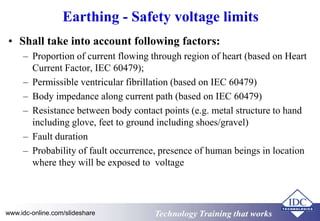

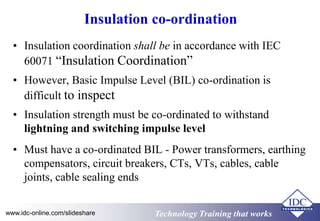

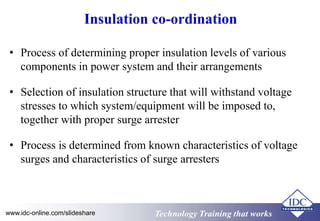

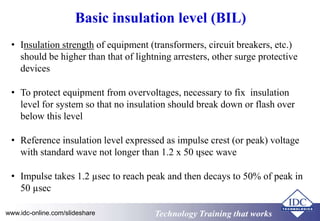

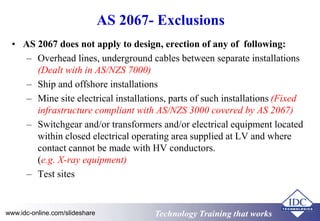

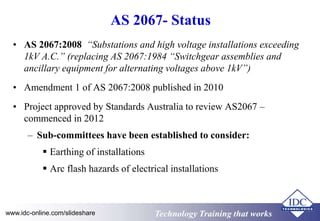

The document outlines best practices and requirements for high voltage installations exceeding 1 kV AC, emphasizing the need for safety measures, proper equipment selection, and compliance with relevant standards. It covers aspects such as earthing systems, insulation coordination, and safety criteria to protect both personnel and equipment from electrical hazards. Additionally, it discusses specific standards applicable to various electrical installations, including those in mining and power generation sectors.