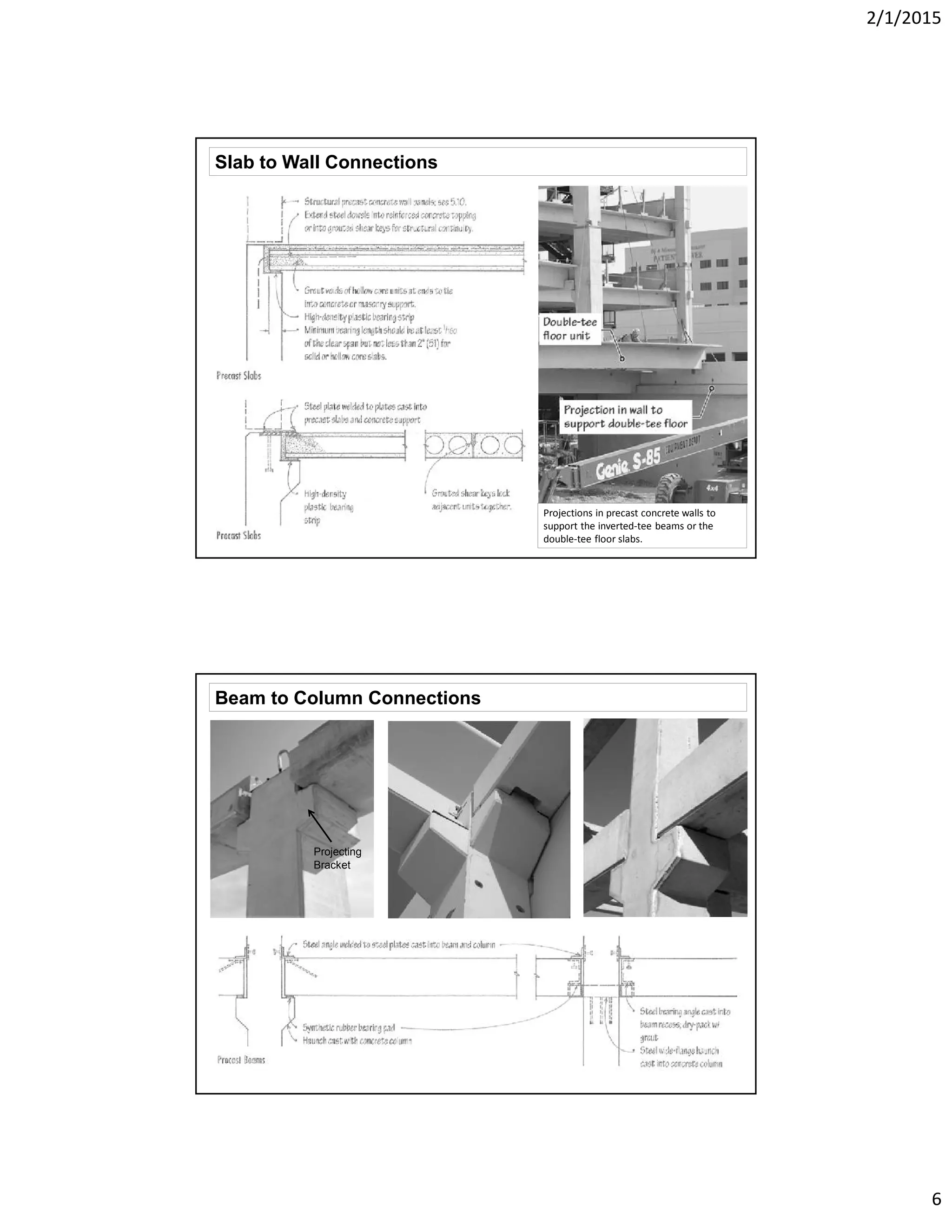

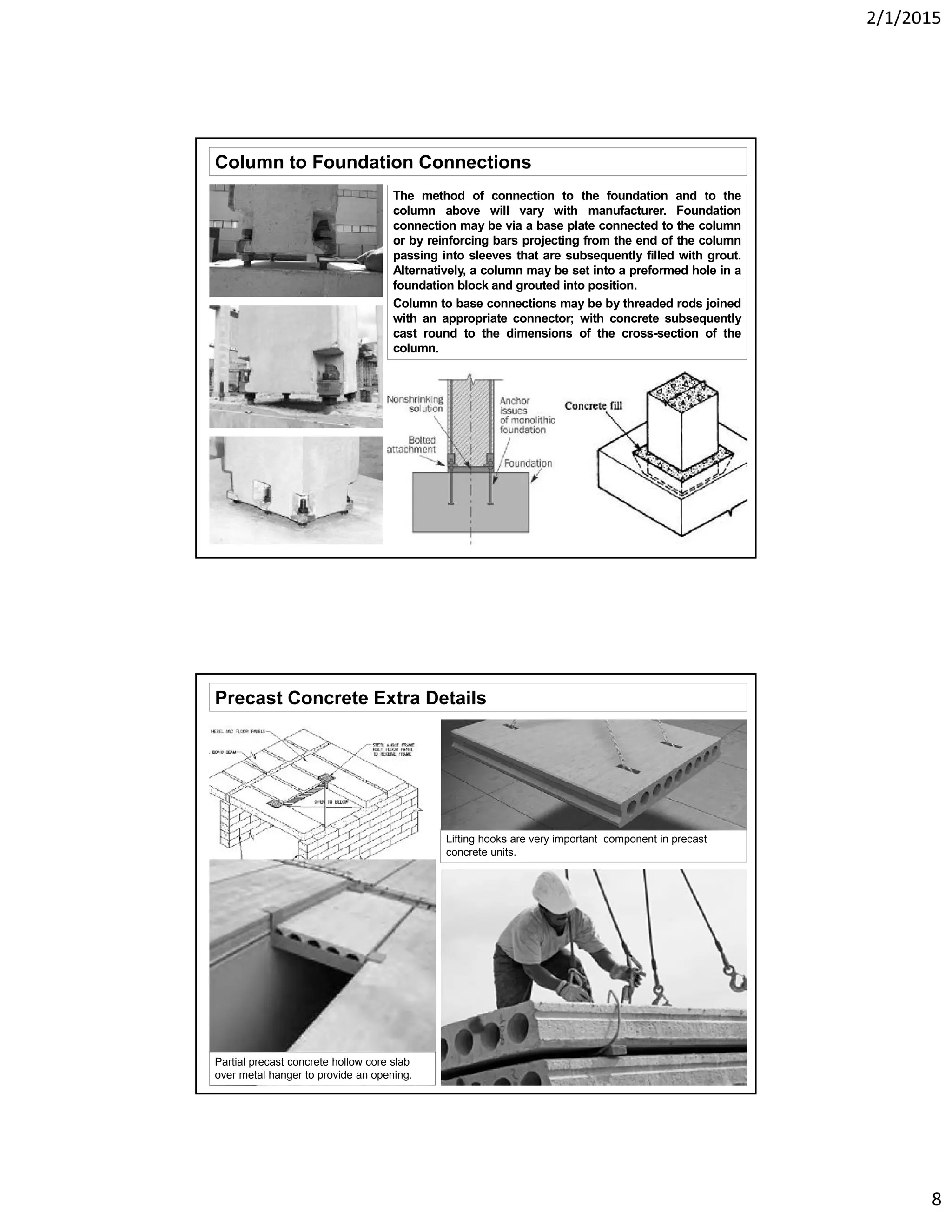

This lecture discusses precast concrete construction. It differentiates between architectural and structural precast concrete. Total precast construction uses only precast concrete for all building elements, while mixed precast combines precast with other materials. Joints and connections between precast elements are crucial and include slab to slab, slab to beam, and column to column connections. The construction process for precast buildings is similar to steel construction, with elements connected by welding or bolting after being lifted into place by crane.