MMF vs Natural Fiber: Which is Better?Natural fibers have benefits like being renewable, biodegradable and softer but can be more expensive. Man-made fibers can be engineered for properties like durability but involve more pollution. A balanced approach using both sustainably is ideal for the textile industry

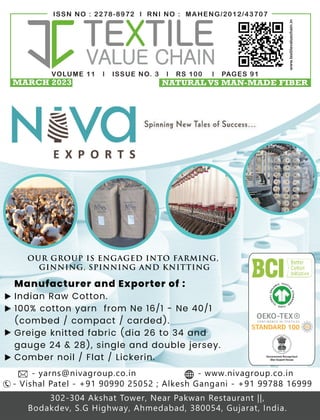

- 1. VOLUME 11 l ISSUE NO. 3 l RS 100 l PAGES 91 ISSN NO : 2278-8972 l RNI NO : MAHENG/2012/43707 www.textilevaluechain.in MARCH 2023 NATURAL VS MAN-MADE FIBER V O L U M E 1 0 | I S S U E N O . 0 9 | R S 1 0 0 | P a g e s 8 0 I S S N N O : 2 2 7 8 - 8 9 7 2 | R N I N O : M A H E N G / 2 0 1 2 / 4 3 7 0 7 www.tex levaluechain.in OUR GROUP IS ENGAGED INTO FARMING, GINNING, SPINNING AND KNITTING Manufacturer and Exporter of : Indian Raw Cotton. 100% cotton yarn from Ne 16/1 - Ne 40/1 (combed / compact / carded). Greige knitted fabric (dia 26 to 34 and gauge 24 & 28), single and double jersey. Comber noil / Flat / Lickerin. - Vishal Patel - +91 90990 25052 ; Alkesh Gangani - +91 99788 16999 302-304 Akshat Tower, Near Pakwan Restaurant ||, Bodakdev, S.G Highway, Ahmedabad, 380054, Gujarat, India. - yarns@nivagroup.co.in - www.nivagroup.co.in TEXTILE VALUE CHAIN 1 SEPTEMBER 2022 TEXTILE VALUE CHAIN 1 SEPTEMBER 2022

- 5. www.lemeriteexports.com yarn@lemeriteexports.com PRODUCT Exports Ltd Raw cotton Yarn Greige fabric

- 6. MARCH 2023 6 www.textilevaluechain.in CONTENT ADVERTISER INDEX : COVER STORY : MMF & Natural Fiber: Opportunities & Co-dependence MMF or Natural Fiber: A Choice or Preference for Sustainability Natural Fiber vs Man Made Fiber Which is Strongest? 12 17 19 Natural Fibers Man Made Fibers US Apparel MARKET REPORT : 24 26 88 INTERVIEW : Interview with Mr. Vishwanath Agarwal, Chairman, PDEXCIL Interview with Mr. Sandesh Saxena, Gencrest Interview with Mr. B. P. Sultania, Ganesha Ecosphere Interview with Mr. Paresh Bhai, Maruti Texprocess Interview with Mr. Harvinder Singh, Amar Jacquard 32 35 39 40 41 Insights about Textile Engineering with Mr. Subrata Ghosh INTERVIEW - EDUCATIONIST : 55 Paramount’s Successful Live Demonstration Khadi and Handloom for Sustainable Fashion Lecture on Budget Highlights at TAI office POST EVENT REPORT : 58 61 63 REVIEW PAPER : The Next Generation of Sustainable and Durable Antimicrobial Technology for Cotton The Role of Supervisors in the Textile Industry 66 79 LeMerite Exports - 5 Rameswar - 7 Real Prince - 9 Yash Machine - 11 Indo German - 15 WellKnown - 16 Elite Conference - 22 Yamuna Machines - 23 Gartex - 27 Unitech - 28 ColorJet - 30 Omax - 31 Amith Garment - 33 COVER : NIVA EXPORTS FRONT GATEFOLD : VATSAL EXPORTS FRONT INSIDE : FIOTEX BACK INSIDE : RAYSIL BACK : RAYMOND 1 2 4 90 91 EVENT CALENDAR 10 Sustainability and Circularity of Textiles The Boom of Recycled Yarns from rPET Bottles ARTICLE - SUSTAINABLITY : 48 52 Union Budget 2023: What is There for Textile Industry? UNION BUDGET 2023 : 44 Status Check on Global Trends and India’s Textile Industry TREND REPORT : 71 Corporate Lessons to Learn from Bollywood ARTICLE - BUSINESS STRATEGY : 75 How Textile Companies are Maintaining Operations Throughout Facility Upgrades ARTICLE - INDUSTRY UPDATES : 85 Artilect Outerwear Features World’s First User-Repairable Zippers FORLOH Introduces American Made Down Expedition Series INNOVATION CORNER : 21 68 Parliamentarians and Industry Deliberation for Cheap and Quality Raw Materials NEWS REPORT : 29 Bruckner - 34 TechTextil - 37 Uster - 38 ITMA - 42 Ken - 43 Astra Tech India - 46 Texfab - 47 Yarnex - 50 Saurer - 51 Cosmos - 54 Kotak Ginning - 59 Alliance Fibres - 60 ATE - 64 Ramkrishna Cotspin - 65 Shahlon Group - 69 Staubli - 70 Chintamani Export - 73 GSCS - 74 SSPL - 77 Zydex - 78 D. Badami - 82 Art Yarn - 83 Meera Industries - 84 Inventicon - 87

- 7. -6 VARIETIES

- 8. MARCH 2023 8 www.textilevaluechain.in Natural Fibers and Man-Made Fibers: Comparison and Market Opportunities Natural fibers have the benefits of being renewable, biodegradable, and frequently feel softer and cozier than synthetic fibers. They are easily recyclable and biodegradable, which means they produce less waste and have a smaller environmental impact. However, depending on the source and quality of the fiber, natural fibers may be pricey and have a variety of qualities. On the other hand, man-made fibers, or synthetic fibers, are created by chemical processes and can be engineered to have particular features, such as water resistance, UV protection, or fire retardancy. They are frequently tougher and more resilient than natural fibers and are perfect for a variety of applications. However, they can cause pollution and waste because they are not biodegradable, and they can feel more manufactured and uncomfortably so than natural fibers. In India, the market for man-made fibers is dominated by polyester and viscose, which make up around 94% of the local market. Polyester makes up around 77.5% of the total, with viscose making up the remainder. Man-made fibers are used to create blended and 100% non-cotton fabrics, which are then used to make ready-to-wear apparel, home textiles, and other industrial textiles. The demand for man-made fibers is anticipated to grow by 3.7% in 2025 due to increased use in nonwovens and technical textiles, shifting consumer preferences, growing brand consciousness, rapidly shifting fashion trends, and expanding female labor participation. However, there is also a growing demand for natural fibers, particularly in the context of sustainable fashion, and India has abundant resources in cotton, jute, silk, and other natural fibers. In the fashion and textile industry, co-dependance between natural and man-made fibers can be seen growing rapidly. The blended yarn markets are one of the major market segments in yarn. The blended yarns provides the best of both fibers, the natural softness and colors of natural fibers as well as the strongness and long lasting of man-made fibers. Hrushikesh Takbhate EDITORIAL TEAM EDITOR AND PUBLISHER Ms. Jigna Shah EDITORIAL ASSISTANT Ms. Gargi Dandegaonkar CREATIVE DESIGNER Mr. Adarsh JUNIOR EDITOR Hrushikesh Takbhate TRAINEE EDITOR Ramya Iyer MARKETING AND ADVERTISING ENQUIRY Mohammad Tanweer +91-9167986305 sales@textilevaluechain.com REGISTERED OFFICE: TVC MEDIA AND PROMOTION PVT LTD. 504, Suchita Business Park, Patel Chowk, Pantnagar, Ghatkopar (East), Mumbai- 400075, Maharashtra, INDIA. Cell: +91-9769442239 Email: info@textilevaluechain.com Web: www.textilevaluechain.com Owner, Publisher, Printer and Editor - Ms. Jigna Shah Printed and Processed by her at, Impression Graphics, Gala no.13, Shivai Industrial Estate, Andheri Kurla Road, Sakinaka, Andheri(East), Mumbai 400072, Maharashtra, India. All rights reserved Worldwide; Reproduction of any of the content from this issue is prohibited without explicit written permission of the publisher. Every effort has been made to ensure and present factual and accurate information. The views expressed in the articles published in this magazine are that of the respective authors and not necessarily that of the publisher. Textile Value chain is not responsible for any unlikely errors that might occur or any steps taken based in the information provided herewith. Textile Value Chain EDITORIAL Subscribe Now +91-9869634305 marketing@textilevaluechain.com SUBSCRIPTION

- 9. Yarn Noil Combed Yarn NE 16’s to 40’s Combed Compact Yarn NE 16’s to 40’s Carded Yarn NE 12’ to 30’s (for Knitting & Weaving) Comber noil Flat strip Licker-in 19.HIN.92143 Hohenstein HTTI Inquiry: +91-9979240389, +919815004417 | sarjil@realprincegroup.com | munish@realprincegroup.com 3 Star Export House Fabric Knitted Fabric Single Jersey Single Jersey With Spandex/Rib/Interlock We, vertically integrated manufacturing Units established in Gujarat, one of the most progressive states and the cotton hub of INDIA. I N D I T E X Supplying quality worldwide

- 10. MARCH 2023 10 www.textilevaluechain.in Yarnex Mumbai Mumbai, India https://textilefairsindia.com/yarnex/mumbai/ 6 - 8 April DENIMS AND JEANS INDIA SHOW Banglore, India https://india.denimsandjeans.com/invite 26 - 27 April INNOVATE: TRACEABILITY CONFERENCE Online Event https://innovatetraceability.wtin.com/#register LIFESTYLE PRODUCT SHOWS Hongkong https://www.hktdc.com/ 19 - 29 April 25 - 27 April INDIAN POLYESTER – 2023 Mumbai, India https://www.eliteconferences.com/ 12 April SAIGON EXPO 2023 Hochiminh City, Vietnam http://sgntex.com/en/online-registration/ 5 - 8 April INDIA FURNITURE & DECOR EXPO – 2023 SLPS Event Center, Dallas https://ifde.sgcci.in/ 27 - 29 April E V E N T C A L E N D A R A P R I L 2 0 2 3

- 11. AUTOMATIC ROLLING & CUTTING MACHINE MAIN FEATURES Automatic fabric winding restart Automatic barcode labelling Cut optimization software Automatic cross cutting Automatic packing www.yashtex.com sales@yashtex.com I +91 9167772065 I H o t air Blower P a cked rolls Hall No. 14, Stall No. B205 VISIT US AT: APPLICATION AREA Samples for shade matching Automatic roll weighing Tension control with load cell Data management software OPTIONS

- 12. 12 MARCH 2023 www.textilevaluechain.in COVER STORY Fibres are utilised in a variety of products, including industrial materials as well as clothes and textiles. Both natural and artificial materials can be used to make them, and each has special qualities and advantages of its own. We’ll examine the distinctions between synthetic and natural fibres in this post. Natural Fibres: Animals and plants both serve as the source of natural fibres. They are renewable, biodegradable, and frequently feel softer and cosier than synthetic fibres. Natural fibres including cotton, wool, silk, hemp, and jute are frequently used. The most popular natural fibre in the world is cotton. It is perfect for garments and textiles since it is supple, absorbent, and breathable. Conversely, wool is frequently used in cold weather apparel due to its inherent insulation qualities. Natural silk is an opulent fibre that is strong, soft, and light. Although less frequently used, hemp and jute are incredibly strong and durable, making them excellent options for industrial purposes. Natural fibres’ sustainability is one of its key benefits. Because they are easily recyclable and biodegradable, they produce less waste and have a smaller environmental impact. Natural fibres do, however, have significant drawbacks. Depending on the source and quality of the fibre, they may be pricey and have a variety of qualities. Market Opportunity: In the upcoming ten years, a significant increase in Man-Made Fibres And Natural Fibres : Opportunities, Co-Dependence And Market Opportunities in India

- 13. MARCH 2023 13 www.textilevaluechain.in demand for natural fibres is anticipated on a global scale. The development of environmental materials is a result of growing public awareness of the harm that synthetic materials have done to the environment. The development of materials based on natural fibres can displace synthetic materials. As a result, various industrial sectors have seen an increase in demand for the commercial usage of natural fibre in recent years. However, there are several obstacles to the market’s expansion. The synthetic fibre sector, which has a strong penetration in a number of end-use industries like textile, automotive, and medical, competes fiercely with the natural fibre sector. Additionally, the cost and energy requirements of manufacturing and other operating processes drive up the cost of the finished goods. This can have a marginally detrimental effect on the sector and slow the market’s rate of expansion. When it comes to Indian markets, cotton, jute, silk, and other natural fibres are abundant there, making it formerly the centre for natural fibres. Although the international ratio now favours artificial fibres, it is beginning to rethink and realign itself in favour of natural fibres with the advent of initiatives like sustainable fashion and the reintroduction of linen. Despite the fact that natural fibres are ideal for a humid tropical nation like India and that cotton is one of the main income crops for Indian farmers, India is sadly still lagging behind the global sustainable fash- ion movement. Man-Made Fibres: Synthetic fibres, commonly referred to as man-made fibres, are created by chemical processes rather than from natural resources. They can be engineered to have particular features, such as water resistance, UV protection, or fire retardancy, and are frequently tougher and more resilient than natural fibres. Polyester, nylon, rayon, and acrylic are a few popular man-made fibres. The most popular synthetic fibre in the world is polyester. It is perfect for garments and textiles since it is sturdy, long-lasting, and resistant to creases and shrinking. Another common synthetic fibre that is strong, light, and abrasion- resistant is nylon. A semi-synthetic fibre made from wood pulp called rayon is frequently used as a replacement for silk. A soft and lightweight fibre, acrylic is frequently utilised in the production of knitwear. The adaptability of man-made fibres is one of their key benefits. They are perfect for a variety of applications since they may be manufactured to have particular features. They are a common option for mass- produced products since they are frequently less expensive than natural fibres. Man-made fibres do, however, have significant drawbacks. They can cause pollution and waste because they are not biodegradable. Additionally, they could feel more manufactured and uncomfortably so than natural fibres. Market in India: Polyester and viscose, which make up around 94% of the local MMF market, are its two main constituents (in volume terms). In this, polyester makes up around 77.5% of the total, with viscose mak- ing up the remainder. MMF is generally used to create blended and 100% non-cotton fabrics, which are then used to make ready-to-wear apparel, home textiles, and other industrial textiles.

- 14. 14 MARCH 2023 www.textilevaluechain.in In fiscal 2020, the total demand for MMF and yarn (made of polyester and viscose) was predicted to be 6,066 ktpa. In fiscal 2022, PFY demand as a whole is anticipated to increase by 15% to 20%. The demand for PSF as a whole is anticipated to increase by 14–19%. Between 2015 and 2025, the demand for textile fibres is expected to grow by an average of 2.80% per year, from 90.10 million tonnes to 119.20 million tonnes, while the demand for man-made fibres is anticipated to grow by 3.7% in 2025. Increased use in nonwovens and technical textiles, shifting consumer preferences—including a focus on hygiene and fitness—growing brand consciousness, rapidly shifting fashion trends, and expanding female labour participation will all help to drive up demand for synthetic fibres. In 2021-22, man-made textile exports would increase by 51% and 18% over FY 2020-21 and FY 2019–20, respectively, reaching $6.3 billion with a 14% share. India has always prioritised cotton textiles, but the world’s mill fibre consumption is shifting towards manufactured fibre (MMF). The Production Linked Incentive (PLI) Scheme for Textiles has been developed with an approved outlay of INR 10,683 crore over a five-year period to promote production of MMF Apparel, MMF Fabrics, and Products of Technical Textiles in the nation. This was done in recognition of the potential for growth and employment in the MMF sector. The goal is to make it possible for the textile industry to grow and scale while still becoming competitive. The textile industry’s use of mixed fiber/yarn will grow overall as a result of the increased availability of MMF and MMF yarn. Co-Dependence: In the realm of textiles, natural fibres and synthetic fibres are frequently seen as competing forces. The vast array of fabrics and textiles that we use every day are actually made from a combination of the two types of fibres and depend on each other. The act of mixing is one of the primary ways that natural and synthetic fibres are interdependent. Blending is the process of blending various fibre types to provide a cloth a desired property, such as softness, strength, or breathability. One type of fabric that combines the softness and breathability of cotton with the durability and wrinkle resistance of polyester is one that is 50% cotton and 50% polyester. The benefits of blending apply to both natural and synthetic fibres. Blending can lessen the inherent weaknesses of natural fibres and increase their overall performance. For instance, cotton is renowned for being soft and breathable, but it also has a high tendency to shrink and wrinkle. The advantages of cotton can be enhanced by adding durability and wrinkle resistance by combining it with a synthetic fibre like polyester. However, combining man-made and natural fibres can also be advantageous for man-made fibres. Although synthetic fibres like polyester and nylon are frequently prized for their strength and speed of drying, they can also feel stiff and uncomfortable when worn. They can be used with natural fibres, such as cotton or silk, to create fabrics that combine the best qualities of softness and breathability with durability and quick drying.

- 15. Digital Business Delegation to India German Technical Textile Companies The participating German companies wish to expand their business activities in India and are looking for business co‑operations with Indian companies. Opportunities to engage with the delegation members: A showcase of innovative technical textile technologies and solutions by German companies. Business Meeting with potential partners in India 15th, 16th & 17th March 2023 Online Presentation Event on 14th March 2023 Industry Overview Interactions and discussions with German companies 13th to 17th March 2023 For Complete overview please visit : https://bit.ly/3Z6XpX9 Scan for more details Organized by The Indo‑German Chamber of Commerce on behalf of The German Federal Ministry for Economic Affairs and Climate Action (BMWK) Companies Participating for the Technical Textile Delegation A. Monforts Textilmaschinen GmbH & Co. KG DIENES Apparatebau GmbH E. Oppermann Mech. Gurt‑und Bandweberei GmbH Iprotex® GmbH & Co. KG Norafin Industries (Germany) GmbH Sanders‑Kauffmann GmbH Tailorlux GmbH Trützschler Nonwovens GmbH ZSK STICKMASCHINEN GMBH Organizer Knowledge Partner Project Partner Media Partner You can reach us on : 020 ‑ 4104 7128 / pune.intern1@indo‑german.com

- 17. 17 MARCH 2023 www.textilevaluechain.in The fashion industry is a ever-growing industry. The fashion industry has two main components namely - Man Made fiber and the natural fiber without which the industry is incomplete.The demand of natural fiber and man – made fiber is increasing with the growth of fashion industry. There are various collaborations and partnerships required in order to keep the fashion industry to sustain and run smoothly. For the fashion to function and sustain in the market, there has to be a coordination between the raw materials, suppliers, retailers, disposal and the sustainability. The relationship between with the environment and the global textile needs to be discrete. With the fashion industry having an establishment over 75 countries with 250 million people following the fashion industry, the need of cotton industry needs to function at a higher rate. For this, the discrete for fiber production, textile manufacturing, garment manufacturing and retailing is required in order to keep it sustaining. A point to be noted is that, all of these industries are facing sustainability issues at every possible stage. Cotton is the best example of this. Cotton is grown and sustained over more than 70 countries all over the world. The cotton production is usually checked on repeated basis by the retailers and the NGOs. The cotton is indirectly checked by the people regarding the lack of water, lack of stitching, kind of fitting,etc. As the fashion industry is a ever growing industry, the overall demand for the cotton industry will be witnessing a continous pick up/growth. The natural fibers might still have to face challenges as there is a disruption/competition to the manmade fibers. Being a competitive fiber, Polyester too is a better option or can be an alternative to the natural fibers. The increase in the sustainability will help in the major growth of the MMF. A major portion of Polyester is imported from China followed by India and the Southeast Asia. China alone constitutes 69% of the MMF imports. Whereas on the other hand, India and the Southeast put together will be 86% of the entire globe. Due to this, the share of polyester has increased by 9% since 2007. What is India’s role in MMF or Natural fiber? Despite of the huge cultural diversity, India is still lacking behind in the matters of production of both natural and man- made fibers. India still relies on the other nations for the heritage fiber and the growth of cotton. The exports of raw materials are lesser in comparison to China, Bangladesh, Vietnam and Turkey put together. The Natural fiber and the MMF industry can be considered as a growing industry in a country like India. MMF Or Natural Fiber : A Choice Or Preference For Sustainability COVER STORY

- 18. MARCH 2023 18 www.textilevaluechain.in Natural fiber is an emerging eco-friendly product which is applied to the textile industry and to the individuals. This paves a way for the clean and green environment. There are many types of natural fibers which includes- seed fibers, leaf fibers, etc. As the name suggests, the natural fibers are extracted from fruits such as pineapple, waste leaf,etc. Due to this, the clothes made of natural fibers are priced higher in the market. It occupies 2.5 to 3.5% of the market. A land of 600 thousand acres is required for the production. The natural fiber works on the principle of Economy. Society, Culture and Environment. Sisal, Screw Pine, Palm leaf, Korai grass, Pineaaple leaf fiber, Sitalpati, Bamboo, Sikki and Mung grass, Bananan, Hemp, Sisal and Himalayan nettle are produced from various states of India. The textile fibers will still continue to be a matter of debate and issue in the sustainable industry and also the clothing sense of people. According to a study conducted, the people choosing more sustainable products have a chance of reducing the hazardous environmental impacts caused due to the clothing industry. According to the High Material Sustainability Index (MSI), the substitution in the material will reduce the climate change to a large extend and focus on the growth of the textile sector. The designs and patterns made in India are known for their excellency, pattern, durability and intricacy. Currently, there are high investments going on in the global market. Though the natural fiber might take time to take the center stage, the MMF might take the centre stage at a faster pace. This can be calculated on the basis of the number of overseas buyers/ direct buyers from the businesses. The textile industry has a 2% contribution to the Gross Domestic Product (GDP). Companies like Aditya Birla Group, Bhilosa industries and Reliance industries top the production list in matters of polyester yarn. The textile industry covers all the segments of the MMF and the natural fiber which is based on textile value chain. This is taken from the fiber/filament manufacturing in order to make the final product. Ludhiana and Surat are the largest producers of MMF whereas Rajasthan,TamilNadu, Karnataka, Andhra Pradesh and Kerala and Maharashtra are known for their natural fibers. The turnover from Surat alone is 3.5 crore which contributes 40% to the MMF. Similarly, in the southern part of India, “pattu”saree is a well known silk saree/ man- made fiber which is woven carefully. The turnover of the “pattu” saree is around Rs. 200 crore. The Kanchivaram saree is produced not only in Kanchipuram but also in Andhra Pradesh and Karnataka to a great extend. Ludhiana and Surat are the largest producers of MMF whereas Rajasthan,TamilNadu, Karnataka, Andhra Pradesh and Kerala and Maharashtra are known for their natural fibers. The turnover from Surat alone is 3.5 crore which contributes 40% to the MMF. Similarly, in the southern part of India, “pattu”saree is a well known silk saree/ man- made fiber which is woven carefully. The turnover of the “pattu” saree is around Rs.200 crore. The Kanchivaram saree is produced not only in Kanchipuram but also in Andhra Pradesh and Karnataka to a great extend. Country Total Exports Cotton Textile Cotton Apparel MMF Textile MMF Apparel Natural fibers China 279 bn UDS 11% 24% 19% 35% 11% India 37 bn USD 26% 23% 16% 17% 18% Bangladesh 35 bn USD 2% 69% 1% 22% 6% Vietnam 33 bn USD 9% 28% 7% 49% 8% Turkey 27 bn USD 12% 34% 22% 21% 11% Natural fiber is an emerging eco-friendly product which is applied to the textile industry and to the

- 19. 19 MARCH 2023 www.textilevaluechain.in Natural Fiber VS Man Made Fiber Which is Strongest? Introduction Fibers are substances used to make textiles and materials including cables, wires, clothing, drapes, and bedsheets. Generally speaking, they are long, thin, and flexible, which makes them ideal for producing strong, bending materials. Cotton, silk, jute, linen, nylon, rayon, and other common fibers are only a few of the most popular varieties.[1] Some of the most popular uses include the production of furniture, automobiles, packaging, military equipment, aerospace goods, and other items used in daily life. Fibers are ubiquitous and play a significant role in modern life.[1] Both plants and animals can serve as a source of natural fibers. Chemical synthesis is used to produce artificial fibers, commonly referred to as man-made or synthetic fibers. The nineteenth century saw the first development of synthetic fibres.[1] In this article we will study the naturally obtained Spider Silk and American chemist Stephanie Kwolek creation of Kevlar: Naturally obtained Spider Silk A protein fiber called “spider silk” is spun by spiders. [2] Silk is used by spiders in nature for a variety of purposes, including the construction of webs, the wrapping of prey, the safeguarding of offspring, and as a lifeline for safe escape from predators. Compared to insects like silkworms, which frequently use their silk for the production of cocoons, spiders use silk for a much broader range of purposes. [3] Silks are produced by all spiders, and a single spider can produce up to seven distinct kinds of silk for various applications. In contrast, an individual rarely produces more than one type of insect silk. There are numerous ecological applications for spider silks, each with properties that complement the purpose of the silk. From primitive tube webs 300–400 million years ago to complex orb webs 110 million years ago, spiders’ silks have become more complex and used for a variety of purposes as they have evolved.[2] The Structure of Spider Silk Schematic representation of the hierarchical structure of a spider MA silk filament. At the macroscopic level, the thermonuclear structure can be identified, and at the submicroscopic level, the presence of aligned fibrils is shown. The nanoscopic structure is represented by poly-Ala β-sheet crystals aligned along the fiber axis and embedded in an amorphous phase containing GPGXX and GGX cluster repeats.[5] Latest updates Presently, there are a number of recombinant spider silk proteins being researched, which are generated in sufficient quantities by a variety of host species to allow for the study of possible material applications. The physical features of spider silk emphasize the possibility of thread acting as high performance fibers. Khyati Sutarii Alumni, S. N. D. T Women University REVIEW PAPER

- 20. MARCH 2023 20 www.textilevaluechain.in The key challenge in this field is the development of adequate spinning technologies to generate threads with qualities close to those of the natural material in a reproducible manner.[5] Spidroins have also been found to be adaptable proteins that can be processed into a variety of non- fibrous morphologies. They are useful for biological applications due to their innate biocompatibility and minimal immunological response. Cell culture and drug delivery uses of these materials are currently being researched. Furthermore, knowing the molecular structure of silks has sparked a slew of studies that use the repeating modules of silk in conjunction with other chemical patterns to create innovative materials.[5] Kevlar created by American chemist Stephanie Kwolek Kevlar (para - aramid) is a strong, heat - resistant synthetic fiber that is linked to Nomex and Technora. Stephanie Kwolek developed the high - strength material at DuPont in 1965, and it was initially utilised commercially in the early 1970s as a substitute for steel in racing tyres. It is often spun into ropes or fabric sheets that may be utilised on their own or as a component in composite materials.[6] Kevlar has a wide range of applications, from bicycle tyres and racing sails to bulletproof jackets, because of its high tensile strength-to-weight ratio; it is five times stronger than steel by this metric. It’s also utilised to manufacture high-impact marching drumheads, as well as mooring lines and other underwater applications.[6] The Structure of Kevlar Kevlar is made in solution by combining the monomers 1, 4 - phenylene - diamine (para- phenylenediamine) with terephthaloyl chloride in a condensation process that produces hydrochloric acid as a by product. Mechanical drawing orients the polymer chains in the direction of the fiber, resulting in liquid-crystalline behavior. The solvent first used for polymerization was hexamethylphosphoramide (HMPA), but for safety considerations, DuPont replaced it with a solution of N-methyl-pyrrolidone and calcium chloride. Because Akzo (see above) had patented this procedure in the manufacturing of Twaron, a patent dispute began. Latest updates Since Kevlar is used in numerous structural operations, NDT plays an important part in determining the integrity of the structure. One of the styles used to check the integrity of structures made from Kevlar is CT. CT is generally used in the examination of essence. Still, this system is now being used for mixes. Fidan employed micro - computerized tomography to fantasize the internal damage impact on glass fiber - corroborated and glass fiber aramid fiber - corroborated polyester mixes. Low-haste impacts were tested at 80 J energy. From the disquisition, themicro-CT showed that the 3D - delamination pattern disfigurement in glass- corroborated mixes is more visible due to the nature Table 1- Types of Kevlar and its Properties [9]

- 21. 21 MARCH 2023 www.textilevaluechain.in of the glass fiber. still, the delamination pattern lost its effectiveness when aramid fiber was added to the glass fiber. Another system used to descry blights is the eddy current system. Still, in the work of Grimberg and Savin, the eddy current system used is for mixes made from synthetic fiber, which are carbon and Kevlar. Eddy current microscopy, involving a micro - focus transducer, was used to probe the individual fiber breakage in the instance after it was impacted by a7.62- mm- quality pellet.[8] Conclusion Kevlar is one of the strongest man- made fibers which is used to create many different design structures. From 1965 the there has been many research conducts and different level of Kevlar are be created. Also spider silk which seen 300 – 400 million times ago to complex sphere webs 110 million times. Spiders’ silk are useful for biological applications due to their innate biocompatibility and minimal immunological response. Kevlar fiber which is strong for safety at the same time spider silk is biologically useful. Reference: • https://www.vedantu.com/chemistry/natural-fibres -and-synthetic-fibres [1] • https://en.wikipedia.org/wiki/Spider_silk [2] •https://www.ncbi.nlm.nih.gov/pmc/articles/ PMC2658765/#:~:text=Spider%20silk%20pri mari- ly%20consists%20of,or%20only%20very%20little%20 tryptophan [3] • h t t p s : / / c e n . a c s . o r g / c o n t e n t / d a m / cen/95/41/09541-scitech2.pdf [4] • https://www.mdpi.com/2073-4360/3/1/640 [5] • https://en.wikipedia.org/wiki/Kevlar [6] • How Kevlar® works: a simple introduction. Explain- thatstuff.com (2009-12-07). Retrieved on 2012-05-26. [7] • Nondestructive testing method for Kevlar and nat- ural fiber and their hybrid composites; in Durability and Life Prediction in Biocomposites, Fibre-Reinforced Composites and Hybrid Composites, 2019 [8] • Potential of natural/synthetic hybrid composites for aerospace applications; Sustainable Composites for Aerospace Applications, 2018[9] Without a doubt, zippers are the most common point of failure on any jacket. And while this can be an inconvenience, if you’re out in the backcountry it can also be dangerous. ARTILECT set out to address this issue, making it much easier for customers (and retail partners) to quickly and easily repair jackets, and avoiding the need to ship the items back and forth for sometimes costly repairs. Founded in 2020, ARTILECT is one of a select few development partners with YKK, the world’s largest zipper company. ARTILECT features many world-first innovations in collaboration with YKK, including TouchLink and PU Conceal Zippers. But the most ground-breaking new innovation is the introduction of YKK’s Revived zipper, which is the first - ever user - repairable zipper. ARTILECT’s Formation 3L Shell and High AF down jacket (available now) are the first two garments to integrate the new zipper technology. This is a feature that will be integrated across ARTILECT’s full product line in future seasons, as well as the introduction of a Vislon tooth repair kit and snap-on sliders for closed-end (pocket/vent) zippers. This illustrates ARTILECT’s leadership in making significantly more sustainable products that last longer, and don’t require additional shipping to repair. ARTILECT Outerwear Features World’s First User-Repairable Zippers Developed in Collaboration withYKK, ‘Revived’ Zippers Featured on ARTILECT’s Formation 3L Jacket and High AF Down Stretch Parka INNOVATION CORNER

- 22. SPEAKERS FROM 9th International Conference 12th April 2023 Hotel Radisson Blu, Mumbai, INDIA INDIAN Polyester - 2023 WHAT TO EXPECT International speakers from leading corporates and consultancies to share their knowledge Over 8 hours of discussions spanning polyester market updates, trends and forecasts Opportunity to network with 150+ major industry players of the Indian & international markets Over 4 hours of networking luncheon and session breaks Dow Jonnes Indian Oil Corporation Oerlikon Textile Reliance Industries S&P Global Commodity Insights Wazir Advisors Call Now to register Tel: +91-22-2385 1430 Mobile: +91-9833022522 E-mail: register@eliteconferences.com Webiste: www.eliteconferences.com How does India capitalize on the global opportunity in polyester

- 24. MARCH 2023 24 www.textilevaluechain.in IMPORT Natural Fibers MARKET REPORT

- 26. MARCH 2023 26 www.textilevaluechain.in IMPORT EXPORT Man-Made Fibers MARKET REPORT HS Code - 55 HS Code - 54 HS Code - 55 HS Code - 54

- 29. MARCH 2023 29 www.textilevaluechain.in Shri Ananda Bhaskar Rapolu, Ex-MP, organised a roundtable at the Constitution Club of India, New Delhi, recently to discuss and deliberate on the scarcity of the various man-made and natural fibres in the country. The dignitaries included parliamentarians from BJP, INC, DMK, SO and others, along with industry representatives from different parts of the country. They joined the discussion to share their perspectives on the consequences of the scarcity of raw materials and the impact of potential duty impositions, such as the Anti-Dumping Duty, on the sector. With the market share of India in the global textile industry increasing, there is also a need to ensure that there is abundant availability of raw materials like fibre in the country. Although India is the 2nd largest producer of man-made fibre/yarns and polyester, there is a huge supply-demand deficit, especially in viscose. Dwindling cotton supply, low cost, and versatility in design/application are key drivers for man-made fibre adoption. In FY 2021-22, the domestic Viscose Staple Fibre (VSF) demand was 7 lakh tonnes, and the availability was only 5.4 lakh tonnes, which is a gap of 1,60,000 tonnes/year. With only one major viscose supplier contributing to over 90% of the supply, India’s entire value chain depends on a single manufacturer. This creates big risks for users. As a result, many small spinners cannot access Viscose as the supply is limited to select spinners only. The dignitaries highlighted the above challenges in the current situation of India’s weaving sector. They further deliberated on the solutions to ensure that there is access to abundant and high-quality raw materials for the downstream community at cheap rates. Some of the suggestions included the non- imposition of duties (like anti-dumping duty) on raw materials such as polyester and viscose and building mechanisms to ensure there is no pricing policy that puts Indian weavers and spinners at a disadvantage. Reflecting and summarising the discussion, Shri Rapolu highlighted that there is a need for an encouraging ecosystem to enlarge the capacities of fibre to fabric. Ensuring sufficient fibre / yarn availability is critical for the labour-intensive textile value chain that generates over 45 million in employment, mostly rural poor and women. He further emphasised that viscose is poor people’s silk, and viscose blended cotton is the future. Inconsistent policy decisions on raw materials will only ruin the chance of participation for the small- scale spinning and weaving industries. Hence, concentrated efforts are needed to ensure an ecosystem that safeguards healthy and fair competition in the market, enabling the availability of quality raw materials for value addition. The parliamentarians and industry representatives came to a consensus that they shall take this discussion forward to the concerned offices. Parliamentarians And Industry Deliberate On The Need For Cheap And Quality Textile Raw Materials ForWeavers And Spinners NEWS REPORT

- 31. F A R M T O F A S H I O N F A R M I N G G I N N I N G K N I T T I N G D Y E I N G A N D P R I N T I N G G A R M E N T I N G S P I N N I N G 1800 - 889 - 6020 info@omaxcotspin.com www.omaxcotspin.com Sr. No. 842,843,845/1, Near. Petrol Pump, Village Rajsitapur , Ta. Dhrangadhra Dist. Surendranagar. Gujarat. (INDIA).

- 32. MARCH 2023 32 www.textilevaluechain.in Can you tell us a little about yourself and your role as the Chairman of the Powerloom Development Export Promotion Council? Sure, I’m Vishwanath R. Agarwal and I’m from Ichalkaranji. I’m the Chairman of the Powerloom Development Export Promotion Council, which was founded in 1995. Our council has over 2000 members and our main objective is to develop the power loom industry in India. Our focus is on promoting government schemes, communicating with the government to solve problems faced by the power loom industry and boosting exports of powerloom products. Can you tell us a bit about the power loom industry in India and its importance? Before 1990 - 95, the power loom industry was relatively unknown, but now it’s a major decentralized sector in India. The textile industry which provides major employment opportunities, just after the farming sector, powerloom is the backbone of it. It employs both unskilled and skilled labour. The textile industry is extremely important for the country as it provides a significant amount of foreign exchange for the government. Our council is working towards boosting this industry and making it more sustainable. What are some of the major problems faced by the power loom industry currently? One of the biggest problems we face is fluctuations in yarn prices and quality. Yarn is around 70% of our investment, and it’s mainly dependent on cotton prices, so when cotton prices fluctuate, it affects our industry. Another issue is indirect routing of Chinese fabrics from Bangladesh and other countries. Unveiling the Challenges and Opportunities of India’s Powerloom Industry with Mr.Vishwanath R Agarwal Vishwanath R. Agarwal Chairman PDEXCIL Without a technology upgradation fund scheme the small weavers will not be able to manufacture export quality fabrics and also will not be able to feed the garment industry as required, which will lead to increase in import of fabrics. This will also lead to decrease in employment and foreign earnings. INTERVIEW : CLUSTER

- 33. Additionally, the difference in electricity prices in different areas creates disparity in the market, affecting the prices of fabrics. Our council has been advocating for uniform electricity prices across the country for powerloom sector. Finally, the anti- dumping duty on viscose yarns increases the pricing of viscose yarns, affecting India’s exports for this also we are continuously representing to government for not imposing any ADD on Viscose fibre/yarn. What are your thoughts on the government’s plans to close subsidy schemes for the power loom industry? Our council believes that the government should not shut down these schemes just yet, as the industries are still in the growing stage. The government is worried about the possibility of a recession, but India is still in a relatively safe zone. If the government stops supporting the progress of these industries due to fear of a recession or any other reason, it will pose great threat to the industries. Earlier, the Technology Upgradation Fund scheme TUFS and the latest ATUFS supported the powerloom sector so well that it increased the speed of upgrading the weaving machinery technology in India. However, due to closing of these kind of subsidy schemes, the progress pathway gets hamper. Without technology upgadation fund scheme the small weavers will not be able to manufacture export quality fabrics and also will not be able to feed the garment industry as required, which will lead to increase in import of fabrics. This will also lead to decrease in employment and foreign earnings. MARCH 2023 33

- 35. MARCH 2023 35 www.textilevaluechain.in Can you tell us about your product portfolio? We have developed a range of sustainable bio fibers, we started our journey three years back as an R D biotech company. We were researching advanced enzymes and we were looking for producing natural fibers using non-chemical pulping routes. Gencrest developed a solution for banana fiber extraction. Our RD team has developed a patented enzymatic technique. And we also have a proprietary cottonising technology where we make the banana raw fiber into staple spin-able fiber which can be blended spun on the regular Ring OE systems. We have an end-to-end in house zero waste process. With Plant located in the banana belt (Jalgaon region) we do extraction and processing in-house. Apart from banana we are doing hemp. We have a chemical neutral process as the enzymes cocktail don’t pollute the environment. We are planning to develop portfolio of Fibers for sustainable apparels. We have already got into commercial route on the hemp and we are introducing these banana fibers which is branded as ‘Vybrana’ for the knits and woven and we are also looking into denims. These fibers are blended with Cotton, Lyocell, Polyester, Viscose any staple fiber and we do counts up to Ne 30s. What are your customer segments? Our customer segments are both in knits and woven and also in denims. We are also looking at upholstery segments to do blends with recycled polyester. We are also actively looking into the bath linen segment as well. Is there any possibility of using other biomass apart from bananas? Our RD is still continuing the research on enzymes solution and we are looking forward to bringing new products into our cycle. We are currently working on fibers from pineapple, Nettle Pine fiber to offer Sustainable Textile Solutions : Gencrest Bioproducts Leads The ChargeWithVybrana Banana Fibers Sandesh Saxena General Manager - Marketing Gencrest Bioproduct “We have currently received invitations from different governments who are in the banana growing range like Gujarat and Tamilnadu, where we already signed contracts. Not only in India but in foreign countries also because stem degradation and leftovers after the fruit being harvested is a big problem.” INTERVIEW : CORPORATE

- 36. 36 MARCH 2023 www.textilevaluechain.in staple spun fiber for sustainable apparels. How do you source your raw materials and what are the challenges? We source our raw materials freshly from farms, the stems have a life cycle of about two days, that’s why we are based in the banana belt of India. We have currently received invitations from different governments who are in the banana growing range like Gujarat and Tamilnadu, where we already signed contracts. Not only in India but in foreign countries also because stem degradation and leftovers after the fruit being harvested is a big problem. So many governments like the Uganda government also approached us to set up a similar facility out there. How do you come up with the idea of using banana fibers? Banana fiber has been present in India for centuries but scattered into small scale industries. Usually for producing handmade saris and other segments like baskets. Banana is one of the major fruit crops and a sizable agri waste is created and its disposal is a major problem where it is left to decay and burn, adding to GHG emission. Our goal is to offer a sustainable environmentally friendly solution by upcycling the agro waste to a value added product. How was your experience in the exhibition? We got a very good response, thanks to our products. Nowadays most of the brands are enriching their portfolio with the sustainable fiber allocations and we have great visits from brands as well as spinners, who were very keen to expand their portfolio.

- 37. 12 – 14 September 2023 Jio World Convention Centre (JWCC), Mumbai Exhibit at India’s foremost expo on technical textiles, nonwovens composites Show Highlights • Special focus on product categories : Filtration, Masterbatches and Composites • Resume in-person interactions with international buyers on a large scale • Meet high quality buyers from 12+ industries like agriculture, automotive, textiles, medical, packaging etc • Display your latest innovations at a world class venue : Jio World Convention Centre, BKC, Mumbai Contact us. Priyanka Pawar +91 22 6144 5990 priyanka.pawar@india.messefrankfurt.com For bookings, scan the QR code

- 38. www.uster.com/qbar2 Inspecting fabrics after weaving is old school. With USTER® Q-BAR 2, smart weavers can pinpoint defects during fabric formation. It’s the right way to reduce material losses and minimize manual checks. When it comes to fabric quality issues, prevention is better than cure. The whole fabric is automatically monitored – warp, weft, selvage and leno – and faults are identified immediately. LEDs signal defect locations to the weaver, with information shown on the control unit touchscreen. It’s automatic inspection, in-process and instant, so weavers can react to prevent long-running or repeating faults. USTER® Q-BAR 2 sets the future standard, controlling the weaving process instead of the output. USTER ® Q-BAR 2 Weave it right: spot defects on the loom

- 39. 39 MARCH 2023 www.textilevaluechain.in Can you tell us about the history of Ganesha Ecosphere? Ganesha Ecosphere was established in 1988 and started producing recycled fibres in the year 1994. Our company is 28 years old in this segment and currently has four manufacturing facilities in India, with the latest set up in Warangal, South India. What are the products that Ganesha Ecosphere offers? We are having a big basket of various R-pet products, mainly recycled polyester staple fibre, spun yarns, R-pet bottle grade and filament grade chips, R-pet filament yarns and polypropylene fibre. We are recycling around 15000 MT pet bottle scrap per month in our different units. Can you tell us about your customer base? Our customers include reputed companies in India like Vardhman textile, Nahar spinning, Trident, Sutlej group, RSWM group, Donear, KPR Mills and other reputed spinning units. We are also approved with international brands like Inditex and Target. We are having a very strong presence in the International market and exporting around 40-50 containers per month to different countries in the worldwide. We are also going to finalise long term contracts with reputed brands to buy and use our R-PET chips into PET Bottles. What are your plans for expansion in the future? We are planning to expand in R-PET bottle grade and filament grade chips, filament yarns, and fibres. Our goal is to gradually increase production capacity over the next 4-5 years, targeting recycling of around 20,000 tons of bottle per month. We aim to make India a production hub for the recycling and increase our market share to 20%. Can you tell us about the growth of the recycling market in India? The market size of recycled products is growing continuously and our goal is to create a sizable value and production capacity to cater to both the Indian and export markets. Recycling has a great future in India as more brands are focusing on their recycled portfolio. The quality of recycled yarns and fabrics has improved over the years and they are effectively equivalent to virgin fibres and fabrics. The production capacity of recycled fibre is growing every year and effectively creating a substitute for the virgin raw materials. Ganesha Ecosphere Aims To Make India A Production Hub For Recycled Products B. P. Sultania Joint President Ganesha Ecosphere “The quality of recycled yarns and fabrics has improved over the years and they are effectively equivalent to virgin fibres and fabrics. The production capacity of recycled fibre is growing every year and effectively creating a substitute for the virgin raw materials.” INTERVIEW : CORPORATE

- 40. MARCH 2023 40 www.textilevaluechain.in Can you tell us a little bit about the Maruti Group of Companies and its products? Certainly. The Maruti Group of Companies offers a wide range of value-added products, from fibers to fabrics. We have our own ginning, spinning, knitting, and processing units, with a production capacity of 300 tons per month for solid and 350 tons per month for printed products. We have in-house yarns and comb-compact yarns, and we are now planning to expand into the garment industry. Who are your key buyers and in which countries do you primarily operate? Our key buyers are brands such as Van Heusen and Jockey, and we primarily operate in Bangladesh, Sri Lanka, and Europe. Maruti Group Of Companies Achieves Full Vertical Integration And Sets Sights On Garment Industry Expansion Can you tell us about your focus on quality control and sustainability? Absolutely. We have a vision to provide top- quality products to our customers, and we achieve this through our full vertical integration within our product portfolio. We have a zero liquid discharge plant, which enables us to produce top-quality fabrics, and we use copper-based dying, which is a rare method in India. We also use salt-less dying, which gives us a higher quality than other dying methods. What is your plan for expansion? We are planning to expand into the garment industry by launching our own in-house brand called Chestoo for knitted garments. With this expansion, we aim to become a complete farm-to-fashion company. Paresh Bhai Director Maruti Group of Companies “Maruti Texprocess will complete fibre to fashion chain with the launch of garment brand Chestoo in the upcoming months. Earlier we were fibre to fabric but with garmenting we will be a complete fashion supply chain” INTERVIEW : CORPORATE

- 41. 41 MARCH 2023 www.textilevaluechain.in What products are you exhibiting today? And how’s the response to the stall? We are manufacturers of high speed rapier looms, electronic jacquards and other textile machines, In STEX 2023 we are presenting our high speed rapier looms with our high speed electronic jacquard. Also we displayed here our drain selvedge jacquard for water jet machines and air jet machines. We are getting very great response here, we are getting so many enquiries, some new customers also. What is your client profile? And what range of products you offer? Now days we are exporting our machines to different countries like South America regions, Chile, Ecuador, Peru, and some countries in Asia also like Bangladesh, Nepal and Malaysia. People are looking for quality and we have in our house so many latest technology machines like, CMC, VMC, HMC, pick and place machines, robotic welding and some quality inspection machines we have got directly from Germany, because of this we can give best quality to our customers. That’s why foreign customers are fond of machines due to our level of quality. Apart from Machines, what other services you offer? As you know our industry is service based, if we give good service to customers, they will be satisfied. To provide best service, we have introduced new application here, AICS, it is a cloud based application for service. With this application we can get all the information and feedback from customers in our server. According to that, our team consults our engineers on how to give best services and backup to customers. It is very good for us as well as customers. How was your experience in SITEX and what kind of collaboration you received from organizers? As mentioned earlier, we got very good response in SITEX from customers. We would like to thank Mr. Himanshu Bodawala for organizing such event. It gave so much footfalls to our stall. What is your observation on currunt market conditions? As we all know, after COVID, the market became very down, but after 2021, now we are getting good response from the market and customers, because now the people are introducing latest technologies which help customers make good quality products with best prices. Amar Jacquard’s Range Of Machines And Quality Of Service Harvinder Singh Director Amar Jacquard “To provide the best service, we have introduced a new application here, AICS, it is a cloud based application for service. With this application we can get all the information and feedback from customers on our server. According to that, our team consults our engineers on how to give best services and backup to customers.” INTERVIEW : CORPORATE

- 42. Show Owner CEMATEX Associations ACIMIT (Italy) AMEC AMTEX (Spain) BTMA (United Kingdom) GTM (Netherlands) SWISSMEM (Switzerland) SYMATEX (Belgium) TMAS (Sweden) UCMTF (France) VDMA (Germany) Show Organiser T: +65 6849 9368 E: info@itma.com Connect With Us @ ITMA2023 Scan for More Info Source, collaborate and future-proof your business at the world’s largest international textile and garment technology exhibition Visitor registration is now open! Scan the QR code to find out why you should visit. Source from some 1,500 leading manufacturers and see live machinery demonstrations Future-proof your business with best-in-class solutions to stay ahead of the competition Collaborate and grow your business with digital transformation and sustainability Access ITMAconnect - the year-round sourcing and knowledge hub for the global textile community

- 44. 44 MARCH 2023 www.textilevaluechain.in The Union Budget 2023 has several provisions to promote the growth of the textile industry in India. The budget allocates a total grant of Rs. 4,389.34 crore for textiles, which is 22.6% higher than the revised budget grant for 2022-23. The launch of new schemes and the allocation of funds is expected to create a positive impact on the industry, increase production, and boost exports. One of the key provisions of the budget is the retention of the 5% import duty on all types of textile machinery until March 31, 2023, followed by an increase to 7.5% thereafter. The budget also seeks to increase the basic customs duty on imports of MMF Yarn to 10% from 5% and restore the duty-free imports facility against made ups exports. Additionally, the budget covers cotton yarn exports under the 3% interest equalization scheme. The textile industry in India holds a 4% share of the global trade in textiles and apparel and is one of the largest producers of cotton and jute in the world. The industry contributes significantly to India’s export earnings, with its share in India’s total exports at 11.4% in 2020-21. India is also the second-largest producer of silk in the world, and 95% of the world’s hand-woven fabric comes from India. While the budget has several provisions to promote the growth of the textile industry, some experts have also expressed certain expectations from the budget. For instance, the industry has been seeking government support for technology integration and the quick production of smart textiles. The textile industry in Tamil Nadu has sought export incentives and additional credit support from the budget. Union Budget 2023 has allocated a significant amount of funds to the MSME sector in general, which is expected to have a positive impact on the Textile Industry as well. The Finance Ministry plans to infuse ₹9,000 crore into the Credit Guarantee Fund Trust for Micro and Small Enterprises Credit Guarantee Scheme, which will facilitate extra financing of Rs 2 lakh crore. This high allocation is expected to boost employment in the country as the MSME sector is among the biggest employers in India. Additionally, the revamped credit guarantee scheme has been hailed by the MSME sector as a positive move. It is worth noting that the MSME sector accounts for about 30% of the country’s total GDP and holds a strong position in the country’s vision of Amrit Kaal (25 years up to 2047). The Union Budget 2023 has also announced several other initiatives to support the Union Budget 2023 :What Is There For Textile Industry? BUDGET 2023

- 45. MARCH 2023 45 www.textilevaluechain.in MSME sector, including simplifying compliances and redesigning the CGTMSE for MSME. Moreover, MSME suppliers unable to execute contracts during the Covid pandemic will get 95% of their forfeited amount back by the government. Talking about the Direct and Indirect benefits to Textile Industry, Mr. Gurudas V. Aras has put some compelling points, Direct Benefits: 1. Special focus on enhancing productivity of extra- long staple (ELS) cotton: The budget has announced a special focus on enhancing the productivity of extra-long staple (ELS) cotton, which is a high-value cotton variety. This will help in increasing the income of cotton farmers and boosting the availability of high-quality cotton for the textile industry. 2. Five new HS Codes for further classification of cotton: The budget has introduced five new HS Codes for further classification of cotton based on staple length. This will help in better classification of cotton and promote the use of high-quality cotton in the textile industry. 3. Increase in outlay for RoDTEP and ATUFS schemes: The budget has increased the outlay for the RoDTEP and ATUFS schemes, which are aimed at promoting exports and upgrading technology in the textile industry. This will provide direct benefits to the textile industry by enabling it to upgrade its technology and compete in the global market. 4. Increase in import duty for textile machinery: The budget has increased the import duty for textile machinery to 7.5% to encourage domestic manufacturing. While this might impact the industry adversely in the short term, it will provide a long-term benefit by promoting domestic manufacturing and reducing dependence on imports. Indirect Benefits: 1. Revised income tax limits: The budget has revised the income tax limits, which will increase the disposable income in the hands of consumers. This is expected to increase the demand for textiles and boost the growth of the industry. 2. Increased outlay for infrastructure: The budget has increased the outlay for infrastructure, including the creation of 100 new transport infrastructure projects, 50 new airports, and the creation of urban infrastructure in Tier 2 and 3 cities. This is expected to increase the consumption of technical textiles, such as geotextiles and composites. 3. Setting up of Agriculture Accelerator Fund: The budget has announced the setting up of an Agriculture Accelerator Fund, which will help in funding research on increasing the yield per hectare of cotton. This will indirectly benefit the textile industry by improving the availability of high-quality cotton. 4. Revamped credit Guarantee Scheme for MSMEs: The budget has announced a revamped Credit Guarantee Scheme for MSMEs, which will enable additional collateral-free guaranteed credit of Rs. 2 lakh crore and reduce costs by 1%. Since the majority of the textile sector is under MSME, this will make it easier for textile companies to access credit and boost their growth. 5. Increased outlay on defence spending: The budget has increased the outlay on defence spending by 13%, which will give an opportunity to spend more on protective clothing for our armed forces. This will indirectly benefit the textile industry, as it will create demand for protective clothing and promote innovation in the sector.

- 46. For QUALITY Products from Europe and EFFICIENT Services in India ------------------------------------------------------------------------------------------------------------------------------------------------------ We represent in India the following Textile Machinery Accessories manufacturers for Technical Textiles : LACOM GmbH, Germany : Hotmelt Laminating and Coating Systems – Multi Purpose, Multi Roller, Gravure Roller and Slot Die for complete range of Technical Textiles (Website: www.lacom-online.de) MORCHEM S.A.U., Spain : PUR Hotmelt Adhesives for Technical Textiles, Solvent Based, Water Based adhesives, cleaners and primers. (Website: https://www.morchem.com/markets-and-solutions/textile-lamination/ ) Fibres, Waste Recycling Nonwovens : Margasa, Spain: Textile Hard Waste Recycling Lines -complete with preparation, cutting, Storage, feeding, tearing, filtration and fiber packing. Peripheral equipment, for nonwovens waste. Complete lines for “Airlay Nonwovens” with thermo or resin bonding. Cotton Waste Cleaning Lines. (Website: http://www.margasa.com) FARE' S.p.A., Italy : Complete Lines for Spunbond / Meltblown nonwoven products /complete line to produce all type of fibers including mono and bicomponent including PET and PET fibers. Machines for producing Tapes and Rafia (website : www.farespa.com) Conventional : Mariplast Spa, Italy : All type of Yarn Carriers for spun and filament yarns - Cylindrical Tubes, Roving Bobbins, Ring Frame Bobbins, Cones and one time use and Reusable Dye Tubes (Website: www.mariplast.com) C + L Textilmaschinen GmbH, Germany : Reeling (Yarn Hank Forming) Machines, steaming, Bulking and Banding Machines for yarns ( Rep.for Western and Southern India) (Website: www.croon-lucke.com) Contact : ASTRA TECH INDIA E-mail : info@astratech.co.in Website: www.astratechindia.co.in Contact Person : Mr. Hemant Dantkale Mobile : 98201 06018 Phone No.: 022-28516018 E-mail : hdantkale@astratech.co.in HEAD OFFICE: 406, “Kaveri” Jagannath Mandir Marg, Opp. Holiday Inn, Near Sakinaka Metro Station, Mumbai–400 072 Regd.Office: B-404, Monarch Manor, 90 Feet Road, Dsouza Nagar, Kurla (West), MUMBAI – 400 072 Branch Office : Coimbatore : email: Coimbatore@astratech.co.in

- 48. MARCH 2023 48 www.textilevaluechain.in Sustainability And Circularity Of Textiles I’m Smriti Sohal, a student of National Institute of Fashion Technology (NIFT), Bengaluru. I am a final year student of Bachelor of Fashion Technology. I recently participated and won a competition organised by the textiles Committee, Ministry of Textiles. The topic of the competition was “Sustainability and Circularity of textiles”. Textile industry is a significant contributor to the global economy, providing employment and generating revenue for many countries. However, the traditional linear model of textile production, where resources are extracted, transformed into products, and eventually disposed of, has serious impacts on the environment and human health. To address these challenges, the concept of sustainability and circularity in textiles has gained widespread attention in recent years. Sustainability in textiles refers to the responsible use of resources and the reduction of environmental impacts throughout the entire lifecycle of a product. This includes reducing the use of hazardous chemicals, conserving water, reducing waste, and using renewable energy sources. Circularity, on the other hand, refers to the closed loop of material flows, where waste and by - products are reutilized or recycled to reduce the extraction of new raw materials. The Indian government has taken several measures to promote sustainable and circular practices in the Smriti Sohal NIFT Bengaluru textile industry. The Ministry of Textiles has launched several initiatives on this. One such initiative taken up by the Textiles Committee, Ministry of Textiles sponsored by the United Nations Environmental Programme (UNEP) is running a campaign on “Enhancing Sustainability Circularity in Textiles” to minimise the negative environmental impacts of the Indian textile industry by promoting sustainable practices and mainstream knowledge of circular production best practices in the textile and apparel sector. The campaign involves bringing about behavioural change in “Youth” to wean them away from fast fashion in favour of more sustainable, environmental and resource friendly behaviour through positive messaging. They organised a competition to collect collaterals like reels, infographics, and slogans for the social media campaign. My creations won prizes in both the categories of reels as well as infographics. The Infographic shown above, created by me, won the first prize in the Infographics category. It is based on all the ways a person can choose Slow Fashion over Fast Fashion and increase Circularity and Sustainability of a textile. The infographic shows various ways, like thrifting, upcycling, washing less often etc., by which each and every person can do their bit to adopt slow fashion. It also tries to break the stereotype that slow fashion and being sustainable is unaffordable and expensive. It conveys to people that by adopting these simple, easy and pocket-friendly ways, they can effectively contribute to sustainability and circularity of textiles. Not just these, there are many more ways of choosing sustainable fashion. STUDENT CORNER

- 49. 49 MARCH 2023 www.textilevaluechain.in The main tagline “Go Slow”, is a familiar slogan to people and hence easier to keep in mind. The only difference here is that it is in the context of fashion. “Go Slow” refers to adopting slow fashion over fast fashion, by inculcating various habits and choosing better with regard to apparel and fashion. unaffordable and expensive. It conveys to people that by adopting these simple, easy and pocket-friendly ways, they can effectively contribute to sustainability and circularity of textiles. Not just these, there are many more ways of choosing sustainable fashion. The main tagline “Go Slow”, is a familiar slogan to people and hence easier to keep in mind. The only difference here is that it is in the context of fashion. “Go Slow” refers to adopting slow fashion over fast fashion, by inculcating various habits and choosing better with regard to apparel and fashion. Third Prize in Reels Category The Reel is based on how a person can increase the lifecycle of a garment by adding value to it by repairing it by means of embroidery, patchwork etc. and hence contribute to the environment and also, in turn, benefit by having a garment as good as new. The practice of repairing garments by means of various methods like embroidery has been an age old practice in India. The famous embroidery technique, Kantha embroidery, was initially a way of using old and ragged cloth. It is not surprising that India has always had a tradition of reuse and recycling. But over time, with the onset of fast fashion and ever- changing trends propagated by brands for monetary profits, people’s mindset started to shift towards buying and discarding clothes as and when the trend changed or they simply got bored of it. People simply did not want to repeat outfits. The slogan at the end of the reel saying, “ It’s time to Rewire, It’s time to Rewear”, propagates the idea of going back to our roots and rewiring our brains to rewear the clothes that we already have, and increase the lifecycle of the same, by also repairing them, if need be, and giving them a new look by various methods mentioned above. In conclusion, the textile industry in India has the potential to play a significant role in promoting sustainability and circularity. By embracing sustainable and circular practices, the industry can reduce its environmental impacts, conserve resources, and contribute to a more sustainable future. Third Prize in Reels Category

- 51. Autocard The new Autocard has been developed to create further value in the fibre preparation chain. The flexible portfolio offers the right solutions for preparation of all kinds of staple fibres for the subsequent processes. The right combination of blow room and carding ensures excellent fibre utilisation and sliver quality for high efficiency and yarn quality in spinning. saurer.com Be prepared.

- 52. 52 MARCH 2023 www.textilevaluechain.in The Boom of RecycledYarns from rPET Bottles in India Since they are eco-friendly and sustainable, recycled yarns manufactured from rPET bottles have attracted a lot of attention. By respinning discarded plastic into new polyester fibre after it has been melted down, recycled polyester, or rPET, is created. The main application for rPET is in PET or polyethylene terephthalate bottles, which are 100% recyclable. Recycled polyester yarns, especially those manufactured from waste clothing and plastic bottles, offer an affordable alternative. In comparison to the original polyester, these yarns’ manufacture uses fewer resources and produces less CO2. These yarns are viable solutions for recycling polyester both physically and chemically. Recycled yarns made from rPET bottles are comparable to virgin yarns made from crude oil in terms of their physical characteristics. This yarn can produce clothing that is just as excellent as genuine polyester clothing. According to research, rPET fibres and their mixes can generate yarns with good tensile strength and elongation, which makes them acceptable for use in the textile industry. One of the main obstacles to the expanded growth and supply of rPET, nevertheless, is the lack of an existing source. Despite these difficulties, the surge in recycled yarns made from rPET bottles is a trend that holds promise for eco-friendly textiles and sustainable design. Recycling In India: In India, the recycling of plastic bottles into yarn is a quickly expanding industry. The quality of yarn obtained from recycled PET bottles is comparable to that of a virgin yarn produced from crude oil, with roughly 80% of PET bottles being recycled. The resulting yarn can be combined with other fibres or used alone to make a variety of fabrics that are just as high-quality as those manufactured from original polyester. Historically, robust, tough, and rough products like jackets, coats, shoes, bags, caps, and accessories were created from recycled fabrics made from PET yarn, but these fabrics were too rough on the skin and might irritate it. A significant portion of the used PET bottles are converted into staple fibre for non-woven fabrics and - TVC Team ARTICLE : SUSTAINABILITY

- 53. MARCH 2023 53 www.textilevaluechain.in fillers after being processed into cleaned flakes. By washing, flaking, and melting the material to be converted into textile - grade fibre or filament, mechanical processes account for the majority of PET that is recycled from PET bottles. But the lack of an existing, readily accessible supply is one of the main obstacles to greater growth and supply of rPET. Despite this, the sector is flourishing in India, where businesses like Polygenta Technologies Limited, a branch of the US-based Perpetual Global, produce recycled PET yarn of the same calibre as virgin yarn. Additionally, the German business BBE has provided tools and technologies that enable the transformation of PET flakes into a substance like a typical main polymer, enabling the casting of polyester. A more sustainable option to virgin polyester is provided by the surge in the use of recycled yarns from rPET bottles in India, which also lessens the quantity of plastic trash that ends up in landfills. It will be interesting to see how the sector can further innovate and create new technologies as it expands in order to handle the supply problem and fulfil the demands of the expanding textile industry. Recycling plastic bottles to make yarn is a practical way to promote sustainability and lessen waste. Recycled PET yarn, also known as rPET yarn, is a viable option for yarn production that uses previously used materials including plastic bottles and waste clothing. This type of recycling is particularly important in India because the nation consumes a lot of plastic and has a waste management issue. Usage: A wide range of materials, including robust and long-lasting items like jackets, coats, shoes, purses, caps, and accessories, can be made using recycled PET thread or yarn. It’s crucial to remember that certain materials might be irritating to the skin and can be harsh. By reusing and recycling PET-based products, the recycled yarns are sent to textile and floor covering producers, which helps to lower carbon footprints. To ascertain which blend ratios and yarn counts are better suited for various products, it is important to note that additional research is required on the use of rPET yarn in India. However, recycling PET bottles into yarn is a potential and green alternative that can support sustainability in India by lowering waste. Furthermore, one method of utilising the solid household waste that has collected in landfills around the world, including in India, is the treatment of polyethylene terephthalate (PET) bottle wastes. A significant portion of the used PET bottles are converted into staple fibre for nonwoven materials and fillers in the form of washed flakes.

- 54. Pre-treatment auxiliaries Dyeing auxiliaries Finishing auxiliaries Printing auxiliaries At Cosmo Speciality Chemicals (CSC), we value bonding. With Innovaaon, commitment to excellence and superior quality products, CSC is a one stop soluuon for a range of Adhesives, Masterbatches, Coaang Chemicals and Texxle Auxiliary chemicals. Maximize Your Mill’s Productivity with the Cosmo's Eco-friendly Texxle Soluuons Reduce Energy Usage Reduce Carbon Footprint Improve Lifestyle Reduce Water Consumption

- 55. 55 MARCH 2023 www.textilevaluechain.in Tell us about your educational qualifications. What motivated you to complete your studies till PhD? And why did you chose this stream? I did my B.Sc. (Tech) from College of Textile Technology, Berhampore (Calcutta University), M. Tech from TIT Bhiwani and PhD from IIT, Delhi. When I was class IX student, my father asked me, can you be like your elder brother. That time my brother was just completed his PhD from IIT Kharagpur. That was the driving force behind me for having PhD in textile. As a teenager during my school days, I had heard from the seniors that if you want to go to Bombay, Textile is the discipline. That had pushed me for picking –up this discipline in my graduation. By the way, I had started my career after B.Sc. (Tech) in a Textile Industry in Bombay. As a part of being an academician, research is an integral part. How do you develop a research temperament or what motivates you to carry out research in your labs? When I was a UG (under-graduate) textile student, the classroom teaching of textile subjects disheartened me. What I observed that what I studied in my school i.e. Physics and Mathematics were missing from textile subjects and the subjects were taught like storytelling. Since then, it was in my mind I will do something and try to teach textiles just like Physics. Finally I had got an opportunity at IIT Delhi to do research work on “Mathematical modeling of Weft Knitting Process”. Subsequently, I have worked on mathematical modeling of weaving, lock stitching process and mathematical models on yarn porosity, stretch bandage and compression, textile fiber filter media and fluid flow through fabric, with my students at NIT Jalandhar. Now I can teach Fabric formation and related subjects just like Physics. This gives me lot of satisfaction. Furthermore, nowadays, I am working in water filtration for rural people, medical textiles (wound dressing, partly reusable sanitary napkin and medical implantable device etc.). All these research works are directed towards the need of the poor people of the world. Would you like to share some interesting incidents/ instances that happened with you while working as a consultant to different industries or while teaching a batch of students? When I had joined NIT Jalandhar, a Professor of Insights About Textile EngineeringWith Dr. Subrata Ghosh Subrata Ghosh is a professor in the Department of Textile Technology, NIT Jalandhar. He joined NIT Jalandhar as an Associate Professor in the year 1989 on the day of inauguration of NIT Jalandhar after completing his PhD. He was elevated to the post of Professor in the year 1996 and continued as professor for the last 26 years. He got selected as Director, NIT Srinagar in the year 2006 but preferred to continue as a Professor at NIT Jalandhar for his love towards teaching and research. His main area of work is on “Mathematical modeling of textile process and materials” He is currently working on mathematical modeling of lock stitching machine and process, surface water filtration by using textile fibrous media, wound dressing and partly reusable sanitary napkin and design of implantable medical device by using textile material. TEXTILE VALUE CHAIN has taken an EXCLUSIVE INTERVIEW with Dr. Subrata Ghosh. Subrata Ghosh NIT Jalandhar INTERVIEW: EDUCATIONIST