The document discusses various topics related to the leather industry including future trends of vegan leather, emerging global trends in leather, exploring sea leatherwear, study of leather fabric, leather made from cactus, leather antiquity, being wholesome, leather machinery exports impacted by COVID-19, leather processing, elevating your career in leather design and technology, future of design education, rejuvenating folk paintings on textile products, environment friendly mushroom leather, empathy as a leadership competency, monpa handmade paper, recycling leather, coir products export opportunities, india edifying cotton demand and supply chain, sustainable agriculture, hemp as a sustainable fibre,

![20

M AY 2 0 2 1

cally [1].

Tanning methods

Tanning processes largely differ in

which chemicals are used in the tan-

ning liquor. Some common types in-

clude:

Vegetable-tanned leather is tanned us-

ing tannins extracted from vegetable

matter, such as tree bark prepared in

bark mills. It is the oldest known meth-

od.

Chrome-tanned leather is tanned us-

ing chromium sulfate and other chro-

mium salts. It is also known as "wet

blue" for the pale blue color of the un-

dyed leather

Aldehyde-tanned leather is tanned us-

ing glutaraldehyde or oxazolidine com-

pounds. It is referred to as "wet white"

due to its pale cream color.

Chamois leather is a form of aldehyde

tanning that produces a porous and

highly water-absorbent leather. Cham-

ois leather is made using marine oils.

Brain tanned leathers are made by a

labor-intensive process that uses emul-

sified oils, often those of animal brains

such as deer, cattle, and buffalo.

Alum leather is transformed using alu-

minum salts mixed with a variety of

binders and protein sources, such as

flour and egg yolk. Alum leather is not

actually tanned; rather the process is

called tawing.

Grades of Leather

Top grain leather

Full grain leather

Corrected grain leather

Split leather

Bicast leather

Patent leather

Suede leather

Bonded leather

Properties of Leather

Leather has High tensile strength

i.e., cow leather is between 8 – 25 N /

mm². Leather with higher fat content

has a higher tear strength. But there

are many other parameters that in-

fluence the tear strength, the tanning

method, the finish, the stiffness, or

the age of the leather. Since leather is

a natural product, every skin behaves

differently. Resistance to tear is an im-

portant property. Good leather is sta-

ble and resistant to tearing, whereas

suede, nubuck or extremely soft lamb-

skin will not have the same stability

as, for example, a belted leather.

High resistance to flexing i.e., the

ability to withstand numerous flex-

ing cycles without damage or deterio-

ration. Better mouldability, it can be

molded into a certain shape and then

remolded into another shape later.

Permeability to water vapor i.e., ena-

bles leather to absorb water and per-

spiration.

Good thermostatic properties i.e. The

leather is warm in winter and cool in

summer. It is resistant to heat and fire.

Leather provides good heat insulation.

The leather is resistant to abrasion

in both wet and dry environments.

This makes leather an excellent pro-

tector of skin.

Resistant to Fire, fungi, and chemi-

cal attack.

Advantages of Leather

Leather is truly sustainable and natu-

ral fiber. Good leather ages well and

can keep for long period. Leather is

easy to repair and easy to maintenance.

Leather products can be recycled and

have natural comfort. Leather is more

luxurious and have beautiful surface

area. It has many ends uses as follows-

Leather can be used as binder for fin-

ished books. It is often used to make

clothing including pants, skirt, rain-

coats, and jackets. Leather has been

used for all types of equestrian related

products, including horse hoof boots.

also, From fashionable winter gloves

to durable work gloves. Fashionable

footwear is one of the most common

uses for leather, including boots, shoes,

slippers, and more. Couches, chairs,

recliners, and even automotive interi-

ors are made from leather. Leather can

be used for accessories like wristwatch

straps, jewellery, belts, wallets, bags,

and purses etc.

Disadvantages

Leather is more sensitive to fluctua-

tions in temperature, where it can feel

warmer in summer and cold in winter.

When it comes to color and patterns,

combinations of color and patterns are

limited. It has main drawback i.e., pro-

ducing leather requires animals to be

killed.

Conclusion

This study gives us basic information

of leather i.e., history, manufacturing

process, applications, etc. Which shows

leather is a natural, biodegradable fab-

ric. It is made from tanning of animal

skin. The rawhide and skin used for

leather manufacturing is comes from,

99% of the raw hides and skins used

in the production of leather derive from

animals raised for meat and/or dairy

production. Leather productions uti-

lize non usable part of dead animals,

so that there will no waste of animals.

References

1. "Interesting Facts about Leather"

https://www.decorium.com/tag/disadvan-

tages-of-leather/ CalTrend. Retrieved 7 Feb-

ruary 2018.

2. Applications

h t t p s : / / e n . w i k i p e d i a . o r g / w i k i /

Leather#Production_processes

3. Properties

https://saddlesindia.com/properties-of-

leather/

https://www.colourlock.com/blog/Advan-

tageLeather/

4. Basic Information- Manufacturing process.

https://en.wikipedia.org/wiki/Leather

C O V E R S T O R Y](https://image.slidesharecdn.com/tvcmay2021webversion-220112074951/85/MAY-2021-20-320.jpg)

![30 H R F O C U S

and along with it long-term damage to

the ability of your organization to at-

tract talent in the future. As business

leaders, as we go through these tough

times, in addition to all the other lead-

ership competencies which you will

have to exhibit to get your company

and your people through, it may be

prudent to focus much more on Empa-

thy, to ensure that the people in your

organization experience you as a hu-

mane and caring leader.

M AY 2 0 2 1

Leather is a long-lasting and flexible ma-

terial made by tanning animal hides and

skins. Cattle hide is the most used raw

material. It can be manufactured on a

variety of scales, from artisan to modern

industrial. Leather production has been

going on for over 7,000 years;[1] the ear-

liest record of leather artefacts dates to

2200 BCE.

Top Grain Leather

The top layer of a hide is known as top

grain leather. The leather hide is me-

chanically split into layers after it has

been tanned but before it is finished. Top

Grain is tough and long-lasting, with the

"hallmarks of the road" like wrinkles,

scars, bug bites, and other natural char-

acteristics. The best portion of the hide is

the top grain.

The Split Hide is separated from the Top

Grain and is used to manufacture suede

and other leather products. Splits aren't

as strong as Top Grain leather and aren't

as excellent in quality. They're more

prone to fading, stretching, and tearing.

Split hides are used by some furniture

producers on the sides and backs of fur-

niture, where the customer is unlikely to

touch or sit.

Full Grain and Corrected Grain Leathe

Full Grain leather is top grain leather

that hasn't been buffed or polished, pre-

serving the natural texture and grain.

The trail's signatures, or markings, will

stay on the hide. Stretch marks, scars,

branding, bug bites, and other imperfec-

tions may be evident. The leather's origi-

nal appearance and feel are kept.

Most natural markings are lightly rubbed

or sanded out with Corrected Grain leath-

ers, and an artificial yet realistic-looking

grain is embossed on the hide. Top grain

leathers that have been corrected are

still top grain leathers. They've been re-

designed to have a more uniform feel and

hue.

Leather for furniture

Only about a third of the world's hides

are appropriate for furniture upholstery.

Just around 5% of the supply matches

the aesthetic characteristics necessary,

thus whole hides with only minor flaws

are necessary. While hides that will be

chopped into smaller pieces and used for

belts, shoes, and small leather products

can have some natural markings and

scars, hides that will be used for furni-

ture must be more flawless. Because

automotive leather hides must undergo

considerable processing in order to meet

durability and severe wear require-

ments, they are not as rare or valuable

as hides used to produce sofas, loveseats,

and chairs. Pure aniline, full grain semi

aniline, or corrected/embossed leather is

required for furniture.

Types of Leather

Aniline

This is the most "organic" and "natural"

sort of leather. This leather, also known

as Pure Aniline or Full Aniline, has no

protective covering. It hasn't been han-

dled or processed in any way to change

the natural grain, appearance, or feel of

the hide. The most luxuriously soft feel

of all the leather varieties is aniline, but

it is more prone to fading, staining, and

soiling. This is a good type of leather for

someone who enjoys the smooth, natural

feel of leather but also appreciates and

values the distinctive natural markings.

It's reasonable to assume that the furni-

ture will only see light to moderate use.

Semi-Aniline

Although not as pure and natural as

aniline leather, this type of leather has

some of the same properties. Following

aniline dyeing, the hides are sprayed

or rubbed with a protective topcoat. To

produce a two-tone or other effect, an

additional color may be used as well.

As with aniline leather, certain natural

markings may show through the topcoat,

making wrinkles, scars, and bites obvi-

ous. While semi-aniline leather is more

protected than pure aniline leather and

the color will likely be more uniform, it is

still susceptible to fading, staining, and

other problems. This is a fantastic sort of

leather for a consumer who wants natu-

ral leather's suppleness and texture but

will use the furniture frequently.

Pigmented

This is the toughest leather, but it isn't

the most natural. Because the natural

markings have usually been sanded or

buffed away, this is the case. The hide is

then embossed with an artificial grain.

As a result, the grain and colouring are

consistent, which some buyers prefer. In

addition, a protective topcoat with col-

our is usually sprayed or rubbed into the

surface. Adding this layer usually takes

away part of the leather's natural soft-

ness and breathability. The colour of Pig-

mented leather may not be as deep and

rich as Aniline leather, and it may not

have the same sumptuous hand, but it is

the most durable and cleanable. This is

a good sort of leather for someone who is

ready to forego some softness and natural

texture in exchange for more functional-

ity.

Nubuck

Nubuck is a soft, rich top grain leather

with a small nap that has been softly

buffed or sanded to give it a suede-like

look. It's worth noting, though, that

Nubuck is a top grain leather, which

means it's more durable and high-quality

than suede. Nubuck leather is a quality,

natural substance that typically lacks a

protective finish. It's prone to fading and

smudging.

This is a good sort of leather for someone

looking for a one-of-a-kind, trendy, and

really comfy leather that demands a little

additional care and maintenance.

LEATHER FUNDAMENTALS

F A C T S](https://image.slidesharecdn.com/tvcmay2021webversion-220112074951/85/MAY-2021-30-320.jpg)

![31

M AY 2 0 2 1

P E E R R E V I E W P A P E R

REJUVENATING FOLK PAINTINGS ON TEXTILE

PRODUCTS: A REVIEW

Guest Faculty, Department of Garment Production and Export Management,

Government Arts Girls College, Kota

NIKITA SACHWANI

Abstract

India is a diverse country with a vast

range of art forms and cultures which

serve as a unique identification for the

area of their origin. These together con-

tribute to the rich heritage of this coun-

try. This study titled “Rejuvenating

Folk Paintings on Textile Products: A

Review” is an attempt to bring together

various efforts made by entrepreneurs,

researchers, academic institutes, de-

signers, organizations and craftsmen

of this country to bring back Indian

folk painting to life through their ap-

plication on textiles/ textile products.

Work done during the last five years

(2016-2020) has been reviewed and dis-

cussed. The aim of this study is to help

and provide necessary inputs related to

past work done in this field. This is ex-

pected to be beneficial for textile reviv-

alists, designers, students and all those

who are working or are willing to work

for the revival of folk paintings of India

by applying them on different media

and product diversification.

Keywords: Heritage, rejuvenating,

craftsmen, product diversification, de-

signers, entrepreneurs.

Introduction

India is a land of diversity, a fact that

is blatantly visible in people, culture,

and climate of this nation. “This coun-

try has hundreds of ethnic groups scat-

tered from north to south and east to

west, each with its own art form rep-

resenting its taste, needs, aspirations,

aims, joys, sorrows and struggles”.

“With regional peculiarities, nature

around and a different pattern of day-

today life apart, their art reveals each

group’s ethnic distinction and creative

talent” [1]. Along with adding richness

to heritage of India, these art forms

have fascinated people all over the

world.

Warli Paintings of Maharashtra are

creative expression of the women of

a tribe known as Warli. The name of

this painting is dedicated to this tribe.

These paintings are a picturization of

daily life. Scenes in these paintings in-

clude animals, birds, humans in their

daily activities, celebrations, hunting

etc. These paintings are expressed by

these words- “Painted white on mud

walls, they are pretty close to pre-his-

toric cave paintings in execution and

usually depict scenes of human fig-

ures” [2].

Another bold and colourful expression

of the feminine creativity is the Mad-

hubani Painting of Bihar which is also

named as of Mithila Art due to its roots

in the Mithila region of Bihar. Origi-

nally painted on mud walls, motifs of

hindu deities like Devi Durga, Devi

Saraswati and Lakshmi, Lord Shiva,

Krishna, Tulsi plant, Moon and Sun,

wedding processions and rituals etc.

are depicted using mineral pigment

colours. Geometric shapes eg: fine lines

are used for the purpose of filling.

Aipan paintings of Kumaon region is

a ritualistic folk art, is believed to pro-

vide protection from the evil. Events

like festivals, auspicious occasions and

even death rituals are prominently

expressed in white colour (cooked rice

paste) in this painting. Floor and walls

of the houses serve as the canvas for

this art. Red ochre mud called ‘Geru’

in local language is coated to provide a

background.

Phad painting of Rajasthan is done on

cloth depicting local deities and sto-

ries, and the legends of local rulers. It

is a type of scroll painting made using

bright and subtle colours. The outline of

paintings are first drawn using blocks

and later on filled with colours. These

paintings are often carried from place

to place by the traditional singers, who

narrate the various themes depicted

on scrolls. Along with Phad, Rajasthan

is also known for its elaborate, highly

intricate and refined, Pichwai paint-

ings. They are used as backdrops in

the famous Shrinathji Temple at Nath-

dwara. Their main theme is Shrinathji

and his miraculous stories [3].

Gond community is famous for their

unique style of painting which is fa-

mous by the name of Gond paintings.

These paintings feature the relation of

nature and its connection to humans

on the walls and floors of the buildings

of this tribe. “It is done with the con-

struction and re- construction of each

and every house, with local colors and

materials like charcoal, coloured soil,

plant sap, leaves, cow dung, limestone

powder, etc. The images are tattoos or

minimalist human and animal forms”

[4] [5]. According to the beliefs of the

tribal people, these paintings attract

good luck, so they used to paint these

on their walls and floors. This artwork

was also very skilfully used by the

Gond tribe to record their history.

Rogan Paintings, an art form used for

painting textiles in the Kutch district

(Gujarat), declined in the latter half

of the 20th century. This is now mas-

tered and practiced by only 2 families

of Kutch. “In this craft, paint made

from boiled oil and vegetable dyes is

laid down on fabric using either a met-

al block (printing) or a stylus (paint-

ing)”[6].](https://image.slidesharecdn.com/tvcmay2021webversion-220112074951/85/MAY-2021-31-320.jpg)

![32

M AY 2 0 2 1

The Mandana paintings are connected

to the Hadoti area of Rajasthan and

that too with the Meena community

residing in this area. This painting

work is executed by the women of this

community on floor and walls. Accord-

ing to the beliefs of this community,

Mandana paintings provide protection

to their homes. For this kind of paint-

ings, limestone powder or chalk pow-

der is used as a painting medium. The

ground is prepared by applying a mix-

ture of cow dung, geru and a clay called

rati. For painting, a date stick, a small

cluster of hair or a piece of cotton fabric

is used as a tool. Figures of women at

work, lord Ganesha, birds and animals

like peacock and tiger respectively, flo-

ral motifs etc. can be noticed in Man-

dana paintings. [7]

The Saura tribe belonging to Orissa

state are known for their wall paint-

ings based on spiritual and ceremonial

themes. “A study of their art and paint-

ing tradition reveals the rich ancient

tribal art idiom, which is still in vogue

with popular appeal” [8]. These paint-

ings appear somewhat like warli paint-

ings and are given the name- ‘Ikons’. In

these paintings, motifs like moon and

sun, tree of life, animals like horses,

elephants and also humans are found

painted using natural colours prepared

using white stone, earth, flower and

leaf extracts.

With advancement in time, growing

industrialization and modernization

there has been a rise in preference for

mass produced, machine made articles

which has posed a threat to our tradi-

tional crafts and has raised concern in

the country to preserve, sustain and

cultivate our traditional assets so that

they sustain the wave of modernization

and remain available to the future gen-

erations. For this purpose, folk paint-

ings can be applied on textile products

which are an integral part of our life.

These products range from small ar-

ticles like handkerchiefs, purse and

pouches, bags, clothing, up to large ar-

ticles like bed covers and draperies. In

this way these paintings can become a

part of our daily lives resulting in their

revival and growth.

The objective of this paper is to present

a review of 5 works published during

each of the past five years (2016-2020)

respectively which aim at reviving In-

dian folk paintings through their ap-

plication on textiles / apparel / lifestyle

accessories.

Material and Methods

This review paper is based on sec-

ondary sources. Extensive litera-

ture review was carried out to obtain

elaborate information about various

attempts made to apply folk paint-

ings of India on textiles for the pur-

pose of their revival; within the span

of past five years (2016-2020). Online

research databases namely Academia,

Researchgate, Krishikosh e-granth,

Shodhganga, Google Scholar have been

used to access research papers, review

papers, conference proceedings, Ph. D/

Dissertation thesis and other related

text. In addition to this books, newspa-

per articles, reports from government

and national institutes, websites have

also been accessed online. Keywords

such as ‘Folk paintings of India’, ‘In-

tervention in folk art for application on

textiles’, ‘Apparel for craft revival’ etc.

have been used. The total works stud-

ied were categorized with reference to

their publication year and five works

from each year starting from 2016 to

2020 were selected for review.

Discussion

This section has been discussed in 5

parts on the basis of the year of publi-

cation of the respective studies.

Table-1: YEAR- 2016

P E E R R E V I E W P A P E R](https://image.slidesharecdn.com/tvcmay2021webversion-220112074951/85/MAY-2021-32-320.jpg)

![37

M AY 2 0 2 1

R E V I E W P A P E R

cies used for the medicinal purpose [7]

(Mitchell P, Tien, Chaitali, F, & John,

2017). In this case, mushrooms are

primal matter in the processing of sus-

tainable leather as they own the com-

petency to grow mycelium underneath

them.

3. Under grown network of hyphae

Mycelium is the largest living struc-

ture on the globe occupies nearly 10

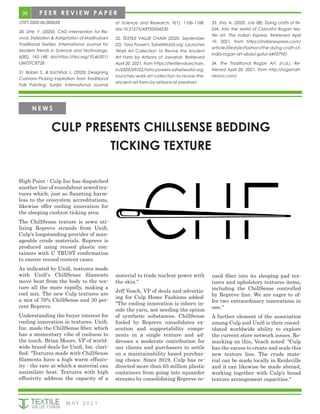

Figure 1: Network of white threads (Myce-

lium)

(Source: Pixabay - https://pixabay.com/

photos/mushroom-mycelium-small-mush-

room-3835397/)

Abstract

A versatile material that has created

outstanding attention among buyers

of apparel, footwear, and furniture

because of its flexibilit and durability

properties. Excluding the features of

leather, the steps are involved in its

manufacturing having a huge impact

on the surroundings. In contrast to the

newest leather made from mushroom

technology, the usual leather accounts

for higher ecological footprints. The

emergency of innovative fabrics formed

from the mycelium of mushrooms is

expected to have huge demand in the

market in the upcoming generation.

This context emphasizes the process-

ing methods involved in designing

mushroom leather, its advantages over

animal leather, and its influence on the

environment.

Key Words: animal leather, envi-

ronment friendly, leather, mush-

room leather, sustainable, etc.

Introduction

Leather is a well-known material in the

field of clothing, furniture, accessories,

and footwear. On account of its long-

lasting, versatility, and good comfort

it has a huge estimation in the mar-

ket with a business value of US$ 100

billion per year. Traditionally the raw

materials that take part in the process-

ing are animal skins which make the

leather industry depend on by-prod-

ucts of the dairy and meat industries.

Subsequently, the leathers are tanned

and processed under several conditions

which release toxic chemicals that ac-

count for carbon emissions and playing

a significant role in the greenhouse ef-

fect. The latest competitor has emerged

in the market showcasing modern

technologies by replacing the leather

derived from animals with sustainable

and environment-friendly leather. The

innovative product that completely re-

moves usage of chemicals, reduction in

carbon emissions, on the other hand

having the supremacy such as recycla-

ble, flexible and can able to mimic the

standard leather is simply awesome. In

this article, the discussion is made on

the process included in the production

of alternate leather with its impact on

surroundings and benefits over animal

leather.

2. Implementation of an exceptional

ingredient

Labels such as sustainable, environ-

ment-friendly, renewable, and organic

are well suited for the innovative class

of textile “Mushroom Leather”. Apart

from the application of fungi in medi-

cal science, edibles, and biofertilizers

the compound multicellular organisms

are utilized in making an eco-friendly

product. Varieties of mushrooms exist

in the environment having divergent

properties in which some accounts for

nourishment and another set of spe-

AN ENVIRONMENT FRIENDLY

MUSHROOM LEATHER

DKTE’S Textile & Engineering Institute, Ichalkaranji

V. LOGA SUBRAMANI A. A. RAYBAGI

B. Tech T.T. Assistant Professor in Textiles](https://image.slidesharecdn.com/tvcmay2021webversion-220112074951/85/MAY-2021-37-320.jpg)

![38

M AY 2 0 2 1

Figure 2: Tightly interlaced pack of mycelium

(Source: Network of Deutsche Welle)

Kilometer square in Oregon’s Blue

Mountains. Mycelium, the vegetative

constituent of fungus incorporated with

a matrix of filaments. In another way,

the term mycelium is defined as a root-

like structure covering mushrooms.

The process of developing the network

of such delicate white strands requires

minimum dissipation of energy and

resulted in the trash can be recycled

[2] (J, T, Rames, & Kavitha, 2015).

4. Construction of an eco-friendly

substitute

4.1 Preparation of substrate

During the processing of mushroom

leather, the surface on which the

mushroom grows should be dampened.

Mushrooms are included with organic

wastes such as sawdust, straw, and

corn. The company named MycoWorks

mixes agar along with mushrooms

whereas Mycotech uses sawdust.

Wet substrate makes it easier for the

mushroom to append with the organic

inclusions and develop. The growing

conditions can be tuned to produce

composites of varied sizes, shapes, and

performance of the outcome [3] (Ma-

daria, 2018).

4.2 Development of mycelium

The process of developing mycelium

also eliminates the involvement of

overpriced and cosmopolitan methods.

Following the cleaning process, the

wastes are mixed with a minute, repro-

ductive unit of mushroom and covered.

Mycelium grows at an exponential

rate ranges from four to nine days [4]

(Mitchell P, Antoni, Sabu, & Alexan-

der, 2020). Other factors also modify

the growth of mycelium is a variety of

mushroom, humidity, and temperature

[3] (Qua, 2019). The cells ultimately

having tightly interlaced mycelium

that grows into a bundle of thread-like

structures with interconnections that

are highly responsible for material

strength. Before drying and utiliza-

tion, the final material is compressed

to obtain the needed size and shape [4]

(Mitchell P, Antoni, Sabu, & Alexander,

2020).

5. Contrasting characteristics of

mushroom leather

5.1 During processing

In the premature stage of the process,

modification of substrates and altera-

tion of growing conditions is possible

[1] (Haneef, Luca, Cloudia, Jose, &

Athanassia, 2017). The material can

be grown in vertically stacked layers

results in better use of space. Polyvi-

nyl chloride or PVC leather [3] (Qua,

2019) is produced by chemical altera-

tion of vinyl polymer whereas myceli-

um-based leather eliminates the usage

of chemicals during processing. The

process implements minimum usage

of water less than one-tenth of water

used in typical leather production. My-

celium fabrics can form the resultant

fabric with different textures, sizes,

finishes, and complex shapes to acquire

desired characteristics.

5.2 Advantages of mushroom leather

over typical leather

The time required in the latest manu-

facturing technology is very less com-

pared to the typical process. Growing

cattle for skin (raw material) may

take three years to produce fragments

of leather while the growth of mush-

rooms is rapid. Hence raising livestock

is not involved in fungi-derived leather

[3] (Qua, 2019). Fewer carbon emis-

sions and processing with a minimum

amount of chemicals are the added

advantage. It helps in controlling

properties such as texture, strength,

elongation, orientation, and un-

matched finishes [6] (Madaria, 2018).

Figure 3: Ebony finish of Black Emboss

Figure 4: Brown Natural leather

(Source: Myco Works Inc. - https://www.

madewithreishi.com/products)

Mycelium has the potential to construct

large-scale structured (macro struc-

tured) fabrics which are robust and

pleasant to breathe. The contribution

of animal agriculture in greenhouse

gas emissions is more considering my-

celium has a soft connection to the en-

vironment from the initial to the final

stage. The watch straps of mushroom

leather can prevent skin annoyance

due to eczema. Light mycelium-based

leather also has more absorbency com-

pared to its competitor [4] (Mitchell

P, Antoni, Sabu, & Alexander, 2020).

Table 1: Properties of mushroom-based

leather compared to cowhide leather

Environmental impact of mushroom

technology

The whole process of fabricating the

mushroom leather happens in a closed-

R E V I E W P A P E R](https://image.slidesharecdn.com/tvcmay2021webversion-220112074951/85/MAY-2021-38-320.jpg)

![39

M AY 2 0 2 1

loop manner. The term closed-loop

means that the raw materials employed

in the process acquired from post-con-

sumer waste and made into recycling

and adapted to use into a variety of

products [3] (Madaria, 2018). Growth

substrates incorporated such as saw-

dust, corn, and straw are usually by-

products of agriculture that facilitate

creative re-use. The effective growth

of mycelium is achieved by an organ-

ic process that makes up the leath-

er-like composite with a low impact

on the environment [6] (Qua, 2019).

Figure 5: Percentage more people ready to pay for sustainable fashion

(Source: Survey on global perspective by KPMG)

Conclusion

The process of making leather from

mushrooms that too inclusive of re-

newable ingredients and customization

technology is unprecedented. With the

constantly evolving technologies, the

leather alternative is expected to have

an extraordinary market in the future.

In addition to enormous benefits, my-

celium-based materials have the least

impact on the environment than mak-

ing them superior to typical leather.

The mushroom leather has been pro-

duced on a small scale now; when it

starts to be manufactured in extensive

volumes then customers will highly get

attracted to such sustainable fashion.

Also, we can state that money is the

big concern in switching to sustain-

able fashion, if there is cost reduc-

tion, hope the leather can draw much

attention from buyers [13]. Every

individual should aware of the term

“Eco-conscious”. Once they started to

show concern for the environment then

green could be an incredible trend in

the world.

References

1) Haneef, M., Luca, C., Cloudia, C.,

Jose, H.-G., & Athanassia, A. (2017, 01 24).

Advanced Materials From Fungal Myce-

lium: Fabrication and Tuning of Physical

Properties. Scientific Reports, 7. doi:10.1038/

srep41292

2) J, K., T, S., Rames, P., & Kavitha, S.

(2015, 02 15). Eco-friendly waste manage-

ment strategies for greener environment

towards sustainable development in leather

industry: A comprehensive review. Jour-

nal of cleaner production. doi:10.1016/j.

jclepro.2014.11.013

3) Madaria, D. (2018). I search paper:

Mushroom Leather.

4) Mitchell P, J., Antoni, G., Sabu, J., &

Alexander, B. (2020, 09 07). Leather-like ma-

terial fabrication using fungi. Natural sustain-

ability. doi:10.1038/s41893-020-00606-1

5) Mitchell P, J., Tien, H., Chaitali, D., F, D.,

& John , S. (2017). Mycelium Composites: A

Review of Engineering Characteristics and

Growth Kinetics. Journal of Bionanoscience.

6) Qua, F. (2019). A qualitative study on

sustainable materials for design through a

comparative review of leather and its mod-

ern alternatives.

7) Stamets, P. (2005). Mycelium Running:

How mushrooms can save the world. New

York: Ten-speed press.

8) “Bolt Threads – Mylo.” Bolt Threads, Bolt

Threads Inc., http://www.boltthreads.com

9) Reishi™: https://www.madewithreishi.

com/products

10) Myco Works

https://www.mycoworks.com/our-

products#an-advanced-materials-platform

11) Mushroom Leather is more than a

sustainable alternative to animal skin by

Katherine Saxon https://wtvox.com/fashion/

mushroom-leather

12) Eco vative design: https://ecovativede-

sign.com/

Sustainable fashion, a survey on global per-

spectives by KPMG, FASHION SUMMIT.

R E V I E W P A P E R

Leather has been around for quite a long time and is produced

using the skins of expired creatures without the requirement

for the utilization of costly engineered materials. It has con-

sistently been eco-accommodating and that is something that

won't ever change particularly with the appearance of biode-

gradable leather in the 21st century.

F A C T S

Figure 5: Illustration of eco-friendly nature

of mushroom leather](https://image.slidesharecdn.com/tvcmay2021webversion-220112074951/85/MAY-2021-39-320.jpg)

![40 R E V I E W P A P E R

M AY 2 0 2 1

RECYCLING LEATHER

ASHWINI TARTE DR. SUMAN D MUNDKUR

Abstract

The leather industry is one of the

leading industries in textiles. It pro-

duces large amounts of waste during

the manufacturing process and after

the use of leather fabric by consum-

ers. This industry is one of the larg-

est waste-producing industries. Al-

most 20% of worldwide waste from

leather is generated in Asia. This can

be very harmful to aquatic life. It oc-

cupies a large landfill space. The waste

should be recycled to minimize the

environmental impact. It produces

solid waste and liquid waste during

processing. There are a lot of studies

done on leather recycling and reus-

ing leather products. Some methods to

recover energy from the heat and en-

ergy which is generated during leather

processing. The restyling technique

also helps reuse and reduce waste.

Keywords: leather manufacturing,

leather waste, leather recycling.

Introduction

Leather has been treated with chemi-

cals to preserve and make it suitable

for use as clothing, footwear, handbags,

furniture, tools, and sports equipment.

The consumption of leather products

by humans is very commonly used. The

primary raw material for any leather

processing industry is derived from

slaughterhouses and waste from the

meat industry. This raw material is

processed and converted into usable

leather in tanneries. Hence, the tan-

ning industry is considered as one of

the primary leather processing units in

the entire leather industry. The chemi-

cal treatment called tanning converts

the otherwise perishable skin to a sta-

ble and non-decaying material. Tan-

ning agents include vegetable tannins

(from sources such as tree bark), min-

eral salts (such as chromium sulfate),

Fig 1. Processing of leather [3]

and fish or animal oils. In this tanning

process, maximum leather waste is

generated; this waste is further used

for generating heat and energy [1].

Process of modern leather Manufacting

Leather production is a very lengthy

process that involves several steps be-

fore tanning. The most important stag-

es in converting the raw animal hide

to leather are listed below [2][3]. The

modern commercial leather-making

process involves three basic phases:

M.Tech Student

Department of Fibres and Textile Processing Technology, ICT Mumbai

Visiting Faculty](https://image.slidesharecdn.com/tvcmay2021webversion-220112074951/85/MAY-2021-40-320.jpg)

![41

M AY 2 0 2 1

Fig. No. 3 Steps to improve waste manage-

ment [8]

R E V I E W P A P E R

Name of Chemical Use Target organs

Chromium sulphate

Principal raw material used in the production

of chrome tanning materials for the leather

industry like Chrome-tanning salts

Blood, kidneys, heart,

lungs, eyes and carcinogen

Chromium used for dyeing Kidney, CNS,

Short chain chlorinated

paraffin's (PBT)

Additive for the leather treatment (renders

smoothness to leather), leather clothing and

belts and as a leather oiling agent.

Liver, kidney, thyroid and

carcinogen

Cobalt dichloride

Used in leather dyeing and

finishing as well found in tanned leather

Lungs, liver, kidney, heart,

skin

Methyl isothiazolinone Biocide, microbiological protection Skin, eyes and carcinogen

Formaldehyde HCHO

Heavy metals Arsenic

Leather finishing Eyes, lungs and carcinogen

1. Preparation for tanning,

2. Tanning

3. Processing tanned leather [4].

No.1 lists down the different steps in

the processing of leather.

Eco-friendly alternatives for the haz-

ardous chemicals used in leather

processing

The consumer consciousness and strict

regulations by worldwide authorities

require leather products with the low-

est possible risk for the environment.

Instead of using chromium sulfate,

we can use vegetable tannin like que-

bracho, chestnut, behra nuts in the

tanning process, which gives a more

stable leather and it is an eco-friend-

ly method [6]. Nitrocellulose lacquer

emulsions can be successfully replaced

with castor oil, which maintains the

typical lacquer emulsion properties

like glossy touch, softness, and elastic-

ity. Enzymes, amino acids, or oxazoli-

dine can be used as an alternative in

tanning processes. As an alternative

for the solvent N-Methyl pyrrolidone

high wear topcoat acrylics being free of

solvents has been used. Formaldehyde

in leather finishing is not only used as

a crosslinker for cases in topcoats but

also as a biocide. Finishing chemicals

may contain formaldehyde even when

no formaldehyde was used for the pro-

duction, as many raw materials are

preserved in a formaldehyde base. To

overcome this problem use of formalde-

hyde scavengers can be adopted as in

the case of some Wet End Chemicals

Inorganic heavy metal pigments like

lead chromate, cadmium sulfide and

others can be replaced by organic pig-

ments or pigments. We can use silver

nanoparticles in the tanning process

which improves the mechanical and

physical properties. It can also be used

as an antimicrobial and UV resistant

application [5][7].

Waste management in the leather in-

dustry

Fig. No.2 below gives the volume of

waste generated from the leather In-

dustry. The largest amount of waste

comes from the Asian Continent. The

waste generated from the leather In-

dustry from China alone contributes

to 13% while, one-fourth of the global

waste comes from the other Asian

countries together.

Table No. 1 Harmful chemicals use in leather industry [4] up in a municipal landfill.

2. Pre-consumer waste: is waste gen-

erated during the manufacturing pro-

cess. Waste originates from all stages

of leather making process, such as fine

leather particles, residues from vari-

ous chemical discharges, and reagents

from different waste liquors (Effluent),

comprising of large pieces of leather

cuttings, trimmings, and gross shav-

ings, fleshing residues, solid hair de-

bris and remnants of paper bags. Out

of 1000 kg of rawhide, nearly 850 kg

is generated as solid wastes in leath-

er processing. Only 150 Kg of the raw

material is converted to leather [9].

Over 80 % of the organic pollution

load in BOD terms comes from the

pre-tanning process this mainly comes

from degraded skin and hair matter.

During the tanning process at least

300 kg of chemicals are added per

ton of hides. Excess of non-used salts

will appear in the wastewater [8].

A large amount of waste generated

by tanneries is discharged in natu-

ral water bodies directly or indirectly

through two open drains without any

treatment. The water in developing

countries, like India and Bangladesh,

is polluted to such a degree, that it has

become unsuitable for public use. In

summer, when the rate of decomposi-

tion of the waste is higher, serious air

pollution is caused in residential areas

by producing intolerable obnoxious

odors [10].

Tannery wastewater and solid wastes

often find their way into surface water,

where toxins are carried downstream

water. Chromium waste can also leak

into the soil and contaminate ground-

water systems [9].

Steps to improve the waste manage-

ment in the leather industry

Two types of waste generated in the

leather industry

1. Post-consumer waste: It is also

called household waste and dirty

waste. Any worn out, damaged, and out

of fashion apparel and textile products,

which are discarded and no longer in

use by the wearer. They are sometimes

given to charities but more typically

are disposed of into the trash and end](https://image.slidesharecdn.com/tvcmay2021webversion-220112074951/85/MAY-2021-41-320.jpg)

![42

M AY 2 0 2 1

Fig. No. 4 UASB Reactor [11]

1. Reduce: We should buy only what

we need because a better way to reduce

waste is by not creating it. Reducing

the amount of buying is the most sig-

nificant of all the options to manage

waste. The key is to only purchase

goods that we need and in the right

amount. If we generate an excess of

products in the first place, we do not

have to extract raw resources, manu-

facture goods from scratch, come up

with shipping materials, utilize addi-

tional resources for shipping, and then

devise ways to dispose of them [12].

2. Reuse: If we have to acquire goods,

try getting used ones or obtaining sub-

stitutes. Waste, after all, is in the eye

of the beholder. One person’s trash is

another person’s trea

sure. If we look at

things we are throwing away, we can

learn to see them as materials that can

be reused to solve everyday problems

and satisfy everyday needs. Most of us,

however, have not even begun to ex-

ploit the resourc

es in our trash. Once

you have made up your mind to use

trash for positive uses, you can begin to

brainstorm and generate ideas. Reus-

ing saves money, conserves re

sources,

and satisfies the human urge to be cre-

ative [12].

3. Recycle: When we discard waste,

find ways to recycle it instead of letting

it go to landfills [12][13].

Old leather recycling

1. Take gently worn leather goods to be

fixed professionally. General shoe and

bag repair shops often have the equip-

ment to make repairs including patch-

ing, stitching, and stretching, and can

restore your leather goods to extend

their life. Do not buy new, fix your fa-

vorites instead as a sustainable option.

2. Take leather scraps to a recycling

outlet for resale. It is a good option

of taking leather scraps to be resold

to others for many purposes includ-

ing craft projects. Some industrial

level companies also recycle leather

to be used again in their products.

3. Donate worn leather shoes to a lo-

cal charity. Many non-profit organiza-

tions will collect used footwear and

pass it on to those in need in the com-

munity. Before giving away, we should

carefully inspect and clean our shoes

to appraise their quality for reuse.

4. Donate clothes and bags. Use the in-

ternet to find a collector in your neigh-

borhood and give back to your commu-

nity [14].

Upcycling Leather Items Creatively

1. We can use old belts to make a ‘shelf’.

Once we have finished wearing a belt,

we can still use it in a variety of handy

ways around the home, including cre-

ating a unique hanging shelf. It’s easy,

cheap, and saves space in your room.

2. We can create funky new handles

for a handbag from leather waste.

3. We can make a set of new nap-

kin rings for your dining room table.

4. Also of kind rug for the living room

can be made from leather waste. If we

have enough scraps, we can make a

large rug for the living room [14].

4. Energy Recovery

UASB technology

The heat and energy generation can

be achieved by treating the wastewa-

ter effluent using Upflow Anaerobic

Sludge Blanket Technology (UASB)

with Sulfur Recovery Plant. The UASB

technology has been well-known for

treating wastewater primarily because

of its low sludge production. The ma-

jor advantage of this technology is

that it provides a potential possibility

to generate energy, rather than con-

suming the same while treating the

wastewater using this technology for

treating tannery wastewater. Because

of the high sulfate content, it results

in the generation of methane gas, con-

taminated with hydrogen sulfide. An

improved system has, therefore, been

developed whereby the sulfate is com-

pletely removed as elemental sulfur.

This also reduces the COD by 60% and

TDS by 90%

UASB uses an anaerobic process

while forming a blanket of granular

sludge which is suspended in the tank.

Wastewater flows upward through

the blanket and is processed by the

anaerobic microorganism, eventually

aggregates form into dense compact

biofilms referred to as granules and

Biogas with a high concentration of

methane is produced as a by-product,

and this may be used as an energy

source, to generate electricity [11].

Biomethanation for Solid Waste Dis-

posal of leather

Solid wastes generated by the leather

processing industry are posing a major

challenge. Tannery, fleshings, which

are the major solid wastes emanat-

ing from the beam house of a tannery,

are subjected to biomethanation. It is

a process whereby the fleshing is liq-

uified completely biologically. The re-

sulting liquefied fleshing is treated in

anaerobic reactors to produce biogas.

Any anaerobic reactor like the UASB

reactor can be used for this purpose.

Biomethanation is a process by which

organic material is microbiologically

converted under anaerobic conditions

to biogas. Three main physiological

groups of microorganisms are involved

in fermenting bacteria, organic acid

oxidizing bacteria, and methanogenic

archaea. Microorganisms degrade or-

ganic matter to methane and carbon

dioxide. Biomethanation has strong

potential for the production of energy

from organic residues and wastes. It

will help to reduce the use of fossil fuels

and thus reduce CO2 emissions [11].

Fig. No. 5 Process Flow of Bio methanation

process [11]

5. Special treatment Regenerated

leather (RGL)

Preparation of leather-like material,

regenerated leather from finished

leather wastes is economical and helps

in reducing the environmental pollu-

R E V I E W P A P E R](https://image.slidesharecdn.com/tvcmay2021webversion-220112074951/85/MAY-2021-42-320.jpg)

![43

M AY 2 0 2 1

tion. Incorporating plant fibers into

RGL enhances its mechanical proper-

ties. Plant fibers are exploited as rein-

forcement materials owing to their low

cost, fairly good mechanical proper-

ties, high specific strength, non-abra-

sive, eco-friendly, and bio-degradabil-

ity characteristics. Fiberized leather

wastes and PFs were mixed in various

proportions to prepare regenerated

leather composites. Plant fibers like

coconut, sugarcane, banana, and corn

silk were used for a study, regenerat-

ed leather composites prepared using

leather waste and coconut fiber (50:40

ratio) proved to be a better composite

with potent properties. Regenerated

leather composites are promising for

the preparation of leather goods and

footwear materials in addition to their

cost-effectiveness and environmental

pollution abatement [16].

some brands are making use of offcuts

or combining leather offcuts with other

materials to create a combination ma-

terial, this is not currently widespread

and often this material is used for

certain products only. There is an ex-

tra cost to recycling goods. If the mar-

ket is not willing to pay the increased

cost for a recycled product, it is un-

likely that companies will invest [18].

Conclusion

As the amount of use of leather in-

creases, the waste generated from the

leather is inevitable. Research Insti-

tutes and Industries are keen to search

for various textile waste recycling op-

portunities at the industrial level for

both economic and environmental

reasons. The waste generated during

the tanning process of leather manu-

facturing contains harmful chemicals

which pollute the groundwater and

is a hazard to living organisms. To

overcome this problem, there are al-

ternative chemicals that can be used

in the tanning process. These alter-

natives give better results, are safe

for living beings, and sustainable.

Some Research Institutes have devel-

oped new technologies related to heat

and energy generation from toxic solid

and liquid waste that is generated in

the leather industry. With the help

modern technology, leather goods can

be recycled more efficiently with mini-

mum waste products.

References

1. Dr. Shilpa Goel ‘An in-depth study of India’s leather in-

dustry with special reference to export prospects of leather

products’ International Journal of Advanced Research in

Management and Social Sciences, January 2014.

2. Karanam Sai Bhavya Raji P, Jenifer Selvarani A ‘Leather

Processing, Its Effects on Environment and Alternatives of

Chrome Tanning’ International Journal of Advanced Re-

search in Engineering and Technology (IJARET) Volume 10,

Issue 6, November-December 2019, pp. 69-79.

3. Moses A Ollengo and Esther W Nthiga Peter Maina,

(2019), ‘Trends in leather processing’: A Review, Internation-

al Journal of Scientific and Research Publications, 9 (12).

4. Sumita Dixit, Ashish Yadav, Premendra D. Dwivedi, Mukul

Das ‘Journal Toxic hazards of leather industry and technolo-

gies to combat threat: a review’ Journal of Cleaner Pro-

duction (2015) 39-49.

5. M. Seggiani, M. Puccini, S. Vitolo, C. Chiappe, C. S.

Pomelli & D Castiello ‘Eco-friendly titanium tanning for the

manufacture of bovine upper leathers: Pilot scale studies’

Clean Technologies and Environmental Policy volume 16,

pages1795–1803 (2014).

6. ‘Leather processing, its effects on environment and alter-

natives of chrome tanning’ laeme publication international

journal of advanced research in engineering and technol-

ogy (ijaret) volume 10, issue 6, november-december 2019,

pp. 69-79, article

7. F.R. Souza, and M. Gutterres, ‘Application of enzyme in

leather processing,A comparison between chemical and

coenzyme processes’. Brazilian Journal of Chemical Engi-

neering, 29(3), 2012, 473-481.

8. J. Hidalgo Ruiz, ‘Wastes generated in the leather prod-

ucts industry’ fourteenth session of the leather and leather

products industry Panel Zlin, Czech Republic 13-15 Decem-

ber 2000.

9. Agarwal, R., Sharan, M. (2015). ‘Municipal textile waste

and its management’, Research journal of Family, Commu-

nity and Consumer Sciences. Vol. 3 (1).

10. Ozgunay H, Colak S, Mutlu MM, Akyuz F, ‘Characteriza-

tion of leather industry waste’. Pol J Environ Stud 6:867–873,

(2015).

11. N.M. Sivaram and Debabrata Barik, ‘Toxic Waste From

Leather Industries’ Department of Mechanical Engineering,

National Institute of Technology Pondicherry, Karaikal, U.T. n

book: Energy from Toxic Organic Waste for Heat and Power

Generation (pp.55-67).

12. Fahzy Abdul-Rahman, ‘Reduce, Reuse, Recycle: Alter-

natives for Waste Management’ Guide G-314, N.M State

Uuniversity, Florida Cooperative Extension Service publica-

tion HE 3157. January 2014.

13. Rick leblanc ‘The Basics of Textile Recycling’ Growth

of Textile Recycling Promises to Divert More Material from

Landfills’. Updated December 30, 2020 https://www.the-

balancesmb.com/the-basics-of-recycling-clothing-and-

other-textiles-2877780.

14. ‘How to Recycle Leather’ Co-authored by wikiHow Staff

Last Updated: March 29, 2019 https://www.wikihow.com/

Recycle-Leather#References

15. Bairagi, N. ‘Recycling of textiles in India’. Department of

Knit wear Design, National Institute of Fashion Technology,

Bengaluru, India, Textile Science and Engineering, (2014).

16. Rethinam, Senthil, Tiruchirapalli, Sivagnanam, Uma,

Bhabendra Nath Das & Thotapalli Parvathaleswara Sastry

’Recycling of finished leather wastes: a novel approach’

17. Islam, M.M., Khan, M.M.R. (2014). ‘Environmental sustain-

ability evaluation of apparel product: A Case study of knit-

ted T-shirts. Journal of Textiles, Hindawi Publishing Corpora-

tion, Article id 643080, 6 pages

18. Clean Technologies and Environmental Policy, (2015),

Volume 17, pages187–197.

Fig. No. 6 Regenerated leather

processing [16]

Benefits of recycling

Reduce, Reuse, and Recycling decreas-

es the landfill space requirements.

This will result in pollution avoidance,

reduced consumption of energy, chemi-

cals, and water. There will be a reduced

demand for dyes. Overall, reducing the

need for processing virgin materials

[15][17].

Challenges with Recycling

Although the recycling of materials

creates a circular economy and there-

fore increases sustainability, there

are potential challenges to recycling

leather. Theoretically, offcuts of leather

created within the leather manufac-

turing process are more easily recycled

than final products at the end of their

life. However, with a potential lack of

market for offcuts, this product is often

disposed of in the tannery. Although

R E V I E W P A P E R](https://image.slidesharecdn.com/tvcmay2021webversion-220112074951/85/MAY-2021-43-320.jpg)

![45

M AY 2 0 2 1

increasing production of Monpa hand-

made paper, it can be exported to other

countries. This is a local product with

great global potential, which is aligned

with the Mantra of "Local to Global"

given by the Prime Minister.

The Government has tried to im-

plement schemes for the people of

Arunachal Pradesh like intra-state

transmission and distribution infra-

structure in the state by providing the

states grid connectivity to remote ar-

eas.

Producing paper from Non-Timber

Forest Products (NTFPs) and non-

wood fibres help in reducing the need to

procure pulpwood from natural forests

and to minimize deforestation. These

products are vital sources of income,

nutrition and sustenance for many

forest-based communities around the

world.

With increasing population, paper

consumption has also been increas-

ing which demand large number of

raw materials from different sources,

such as wood, non-wood fibre and non-

timber forest products to increase the

production.

Conclusion

With the strong resolve of the higher

management of KVIC, the unit was

successfully established despite many

challenges. The 1000-year-old herit-

age art the monpa handmade paper

of Arunachal Pradesh which was driv-

en to extinction has come to life once

again with the committed efforts of

KVIC.The revival of this paper indus-

try brings an encouragement to the art

and heritage to the people of Tawang.

This initiative not only brings the re-

vival but the employment to the people

of Arunachal Pradesh making it a part

of their livelihood by the prime minis-

ter mantra “local to global”. The mak-

ing process of monpa handmade paper

is eco-friendly and the product is biode-

gradable which made from non-timber

forest product. It also encourages the

value of monpa (scheduled tribe) to the

world recognition. Not only this revives

the Indian heritage but also play a vi-

tal role to boost the Indian economy.

References

[1] PIB Delhi (2021, February 04). Press Infor-

mation Bureau, Government of India, Minis-

try of Micro, Small & Medium Enterprises; Ar-

ticle. People Patronize Monpa Handmade

Paper of Tawang after PM’s push in Mann Ki

Baat.Retrieved from https://pib.gov.in/Press-

releaseshare.aspx?PRID=1695156

Figure [1] [3]- PIB (2020) Monpa Hand-

made Paper [Photograph] Arunachal re-

vives 1,000-year-old handmade paper

industry https://acumenias.in/uploads/

affair/Monpa%20Handmade%20Pa-

per20201230070138.jpg

Figure [2] PIB (2020 December 28). monpa

handmade paper[photograph]. https://va-

jiramandravi.s3.us-east-1.amazonaws.com/

media/2020/12/28/10/12/4/jjjjj.jpg

Figure [4][5] Holiday Scout (2017, 04 June)

Tawang Focus – The Art of Making Paper.

[Photograph] https://theholidayscout.com/

indigenous-knowledge/arts-and-crafts/ta-

wang-focus-the-art-of-making-paper/

Figure [6] Sentinel Digital Desk (2020 28

Dec). KVIC revives Monpa handmade pa-

per industry, historic event for the locals of

Tawang. [photograph]. https://www.sen-

tinelassam.com/north-east-india-news/

arunachal-news/kvic-revives-monpa-hand-

made-paper-industry-historic-event-for-the-

locals-of-tawang-518374

R E V I E W P A P E R

Lenzing and Södra are expecting to

transform a yearly 25,000 tons of ma-

terial waste into the new item by 2025.

Lenzing is collaborating with mash

maker Södra, settled in Växjö, Swe-

den, on the further improvement of

OnceMore Pulp created from material

waste.

The arrangement includes the ex-

change of information between the two

organizations which have been proac-

tively driving the roundabout economy

numerous years and following joint

turn of events and a limit extension,

OnceMore Pulp will be utilized as a

crude material for the creation of Len-

zing's Tencel x Refibra marked forte

strands. The two organizations are in-

tending to turn a yearly 25,000 tons of

LENZING CLAIM TO FAME FILAMENTS TO BE

PRODUCED USING MATERIAL WASTE

material waste each year into the new

item by 2025.

The OnceMore cycle joins wood cel-

lulose with up to half material waste

substance to make an unadulterated,

excellent dissolving mash which can be

utilized to create new attire and other

material items.

"The participation with Södra is a sig-

nificant achievement towards accom-

plishing our yearning environment

and manageability objectives. We are

pleased to have the option to go this

route with a capable accomplice.

"One organization alone can't address

the major problem of material waste,"

said Christian Skilich, individual from

the overseeing leading group of Lenz-

ing. "It is proactive organizations like

this one that will empower us to push

ahead and achieve genuine fundamen-

tal change."

"With OnceMore mash, Södra has

made an internationally one of a kind

answer for putting together materi-

als with respect to a reused source,"

added Lotta Lyrå, President and CEO

of Södra. By uniting with Lenzing, we

will carry a-list reusing to the material

worth chain. Through another specula-

tion, we will likewise build our crea-

tion limit with regards to OnceMore

mash ten times during 2022 and have

a more significant level of reused ma-

terial substance. These are significant

strides towards our drawn out focus of

making a round material industry."

N E W S](https://image.slidesharecdn.com/tvcmay2021webversion-220112074951/85/MAY-2021-45-320.jpg)

![46

M AY 2 0 2 1

R E V I E W P A P E R

COIR PRODUCTS EXPORT OPPORTUNITIES

DR.J.ANANDHA KUMAR

Lecturer, Department of Textile Processing, GRG Polytechnic College

Abstract

Coir is a versatile lingo-cellulosic fiber

obtained from coconut trees (Cocos nu-

cifera). Coir is available in large quan-

tities, in the order of 5 million tons a

year globally. The export of coir and coir

products from India was Rs. 2757.90

crore for the year 2019-20. Register-

ing an all-time high record, which was

around Rs. 30 crores higher than that

of the last year i.e., 2018-19 at Rs.

2728.04 crore. While the exports of coir

pith, tufted mats, coir Geo-textiles,

coir rugs and carpets, coir ropes and

power-loom mats grew both in terms of

quantity and value. The products like

hand-loom mats, coir yarn, rubberized

coir and power-loom matting showed a

decline in terms of the quantity and in-

crease in terms of value. Coir pith with

export earnings of Rs. 1349.63 crore

constituted 49% of the total export of

coir products from the country. The

value-added items put together con-

stituted 33% of the total exports. The

best way to bring the existing coir in-

dustry to a higher level is the develop-

ment of new value-added coir products.

This review article throws light on the

opportunities in coir spinning and the

various value-added coir products for

Export.

Introduction

Coir is the fibre obtained from the fruit

of coconut tree (Cocos nucifera). It be-

longs to the palm tree family (Arecace-

ae) grown in tropical and sub-tropical

countries [1]. Coconut fruit consists

of exocarp (the outer husk), mesocarp

(the fibrous husk), endocarp (the hard

shell) and the endosperm (the meat)

[2]. Coir fibre is extracted from the co-

conut fruit after the removal of husk af-

ter the removal of the endocarp and the

endosperm. The husk consists of 75%

of fibre material and 25% fine material

called pith [3]. Though coconut tree

grows in several countries, majority of

fibre extraction takes place in countries

like India, Sri Lanka and Philippines.

Less than 50% of coconut husk are uti-

lised for fibre extraction and remaining

husks are used as domestic fuel and

left over as waste which decomposes in

due course of time. Coir fibre consists

of 43.44% of cellulose, 45.84% of lignin,

0.25% of hemi cellulose, 3.00% of pec-

tin, 2.20% of ash and 5.25% of water-

soluble compounds [4]. Due to the high

quantity of lignin, coir fibre is brown,

stiff and has high flexural rigidity [5].

Two types of of course fibres are avail-

able in the coir industry like white fi-

bre and brown fibre [6]. Fibre obtained

from the immature green husk after a

long retting process of 10 to 12 month

is known as white fibres. Brown fibres

are extracted from matured husk with

a getting process of 10 days.

Spinning of coir fibres has been carried

out in India, Sri Lanka and Thailand.

Coir fibre yarn is produced by the tra-

ditional hand spinning process and the

mechanised spinning process. Hand

spinning is being carried out by women

workers in the rural regions of Kerala

and provides livelihood to a sizable

women population. Mechanised spin-

ning process has got its importance

as the demand for coir yarns is not

fulfilled by the low production of hand

spinning process [7]. Most of the white

fibres are processed in hand spinning

and the brown fibres are processed in

the mechanised spinning system.

Coir Fibre Industry in India

Coir Industry in India, manufac-

tures yarns, mats, mattings and other

products using age-old processes due

to which the quality of the products

leaves much to be desired. The fibre

properties and chemical composition

are given below in Table 1. and Table

2. respectively:

Table 1. Physical Properties of Coir Fibers

Table 2. Chemical Composition Coir

Fibers (% by mass on dry basis)

Spinning

Spinning is mostly done manually. The

output is low, and the nature of work is

tiresome. Mechanised ratts are avail-

able, but in most of the cases, the qual-

ity of yarns from these ratts does not

conform to the exporter’s quality re-

quirements. Majority of the coir yarns](https://image.slidesharecdn.com/tvcmay2021webversion-220112074951/85/MAY-2021-46-320.jpg)