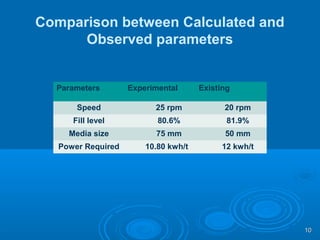

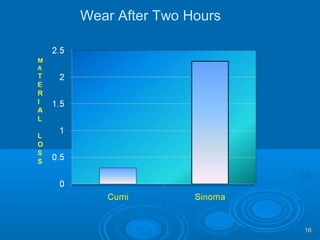

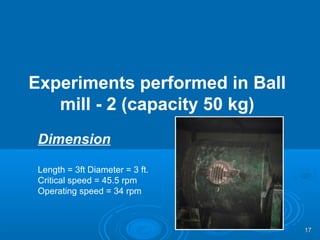

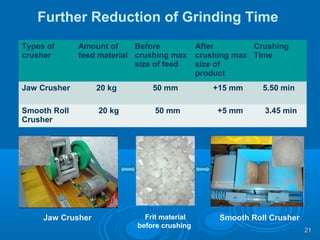

The document discusses experiments conducted to improve the efficiency of a ball mill. It outlines the objectives, which were to analyze the existing grinding system, optimize factors affecting efficiency, and generate a standard operating procedure. Experimental results showed that optimizing operating speed to 25 rpm, fill level to 80.6%, media size to 75mm, and adding a grinding aid reduced grinding time from 10-11 hours to 5 hours. Using a jaw or roll crusher to pre-crush feed materials before grinding also decreased grinding time. Based on the results, it was recommended to implement these optimized parameters and use cumi media in the ball mill.

![Maximum Media Size

M = √[(FWi/KCs)/√(S/√D)]

Where M = Diameter of the top size media (inch)

F = Feed size (µm)

Wi = Work Index, Cs = percent critical speed

K = constant S = Sp. Gravity of feed (g/cc)

D = Inside diameter of Mill (ft)

Observation

F = 10000 µm, Wi = 13.57

K = 200 Cs = 75,

S = 2.23 g/cc D = 5.58 ft

M = (10000*13.57)/(200*75)

√(2.23/√5.58)

M = 2.9647 inch = 75.30 mm 88](https://image.slidesharecdn.com/87e6fab1-f01e-40f4-94e5-70052cfd8630-160919044431/85/Ball-mill-grinding-Ramkrishna-8-320.jpg)