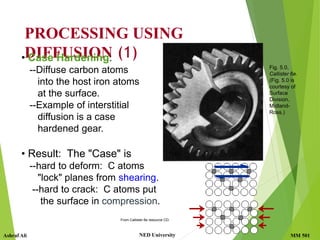

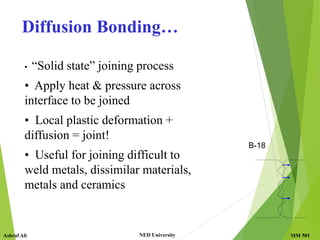

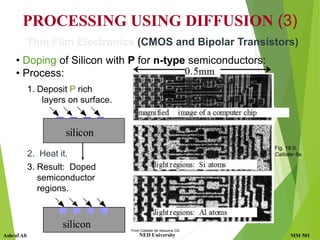

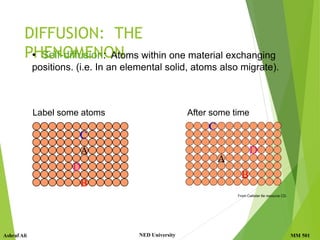

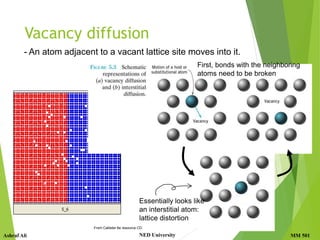

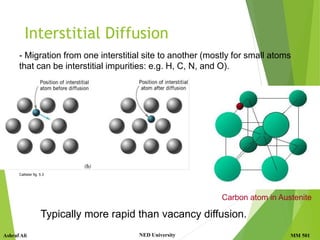

This document discusses diffusion in solids, which is the phenomenon of material transport through atomic motion even in crystalline solids. Diffusion plays an important role in materials processing and phase transformations. It occurs through mechanisms like vacancy diffusion or interstitial diffusion. Fick's laws of diffusion can be used to model and predict diffusion rates based on factors like concentration gradients, diffusion coefficients, and temperature. Applications of diffusion include alloying, case hardening, doping of semiconductors, corrosion protection, and diffusion bonding.

![MM 501

Ashraf Ali NED University

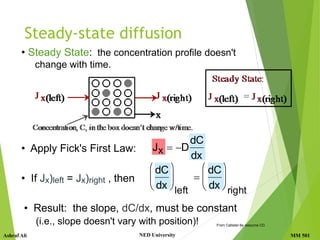

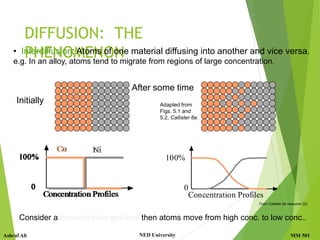

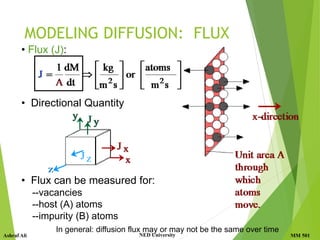

MODELING DIFFUSION

What causes net flow of atoms?

• Concentration Profile, C(x): [kg/m3]

• Fick's First Law:

Concentration

of Cu [kg/m 3]

Concentration

of Ni [kg/m 3]

Position, x

Cu flux Ni flux

• The steeper the concentration profile,

the greater the flux!

Adapted from

Fig. 5.2(c),

Callister 6e.](https://image.slidesharecdn.com/diffusioninsolids-lecture-1-220912150542-a40c90f6/85/Diffusion-in-Solids-Lecture-1-ppt-20-320.jpg)