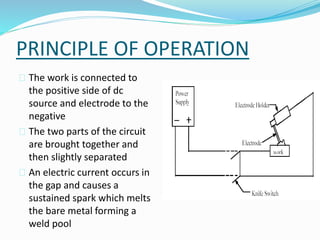

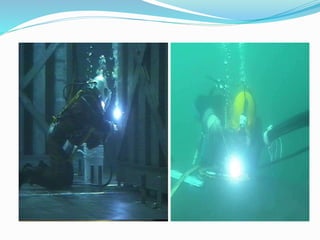

Underwater welding is used for repairing offshore structures like oil rigs and pipelines. There are two main types: wet welding, where welding occurs directly in water using techniques like MMA; and dry welding, where a chamber is created to weld in a dry environment, with techniques like GTAW and GMAW. Wet welding is cheaper but results in poorer weld quality due to quenching, while dry welding produces higher quality welds but requires more complex and expensive equipment like hyperbaric chambers. Proper insulation and ventilation are needed to address risks like electric shock and gas accumulation. Underwater welding is an important but challenging field with ongoing research into deeper diving capabilities.