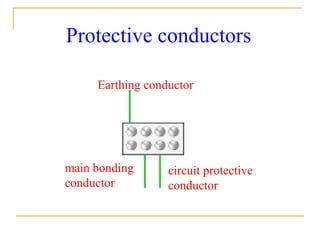

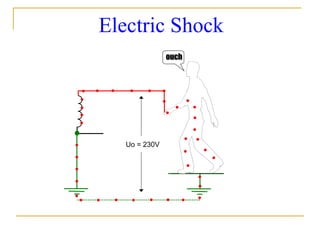

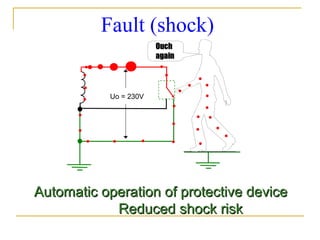

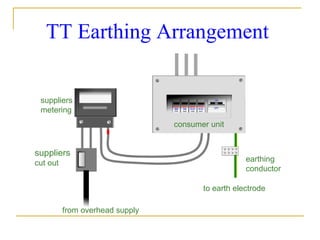

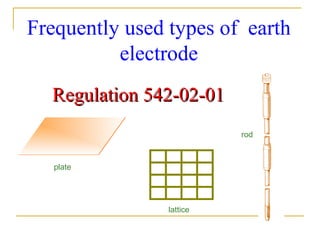

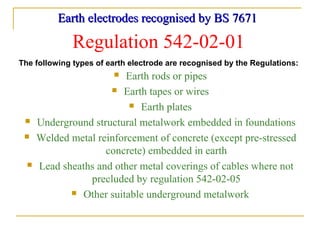

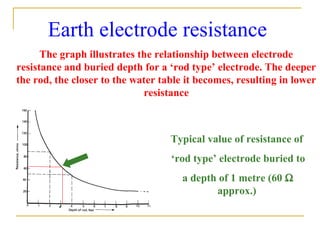

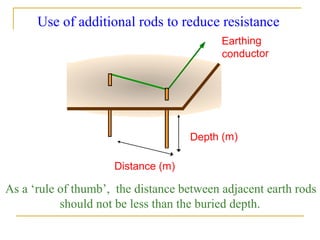

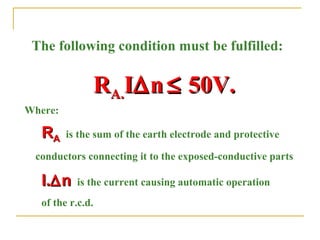

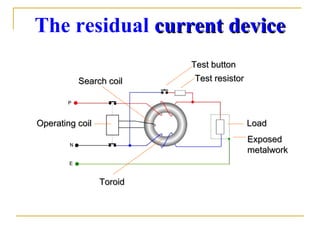

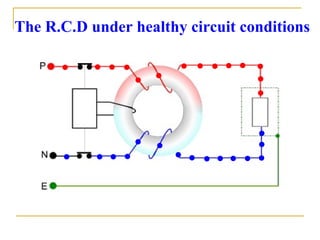

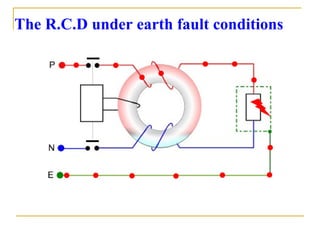

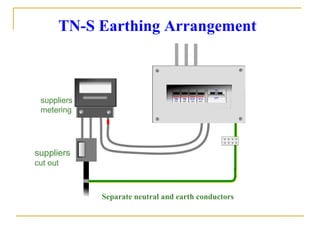

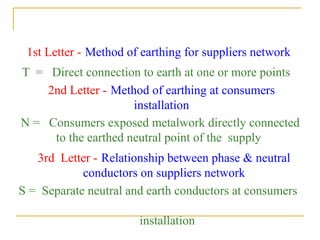

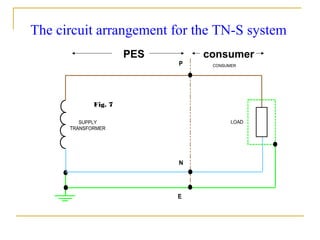

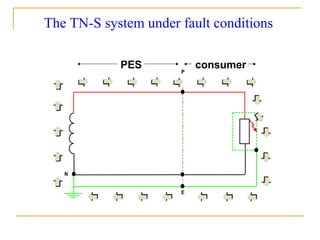

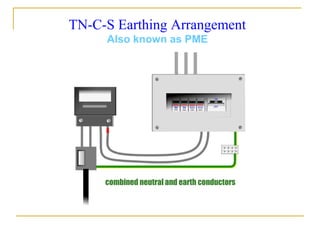

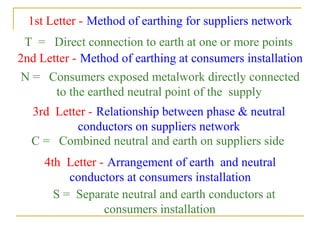

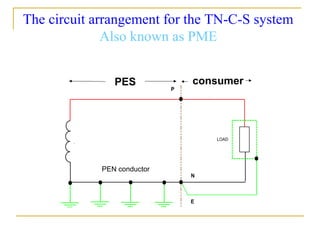

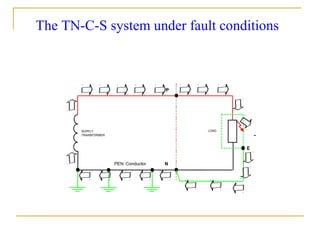

The document discusses earthing arrangements and protection against electric shock. It defines key terms like earthing, protective conductors, and fault conditions. It describes the three common earthing arrangements - TT, TN-S, and TN-C-S systems. For each system, it explains the wiring configuration and how fault currents flow. Protection methods like RCDs and their operation are also covered to prevent electric shock. Diagrams and formulas are provided to calculate touch voltages and ensure safety.