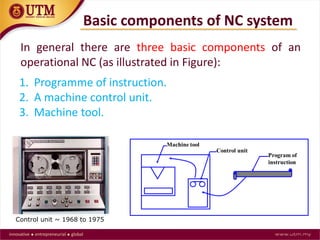

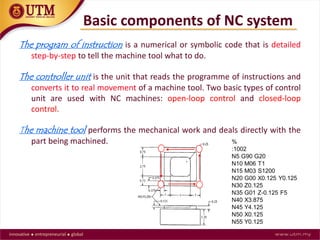

This document provides an introduction to CNC milling. It begins by defining NC and CNC, explaining that CNC refers to a computer connected to an NC machine to increase versatility. It then discusses the basic components of an NC system, including the program of instructions, control unit, and machine tool. The document outlines different milling processes like face milling and end milling. It also explains machine coordinate systems and CAD/CAM software integration. Advantages of CNC include increased productivity and accuracy while limitations include high costs.