Textile Value Chain- Nov 2021

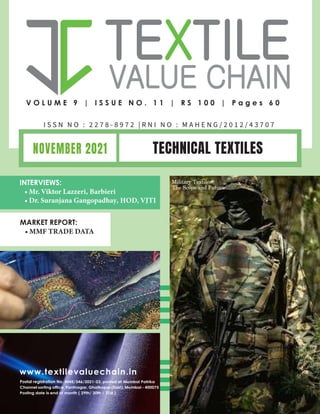

- 1. 1 TVC | Nov 2021 V O L U M E 9 | I S S U E N O . 1 1 | R S 1 0 0 | P a g e s 6 0 I S S N N O : 2 2 7 8 - 8 9 7 2 | R N I N O : M A H E N G / 2 0 1 2 / 4 3 7 0 7 www.textilevaluechain.in Postal registration No. MNE/346/2021-23, posted at Mumbai Patrika Channel sorting office, Pantnagar, Ghatkopar (East), Mumbai - 400075 Posting date is end of month ( 29th/ 30th / 31st ) INTERVIEWS: • Mr. Viktor Lazzeri, Barbieri • Dr. Suranjana Gangopadhay, HOD, VJTI MARKET REPORT: • MMF TRADE DATA NOVEMBER 2021 TECHNICAL TEXTILES Military Textiles: The Scope and Future

- 2. 2 TVC | Nov 2021

- 3. 3 TVC | Nov 2021

- 4. 4 TVC | Nov 2021

- 5. 5 TVC | Nov 2021

- 6. 6 TVC | Nov 2021

- 7. 7 TVC | Nov 2021 CONTENTS ADVERTISER INDEX COVER STORY Back Page: Raymond Back Inside: Raysil Front Inside: Rimtex Page 3: BIRLA CELLULOSE Page 4: SITEX 2022 Page 5: COLORJET Page 6: UDYOG 202 Page 11: Meera Industries DENIM FUSION MACHINES AND PROCESSES FASHION FOCUS NEWS UPDATE 09 Military Textiles: The Scope and Future 12 Techtextil India 2021: Foreign Investment Opportunities in Tamil Nadu 12 PROCESSING OF FLAME-RETARDANT TEXTILES IN INDUSTRIES 17 India’s Exports of Technical Textiles Witnessed a Hike 19 Despite Covid-19 disruption, capacity use of TEI dips to only 46% from 49% 30 SUSTAINABILITY, A MAJOR THEME AT INNOVATE 2021 TEXTILE MACHINERY 39Stäubli at SITEX 2022 Surat International Textile Expo 42AMALGAMATION OF DENIM WITH INDIAN CRAFTS & TEXTILES 49 How Festivals Influence Indian Fashion Industry 27 $2 bn Import Substitution Scope for TEI: Varun Sood EVENT CALENDAR 21 Citation of Export Excellence and R&DAwards 26 ROADMAP FOR ATMANIRBHAR BHARAT IN TEXTILE MACHINERY MOOTED INTERVIEW 33 Spectro LFP qb, a Cutting-edge Technology of Barbieri 35 Textile Industry “Entering a More Mature Stage” 37 Picanol launches new “Connect” generation airjet & rapier weaving machines 63 Show calendar 51 Handloom Textiles of Odisha: History and Types 53“Better Industrial Practices for Improved Productivity” by CTF POST EVENT REPORT 55CanvaLoop: Creating Natural & Bio-degradable Fibre from Himalayan Hemp 58GSCS International Offers Certifications & Audits 60Over 20,000 visitors at HGH India 2021 61 Trends 2021-22 62 MMF- Trade statistics HGH TREND BOOK MARKET UPDATE Page 25: Amritlakshmi Page 29: Sakthi Inustries Page 32: Unitech Texmach Page 41: Bishnu Exports Page 47: KEN Page: 54: OMAX Page: 59: Mahalaxmi Ceramics

- 8. 8 TVC | Nov 2021 All rights reserved Worldwide; Reproduction of any of the content from this issue is prohibited without explicit written permission of the publisher. Every effort has been made to ensure and present factual and accurate information. The views expressed in the articles published in this magazine are that of the respective authors and not necessarily that of the publisher. Textile Value chain is not responsible for any unlikely errors that might occur or any steps taken based in the information provided herewith. REGISTERED OFFICE Innovative Media and Information Company 189/5263, Sanmati, Pantnagar, Ghatkopar (East), Mumbai 400075. Maharashtra, INDIA. Cell: +91-9769442239 / +91. 9860634305 Email: info@textilevaluechain.com innovativemedia012@gmail.com Web: www.textilevaluechain.com OWNER, PUBLISHER, PRINTER AND EDITOR -MS. JIGNA SHAH Printed and Processed by her at, Impression Graphics, Gala no.13, Shivai Industrial Estate, Andheri Kurla Road, Sak- inaka, Andheri (East), Mum- bai 400072, Maharashtra, India. SUBSCRIPTION Digital + Print Copy issue 1 Year : 12 issues : Rs. 800 2 Years : 24 issues : Rs. 1500 3 years : 36 issues : Rs. 2100 Online Registration https://textilevaluechain.in/subscription/ Subscription Enquiry Ms. Vaibhavi Kokane +91-9869634305 ; textilevaluechain123@gmail.com Marketing and Advertising enquiry Mohammad Tanweer +91-9167986305 ; sales@textilevaluechain.com EDITOR AND PUBLISHER Ms. Jigna Shah EDITORIAL TEAM Natural fibres need more research on functionalities because these fibres are being increasingly used in technical textiles. Cotton and jute need to be explored. All fibres cannot be used to produce tech- nical textiles because of their mechanical and chemical properties. Some fibres have been selected for making technical textile for their special properties. Sustainability in technical textiles is emerging as a potential area. Sisal fibre largely imported from South Africa holds out scope. Product and technology should match. Innovation out of raw materials is less than what is required in today’s vast growing market. Renewable fibres are a great asset in this field. Suresh Kotak’s formula is:Identify functions, go back and find out the right natural fibre. Cotton—its function came by itself, and to- day China has stolen a march over many others in wipes & masks. Another example is by coating cotton with some materials, it can be converted into a material for various repellents. In India, minds are traditional bound. Bamboo fibres are an insecticide, naturally. A cotton research body has 39 innovative uses, but has not been ap- proached for commercial purpose. Cotton coated with acrylic is used for conveyor belts. In order to bring down the cost of production of some new material, innovation in technology is a prerequisite. Environmental damages are made by materials like plastics. An al- ternative with cotton and other natural fibres can be tried out. For instance, why still jute and PP are used for packaging cotton bales, resulting in contamination. A good cotton packaging material can be realised by R&D. Super Hybridisation must be part of our vision. To achieve all these, we should incentivise inventions. Innovations from institutions like VJTI and CIRCOT must be encouraged. During the last few years, the use of technical textiles has made rapid strides. Natural, synthetic, and high-performance fibres are being used in many technical textile applications. The application and use of natural, synthetic, and high-performance fibres and for Indutech, Hometech, Clothtech, Buildtech, Packtech, and Oekotech. As the strength of natural fibres is not so good, the use of synthetic and high-performance fibres is increasing in industrial and techni- cal products. One of the major applications of technical textiles is in the filtration media. The performance of a specific filter is based on the selection of fibre, textile material, and the way they have been assembled. The properties of fluid for which the filter has to be de- signed must be considered carefully as well. Human beings have been using regular clothing to protect themselves from a very hot and cold environment. The workers in some occupations (like military, po- lice, firefighting, and healthcare) are exposed to different hazards, so they are required to wear protecting textile clothing. Today the people around the world have become more educated with higher liv- ing standards. Therefore, the use of high technology products, which offer enhanced performance, durability, hygienic conditions, and aes- thetic, has become the need of the day. The demand for eco-friendly and bio-degradable packaging is growing now as they have a great impact on human health and the environment. The use of natural fibres for environmental protection is not new. While the use of syn- thetic and high-performance fibres for environmental protection is a revolutionary change in the current century. One of its uses is in protecting the crops and soil artificially by weather changes to in- crease productivity. The new and advanced developments for envi- ronmental protection will keep on increasing across the world in the coming years. The scope for natural fibres, of which India has plenty, is increasing too. More R&D in Natural Fibres is Need of the Hour CREATIVE DESIGNER Ms. Poiyamozhi P S CONTENT WRITER Ms. Somasree Roy ADVISOR - EDITORIAL & MARKETING Mr. Samuel Joseph

- 9. 9 TVC | Nov 2021 Military Textiles: The Scope and Future TVC Editorial Team T echnical textiles are fabrics that are made for a particular function. They are used due to their unique characteris- tics and technical capabilities. Military, marine, industrial, medical, and aerospace are just a few of the areas where these materials are used. For a wide range of applications, the military sector is highly reliant on technical textiles. Severe climatic situations, abrupt body movements, and dead- ly atomic or chemical reactions are all protected by the fabrics, which are specifically tailored for the soldiers. Furthermore, the utility of technical textiles doesn’t really end there. The useful- ness of such fabrics has long been acknowledged for improving fighter efficiency and saving people’s lives in battle. Following World War II, this industry experienced significant de- velopment and growth. The progress of textile technology has led to significant improvements in military uniforms nowadays. The military uniform has evolved into an integral element of their fighting gear, also serving as a means of protection. Smart textiles are increasingly integrating with service eco- systems that extend further than the typical horizontal textile supply chain. It is intended to expand the material and tangible qualities of technical textiles to intangible characteristics derived from services like the ability to measure and store information and adjust a material’s usefulness over time. In a Webinar conducted by Techtextil India 2021, Yogesh Gaik- wad, Director of SDC International Limited said, “When we talk about military textiles, it covers a lot of spectrums such as appar- els, helmets, tents, gears. The top 10 militaries have around 100 million soldiers and at least 4-6 meters of fabrics are required per soldier. Around 15-25% are repeat orders for replacing the damages or worn-out pieces. Camouflage and protection, secure locations and logistics (Rucksacks bags) are three major areas where military textiles are used.” Major Drivers Behind Market Demand for Military Tex- tiles: » Military officials all throughout the world make considerable use of technical textiles. Textile-based materials combining nanotechnology and electronics are essential in the creation of high-tech military clothing and supplies. Active and in- telligent textiles, when combined with technology, have the potential to increase a soldier’s efficiency by detecting and adjusting to the pre-set condition, as well as reacting to sit- uational needs. » Armed personnel will be able to complete all of their tasks with fewer equipment and less burden thanks to technolog- ical solutions. Uniforms with smart fabrics have a unique power source. It permits military to carry a single battery rather than multiple batteries, reducing the number of wires needed in their gear. Talking about the market demand, Mr. Gaikwad further said, “One of the major purchases of ministry of defence is camouflage textiles as the survival of the soldiers depends on this fabric. The purpose of camouflage is to blend the combat suit and equipment to the natural surroundings as well as reduce the visibility of soldiers and tools. Camouflage textiles are of two types – with IR (Infrared) spec- ification and without IR specification. Such materials can also obscure a person’s vision in UV and infrared light from a certain range. Furthermore, nanotechnology is being used to produce new technological fibres that can stimulate muscular strength, giving soldiers additional power when performing difficult tasks. The newly designed zero permeability parachute material has an incredible ability to function with high safety and efficiency.” Physical Properties of Military Textiles: » The attire of military personnel must be made of light- weight fire- and UV light resistant-fabric. Designed for engi- neers who operate in hot environments, it should be able to control the odour. » It has to be biodegradable, water repellent and durable. » The fabric should be breathable, chemically protected » Military apparel should also be able to keep them warm and buoyant. There are many more parameters to be considered while making the military textiles. Fibres that could provide solutions: » Para-Aramid COVER STORY Image Source: wikimedia.org

- 10. 10 TVC | Nov 2021 » Modacrylic » Aromatic Polyamide Fibres » Flame Retardant Viscose » Nanotechnology-enabled Fibre » Carbon Fibre » High Modules Polyethylene (UH MPE) » Glass Fibre » Bi-Component Knit Construction » Gel Spun Polyethylene Competitive Market Analysis of Military Textiles: The marketplace is quite competitive. Companies compete on improved smart textile performance, cost-effective technologies, quality of products, durability, and market share. Suppliers must deliver cost-effective and high-quality goods and services to sur- vive and prosper in this climate. Governments across the globe have put a great priority on pro- viding their forces with the most up-to-date equipment and facili- ties, especially advanced military gear. As a result, the worldwide technical textiles for defence market have grown. Smart textiles have improved the efficiency and features of military apparels by increasing aspects such as maximising camouflage, incorporating technologies into the garments, reducing the weight carried, and boosting ballistic protection utilising cutting-edge technologies. Application Segment of the Military Smart Textiles Mar- ket: Camouflage, power harvest, temperature monitoring & control, security & mobility, health monitoring, etc. are some of the ap- plications that the worldwide military smart textiles market can be divided into. By 2027, the worldwide military smart textiles market is expect- ed to be dominated by the camouflage sector. Energy harvesting, temperature monitoring & control, and health monitoring categories are likely to increase at a robust pace during the predicted period, creating considerable incre- mental possibilities. Other sectors are expected to grow at a me- dium to high rate in the coming years in terms of quantity. According to a UK Publication, A “smart” skin influenced by chameleons which changes colour depending on the light might be the future of military camouflage. As per researchers, the revolutionary material may also be useful in anti-counterfeiting activities. Chameleons and neon tetra fish, for example, can change their colours to disguise themselves, attract a partner, or scare attack- ers, according to the researchers. Experts have attempted to recreate similar characteristics in synthetic “smart” skins, but the substances used have still not proven to be durable. Regional Analysis of Military Textiles: Asia, particularly growing countries like India and China, has seen a significant rise in the military sector. In the APAC region, defence budget is increasing at one of the fastest rates throughout the world. Combined with the need to prepare military soldiers for modern combat, large sums of money have been invested in new military equipment as well as improved military apparel. Asia Pacific leads the worldwide market demand for military, smart textiles. Europe and the US come in second and third posi- tion, respectively. The market of military textiles in North Amer- ica is expected to grow as the nation’s textile sector expands. The textile industry employs 6% of the entire manufacturing work- force in Europe. The United Kingdom spent 21 billion pounds in 2019-2020 in this sector. Thus, the market in Europe is predicted to grow as the textile industry in Europe expands. Military Camouflage Image Source: made-in-china.com

- 11. 11 TVC | Nov 2021 Futuristic Twisting Futuristic Twisting Twisting Solutions Twisting Solutions Textiles Textiles FIBC Threads Belting Fabrics Dipped Cords Geo Textiles Bullet Proof Jackets direct twisting + precision winding Tapes / Twines / Multifilament Meera Industries USA, LLC 209, Swathmore Ave, High Point NC, USA 27263 Meera Industries Limited 2126, Road No.2, GIDC, Sachin, Surat 394230 Gujarat, INDIA +91 98795 97041 | sales@meeraind.com | www.meeraind.com

- 12. 12 TVC | Nov 2021 Techtextil India 2021: Foreign Investment Opportunities in Tamil Nadu TVC Editorial Team A fter two years, Techtextil India 2021 opened on 25th November in Mumbai, bringing together the technical textile sector. The trade event featured a variety of ed- ucational seminars, live product demonstrations, as well as B2B meetups to highlight the future prospects of technical textiles. Ajit Chavan, secre- tary of the Textiles Committee, opened the trade event. The trade fair took place in both physical and hybrid edition. According to a press release from show organiser Messe Frankfurt India, the goal of the revised edi- tion first post-lockdown—is to encourage indus- try cohesion and help economic recovery through- out the value chain of technical textiles. “The policies of Indian government are complete- ly intended for the development of technical tex- tiles. We have fixed a target of Rs. 2 lakh crores for the nation, and the Indian market is prepared to meet that goal. “Our country have a great deal of potential in Image source: indiantextilemagazine.in COVER STORY

- 13. 13 TVC | Nov 2021 medtech and agrotech, and we have always been always been at the forefront of packtech, geotech, as well as other high-tech fields,” Chavan stated during the inaugural ceremony. The three-day trade event featured top technical textile businesses from Tamil Nadu and through- out the country. The Tamil Nadu government an- nounced a strong partnership with Messe Frank- furt India for the 2021 edition, adding that this will promote textile policy and investment oppor- tunities at the expo in way to lure enterprises and investors to the state. “Although, there are numerous natural benefits for the development of technical textiles in Ta- mil Nadu particularly, majority of raw materials required to make artificial ligaments, seat belt webbings, sanitary items, and airbags are still imported. In this scenario, by working alongside international technical textiles firms, the Tech- textil India Group can assist us in reducing de- pendence on imports and attracting r&d invest- ments, production, and innovation.” said Ms. Pooja Kulkarni, MD & CEO, Guidance Tamil Nadu. During the Techtextil India webinar session on ‘Investment opportunities in Tamil Nadu’, she also said, “Tamil Nadu is the top investment destination of India due to the state’s advanced infrastructure, network capacity, strong indus- trial base, skilled manpower as well as location- al advantages and connectivity that cater to its well-established manufacturing ecosystems and facilitate exports.” She further added, “33% of all textile business in India comes from Tamil Nadu itself. Tamil Nadu accounts for 28% of the total employment in the textile sector of India. The state is also leading manufacturer and exporter of cotton yarns in In- dia. Coimbatore, Tirupur, Karur which were the hub for natural fibre are now also strongly growing into man-made fibres. Also, during the pandemic situation last year, the region was a great sup- port in quickly adopting to manufacturing PPEs and masks. The local manufacturers were quickly able to scale up their operations as well as new operators came in and they beat the demand for PPEs. Therefore, the region has now a strong presence MedTech.” Ms. Pooja also talked about some attracting tech- nical textiles investments to Tamil Nadu which include Technical Textile investment worth Rs. 1771 Cr. and Textile investment worth Rs. 2170.04 Cr. The overall investments in Tamil Na- du’s textile sector totalled Rs. 3,941.04 Cr. Jayashree Spun Bond, Cyber Textiles India Pvt. Ltd., Lenzing Ag India, Loyal Textile Mills Ltd., Liester Technologies, Uster Technologies (India) Pvt. Ltd. and Milltex Engineers Pvt. Ltd., are among the technical textile companies from Ta- mil Nadu who attended this important trade fair. “The state excels in Agrotech, Meditech, Cloth- tech, Buildtech, and “ Ms. Kulkarni stated, em- phasizing Tamil Nadu’s proficiency in technical textiles. Tamil Nadu’s automotive ecosystem is well posi- tioned to attract high-value, high-technology Mo- biltech investment, as it has India’s largest auto- mobile and auto-component hub. Likewise, Tamil Nadu is home to half of India’s textile factories, as well as related hubs of knit- ting, weaving, and medical equipment manufac- ture in Coimbatore and Tirupur. Production in India can be a huge victory for companies because investments in Tamil Nadu will give them access to a growing market.” The Market in India for technical textiles, valued at USD 19 billion, is increasing at a CAGR of 12%, 3 times quicker than the global pace, showing great export potential. The Government of Tamil Nadu recently announced a budget that prioritis- es infrastructure building for the textile industry, with special emphasis on upcoming technical tex- tile parks in Karur and Virudhunagar. Reference: Webinar conducted by Techtextil India 2021

- 14. 14 TVC | Nov 2021 T he term flame retardant is used to describe fabrics which will not support combustion and are self-ex- tinguishing. Fabrics of this type, when involved in an accidental fire would not contribute to spreading the flames. Other descriptions, such as flame proof, fire proof and flame resistant, are either meaningless or misleading. Nearly all fabrics are combustible to some degree. The rate of burning ranges from that of guncotton (nitrocellulose), which burns so quickly that it produces an explosion, to that of asbestos, which is virtually unaffected by fire. Flame retardant fabrics can be produced in two ways. 1. by making them of fibres which do not burn. 2. by chemically treating the fibres to produce the desired effect. There was a time originally when such materials could only be produced by employing a chemical finish. Howev- er, this can often cause problems in terms of durability of the process and its impact on the environment. Strict controls are required to achieve consistency and problems arise likewise with the final look of the material. Even where the flame-retardant quality is guaranteed over a certain number of washes, there can be no certainty of the effectiveness of the procedure, as it is practically impossi- ble to monitor the number of washes in practice. All such difficulties are avoided by the use of permanently modified chemical fibres. The polymer was invented in 1974. The development of staple fibres and filament took place in 1976-79. It was introduced in the USA in 1979 and Europe in 1980. The permanent flame-retardant proper- ties were due to the organic phosphorous compound in- corporated into the polymer chain. As it was a low-level modification the textile properties of the polymer remain unchanged. Fire Retardant polyester fibre came to India by Hoechst AG, Germany by the trade name of Trevira CS (CS stands for Comfort and Safety). From the outset there was also a large role for home tex- tiles; today the most important sector for Trevira. The product range extends from drapes, decorative and uphol- stery fabrics to carpet fibres. Yet here too, the portfolio began to change towards specialities early. In 1980 one such was Trevira CS, a flame retardant fibre, which from its launch recorded ever-rising growth rates and is today the star product of the company. With over 1000 flame retardant Trevira CS fabric collections for the home tex- tiles sector worldwide, Trevira is the market leader in this segment. Since then, the range of flame retardant fibres and yarns has undergone a steady flow of changes and in- novations. In 2004, Reliance crossed another milestone in its polyester journey when it acquired Trevira GmbH, an erstwhile division of the German giant Hoechst AG, a lead- ing producer of branded polyester fibres in Europe. Specific moisture absorption of Trevira is around 0.4% at 20 deg C and 65% RH. It can however be made consid- erably higher by the hydrophilic surface of the material and the capillary effect between the fibres. Moisture pen- etration is very high, thus releasing humidity, something very important for instance for sitting comfortably. Trevi- ra CS has been tested to German, American and Japanese health standards and being adjudged non-toxic, not aller- genic or mutagenic and non-irritant. The Eco-Tex 100 test confirms that Trevira CS is free from harmful substances. Trevira CS has three flame retardant mechanisms like it melts away from the flame, absorbing ignition energy. Flame retardant groups quench reactive species, chain re- action cannot propagate. The polyester modification creat- ed by Trevira performs a very important function. Within a flame, highly charged elements called radicals are re- leased which rapidly propagate more flames. The Trevira modification captures and neutralises the radicals before they can propagate more flames. Trevira belongs to the polyester group of fibres, which are rendered permanently flame-retardant by the inclusion of a small proportion of a phosphorous-organic component. They display all the typ- ical properties of polyester fibres and offer industry and consumer considerable advantages. Hoechst (Germany) gave the licence only to Rajasthan Spinning and Weaving mills, Gulabpura (Rajasthan) to use this fibre in India. Trevira supplies 100% Trevira flame retardant fibres or filament yarns. Trevira CS fabrics are made from flame retardant fibres and used therefore in the home textile and contract fur- nishing sectors. They are flame retardant to all appropri- ate fire protection requirements and produce only slight amounts of smoke fume. For the first time, the flame re- tardant qualities combine with bioactive properties to also provide safety from microbes. These qualities are not lost by cleaning, ageing or wear. Trevira CS is easy care, light, fast, comfortable and kind to the skin. Trevira CS is used in hotels, and hospitals, offices and event rooms and prin- cipally where people are traveling on aircraft, buses on PROCESSING OF FLAME-RETARDANT TEXTILES IN INDUSTRIES Dr N.N.Mahapatra Business Head(Dyes) SHREE PUSHKAR CHEMICALS & FERTILISERS LTD. Mumbai, India COVER STORY

- 15. 15 TVC | Nov 2021 trains and at sea. The following are the advantages of using Trevira: 1. Outstanding running properties in spinning and twist- ing. 2. Very good processability, high yarn uniformity and te- nacity for weaving, circular and warp knitting. 3. Excellent dyeability using a variety of methods, environ- mentally friendly finish processes giving crease resistant fabrics with good shape retention. 4. Good hard-wearing properties. 5. Easy-care. 6. Outstanding light fastness. 7. Permanent flame retardance. The following are the processes involved in making fire retardant textiles: 1. Spinning 2. Bleaching. 3. Dyeing. 4. Finishing. 5. Printing. The above processes are discussed as below. 1. Spinning - It is classified into two types: a. Grey CS yarn b. Dyed CS yar Grey fibre is normally available in 1.4 D x 44 mm. The spinning is done in the same manner like 100% normal polyester fibre. The process is as follows: Blowroom - Carding - Draw frame – Simplex - Ringframe – Winding – TFO – Packing . The grey yarn goes for weaving and making of soft package for yarn dyeing. Secondly, the dyed fibre is received from dyehouse. The dyed fibre is sprayed with LV 40 and 2152P and condi- tioned for 16 hrs. Then it follows the similar route in spin- ning as prescribed for 100% dyed normal polyester fibre. The dyed yarn is sent to weaving /knitting Flame retardant Trevira CS spinning yarns can be used in any spinning process, resulting in outstanding with ring spinning, OE–rotor and airjet spinning, as well as with carded yarns and worsteds. A variety of effects is possible for which the product range includes dull, semi-dull and bright types. Extremely fine three-cylinder yarns are used in delicate fabrics, decorative materials and bed linens. The OE–rotor yarns with a flat, soft structure form the basis for decorative fabrics, vertical blinds and mattress materials. The current demand for soft, transparent and bright yarns is particularly met by filament yarns of the high-capillary type for drapes and decorative fabrics. De- gree of fineness range from 50 dtex with delicate goods through to 3000 dtex for cover fabrics with high wear and light fastness properties. With false twist yarn one can achieve light but bulky weaves. The wide range of fire-retardant Trevira spun yarns en- ables spinners to offer complete collection of yarns. They have a quality which is not only ideal for their purposes but is fire-retardant as well. The range comprises degrees of fineness for practically every application; from the fin- est (1.3 >1.7 dtex) for delicate fabrics right through to the extremely coarse (13 dtex) for carpets. Image Source: What they think

- 16. 16 TVC | Nov 2021 2. Bleaching - Bleaching is not required prior to dyeing of dark and medium shades. It is almost white. But in case of clear and pastel shades bleaching with peroxide is re- quired prior to dyeing. 3. Dyeing - There are four types of dyeing. a. Filament yarn dyeing. b. Spun yarn dyeing c. Loose staple fibre dyeing. d. Fabric dyeing. a. Filament yarn dyeing- normally 165 dtex is used in filament dyeing. Soft package of 700-800 gm is made on perforated polypropylene tubes by precision soft winding machine having overfeed attachment. Then it is dyed in HTHP Dyeing Machines at temperature of 120 deg C for 30-45 min depending on shades. It is Hydroextracted in Dettin package Hydroextractor. It is dried in RF Dryer. It is rewinded on paper cone. The dyed package goes for Weaving or Knitting. The principal applications for flat yarns are in curtains and decorative fabrics, irrespective of whether these are false twist, jet –tax, jet-tweed, multicolour or chenille yarns. A further possibility involves use of texturised filament yarns, where a very wool-like character can be achieved with specially air-textured types for furniture fabrics. b. Spun yarn dyeing- Similarly spun yarn is made in various counts ranging from 2/5, 2/8 ,2/12, 2/20, 2/24, v2/30, 2/50.Then soft package is made on PS Mettler or SSM winding machines. Package weight is 900 gm to 1 kg. It is loaded in HTHP dyeing machines. It is dyed at 120 deg C. The rest process is as above. An even wider range of design perspectives is opened up by combining filament and fibre yarns. Employing fancy yarns, such as knit-deknit types, produces striking designs. Jet-tex and tweed types are mainly used as upholstery and decorative material and as wall coverings. c. Loose staple fibre dyeing - Normally 1.7 d x 44 mm Trevirs CS fibre are available for dyeing. The CS fibre is loaded in the carrier. Then the loaded carrier goes into the HTHP Dyeing Machines. It is dyed at 120 deg C at a pH of 4-5. with a leveling agent like Lyogen DFT (of Clariant) is added. Dark shades are reduction cleared with Caustic Soda and Sodium Hydrosulphite. (1 gpl and 2 gpl respectively) . Then hot wash at 85-90 deg C. Then acid neutralised by acetic acid. Then Antistatic Agent Sapcotex F (Henkel)– 0.4 % (o w g). Then the carrier is offloaded. The dyed fibre goes for Hydroextraction . Then it is dried in RF Dryer / Steam Dryer. Total dyeing time takes about 4-4.5 hrs. With a 40 deg C wash there are no discernible differenc- es between normal polyester and Trevira CS fibres. At 60 deg C with the same dyeing similar values are achieved on flame retardants as on non-modified types. d. Fabric dyeing – Trevira CS fabric is dyed in jet dyeing machines. The process is followed as above. Af- ter dyeing it is squeezed and dried in stenter at a lower temperature of 140 deg C to 150 deg C. Dispersion dyes take on fire–retardant somewhat faster than the corre- sponding normal polyester types. Due to these light shades can be dyed at boiling temperature without adding carrier. Medium to dark shades are dyed without carrier at a max- imum temperature of 120 deg c. Disperse dyes used are high energy dyes from Dystar, Germany known as Diani FG dyes or Foron RD dyes from Clariant, Basle. In raw white for piece dyeing or as multicoloured yarns, flame retardant textiles can be made in all desired qualities. In general dyeing with coloured and patterned fabric results in adequate wash fastness. Preliminary tests are recom- mended, however as there is a possibility of staining adja- cent material. Dyes on Trevira cs are fast to washing at boiling temperatures in bright shades and with selected dyestuffs. A chlorine-fast finish is possible with the appro- priate dyestuffs. Boiling is not recommended for drapes and decorative fabrics. 4. Finishing - Selection of softeners is very critical. It has to be seen there is no negative effects on burning behav- iour. Leomin ni of Clariant is the recommended softener to be used for CS fabrics in the dose level from 1 to 5 gpl. Trevira CS materials may be coated with PVC or polyu- rethane. An antimicrobial or fungicide finish is possible with Dodigen (from Clariant) or Afrotin LC (the Schill and Seilacher company). While maintaining the relevant fire category. Whilst being processed trevira cs fabrics can be exposed for brief periods to temperatures above 210 deg c. where they are exposed to temperatures for longer times, we recom- mend a maximum of 150 deg c in dry atmospheres and 100 deg C in humid conditions. With flame-retardant types in deep shades the fastness properties reduce bu ½ degrees as compared to dyes on normal types. 5. Printing - Pigment printing is not recommended for Trevirs CS fabrics because the use of binder and thicken- ers influence the flame retardant properties negatively. Transfer printing can be done on Trevira CS fabrics. Any papers printed with dispersion dyestuffs can be employed. Checks should first be made to ensure the Light Fastness of the dyestuffs involved is adequate. Varnish should not be used as part of the residue may adhere to the fabric in printing and exercise a negative effect of the flame-retard- ant behaviour on Trevira CS material Wear properties of Trevira CS fabrics 1. Stability – very good. 2. Abrasion resistance - > 60,000 Martindale 3. Durability – very good.v 4. Light- fastness – 7-8 . 5. UV-Stability Hrs – 80% (1400 Xenotest) 6. Washability – 60 deg C. 7. Stain removal – very good. Trevira CS fabrics satisfies all the relevant and important fire protection standards.

- 17. 17 TVC | Nov 2021 India’s Exports of Technical Textiles Witnessed a Hike TVC Editorial Team T echnical textile is a rapidly expanding sub-segment used in a wide range of industries. The ultimate application of technical textiles is diverse and may be found in sectors including agriculture, sportswear, construction, healthcare, automobile and so on. A few of the important factors to the de- velopment of this market include India’s push towards modernisation and its production ef- ficiency. Because of increasing market situation, tech- nical textiles have witnessed a worldwide in- crease in recent times. Advanced technologies, a growth in end-use applications, cost-effec- tiveness, resilience, customer-friendliness, and sustainability of technical textiles have result- ed in a rise in their market share in the global market. In terms of revenue, Mobiltech, Indutech, Buildtech, Packtech, and Hometech account for almost two-thirds of the worldwide indus- try. India’s Export of Technical Textiles COVER STORY

- 18. 18 TVC | Nov 2021 Technical textile makes around 13% of India’s overall textile and garment industry and adds 0.7 per cent to India’s GDP. India exported textile wall coverings worth US$0.03 million in September, 2020 which increased to US$0.05 million in September, 2021. Between January and September 2021, the total exports were US$0.21 million, up by 58.56% from the last year. Exports of transmission/conveyor belts/belt- ing of textile material wh/nt impregnated coat- ed, covered/laminated with plastics reinforced with mettle/other material September 2020 totalled US$1.01 million which declined by 12.59% to US$0.88 million in September 2021. By the end of September 2020, the exports were worth US$5.27 million and it increased to US$7.93 million in the corresponding peri- od of next year. Textile wicks, woven, plaited/knitted, for light- ers, candles etc; incandescent gas mantles etc, w/n impregnated exports which were totalled US$0.8 million in September 2020, decreased by US$70.74% to 0.23 million in September 2021. From January to September 2021, the to- tal exports increased by 6.7%. India exported Textile fabrics coated with gum or amylaceous substances, of a kind used for the outer covers of books or the like were worth US$1.36 million, up by 40.04% from the previous year. Between January and September 2021, the overall exports were up by 32.45%. Tyre cord fabric of high tenacity yarn of ny- lon or other polyamides, polyesters or viscose rayon exports in September 2021 witnessed a fall by 2.76% to US$4.48 million. By the end of September 2020, the exports were totalled US$27.36 million which increased to US$39.14 million at the end of September 2021. India’s exports of Linoleum, whether or not cut to shape; floor coverings consisting of a coat- ing or covering applied on a textile back were worth just US$0.01 million by the end of Sep- tember 2021. In September 2020, the exports of textile prod- ucts and articles for technical uses were about US$3.64 million and it grew by 15.64% in next year September to US$4.21 million. Total ex- ports between January and September 2021 were also up by 44.89% from the previous year. Textile fabrics impregnated, coated, covered/ lamented with plastics excel those of heading No. 5902 exports were worth US$21.21 million in September 2020 which increased by 4.08% in September 2021 to US$22.08 million. From January to September 2020, the total exports were US$139.71 million which hiked up to US$223.48 million during the same time span of next year, up by 59.96% from the previous year. India exported textile hose piping and similar textile tubing, with or without lining, armour oraccessoriesofothermaterialsworthUS$0.19 million during September in both years. India’s exports of rubberised textile fabrics, other than those of heading 5902 totalled US$1.27 million in the month of September 2021, increased by 89.43% from the last year. By the end of September 2021, the overall ex- ports totalled US$9.04 million. India exported Textile fabrics otherwise im- pregnated, coated/covered; painted canvas being theatrical scenery, studio back-cloths or the like worth US$1.5 million in Septem- ber 2020 which witnessed a spike of 12.21% in September 2021. Between January and Sep- tember 2020, the total exports about US$8.84 million which rose to US$15.32 million during the corresponding time of next year.

- 19. 19 TVC | Nov 2021 I n his welcome speech, Mr. Vallabh Thumar, Chair- man, Textile Machinery Manufacturers’ Association (India) at the “61st Annual General Meeting of the Asso- ciation, said that in the year gone by the global Covid-19 pandemic struck a complete structural disruption around the world throughout 2020- 21. “The big churn of the first wave got the entire world to witness; ‘too big to fail’ econo- mies shatter, numerous un-or- ganized industries purged, unproductive business prac- tices consolidated, training and skill development of the experienced manpower into multitasking roles increased, new R&D and indigenisation efforts of key technologies in- stituted, collaboration among competitors for survival founded, credit utilisation and resources at hand optimised, and novel business models based on internet incepted. Interestingly, the market bounced back from the ‘Zero Production’ days to the more than ‘100% Capacity Utiliza- tion’ days unheard of in dec- ades post 1st & 2nd pandemic waves. However, the uncer- tainty remains among the entrepreneurs pertaining to rising prices of the raw mate- rial, vagary of freight and con- tainers’ availability, crunch of liquidity and geopolitical ten- sion,” Mr. Thumar said. The TEI has currently an es- timated annual installed ca- pacity of Rs.11,000 crore per annum. The total provisional production of textile machin- ery, parts & accessories during 2020-21 recorded a marginal decrease of 5% viz. Rs.5,093 crore as against Rs.5,355 crore achieved during the previous year. During the fiscal year the capacity utilisation decreased from 49% to 46% as compared to the preceding year. This is despite the fact that there was negligible business during first two quarters of 2020-21. The exports during 2020-21 rose to Rs. 3,307 crores as against Rs. 2,556 crore achieved during 2019-20. On the other hand, the import was reduced to Rs. 8096 crore as against Rs. 9,273 crore during the year. Mr Thumar disclosed that the total domestic demand for tex- tile machinery during 2020-21 was Rs. 9,118 crores of which supplies from the domestic machinery industry amounted to Rs.1,786 crore, aggregating 20% of the total demand. The bulk of the demand was met through imports. Measures for Growth Ori- entation The Government of India pre- pared PANDEMIC Specific strategies and action plans not only for business con- tinuity and sectoral revival but also to improve Ease of Doing Business in the coun- try by releasing notifications/ amendments/circulars high- lighting measures to improve the business environment in India, Mr Thumar said. Con- tinuing on the momentum of the previous year, the office of the Textile Commissioner co- ordinated and processed the ATUF Scheme efficiently, bar- ring a few months of complete lockdown. Majority of the cas- es related to the enlistment of textile machine manufactur- ers, induction of new machine types in the ATUF scheme and the release of ATUF sub- sidy were cleared on time. The association worked close- ly with Kalam Institute of Health Technology (AMTZ Vishakhapattanam) and In- vest India both of whom con- ducted separate studies on the Indian Textile Engineer- ing Industry (TEI) under the aegis of ‘Ministry of Textiles’ Despite Covid-19 disruption, capacity use of TEI dips to only 46% from 49% TVC Editorial Team TEXTILE MACHINERY

- 20. 20 TVC | Nov 2021 during the year. The KIHT was assigned to conduct ‘Technology Gap Analysis in the Indian TEI’ and suggest measures to enhance the po- tential of the domestic indus- try. On the other hand, In- vest India published an article on the status of the industry in the post-Covid-19 scenar- io and started working on an Opportunity Paper covering the Textile Machinery Indus- try in India. Written in asso- ciation with TMMA, its aim is to showcase India’s strengths in Textile Machinery to both global and domestic players and highlight the opportuni- ties and advantages of invest- ing in the Indian TEI. Mr Thumar said that besides, a study done by Ernst and Young instituted by Nation- al Committee on Textiles and Clothing also covered about the Indian TEI in a chapter. This study was partly funded by the India-ITME Society. This study may also help In- dian TEI in working closely with the textile industry and the MoT on various projects to participate more efficiently in the ‘Make in India’ campaign. During the year the associ- ation also took initiatives in putting forward proposals for “Incentives for Commerciali- zation of the Indigenously De- veloped and Acquired Tech- nologies from Overseas”, to the Ministry of Textiles and Ministry of Heavy Industry & Public Enterprises. The main purpose was to support the domestic research and de- velopment and joint ventures under the ‘Make in India’ in- itiative of the Government of India to become commercially competitive not only in the do- mestic but also in the export markets. Both the ministries may be considering our pro- posal positively, and the asso- ciation is quite optimistic of a suitable scheme in the coming fiscal year. Mr Thumar congratulated Mr. Pratik Bachkaniwala, the incoming Chairman and his co-Office Bearers, Mr. M. Shankar, Mr. Prashant Man- gukia and Mr. Shailesh Wani and wished them a successful tenure. “I would like to sin- cerely thank the past chairmen of TMMA for all their help and guidance – in particular; Mr. Mehul Trivedi, Mr. R. Rajen- dran, Mr. Prakash Bhagwati, Mr. Rajnikant Bachkaniwa- la, and others who helped me during my tenure,” he added. Export and R&D Awards He said: “It is our normal practice to present Export and R&D Awards at the Annual Session of the Association. In this Session, we are giving 8 Awards for Export Excellence, 3 Awards and 1 Certificate of Appreciation for R&D for the year 2019-20. Besides, we are giving 8 Awards for Ex- port Excellence for 2020-21.” He congratulated the award winners for putting in great efforts in the promotion of exports and the development made in textile machinery to win the Awards.

- 21. 21 TVC | Nov 2021 Citation of Export Excellence and R&DAwards 2019-20 T he Textile Machinery Manufacturers Asso- ciation Export Awards Scheme covers the following categories of Awards: - 1. Apex Export Award 2. Segment Export Awards for each of the major sectors of the Textile Machinery Industry i.e. i. Textile Machinery Sector ii. Parts and Accessories Sector iii.Textile Testing, Monitoring & Controlling Instruments Sector 3. Special Export Awards: Category-wise The Association also presents Research and De- velopment Awards for indigenous development of new technology/processes under different cat- egories in the field of Textile Machinery Indus- try. 1. EXPORT EXCELLENCE AWARDS: The Association received 21 nominations for dif- ferent categories of Export Excellence Awards, out of which 8 winners were declared. These nominations were evaluated by the Awards Committee of the Association and selected eight nominations as winners. a. Apex Export Award: The Apex Award Winner is: TEXTILE MACHINERY Kirloskar Toyota Textile Machinery Pvt. Ltd., Bangalore. Recipient of the Award is: - Mr. Hisahiro Koketsu – Managing Direc tor of the Company. b. Segment Export Awards: i.Machinery Sector: - Winner of the Award is: Saurer Tex tile Solutions Pvt. Ltd., Vadodara Recipients of the Award is: Mr. Vikas Sharan – Director India Operations of the Company. ii. For Parts & Accessories Sector:

- 22. 22 TVC | Nov 2021 Winner of the Award is: Inspiron Engineering Pvt. Ltd., Ahmedabad Recipient of the Award is: Abhijeet Kulkarni, representative of the Company. iii.For Textile Testing, Monitoring & Controlling Instruments Sector: Winner of the Award is: Premier Evolvics Pvt. Ltd., Coimbatore Recipient of the Award is: Mr. Sanjay Gandhi – Deputy General Manager - Sales of the Company Special Export Awards: - i. Spinning Machinery Sector: - Winner of the Award is: Rieter In dia Pvt. Ltd., Pune Recipient of the Award is: Mr. Pras anta Kumar Deka – Market Head India of the Company. ii. Processing Machinery Sector: - Winner of the Award is: Stovec Industries Ltd., Ahmedabad Recipient of the Award is: Mr.Sachin Patil representative of the Company. iii.Parts and Accessories Sector: - Winner of the Award is: Maksteel Wire Healds Pvt. Ltd., Vadodara Recipient of the Award is: Mr. Ramesh Bhai Sidhpura – Director of the Company. iv. Small Scale Sector: Machinery- Winner of the Award is: Weavetech Engineers Ltd., Surat Recipient of the Award is: Mr. Vallabh Thumar - CMD of the Com pany. 2. RESEARCH & DEVELOPMENT AWARDS: Four member companies sent nominations for 7 product R&D Awards. The Jury considered three nominations eligible for the Award for their

- 23. 23 TVC | Nov 2021 jeet Kulkarni, representative of the Com pany. 2) Lakshmi Card Clothing Mfg. Co. Pvt. Ltd., Coimbatore for their development of “Flat Tops Used in Carding Machine at Textile Spinning Mills” Recipient of the Award is: Mr. M. Sundaresan, Asst. General Manag er – Product Development of the Company 3) Lakshmi Machine Works Ltd., Coim- batore for their development of “Draw- frame LDB3” Recipient of the Award is: Mr. Tharani Prabhu - Team Leader R&D of the Company 4) A Certificate of Appreciation Present- ed to Maksteel Wire Healds Pvt. Ltd., Va- dodara for their development of “Twin Wire Healds with Oil Tempered Wire” Recipient of the Award is: Mr. Ramesh Bhai Sidhpura – Director of the Company. [Executive Director to request Office Bearers & Chief Guest to Felicitate] 2020-21 Citation of Export Excellence and R&D Awards Similarly for the year 2020-21, the Association received 22 nominations for different catego- ries of Export Excellence Awards out of which 7 applications were considered to be the win- ners. These nominations were evaluated by the Awards Committee of the Association and selected eight nominations as winners. a. Apex Export Award: The Apex Award Winner is: Rieter India Pvt. Ltd., Pune R&D efforts during the year 2019-20. Whereas, 1 application received a Certificate of Appreciation for the product improvisation. The Award winner are: 1) InspirOn Engineering Pvt. Ltd., Ah- medabad for their development of “Press- er Finger Automatic Tucking-In for Auto Doffing Roving Frame” Recipient of the Award is: Mr. Abhi

- 24. 24 TVC | Nov 2021 Recipient of the Award is: - Mr. Prasanta Kumar Deka – Market Head India of the Company. b. Segment Export Awards: i. Machinery Sector: - Winner of the Award is: Lakshmi Machine Works Ltd., Coimbatore Recipients of the Award is: Mr. S. Saravanakumar – Manager - Global Sales of the Company. ii. For Parts & Accessories Sector: Winner of the Award is: Lakshmi Card Clothing Manufacturing Co. Pvt. Ltd., Coimbatore Recipient of the Award is: Mr. N. Jagadeesan Asst. General Manager – Exports of the Company. c. Special Export Awards: - v) Spinning Machinery Sector: - Winner of the Award is: Truetzschler India Pvt. Ltd., Ahmedabad Recipient of the Award is: Mr. Kashyap Bhavsar of the Company. vi) Processing Machinery Sector: - Winner of the Award is: Kusters Calico Pvt. Ltd., Vadodara Recipient of the Award is: Mr. Sushil Verma Managing Director of the Company. vii) Parts and Accessories Sector: - Winner of the Award is: Inspiron Engineering Pvt. Ltd., Ahmedabad Recipient of the Award is: Mr. Naveen Aggarwal, representative of the Company. viii) Small Scale Sector: Machinery- Winner of the Award is: Yamuna Machine Works Ltd., Mumbai Recipient of the Award is: Mr. Prashant Mangukia – Director of the Company.

- 25. 25 TVC | Nov 2021 DIRECT WARPING- COTTON DIRECT WARPER WITH EVENISER HIGH SPEED FILAMENT SIZING MACHINE +91 80800 62392 amritlakshmi@amritlakshmi.com amritlakshmi.com "PioneersInWeavingPreparatorySince1978” HIGH SPEED SIZING MACHINE JUTE SIZING FILAMENT BEAMING MACHINE Contact Us V a r i e t i e s o f P r o d u c t s O ffered

- 26. 26 TVC | Nov 2021 T he Office Bearers of Textiles Machinery Manu- factures Association (India), led by Mr. Vallabh Thumar, Chairman (CMD-Weavetech Group), Mr. Sachin Kumar-Executive Director, and foremost in- digenous and foreign Textiles Machine Manufacturers had a hybrid interaction (Physical + Virtual) with the Hon’ble Union Minister of Textiles, Mr Piyush Goyal and Hon’ble Minister for State for Textiles, Ms Darsha- na Vikram Jardosh on 22nd October 2021 to develop a facilitating Ecosystem for growth of the Textiles En- gineering Industry (TEI) in India under Atmanirbhar Bharat India in order to (1) Compete globally in all in- dustry segments on strength of technology and scale, (2) Initiatives towards Atmanirbhar Bharat: Meet 75% of domestic demand by 2026-27 and (3) Cost reduction for the textile manufacturers and enhancement of value exports. In this meeting 15 textile machines manufac- tures of foreign regions; 20 leading indigenous textile manufactures and 7 textile machinery and associated industry associations have participated and submitted their viewpoints. Mr Piyush Goyal urged the industry to focus on speed, skill and scale by getting into inno- vative partnerships and developing 100 Indian Textile Machinery Champions recognized across the world. Mr Piyush Goyal Ji also urged all to get out of Com- mand-and-Control mindset and work through Plug and Play model to make the textile sector more vibrant in name and sprit. Alluding to achieving 100 crore vaccination and the Chandrayan-1 mission, Mr Piyush Goyal urged the in- dustry to be inspired by the volumes in vaccination to scaleup while look at the precision in Indian space pro- gramme sector to bring the Mojo back. The Ministry of Textiles, Government of India being the Ministry of user industry of textile machines and with the aim to reduce the capital cost of our textiles and apparel man- ufactures is well aware that the machinery is the most critical input underlying the production and capacities of the whole textile value chain. However, there are var- ious issues hindering manufacturing of textile machin- ery used particularly for weaving, knitting, processing, embroidery, garmenting and technical textiles sub-sec- tors benchmarked to international standards. Presently 75% of requirement of machinery is being imported and though we have certain strengths, domestic textile en- gineering industry is able to meet 25% of requirements. As such a number of measures with PLI and MITRA have been taken to expand the textile production and export which consequently would result in higher de- mand of technology and machinery. Kalam Institute of Health Technology (KIHT), Visakhapatnam (which has developed required infra- structure for manufacturing of medical devices in a limited time) after due consultations with all related stakeholders, has suggested manufacturing of critical components of the textiles machines as one of the in- terventions for promotions. These are at present being imported by our textiles machine manufactures. Hence, manufacturing of critical components needs critical support consideration since strengthening of the ver- tical would enable reducing costs while augmenting benchmark technology riding on possibilities of Make in India. This would contribute to value enhancement and employment generation. Efforts of strengthening machinery manufacturing would go a long way in our quest for sustainable textile ecosystem, enhancement of value exports of textile goods and contribute signifi- cantly to building an Atmanirbhar Bharat. Based on the submissions and inputs provided by the industry leaders during this interaction meeting, the Government would be able to further strengthen the ecosystem among the related ministries as well as relat- ed industry associations including IT Industry, machine tools and plastic industries for manufacturing of the textiles machinery which are currently being imported into the country. This would also help the Government to devise short term, medium term and long-term ac- tion plan in the direction of Atmanirbhar Bharat initia- tives of our Hon’ble Prime Minister, Mr Narendra Modi. ROADMAP FOR ATMANIRBHAR BHARAT IN TEXTILE MACHINERY MOOTED TVC Editorial Team TEXTILE MACHINERY

- 27. 27 TVC | Nov 2021 I n his Guest speech at the TMMA AGM, Mr Varun Sood, Vice President of Invest India, the National Investment Promotion and Fa- cilitation Agency, promoted by the Central Gov- ernment touched upon various topics and stressed the growing textile industry’s capability to scale new peaks in production and exports. He said that the growing textile industry currently valued at US$150 billion has provided much buoyancy to the textile machinery industry in India. Growth in the domestic market and potential export opportuni- ties imply that textile machinery demand is stead- ily growing as well, both in India and the world. He revealed that there are about 3,250 companies involved in manufacturing of textile machineries, accessories and trading of the equipment in India. The industry not only caters to rising domestic de- mand but also has the potential to establish In- dia as an export hub for textile machinery with spinning machines representing the largest ex- port opportunity. “A major component of textile machinery industry in India thrives on the global partnerships that companies in India have forged with their global counterparts be it in Germany, Italy or Japan. 100% Foreign Direct Investment (FDI) is allowed through the automatic route in this segment which coupled with a supportive pol- icy ecosystem, is keen on welcoming more inves- tors to India and take advantage of its manufac- turing competitiveness,” he said. Talking in detail about the textile machinery in- dustry, Mr Sood said that “a US$2.5 billion tex- tile machine industry which is growing at 5% currently reflects on the growing strength of this sub-segment in the textiles value chain in India. A strong textile engineering industry that can grow, compete, and export would be able to provide sup- port to the rising Indian textile industry, adding vibrancy and competitiveness. “As per the 60th Annual Report by the Textile Machinery Manu- facturing Association (TMMA), the Asian region will account for more than 90 per cent of the total textile machinery market share, and in order to ex- pand its technical horizons, many textile machine companies in the country are joining hands with their western counterparts to produce technologi- cally advanced machines,” Mr Sood said. Speaking about the India Advantage, Mr Sood said that “production costs in China are rising at a faster rate than any other developing countries. Increase in manpower cost is a major factor which will impact the cost of machinery manufacturing as well. The hourly labour cost in China has almost quadrupled since 2000 and is further expected to increase in the near future. In addition to it, the demographic shifts in China will inhibit the labour force in coming years due to ageing population. In contrast, India has favorable demographics with a young population base with 65 per cent of its pop- ulation below 35 years of age.” Talking on export potential, Mr Sood said that presence of textile industries in neighboring coun- tries like Bangladesh pose tremendous export op- portunities (~17 per cent export demand). India has signed bilateral and multilateral treaties with different countries that have consequentiality presence in textile manufacturing. Touching upon the India’s strong manufacturing competitiveness leading to import substitution, Mr Sood stated that India is a cost competitive manufacturing base for all types of products across the textile value chain. In 2020, Government of India announced Produc- tion Linked Incentive (PLI) Schemes for 13 key sectors for US$26 billion which will further boost the manufacturing ecosystem of the country pro- viding the much-needed impetus to tap the US$2 $2 bn Import Substitution Scope for TEI:Varun Sood TVC Editorial Team TEXTILE MACHINERY

- 28. 28 TVC | Nov 2021 billion import substitution opportunity. He dwelt on the Government Schemes and Initia- tives for the Capital Goods Sector as follows: Export Promotion Capital Goods Scheme - Un- der the Scheme, EPCG Authorizations are issued with actual user condition and import validity of 24 months to import capital goods (except those specified in negative list) for pre-production, pro- duction, and post-production at zero customs duty. Capital Goods Scheme - The DHI Capital Goods Scheme is a pilot scheme designed to support the industry to modernize domestic technologies Technology Acquisition Fund Programme - Fund- ing is provided to explore opportunities for accel- erated technology upgradation through acquiring technologies for specific projects and activities Indian Electrical Equipment Industry Mission Plan 2012-2022 - Vision 2022 for the Indian elec- trical equipment industry is to make India the country of choice for the production of electrical equipment and reach an output of USD 100 Bn by balancing exports and imports. National Capital Goods Policy 2016 - Aimed at in- creasing the production of capital goods from the 2014-15 value of approximately USD 31 Bn to USD 101 Bn by 2025 Central Manufacturing Technology Institute - CMTI in association with Textile Machinery Man- ufacturers’ Consortium (TMMC) and TMMA had undertaken the development of advanced technol- ogies for high-speed shuttle-less looms under De- partment of Heavy Industries’ (DHI’) ‘Scheme for enhancement of global competitiveness of Indian Capital Goods sector’ in April 2015 Textiles Committee, Ministry of Textiles - The Tex- tiles Committee is the statutory body for ensuring the quality of textiles and textile machinery. Capital Goods Sector Skill Council - DHI and Fed- eration of Indian Chambers of Commerce & Indus- try (FICCI) launched a Capital Goods Sector Skill Council in 2013 under the aegis of National Skill Development Council (NSDC), New Delhi. The ob- jective was to develop skills of a new generation of workers which would match the expectations of the industry Custom Bonded Warehouse Scheme - The Central Board of Indirect Taxes (CBIC) is allowing import of raw materials and capital goods without pay- ment of duty for manufacturing and other opera- tions in a bonded manufacturing facility Opportunities in the Capital Goods Sector are due to 100 % FDI through Automatic Route; Industri- al Licensing- no industrial license required (Free); Import Policy- No import license required; Expatri- ation Policy- Liberal work visa regime; Formation of Company- Company can be formed online; Cor- porate taxes 25%, Import duties maximum 10%, General Import duty 7.5%, GST 18%; Proximity to the customers and ASEAN countries; Excellent manpower availability as well as skilled workforce for R&D; ; With campaigns such as “Make in In- dia” manufacturing sector is the prime focus sector of the government Besides other Government Schemes and Initiatives of the Ministry of Textiles, Mr Sood said that the upcoming Initiatives by the Ministry of Textiles to benefit machinery manufacturers included Mega Integrated Textile Region and Apparel Parks (MI- TRAs) – A dedicated textile machinery park could come up under the scheme which aims to attract large investment and employment generation in the sector to further boost domestic manufactur- ing and to create world class infrastructure with plug and play facilities. Mr Sood revealed that a Consultative Session was organized on 8 September 2021 by Ministry of Textiles with support from Invest India & TMMA to seek feedback on how to make India a leading Textile Machine Manufacturing destination.”The session witnessed participation from 40+ compa- nies along officials from Ministry of Textiles, Of- fice of the Textile Commissioner, Textiles Com- mittee, Ministry of Heavy Industry, Ministry of Steel, Office of the Principal Scientific Adviser to the Government of India and Textiles Machine Manufacturers Association to hear out industry concerns and resolve ongoing issues, seek industry feedback on the current schemes pertaining to tex- tile machinery and discuss the recommendations for implementation guidelines.”Invest India in col- laboration with Textile Machinery Manufacturing Association launched the report Textile Machinery in India during the Consultative Session for mak- ing India a leading textile machinery manufactur- ing destination.”

- 29. 29 TVC | Nov 2021

- 30. 30 TVC | Nov 2021 SUSTAINABILITY, A MAJOR THEME AT INNOVATE 2021 TVC Editorial Team I nnovate 2021: Textile Innovation Week and the Innovate Summit, which has drawn to a close recently, has been hailed a great success by innovators, exhibi- tors and visitors across the globe. The event had around 60 exhibitors and over 100 live streams, 86% of which were exhibitor live streams. Exhibitors included Sun Chemical, DuPont, AFFOA, ITMA, Oerlikon, Velcro, Epson, Ricoh, Polygiene, Evon- ik, Kornit Digital and Roland DG. Ricoh announced its partnership with direct-to-garment (DTG) printing OEM spe- cialist Aeoon Technologies at the event. The partnership, according to the compa- nies, aims to bring solutions to the market that actively supports digital print ser- vice providers with modular growth strategies. It will allow Ricoh the opportunity to extend its DTG offering into higher productivity market segments and further demonstrate a focus on sustainability and cost-efficiency, Ricoh says. Ink specialist Sun Chemical launched its Xennia® Pearl pigment inks for high-speed industrial applications at Innovate 2021. The range, which includes inks for both mid-viscosity and high-viscosity print heads, has been developed following a careful assessment of the market and specific customer needs, particularly the requirement for high fastness, multi-substrate compatibility, consistent colour, and outstanding print performance. A recurring theme throughout the textile & ap- parel industry, sustainability was a primary topic of conversation through the Summit. Delegates heard a keynote presentation from Xu Yingxin, Vice President, China National Textile & Ap- parel Council, on how China’s textile & apparel sector aims to mitigate climate change. For Eu- ropean policy, we heard from Dirk Vantyghem, Sustainability Director General, Euratex, who discussed a new more sustainable framework for the European textile & apparel industry. On the third and fi- nal day of the event, a panel of materials spe- cialists (for both man-made and natural fibres), hosted by Friedrich Weninger, Managing Direc- tor, Dornbirn Global Fiber Congress discussed the desperate need for enhanced sustainability in the fibres market arguing that this must come from putting differences and competition aside and collaborating. TEXTILE MACHINERY

- 31. 31 TVC | Nov 2021 Industry 4.0 Skills gap Digitalisation, not surprisingly, was also a recur- ring theme. In particular, how Covid accelerat- ed digitalisation was assessed (for example, in a panel session hosted by the ITMF and others) as well as how it can help in futureproofing supply chains by providing tools for authentication – as discussed by Ian Cronin, Community Curator at the World Economic Forum – transparency and traceability. It is thought that digitising process- es and technologies is enabling the movement of manufacturing back to developed economies and although there was hope among speakers that this movement remains strong, it is appre- ciated that these markets cannot compete with the backward linkages and manpower of China. Additionally, digitalisation, it was discussed, can be leveraged to improve sustainability strate- gies and supply chain resilience (as mentioned by Joshua Hinkel, Partner, Bain & Company in a keynote presentation). However, digitalisation also means the industry requires a new set of skills. As well as part of addressing the need for collab- oration, is collaborating to reduce the industry’s skills gap. The Summit showed that the skills gap is not just prevalent in the US and Europe as previously thought but is also a global issue, with large manufacturing nations such as India struggling to find the right skilled workers to meet the demands of the global textile & apparel industry. Every industry, from fibres to print- ing, is suffering from a skills gap. In particular, the nonwovens industry – as discussed in a pan- el session hosted by David Rousse, president, INDA, is struggling to recruit new talent. This is despite the boom in the nonwovens market, with the growth of medical applications for non- wovens and face masks since the outbreak of the pandemic. With the growing nearshoring trend across the industry, there is the worry that with- out action, there will be no-one to fulfil the roles, or spark innovation, in this movement. Show sponsor Ricoh said during the show that the company was so happy that “[the WTiN] team will get an open invitation for Christmas dinner!” Friedrich Weninger, Managing Direc- tor of exhibitor Dornbirn Global Fiber Congress, said: “It is a great show and the potentials in terms of contacts one could explore are excel- lent.” Mike Wang, specialist at innovate exhibi- tor, Taiwan Textile Federation (TTF), said: “We heard great feedback from our exhibitors regard- ing how WTiN had invited diverse visitors from the technology industry to participate in this great exhibition. “Once again, thank you and we look forward to joining your wonderful event next time.” Mark Jarvis, Managing Director, WTiN, says: “Innovate 2021 has shown how fruitful and en- gaging live, virtual events can be. We are hon- oured to have had so many visitors to Innovate 2021 and, importantly, so many fantastic ex- hibitors and speakers who have helped to make the platform the rich, engaging space it is today. “This has made it clear that innovation is key for our industry to thrive – in all areas of the indus- try – and we plan to do that with Innovate going forward. We are excited for the next Innovate chapter, to be announced soon.” The event was sponsored by Ricoh and the Inno- vate Summit was sponsored by Epson. Collaboration was discussed as a necessity for a more sustainable textile & apparel industry by many at the Summit. Not only that, but it’s also necessary for future innovation, too. For example, Leeds City Region in the UK and India are collaborating to ensure greater in- novation throughout the textile & apparel in- dustry, as well as in a bid to close the growing skills gap. What’s more, a fireside chat from supply chain technology company QIMA dis- cussed how data and transparency are key to future-proofing supply chains but also, that supplier and buyer relationships are becom- ing more entrenched. The discussion conclud- ed that we must work together to ensure our supply chains are streamlined and more able to handle disruption, such as that at the begin- ning of 2019, when the Covid pandemic broke out. Collaboration

- 32. 32 TVC | Nov 2021

- 33. 33 TVC | Nov 2021 Spectro LFP qb, a Cutting-edge Technology of Barbieri Mr. Viktor Lazzeri spoke to the Textile Value Chain in an exclusive interview. Excerpts: Textile Value Chain (TVC): In today’s textile world of changing fashions, colour accuracy plays a vital role. Give us a brief history of Barbieri Electronic since its inception. Viktor Lazzeri (VL): Barbieri Electronic was founded in 1983 in Brixen, a town in Northern Italy by Mr. Siegfried Barbieri. From its roots building densitometers, the company switched in 1997 to the digital printing market by building one of the first spectrophotometers for measuring colour in digital printing. Since then, many innovations fol- lowed, from automated measurements, to variable measurement apertures to offering backlit meas- urements. Today the Spectro LFP qb textile edi- tion is the cutting-edge technology when it comes to measure textiles and other materials in digital printing. TVC: Where are your major markets for the various products? VL: Measurement technology is a key piece of technology in various markets. Our Barbieri meas- urement devices are used in digital textile printing, signage, label and packaging, flatbed, fine art and industrial printing (for example ceramics, glass and other applications) T here are a number of challenges in obtaining accurate colour measurement data in digital textile printing. However, automated colour measurement devices can help to overcome these challenges. The Barbieri Spectro LFP qb textile edition is able to accurately measure textiles in digital textile printing. In a webinar recently, Barbieri discussed how to enable an accurate and stable linearisation and calibration process in digital textile printing and how to ensure colour accuracy through verification with automated colour measurement. Mr. Viktor Lazzeri is the Business Development Manager for Barbieri Electronic. Barbieri Electronic builds spectrophotometers for colour measurement in professional digital printing and is the colour measurement market leader for large format, flatbed and industrial printing. Viktor’s focus is expanding Barbieri’s international business into new markets, applications, and indus- tries. He started at Barbieri in 2011, initially working as Supply Chain Manager. Later he took the role of the VP of Product and Innovation and also managed the operations of Barbieri North America Inc. Mr. Viktor Lazzeri Business Development Manager Barbieri INTERVIEWS

- 34. 34 TVC | Nov 2021 TVC: What are the latest products and their salient features? VL: The Spectro LFP qb Textile Edition is the worldwide unique solution for automatic col- our measuring in digital dye-sublimation and di- rect-to-garment printing. It is based on the Spectro LFP qb and has dedicated software and accessories who makes it possible to measure fully automati- cally and with highest precision and repeatability any kind of textiles and fabrics. The special hold- er fixes the textile firmly, the camera and accord- ing software detects the centre of each patch to be measured and the measurements will be done fully automatically – even if the chart is distorted! The measurement head can be detached for manual spot measurements and results sent to the com- puter. Two devices in one and automatic and spot measurements done with the same device which leads to a maximum accuracy. TVC: How are you placed in the Asian mar- ket, especially the Indian market? VL: In the Indian market we work with our part- ner: Fortuna Colours & Prints LLP, Gurgaon or directly through manufacturers. The best way to reach out to us is directly via our website www. barbierielectronic. We do have a service and sup- port centre in Taiwan and Shanghai. The contact details are available on our website. TVC: Digital printing has made big strides in India. What is your strategy for this mar- ket? VL: Our strategy over the past months and years has been to innovate and build the best, most intel- ligent colour measurement devices for digital print- ing. We know of many ongoing challenges in digi- tal printing and want to support our customers to help them become top performers in digital print- ing. We work closely with manufacturers, software companies worldwide and local partners to be close to the customer and make sure our technology can be used to solve critical color challenges. TVC: Give us a view of your future plans and R&D efforts in colour measurement. VL: Our mission is to build Intelligent colour measurement technology for top performance in professional digital printing. That is why we are working with selected research partners across the globe to innovate and predict new trends and chal- lenges. We will continue to work on new innovative solutions that make colour measurement as accu- rate as possible. Spectro LFP qb Textile Edition 2

- 35. 35 TVC | Nov 2021 Textile Industry “Entering a More Mature Stage” D r. Suranjana Gangopadhay was the First woman Head of Textile Department of Veermata Jijabai Tech- nological Institute (VJTI) since its inception in 1887.VJTI started with only two Departments -- Textile and Mechanical Engineering. That time the institute was founded to provide trained manpower to the booming Textile Mills in Mumbai...that’s the reason VJTI started with Textile Department known as Ripon School of Textiles with Mechanical Engineering Department to supplement manpower for maintaining Textile Machinery. Dr. Gangopadhay has a Ph. D. from the IIT Bombay, with M.Text from the MS University, Baroda and B.Tech from the University of Calcutta. She is a member in BIS Committees of TXD-14: Textile Machinery and Accessories Section- al Committee, TXD-01: Physical Methods of Tests Sectional Committee and TXD-31: Man-Made Fibres, Cotton and their Products Sectional Committee. Dr Gangopadhyay calls herself an ‘Accidental Textile Professor’… landed with Textile Technology while entering engineering education and then the uniqueness of the domain made her to “become extremely passionate; the reach of Textile Field encompasses between handloom-Handicraft to extremely high-end “Technical textiles”; which I enjoy from the perspective of both a Material Scientist and a Textile Technologist.” Dr Suranjana Gangopadhyay replies succinctly to some of the questions posed by the Textile Value Chain: Excerpts: Explain your particular teaching strategy or tech- nique that is helps you to teach. Always linking the content of the syllabus with relevant ap- plication in practical field which the students are familiar and excited about, e.g., » while teaching nuances of active wears, I mention about the famous adventure sports programme which students are familiar with. » while teaching nuances of Extreme weather clothing, I relate it to some famous scenes of Hollywood/ Bollywood movies. How will you encourage your students to be creative in the textile industry? » Always persuade/train them in giving customised and in- dividualised lines of attack and resulting solutions for var- ious scenario shared with them as part of “Case Studies” and “Mini Projects”. » Highlighting to them the rich heritage and facets of Arti- san Knowledge and culture. » Highlighting to them scientific and textile domain knowl- edge application in mythology. Describe your work ethic. I think of myself as am a strategizing and goal oriented Profes- sional with hawk-eyes on perfection and finishing. I believe, a good listener by being so can encourage a very meaningful yet guided communication not only in Textiles but in every field. If I have multiple projects in front of me, I handle completing them on time by Strategising, Multi-tasking and Delegating. What are your strengths as a professor and how do you measure success as a professor? Students feel their time spent with me adds some incremental values to their knowledge repository both in technical as well as other domains…ensuring a holistic growth of their person- ality. Dr Suranjana Gangopadhyay HOD, VJTI INTERVIEWS