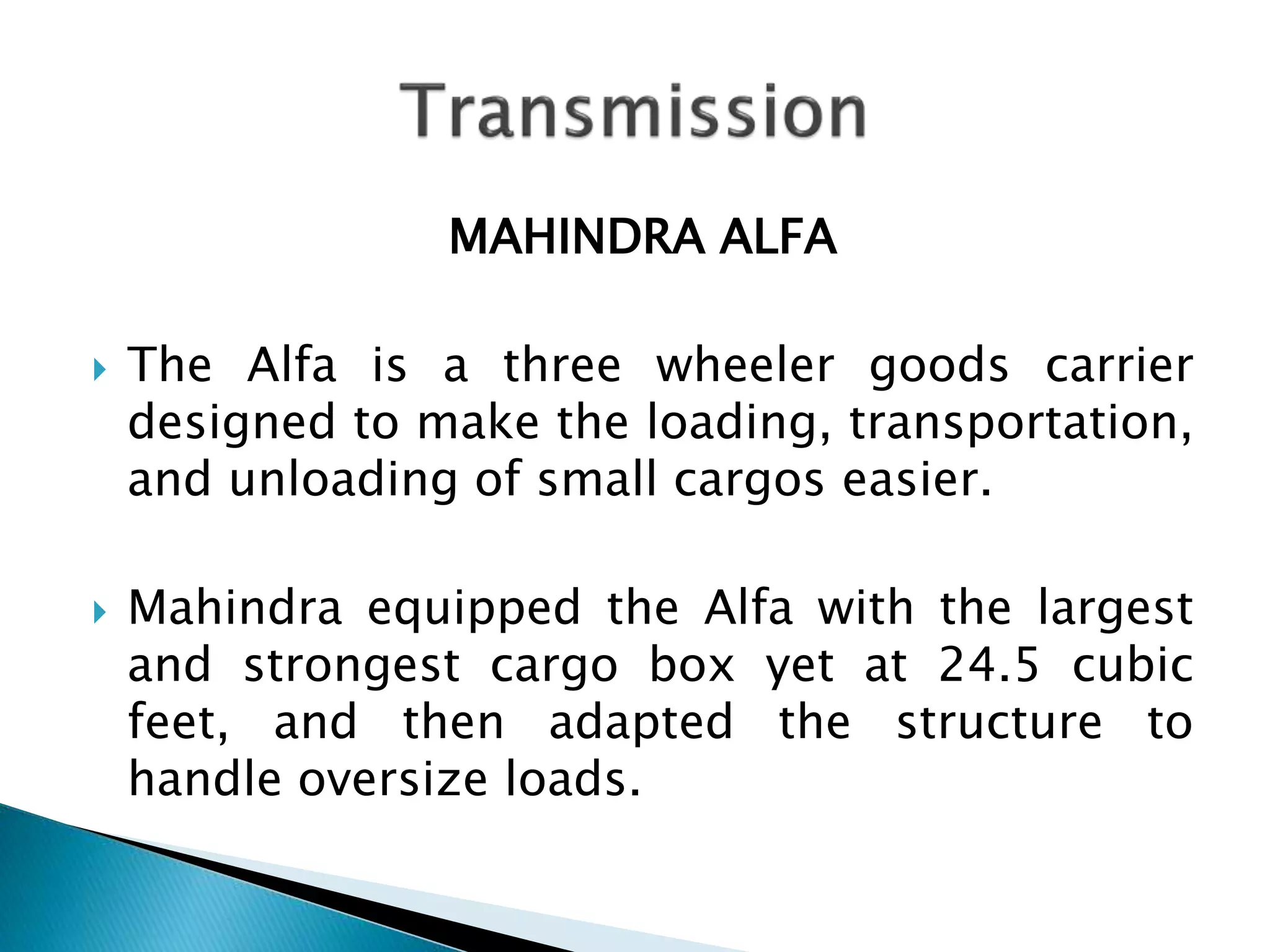

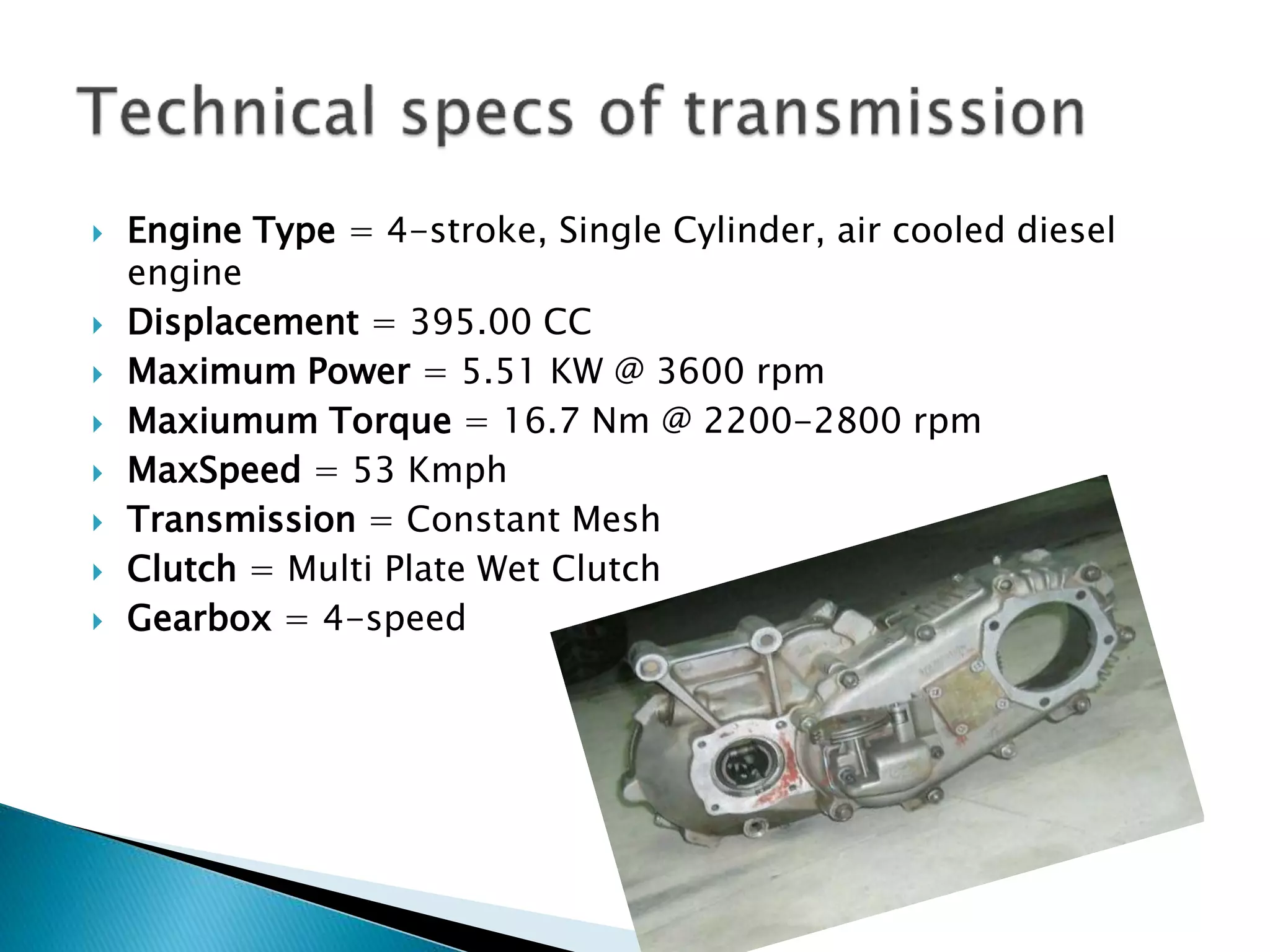

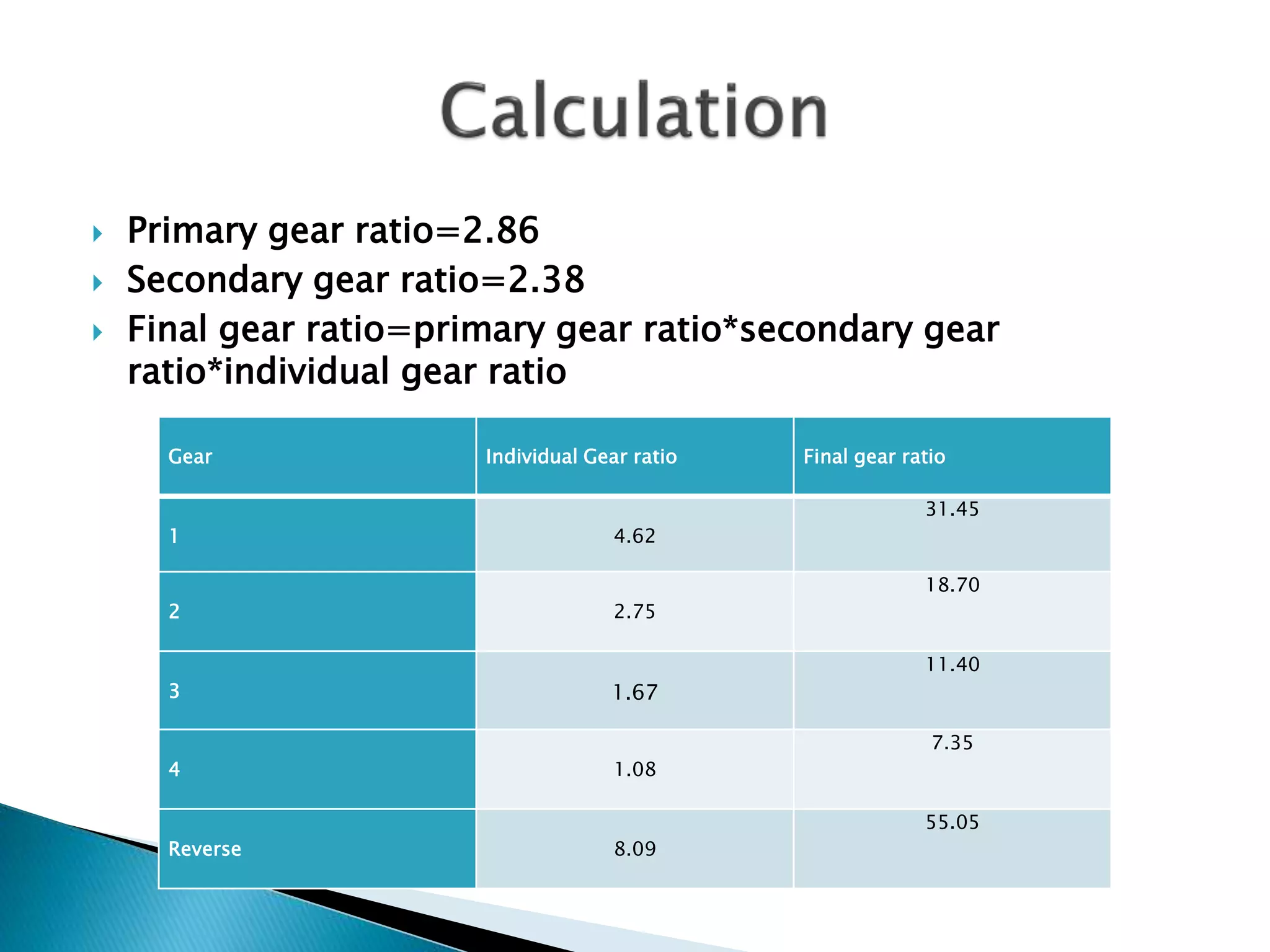

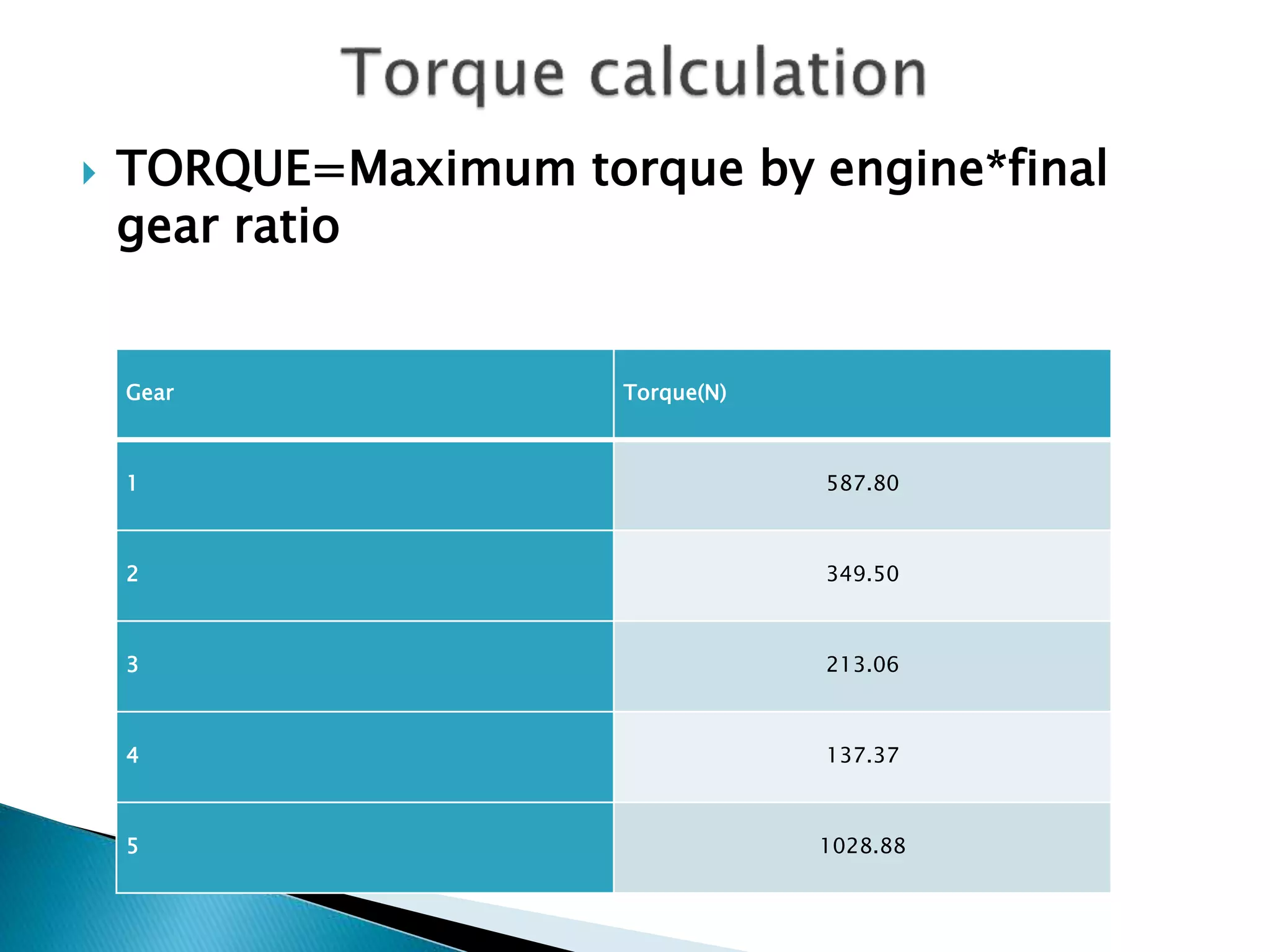

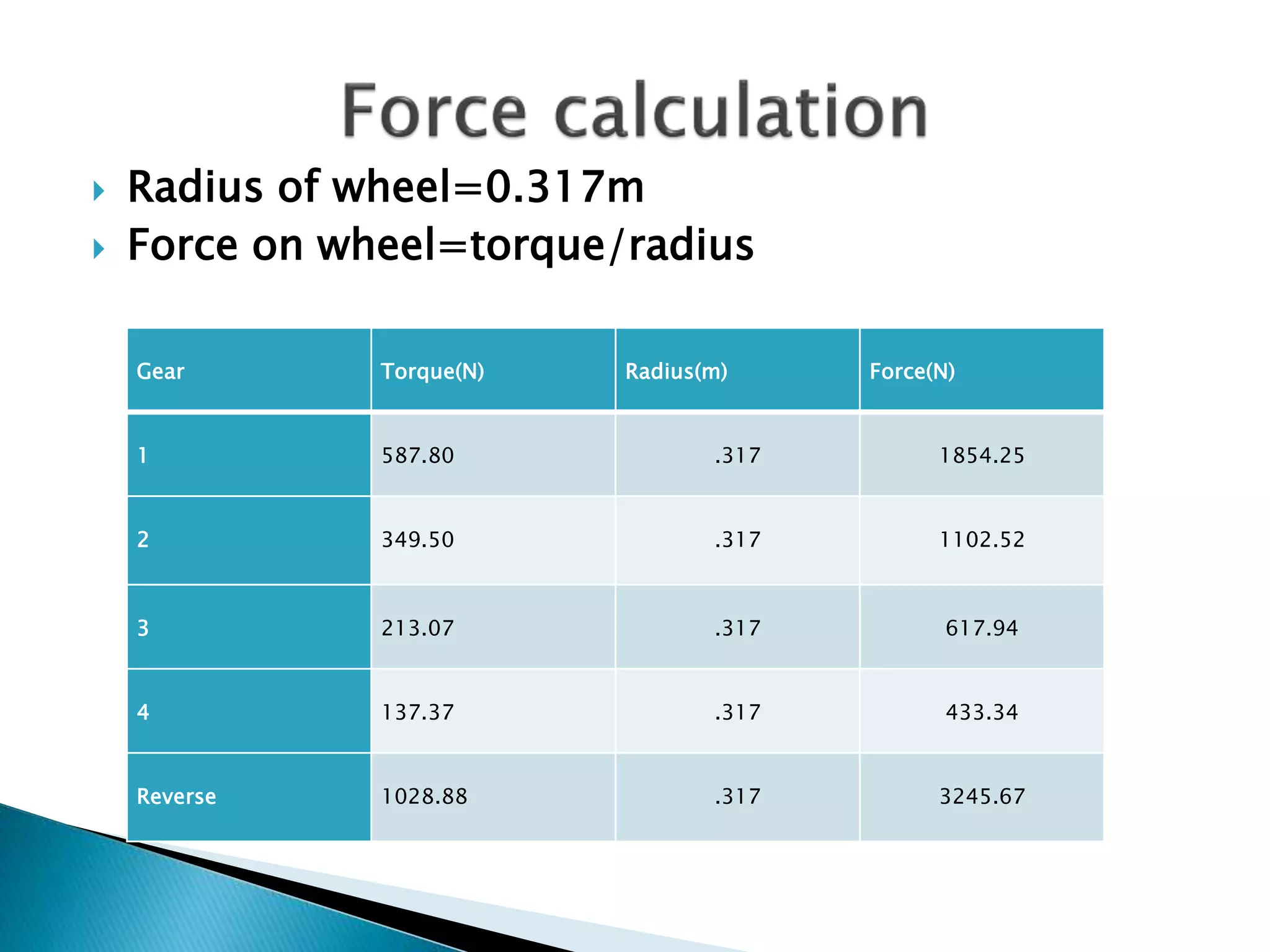

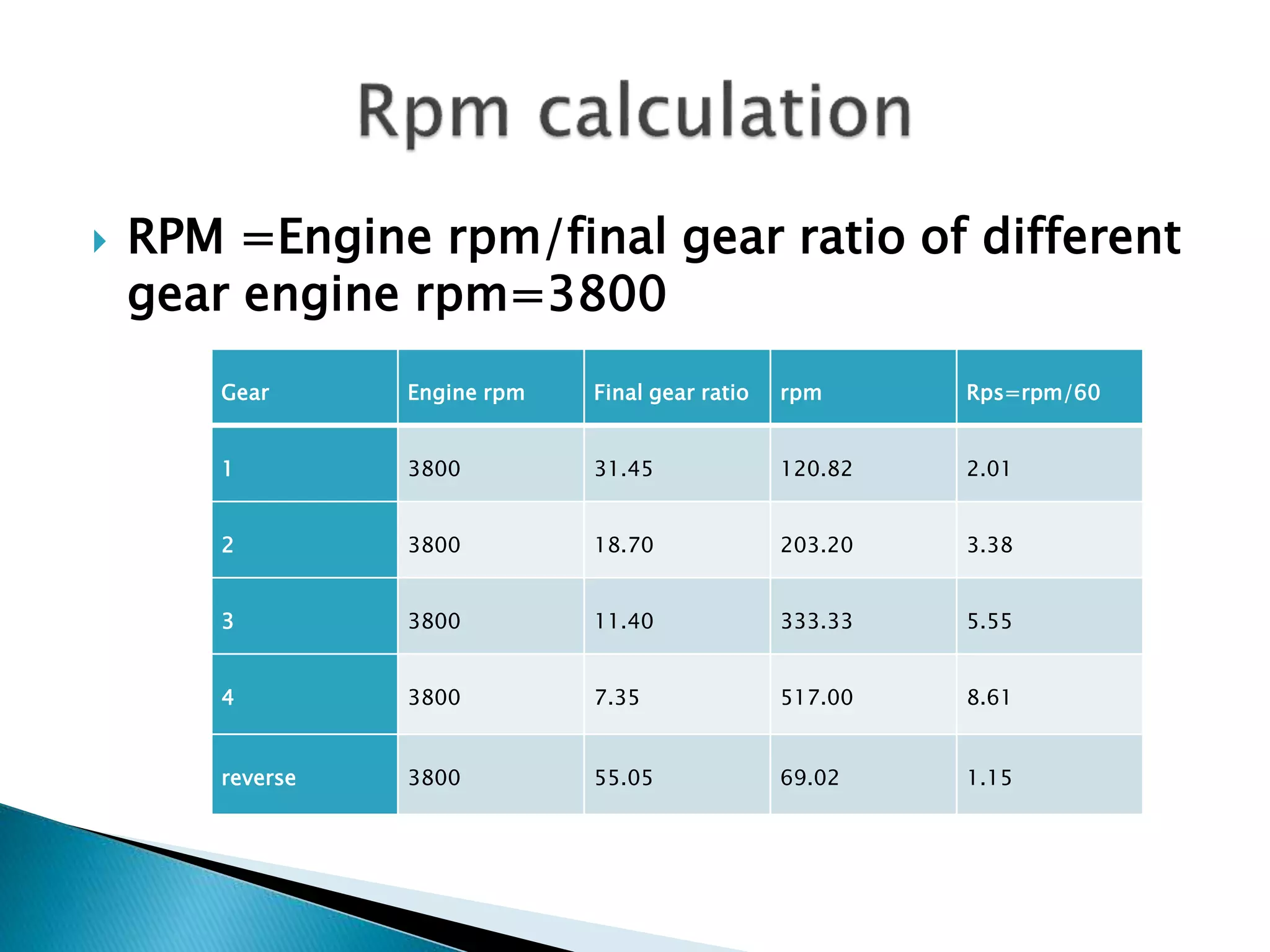

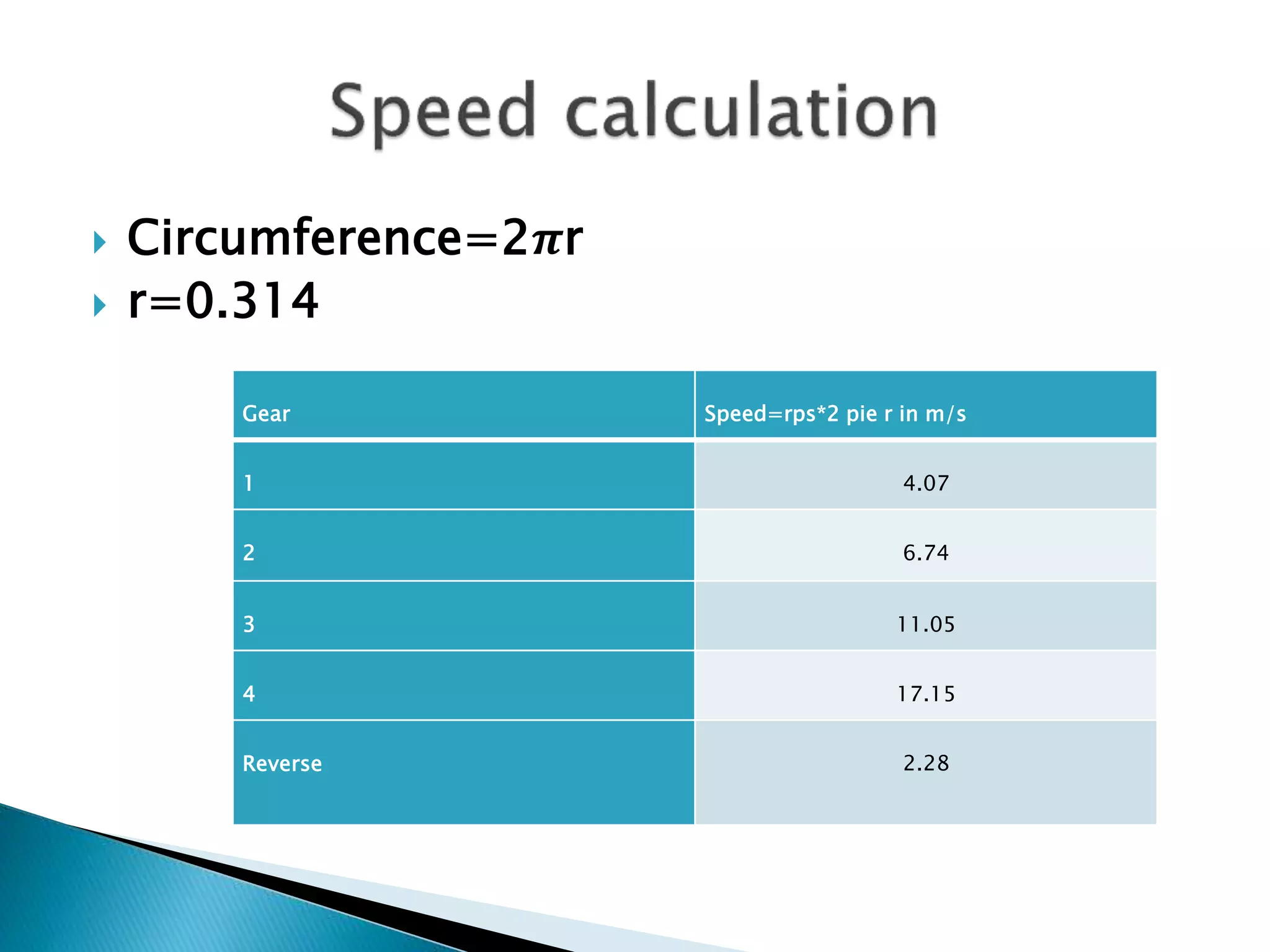

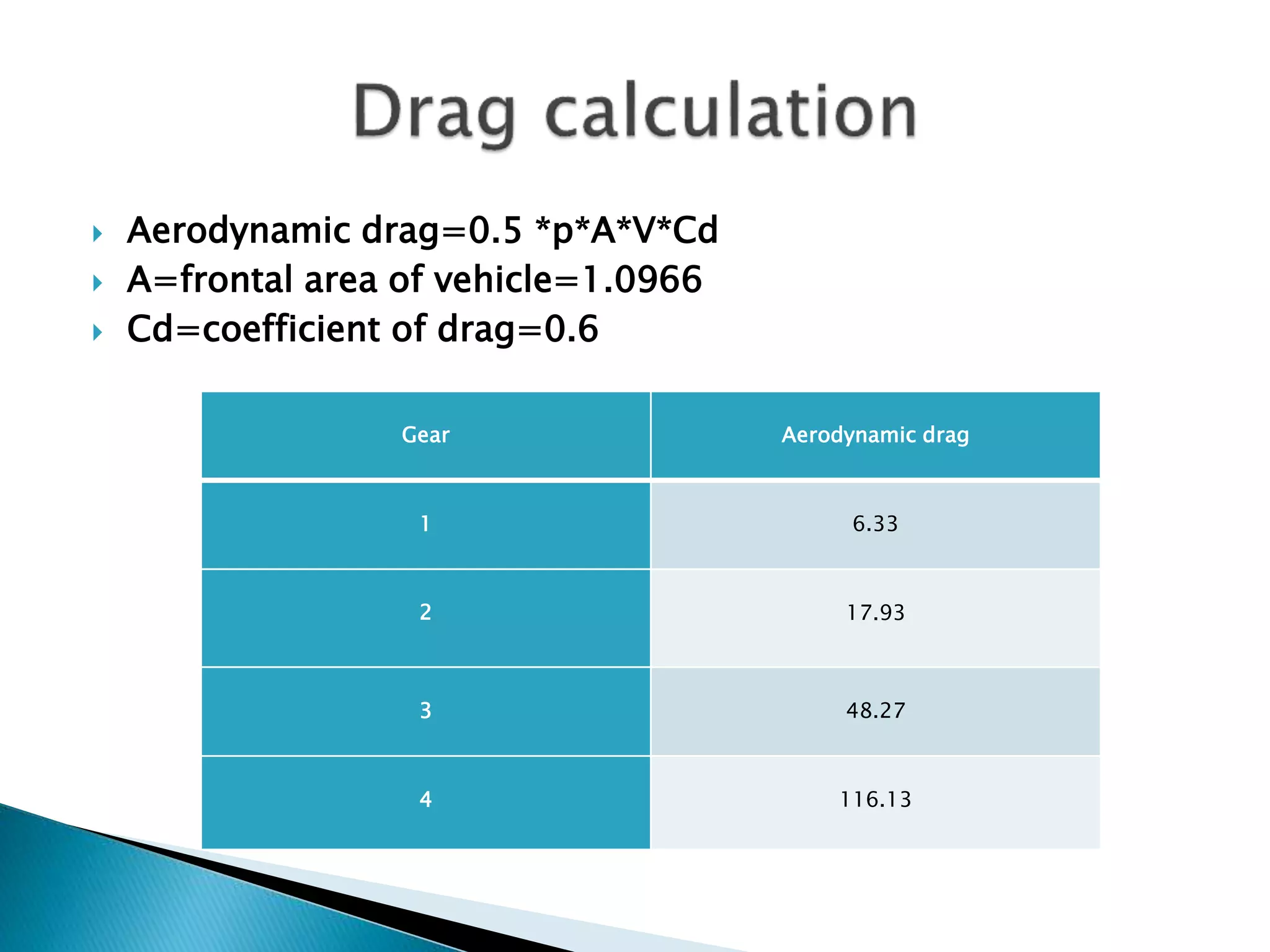

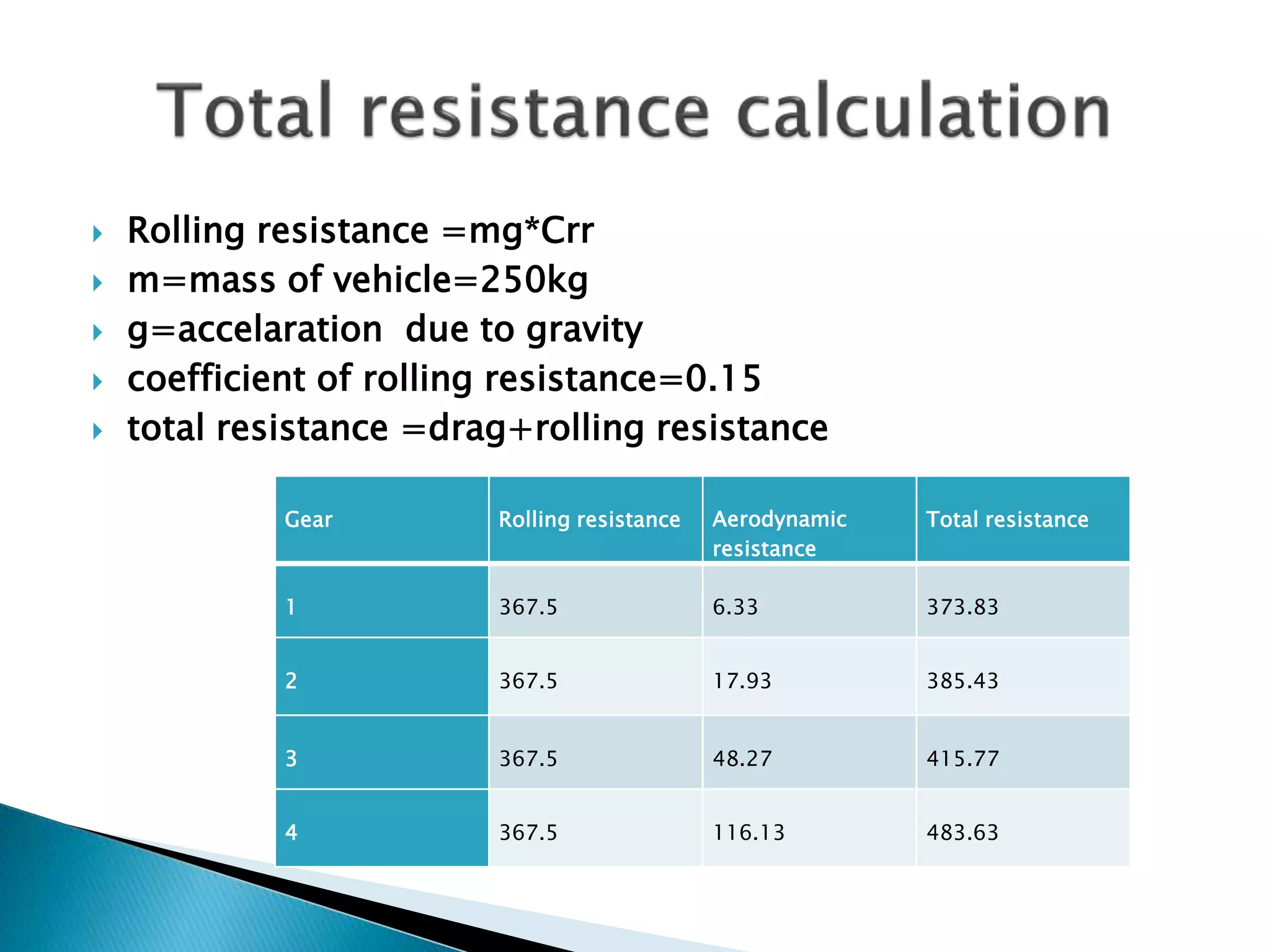

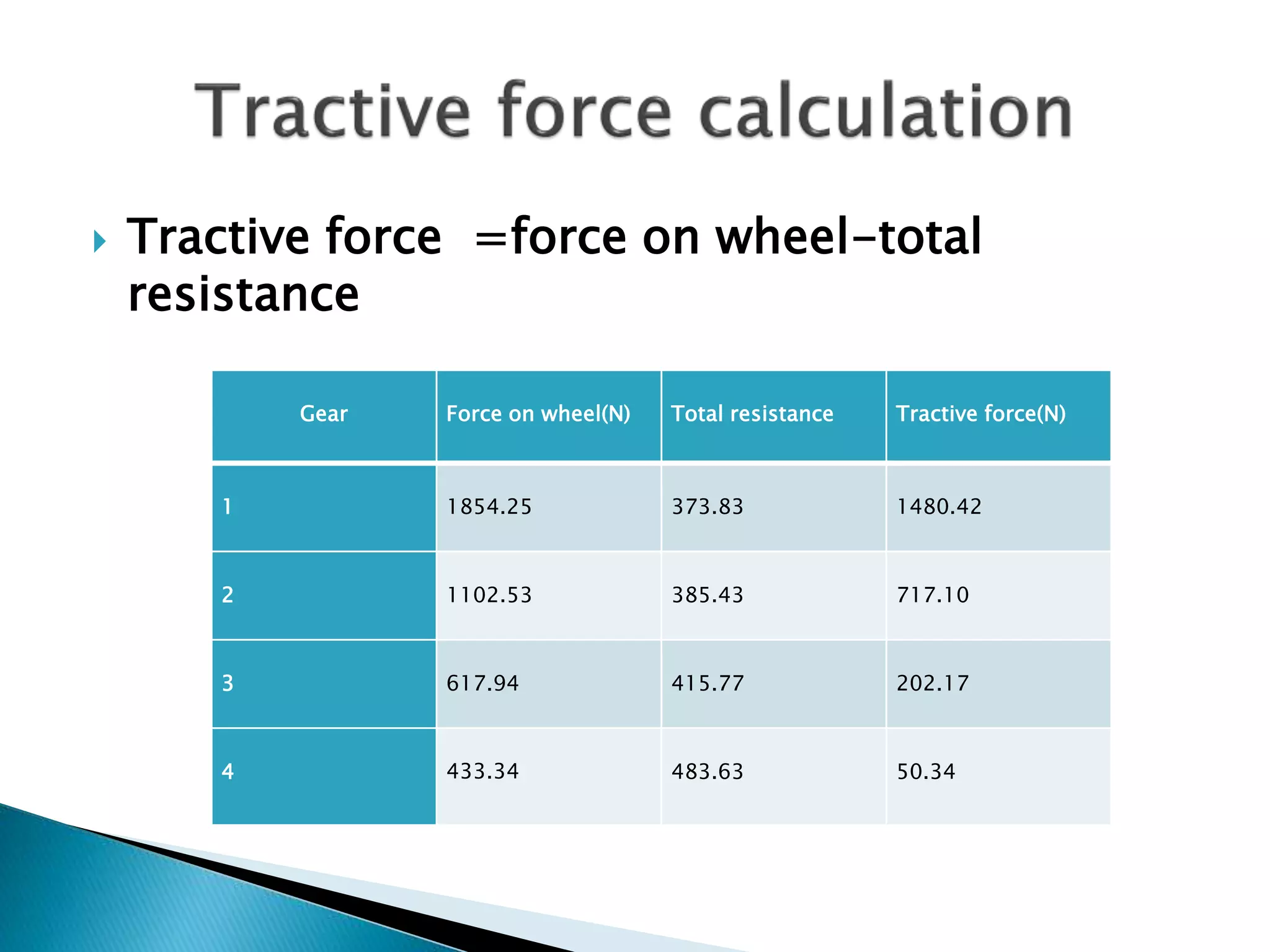

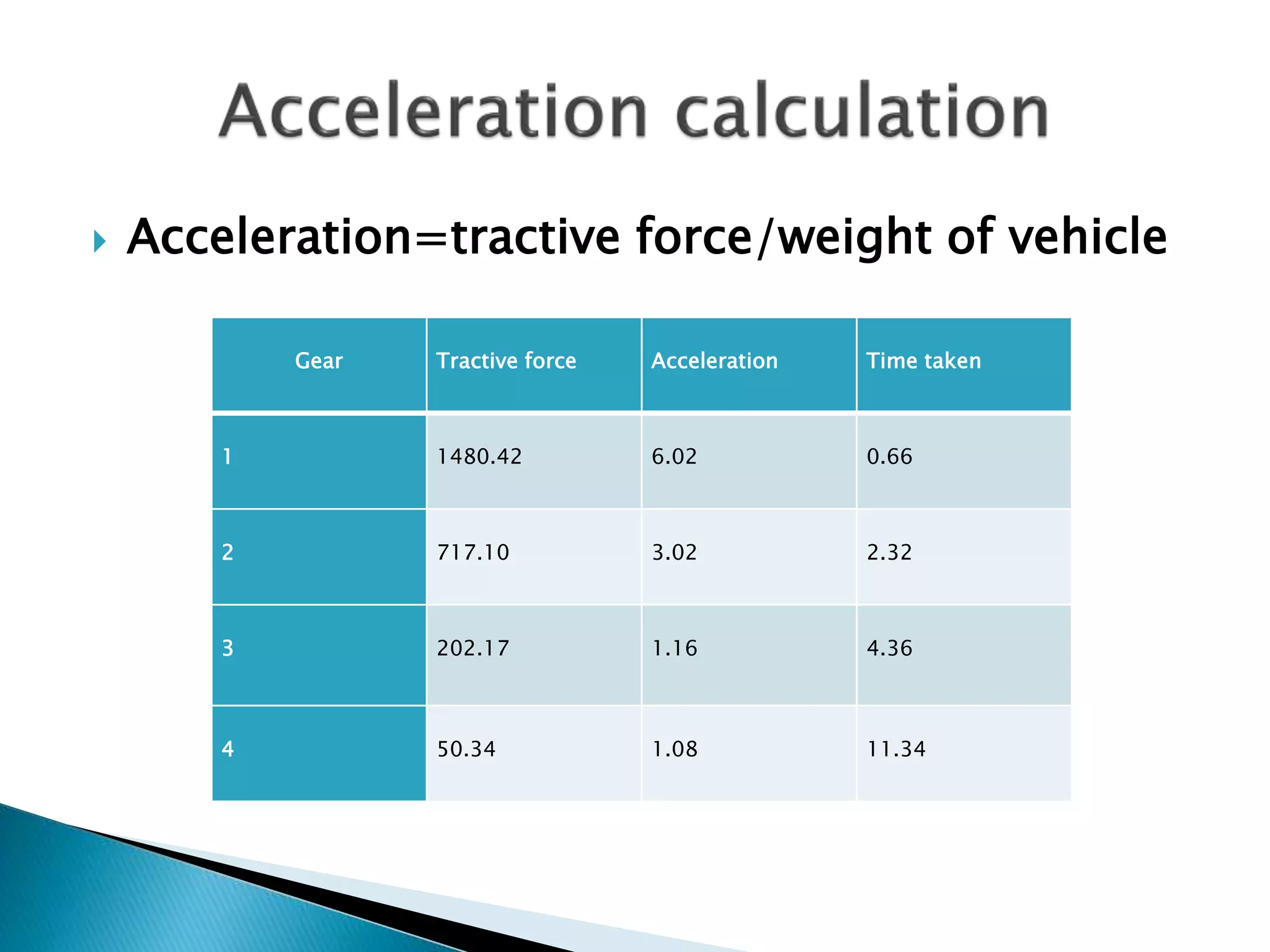

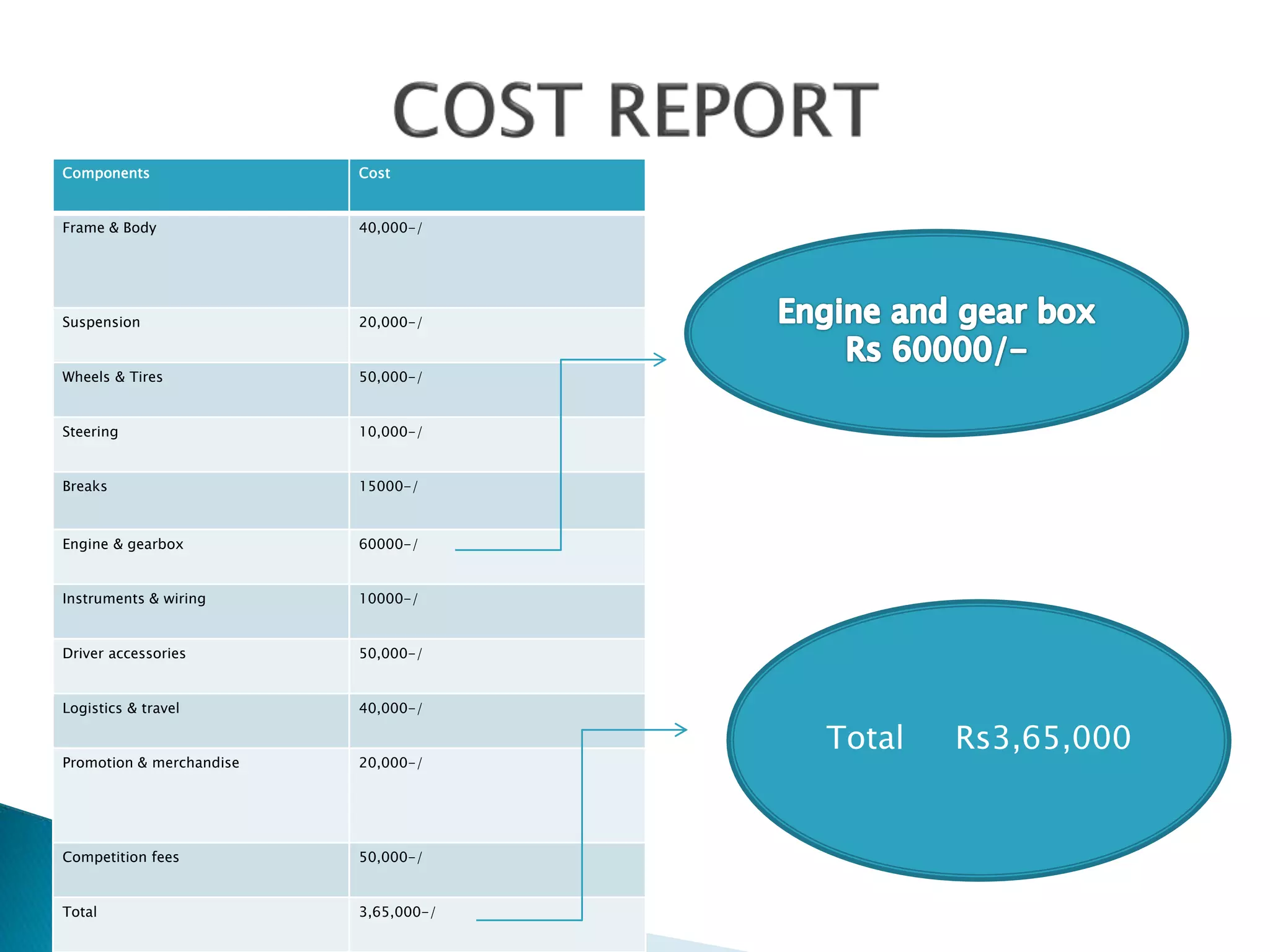

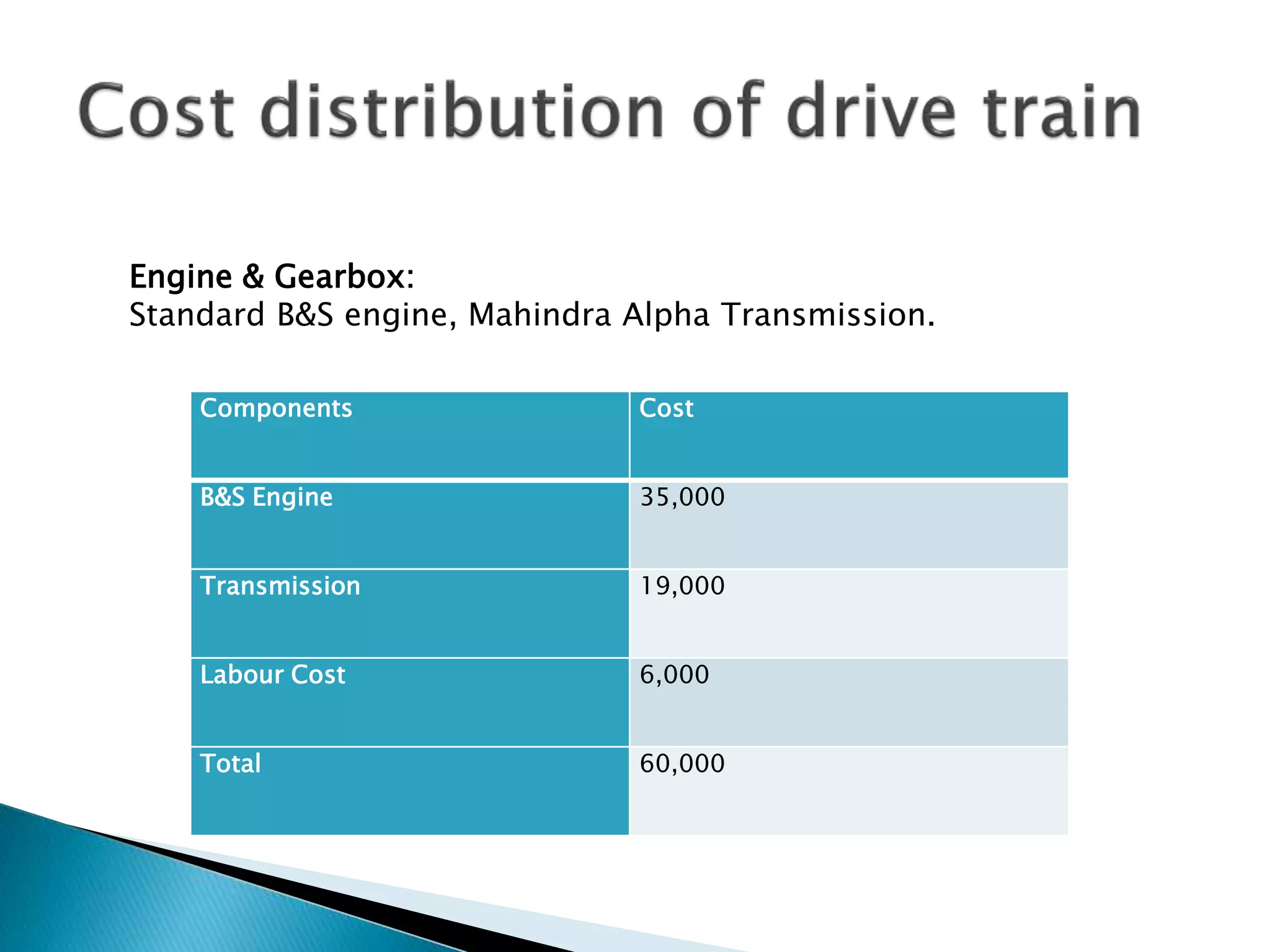

Team Thunderbirds designed and constructed an all-terrain utility vehicle called the Trendnought that uses two treads to traverse various terrains such as snow, mud, grass and gravel. The team selected a Briggs & Stratton 306cc air-cooled gasoline engine and Mahindra Alfa transmission for the vehicle. An analysis of the vehicle's performance in different gears was presented, including tractive force, acceleration, speed and resistance calculations. The total estimated cost of the vehicle project is Rs. 3,65,000, of which Rs. 60,000 is allocated for the engine and transmission.

![ Displacement [cc] = 306

Bore [mm] = 82

Stroke [mm] = 58

Weight [kg] = 25

Oil Capacity = 1.1

Compression Ratio = 8.0 to 1](https://image.slidesharecdn.com/fabricationandtestingofengineanddrivetrain-141110121758-conversion-gate02/75/Fabrication-and-testing-of-engine-and-drive-train-4-2048.jpg)