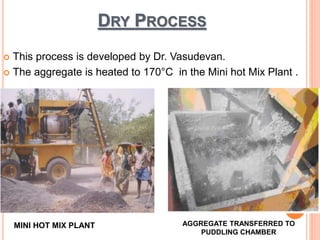

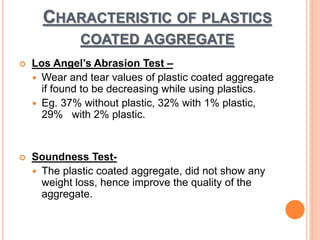

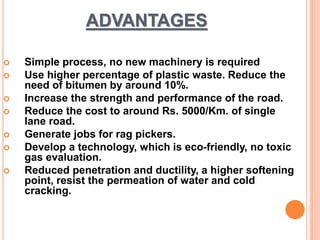

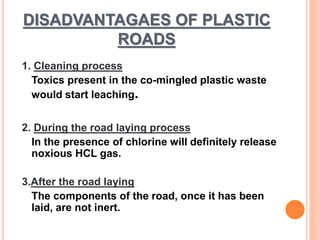

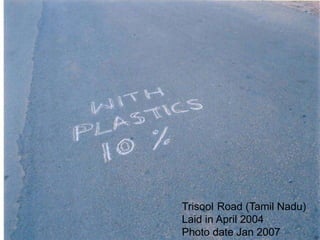

This document discusses using plastic waste in road construction. It begins by outlining the process, which involves segregating, cleaning, shredding and collecting plastic waste. There are two methods for incorporating plastic into roads - a wet process that mixes plastic directly with hot bitumen, and a dry process where plastic coats heated aggregates before adding bitumen. Using plastic in roads provides benefits like increased strength and reduced costs, while helping address the problem of plastic waste. However, there are also potential disadvantages like toxic chemical leaching during construction and use. Overall, plastic roads present an environmentally-friendly way to strengthen pavements and reduce plastic pollution.