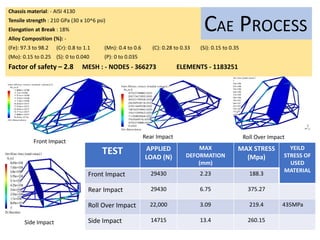

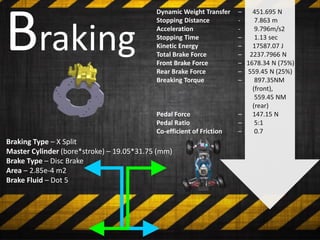

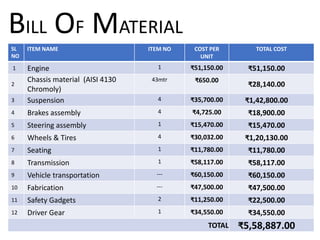

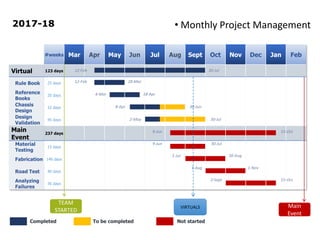

The document provides technical specifications and design details for an electric vehicle called ANDROSPHIN. It includes the vehicle's dimensions, weight, performance characteristics, component designs, analysis, and project planning. Key details are the vehicle's wheelbase of 1517.41mm, max speed of 60kmph, stopping distance of 7.867m, and total weight of 294kg. The chassis is made of AISI 4130 steel alloy. Components like the suspension, brakes, steering, and powertrain are also described in detail along with analysis of stresses and forces. The project timeline is outlined in a Gantt chart spanning 2017-2018.