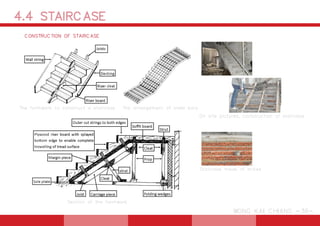

1. Concrete beams, columns, slabs, walls and staircases were constructed on site using formwork and reinforcement bars.

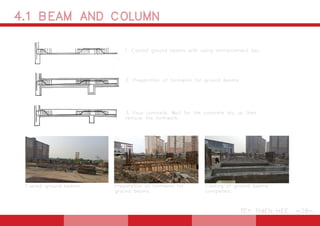

2. For beams and columns, formwork was erected, reinforcement bars were installed, and then concrete was poured and allowed to cure.

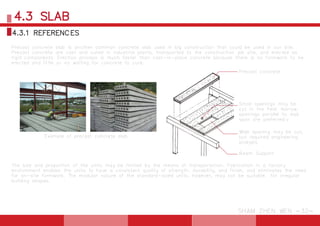

3. Concrete slabs were either precast off site or cast in place using formwork, reinforcement, and concrete pouring and curing.

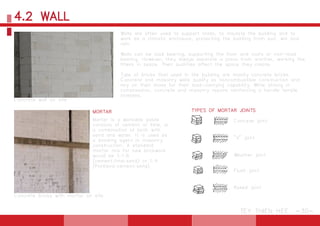

4. Walls were constructed using concrete bricks laid with mortar.