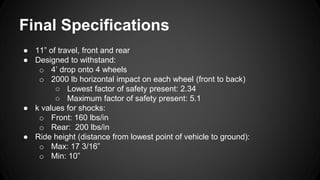

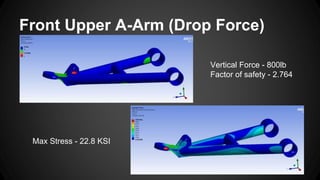

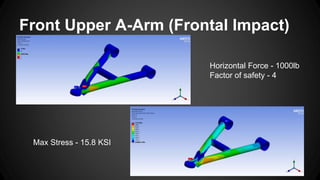

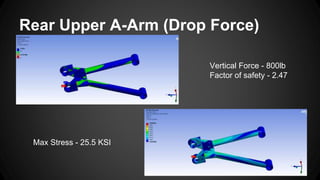

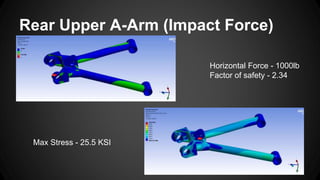

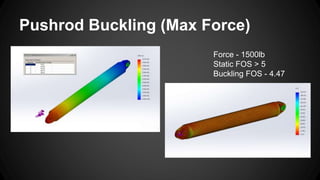

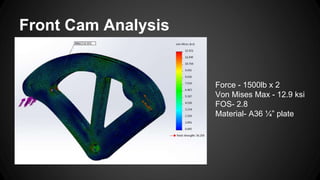

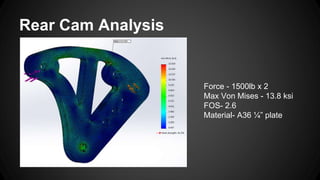

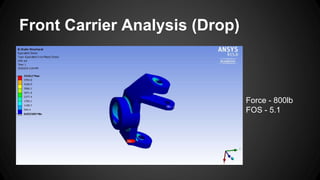

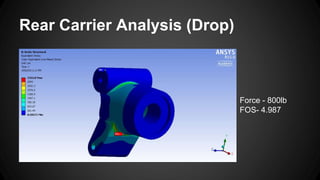

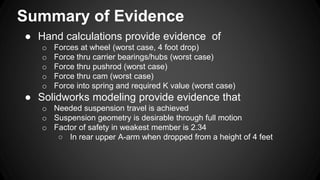

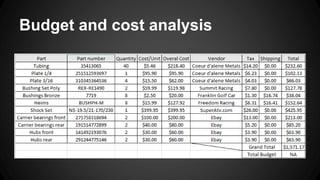

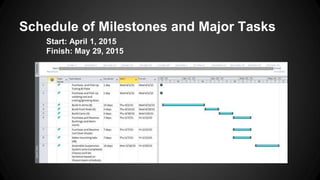

The team designed a suspension system for an SAE Mini Baja vehicle with 11 inches of travel front and rear. The suspension uses a dual A-arm design to allow full travel without interference while maintaining optimal camber. It is adjustable for ride height and stiffness via the pushrod connection on cams. Analysis and modeling showed the design can withstand impacts of 4 feet drops and 2000 pound horizontal impacts on each wheel, with a minimum safety factor of 2.34. The presentation provided details on the final specifications, component designs, analysis results, budget and schedule.