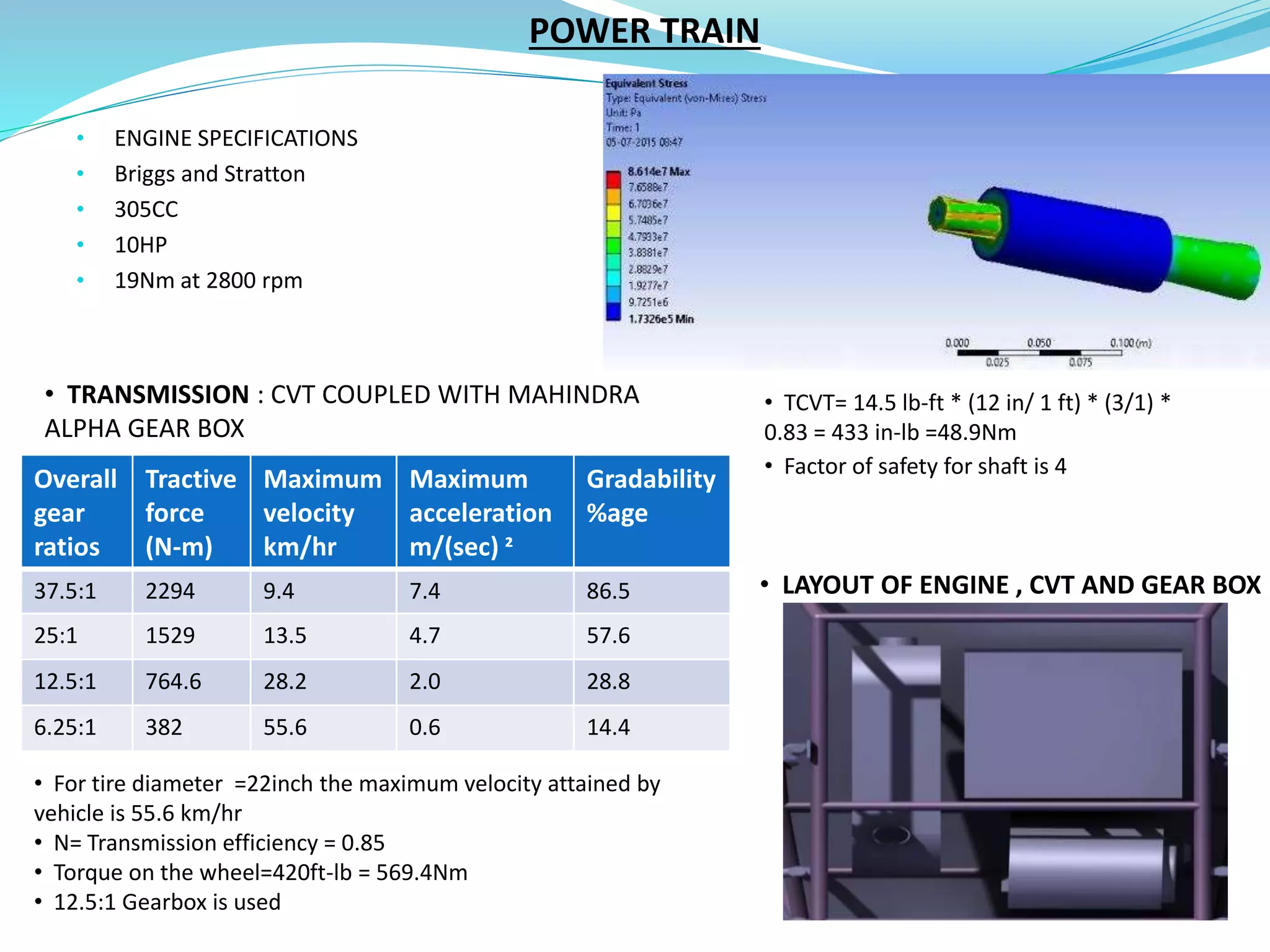

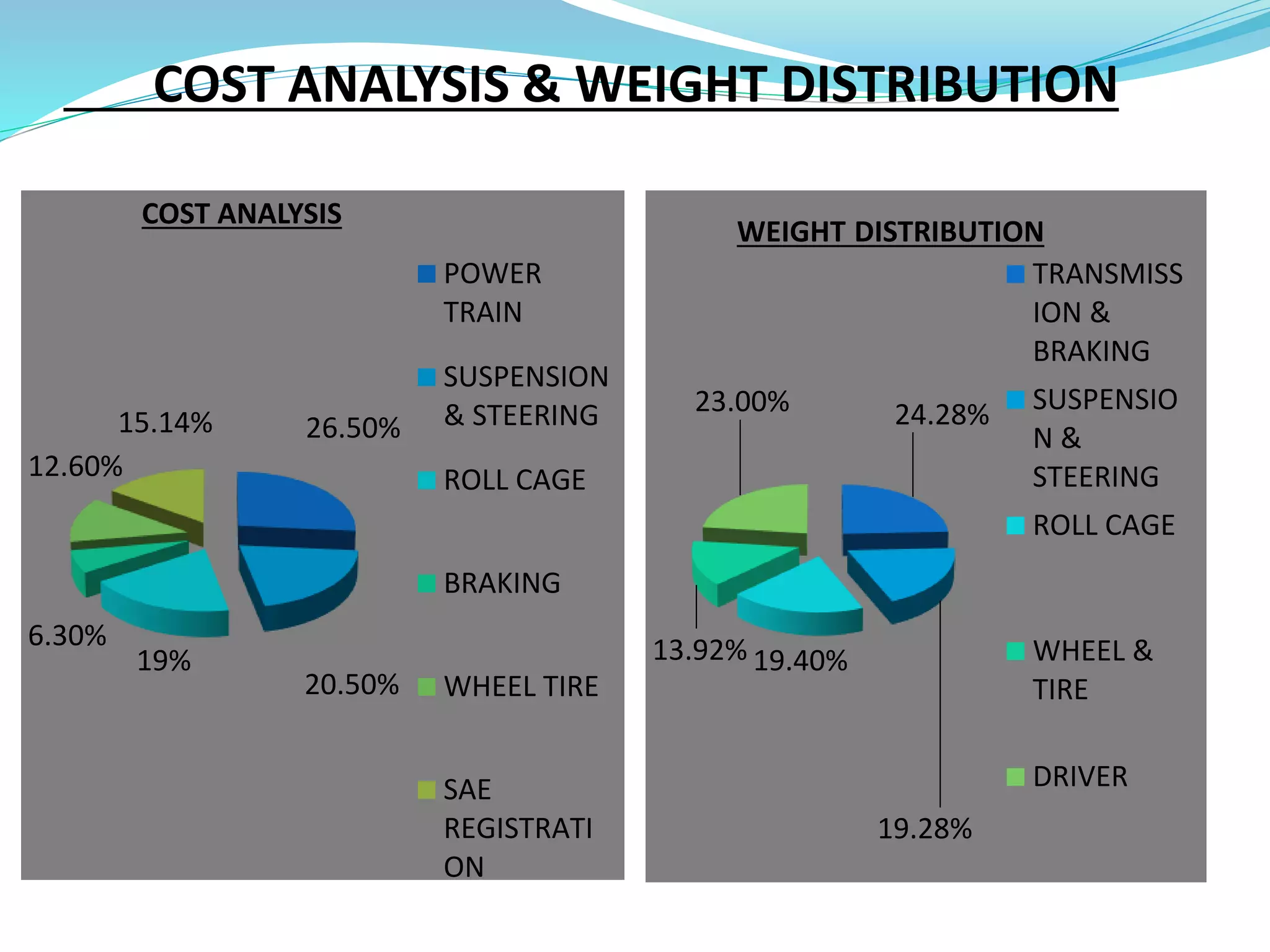

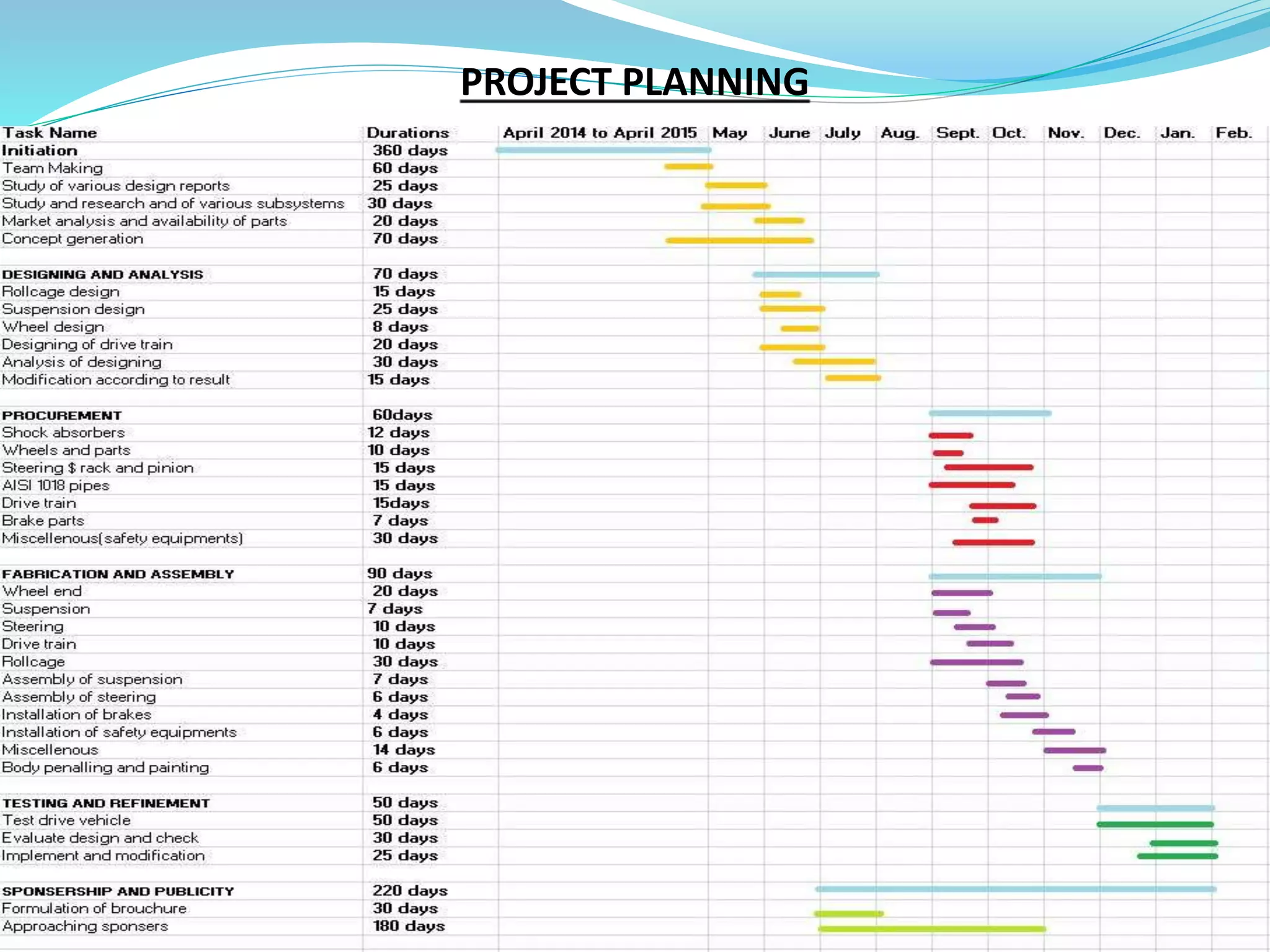

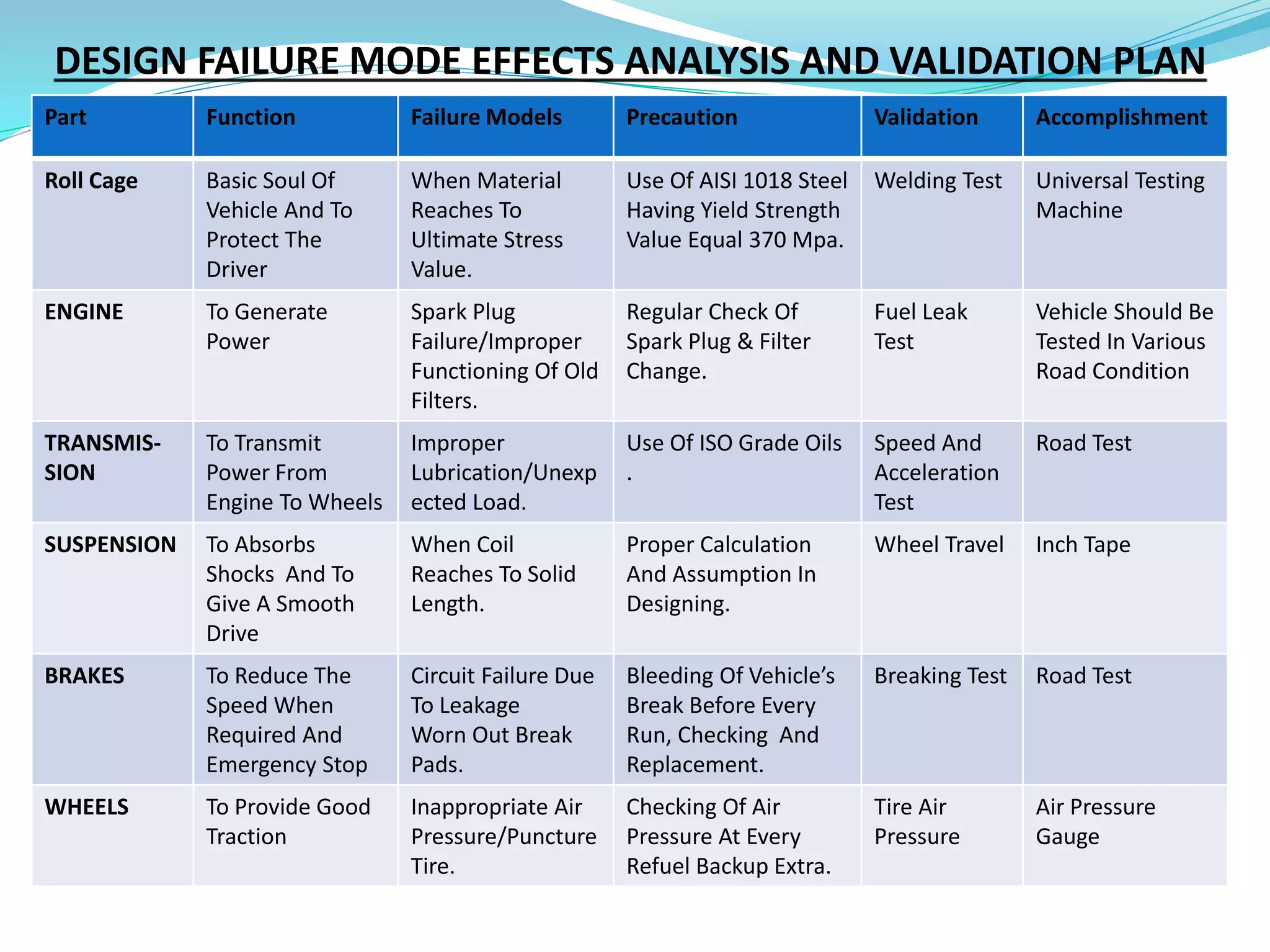

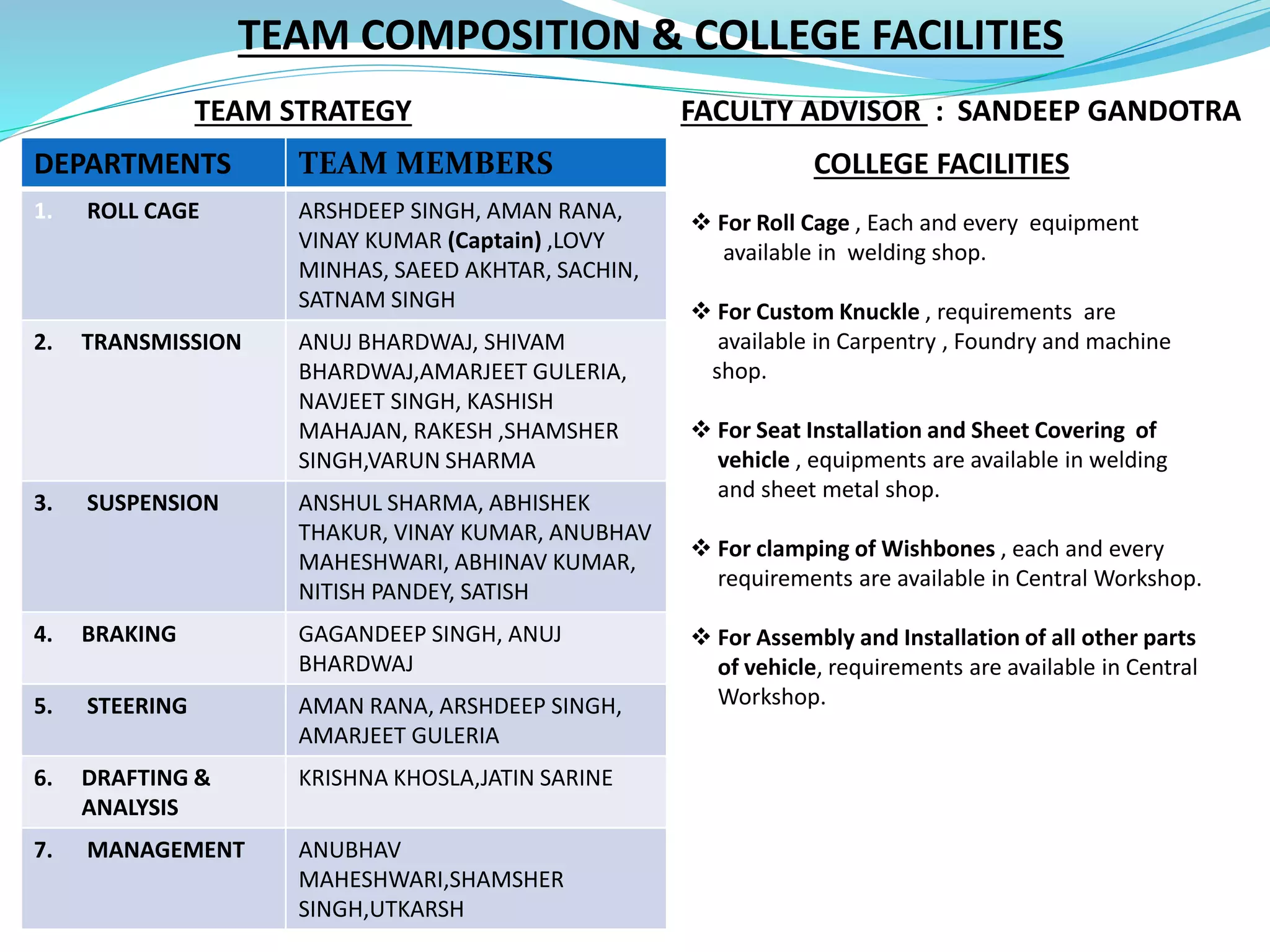

The document provides specifications and design details for a formula-style racing vehicle. It includes dimensions, materials used, analysis of various components like the roll cage, brakes, suspension, and steering. Analysis of the roll cage shows safety factors meet requirements. Suspension design was optimized through iteration. The braking system was designed to meet performance targets. Cost analysis showed largest expenses were the powertrain and suspension systems. The project plan involves various team members focusing on different vehicle subsystems and includes failure mode considerations.