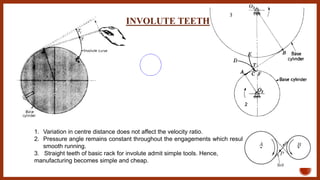

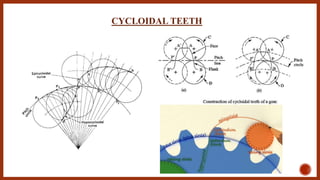

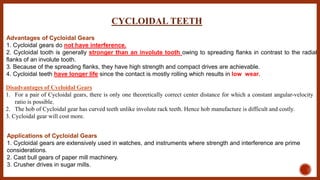

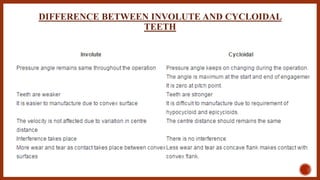

This document discusses gear tooth profiles, specifically comparing involute and cycloidal teeth. It begins by stating that involute teeth have constant pressure angle throughout engagement, resulting in smooth running. It also notes that involute teeth can be manufactured simply and cheaply using basic rack tools. The document then lists advantages of cycloidal teeth, such as no interference, higher strength, and longer life due to mostly rolling contact. However, it also outlines disadvantages of cycloidal teeth, namely that they require a specific center distance and have more difficult hob manufacture. Applications of cycloidal gears include watches and paper mill machinery where strength is important.