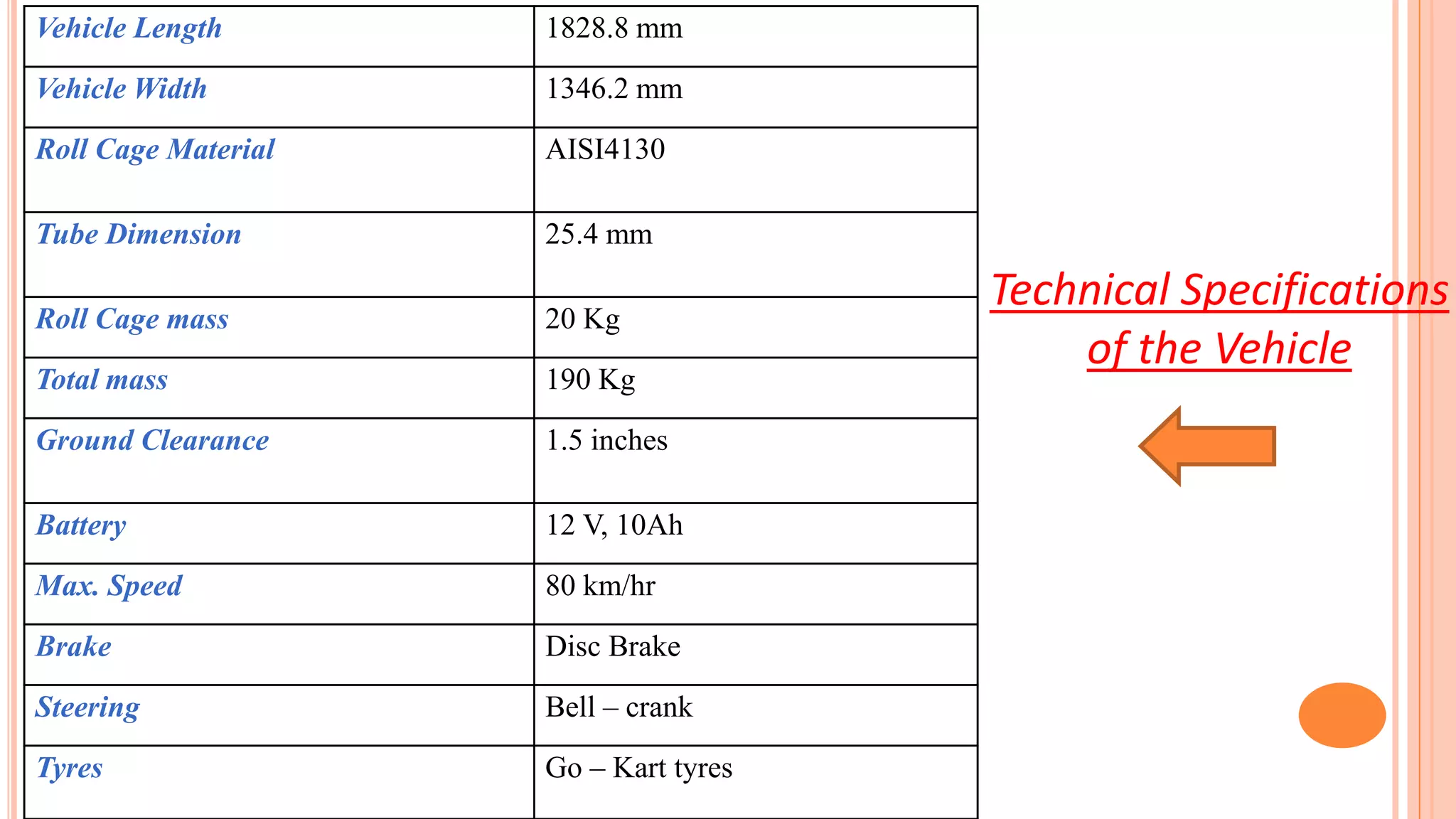

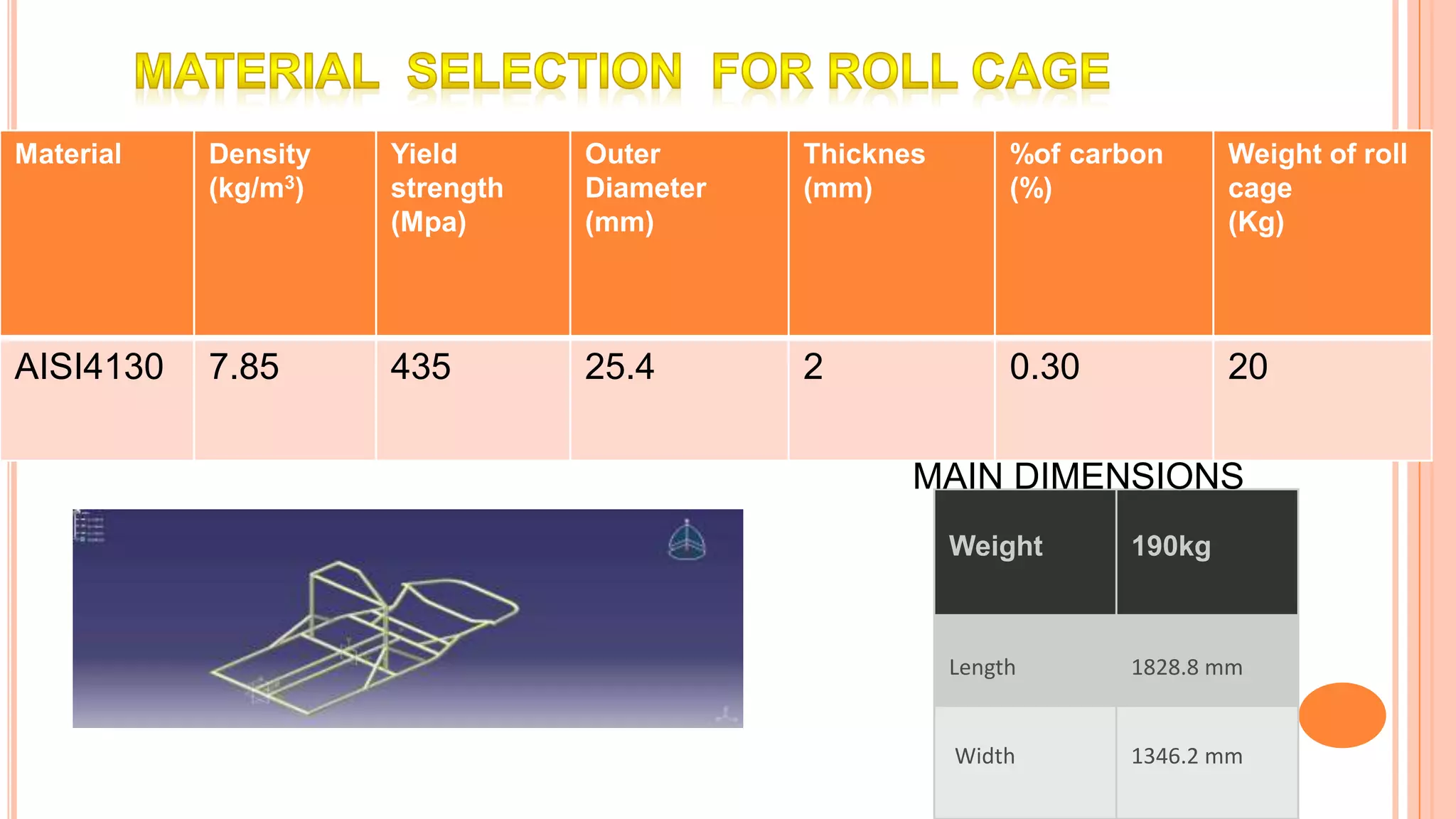

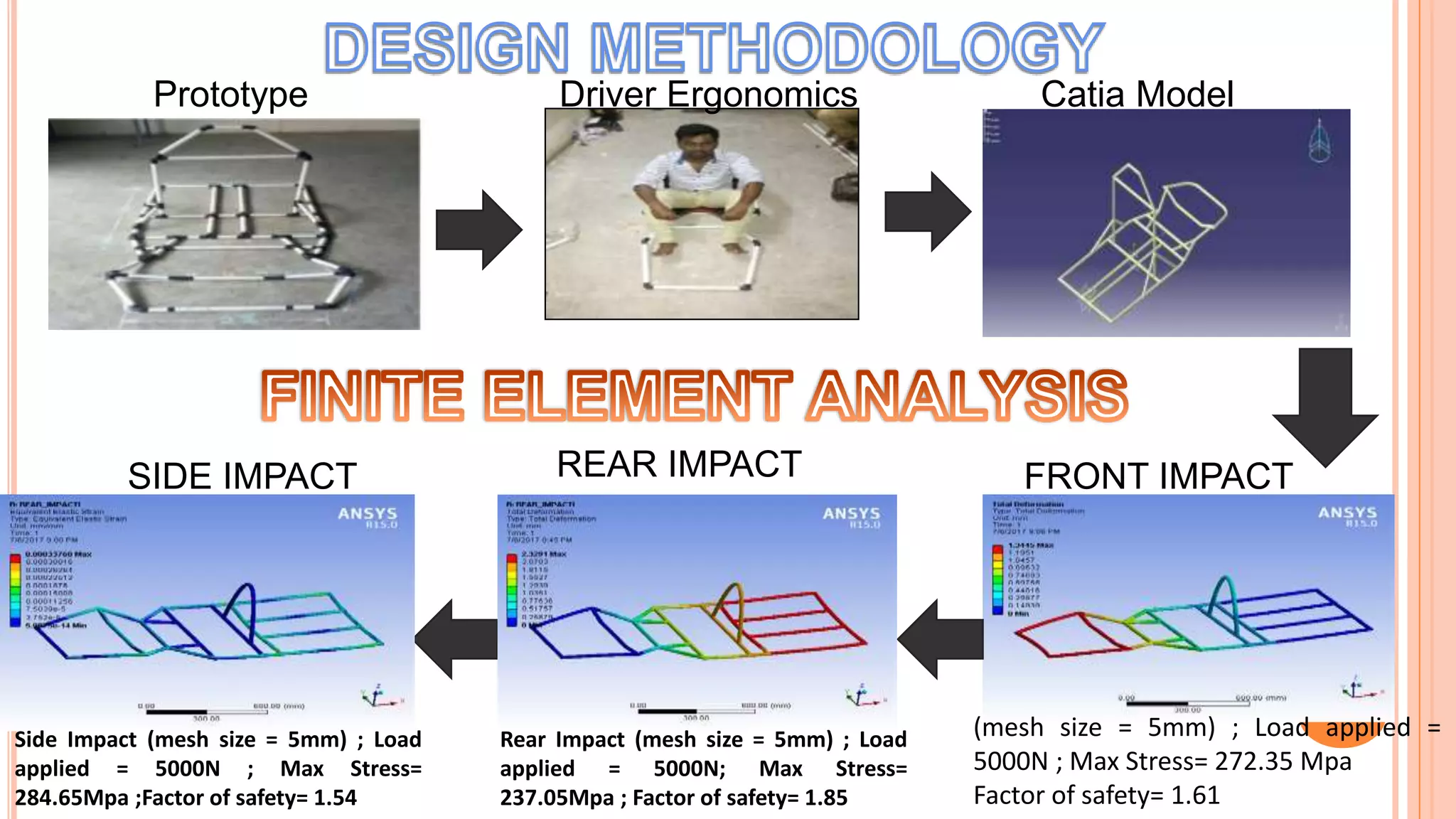

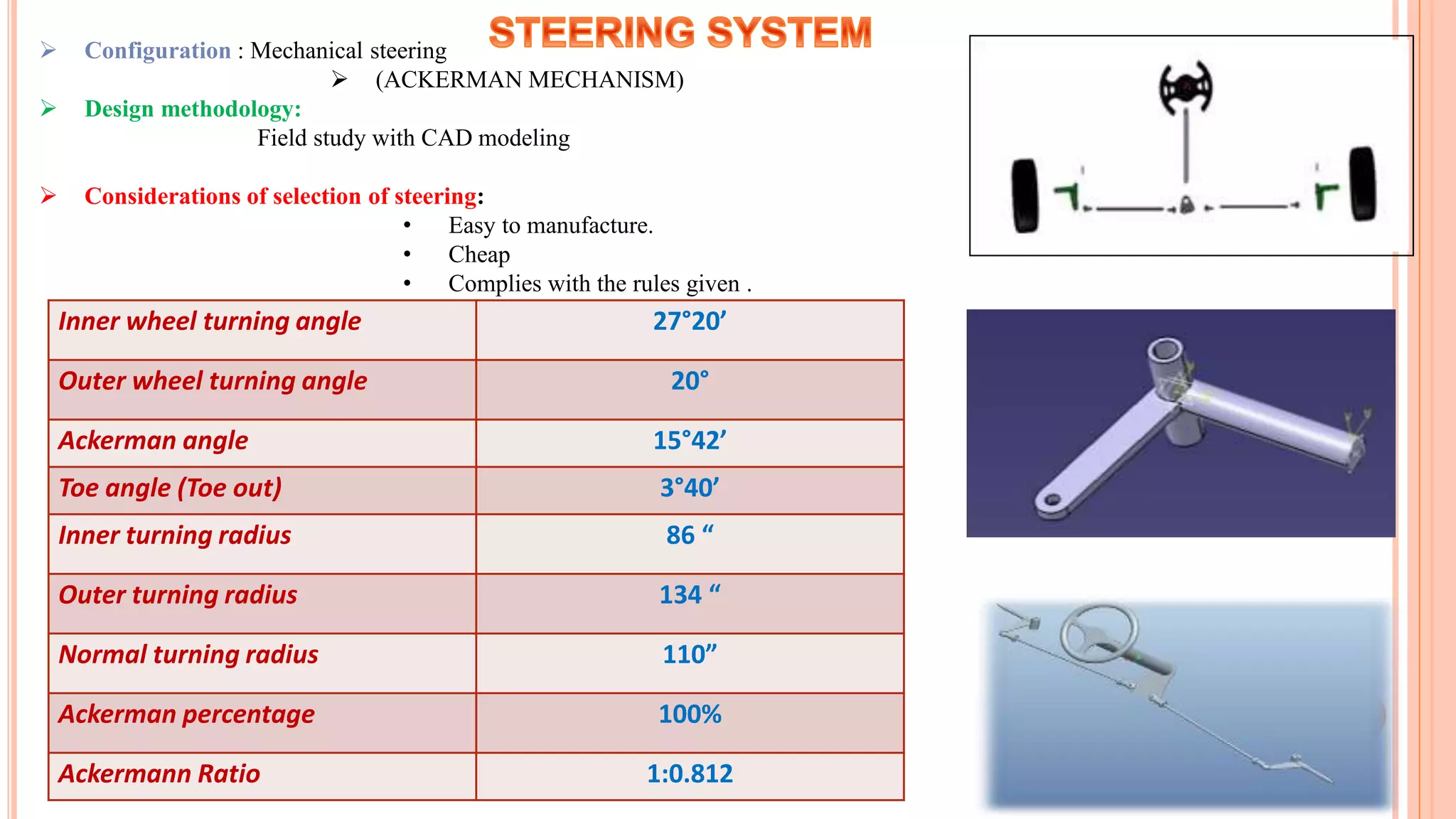

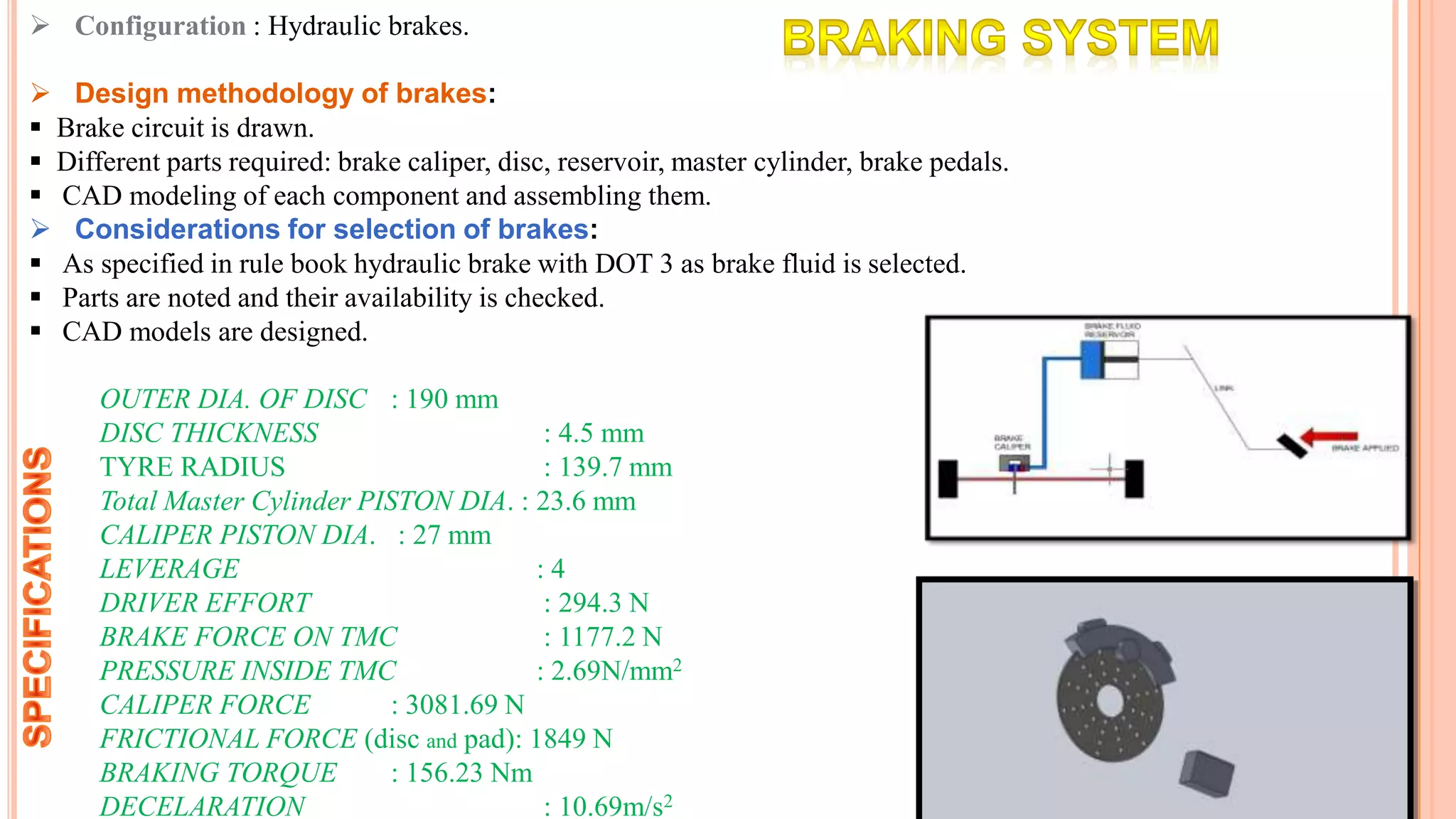

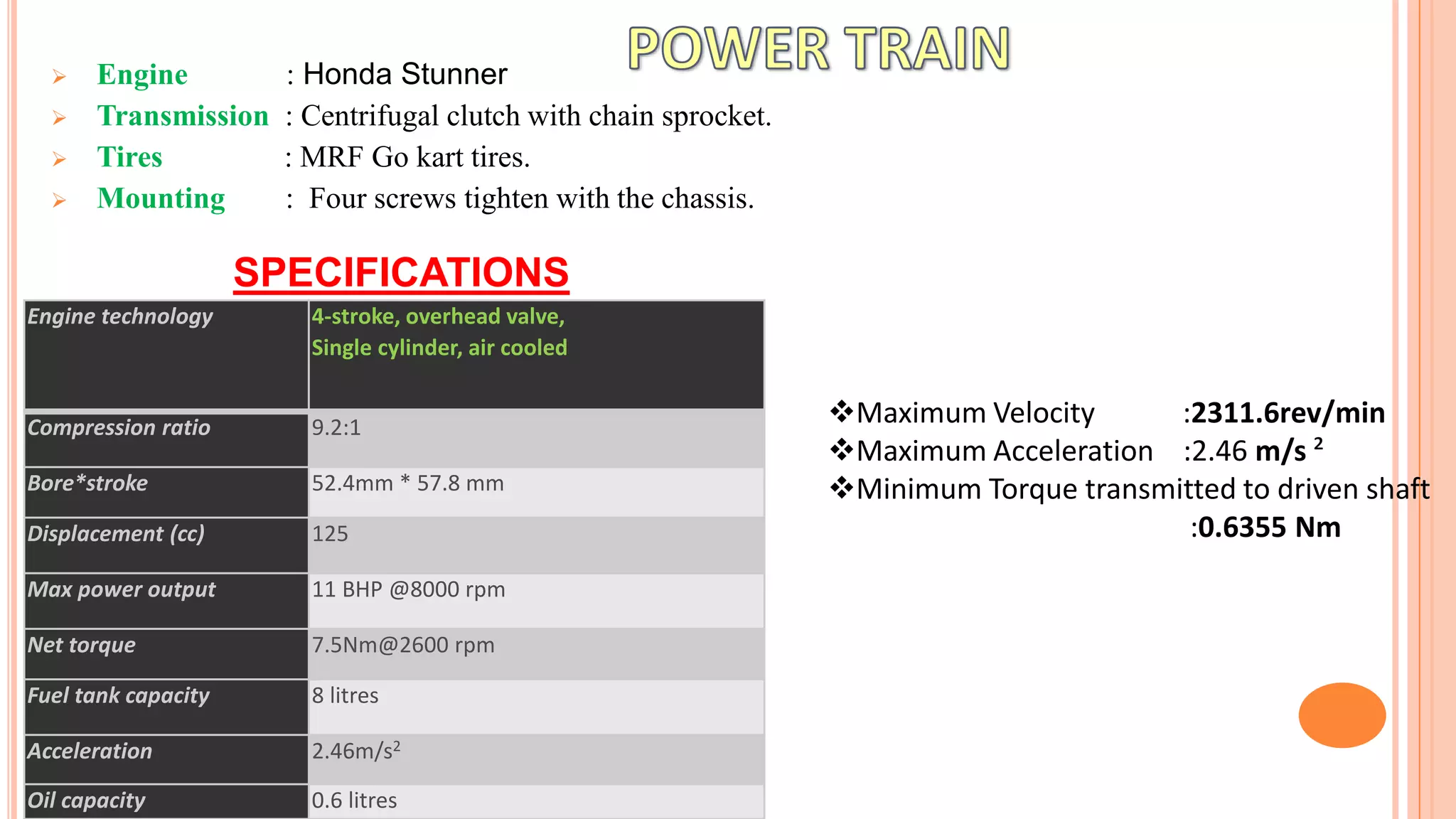

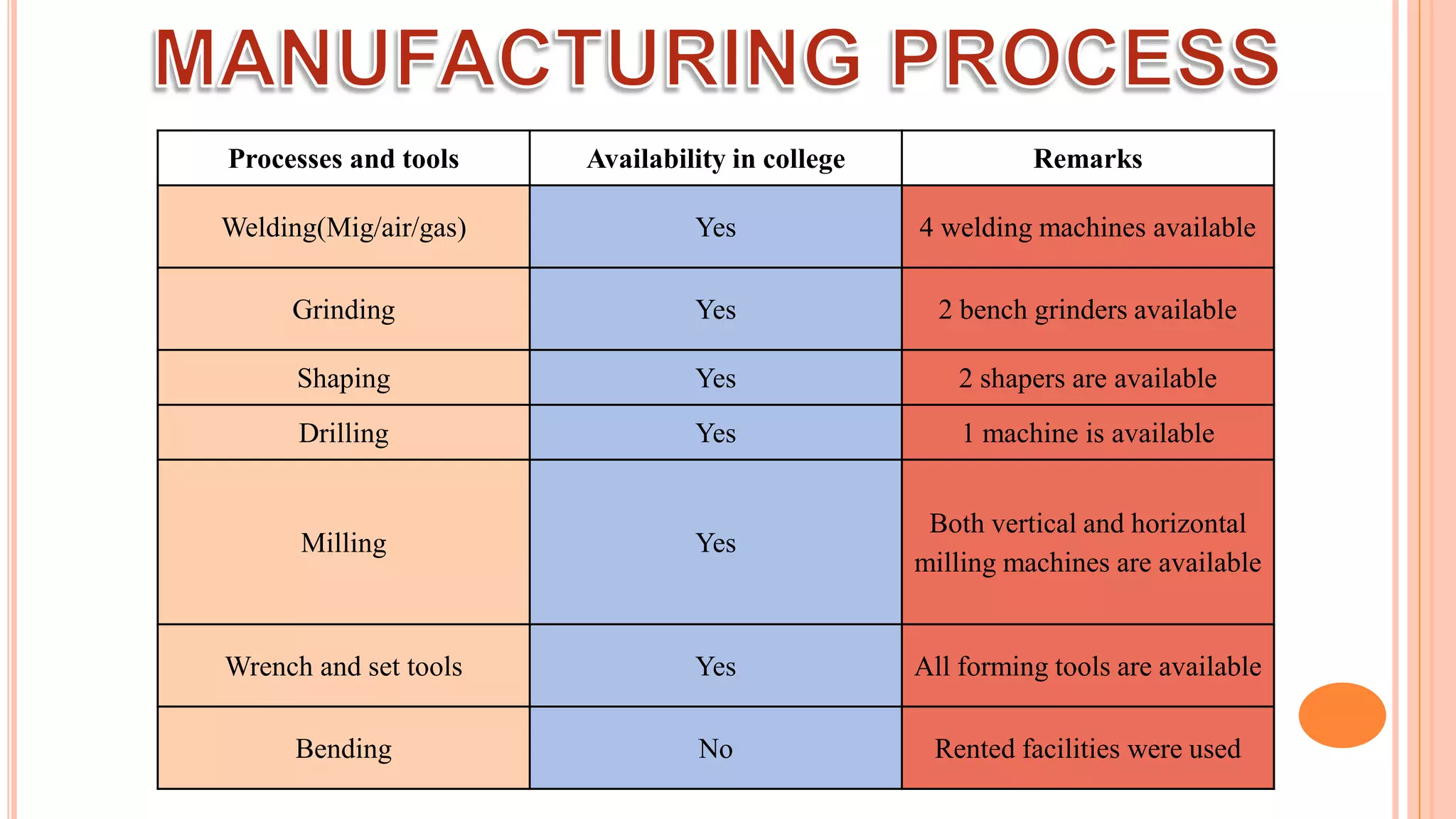

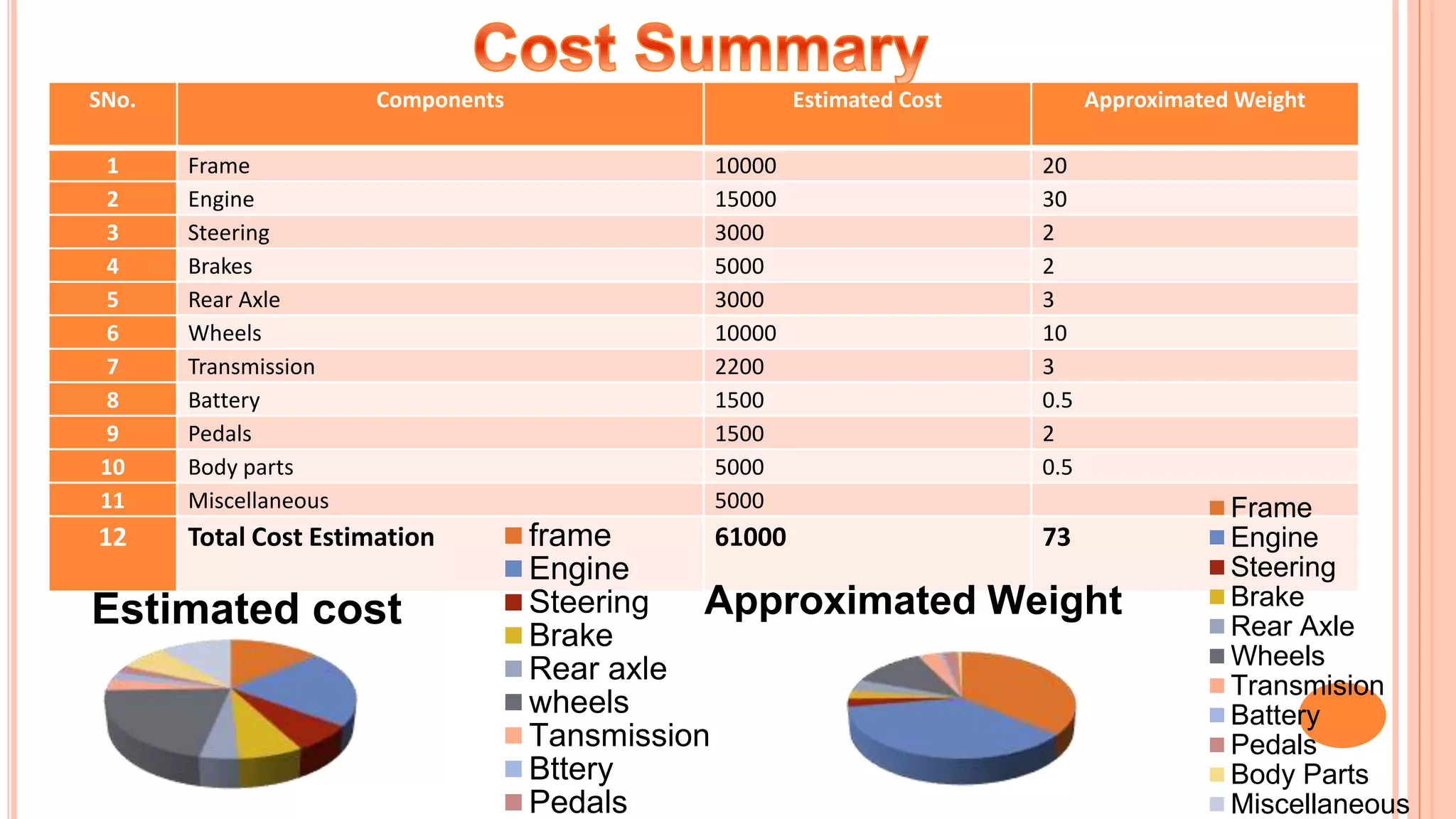

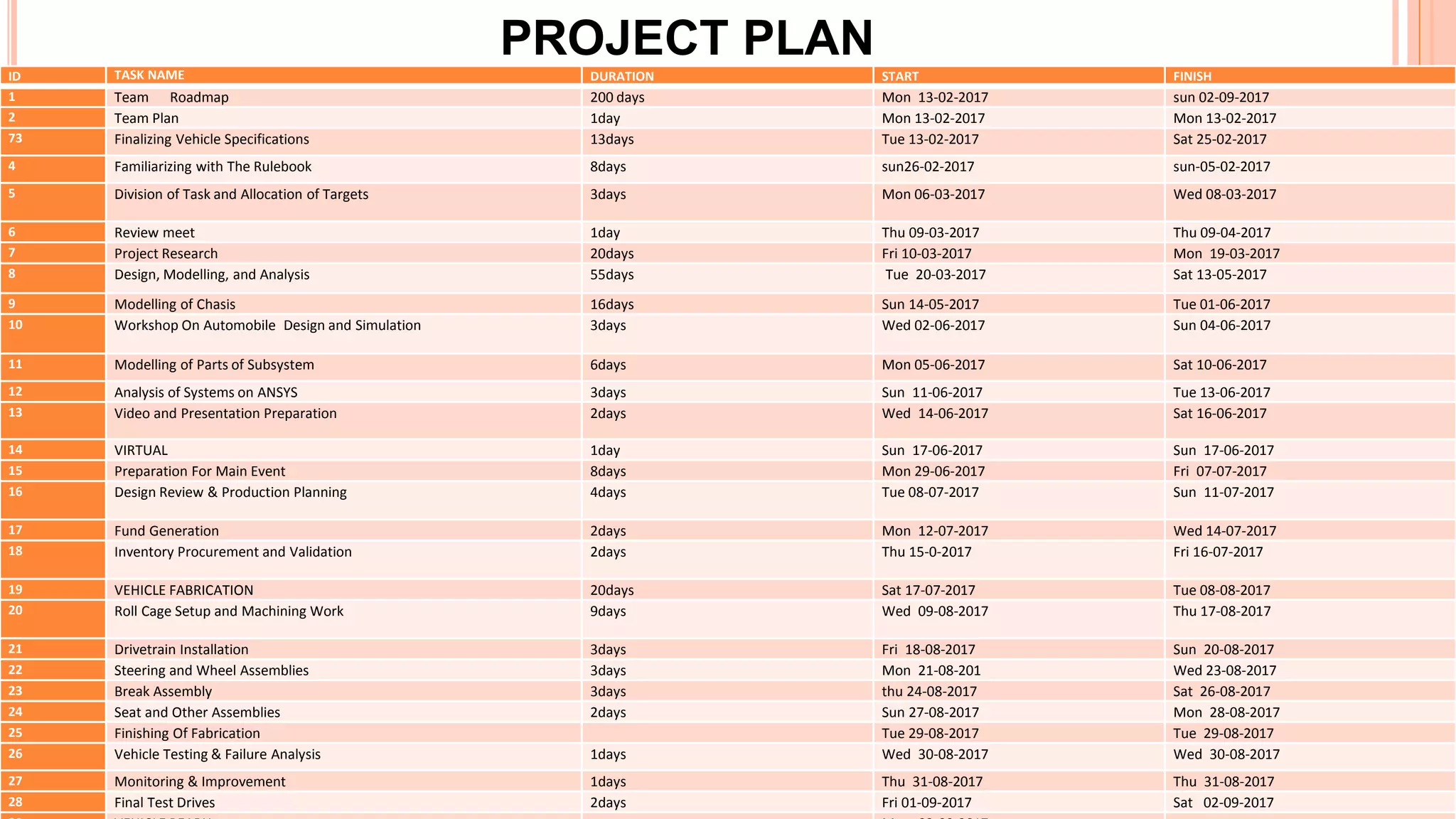

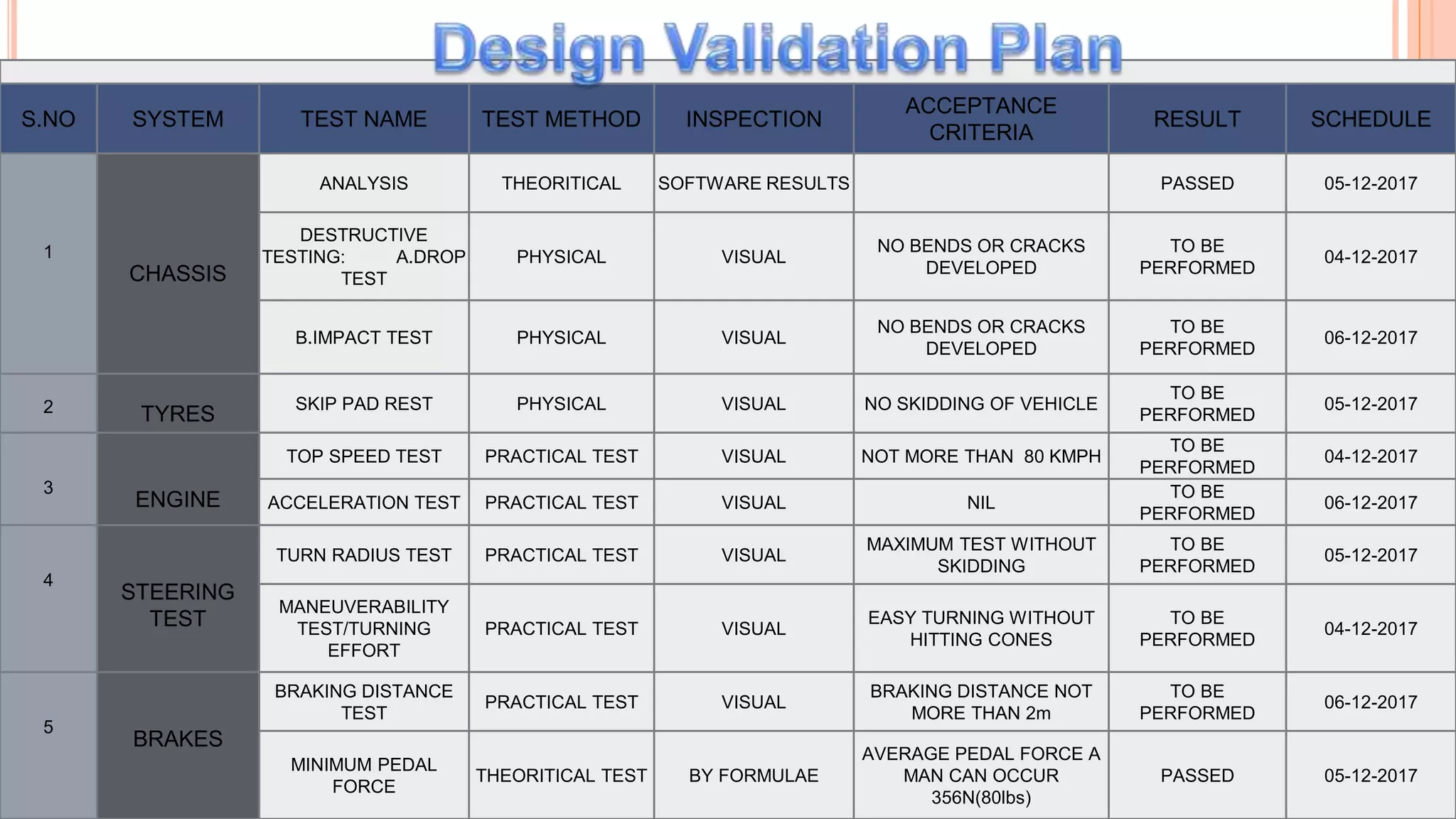

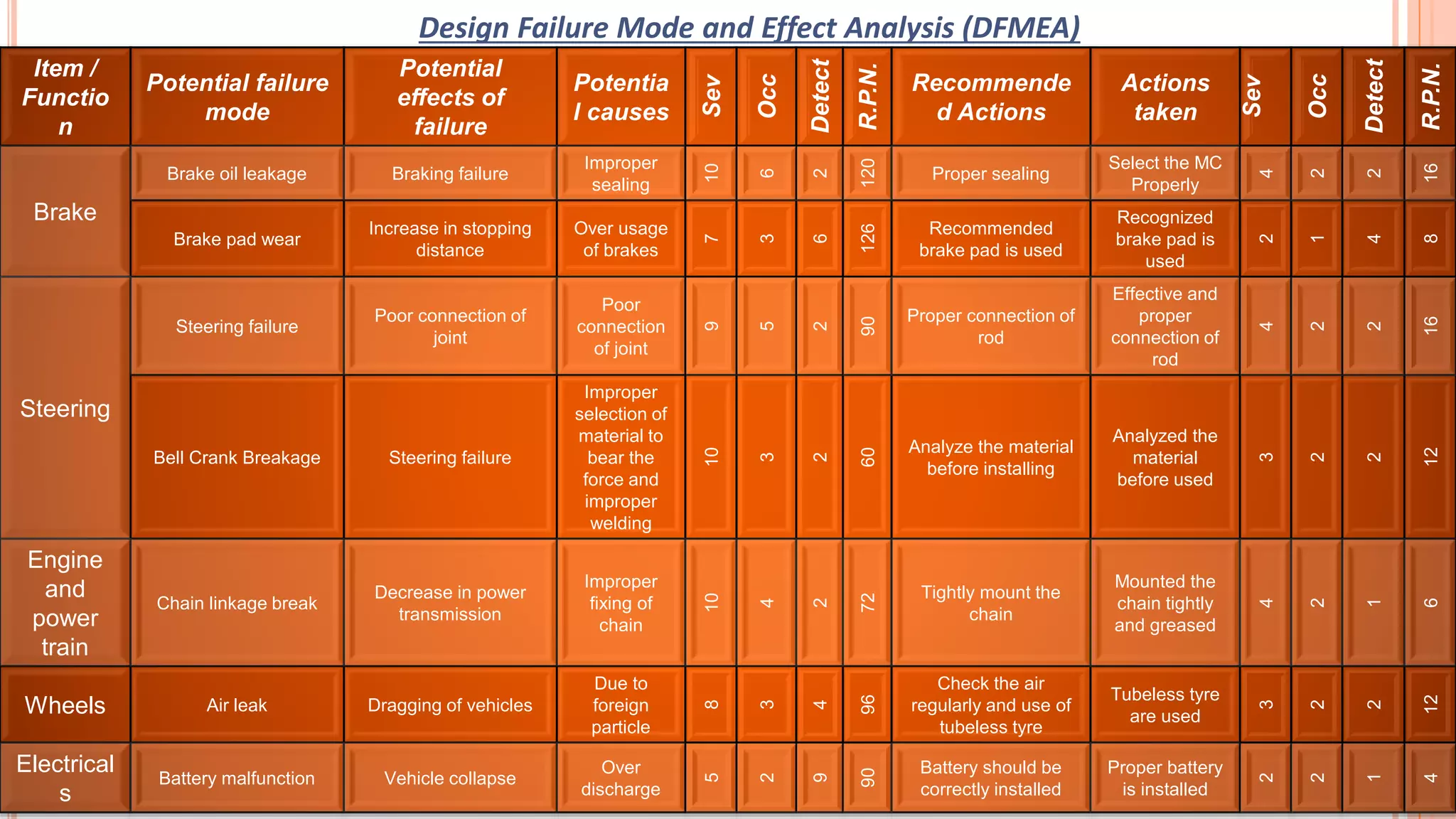

The document details the technical specifications, design, and manufacturing processes of a vehicle created by Valliammai Engineering College, including its dimensions, materials, and components. Key features include the engine type, braking system, and safety measures, alongside a project timeline and cost estimation. It also includes a failure mode and effect analysis to ensure reliability and performance during testing.