Textile value Chain- Oct 2023

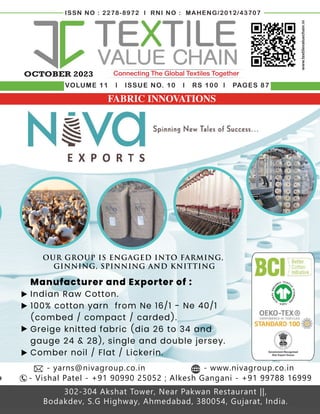

- 1. OUR GROUP IS ENGAGED INTO FARMING, GINNING, SPINNING AND KNITTING Manufacturer and Exporter of : Indian Raw Cotton. 100% cotton yarn from Ne 16/1 - Ne 40/1 (combed / compact / carded). Greige knitted fabric (dia 26 to 34 and gauge 24 & 28), single and double jersey. Comber noil / Flat / Lickerin. - Vishal Patel - +91 90990 25052 ; Alkesh Gangani - +91 99788 16999 302-304 Akshat Tower, Near Pakwan Restaurant ||, Bodakdev, S.G Highway, Ahmedabad, 380054, Gujarat, India. - yarns@nivagroup.co.in - www.nivagroup.co.in ISSN NO : 2278-8972 l RNI NO : MAHENG/2012/43707 www.textilevaluechain.in OCTOBER 2023 VOLUME 11 l ISSUE NO. 10 l RS 100 l PAGES 87 FABRIC INNOVATIONS

- 4. Grasim Industries Limited (VFY - Fashion Yarn Business) www.raysil.co.in | raysil@adityabirla.com For trade inquiries, please contact: (Mumbai): +91 22 22027570-77 (Surat): +91 261 4003361/62/66 LUXURIOUS ELEGANCE for Made with premium wood pulp, Raysil® , of 100% natural origin, gives fabrics a rich lustre, vivid colour, superior drape and a feather-light feel.

- 6. COVER STORY TECHNICAL ARTICLE SUSTAINABLE FIBER INTERVIEW TEXTILE EDUCATION INNOVATION EVENT UPDATE Market Report: Fabric Imports 13 Market Report: Fabric Export 16 Upcoming Events November 2023 10 Fabric and Finishes Innova on: Redefining Tex le Industry Standards 19 Fabric Trends in the Fes ve Season: A Feast for the Senses 23 Unraveling the Fabric Trade: Exploring Trends in Imports and Exports and Their Industry Implica ons 27 Con nuous Fabric Dyeing with Ultra Rapid Indigo Dyeing (PG) with Sustainable approach. 33 Empowering Style With Sustainability: Birla Cellulose Expands Por olio With Innova ve Bamboo Rayon Fabric 46 The Yarn Bazaar’s Role in Shivkrupa Cotspin’s Market Expansion 38Nano-Tex les: Applica ons and challenges 49 Rejuvena ng the Tex le Engineering Educa on in Indian and South-Asian Universi es 54 The EMPELR Tex le Finish 78 Hewa host First Interna onal Home Tex le Summit (IHTS) in Varanasi Sparks Global Collabora on and Innova on 66 A rac ng 14,895 trade visitors, Gartex Texprocess India spins a new success story 74 ITAMMA taking forward the slogan “Atmanirbhar Bharat” through Seminar on “Skilling, lean Tex le Technology” 82 NIVA FRONT COVER RAYSIL FRONT INSIDE RADHESHYAM SPINNING 3 RAMESWAR 5 SAMBANDAM 7 ITMA ASIA 8 SALONA GROUP 9 OMAX 11 GOKUL YARNS 12 BRUCKNER 14 MICROCHEM 15 RIMTEX 17 ART YARN 18 YAMUNA 21 SSPL 22 SITEX 2024 25 LMW 26 DOMOTEX 31 ALLIANCE FIBRES 32 ZYDEX 36 COLORJET 37 REAL PRINCE 41 TUREL 42 PAMEX 44 UNITECH TEXMACH 45 MEERA INDUSTRIES 47 MOROCCO FASHIONTEX 48 USTER 52 THE X AXIS 53 GSCS 57 AMBICA COTSEEDS 58 JOLLY 62 BADAMI FASHION 64 FIOTEX 65 SHIDDHANATH 69 NEEVA TRADELINK 73 ALLIANCE 76 SHREEJI 77 KING YARNS 79 UNIFORM SPORTSWEAR EXPO 80 ITMACH 81 SAURER 84 TRUTZCHLER 85 SIYARAM BACK INSIDE RAYMOND BACK COVER ADVERTISER INDEX MARKET REPORT EVENT CALENDER CONTENT OCTOBER 2023 4 www.textilevaluechain.in OUR GROUP IS ENGAGED INTO FARMING, GINNING, SPINNING AND KNITTING Manufacturer and Exporter of : Indian Raw Cotton. 100% cotton yarn from Ne 16/1 - Ne 40/1 (combed / compact / carded). Greige knitted fabric (dia 26 to 34 and gauge 24 28), single and double jersey. Comber noil / Flat / Lickerin. - Vishal Patel - +91 90990 25052 ; Alkesh Gangani - +91 99788 16999 302-304 Akshat Tower, Near Pakwan Restaurant ||, Bodakdev, S.G Highway, Ahmedabad, 380054, Gujarat, India. - yarns@nivagroup.co.in - www.nivagroup.co.in ISSN NO : 2278-8972 l RNI NO : MAHENG/2012/43707 www.textilevaluechain.in OCTOBER 2023 VOLUME 11 l ISSUE NO. 10 l RS 100 l PAGES 68 RQQHFWLQJ7KH*OREDO7H[WLOHV7RJHWKHU FABRIC INNOVATIONS RSB COTTEX GATEFOLD

- 7. Super Combed Compact Yarn (Ne 10s to Ne 80s) Combed Yarn (Ne 10s to Ne 50s) Carded Yarn (Ne 10s to Ne 40s) Open End Yarns (Ne 6s to Ne 20s) TFO Doubled Yarns All Yarns for Knitting and Weaving purpose RAMESWAR UDYOG PRIVATE LIMITED 404 BALLESWAR SQUARE, 4TH FLOOR, S. G. ROAD, OPP ISCON TEMPLE, AHMEDABAD 380015, INDIA +919998007171 +91 79-40215500 www.rameswar.com ruchi@rameswar.com

- 8. OCTOBER 2023 6 www.textilevaluechain.in Fabric Trends : Sustainable , Recycling , NonWovens ndian and Global tex le industry developing innova on with Sustainable and Recycled fabrics. This segment have highest innova on possibility in terms weave cra ing, knit design, lamina on, non wovens with print, dyes and colors, processing etc.. Sustainable Fabrics are new trends where natural fibres , dyed with natural and organic products and finished with again the organic products. This trend is new in India, acceptance is miniscule due to cost and price sensi ve market. Sustainable fabrics are also have many medicinal proper es which is important for skin protec on, keep away skin irrita on, rashes, damages of internal organ and many more. In Developed economy , consumer knows the importance of the global environment changes which is impac ng life and physical well being, they are moving towards the sustainable products. Recycled Fabrics have 2 trends, mechanical recycled fabrics and chemical recycled fabrics. Recycled fabrics trends are also used in many areas like sports tex les ( garments, shoes ), home tex les , apparels . Recycled fabrics can be from natural fibres but majorly its synthe c fibres , due to pet bo le usage in the process, kni ed and woven. Recycled Fabrics in apparel may have some implica on, as synthe c material touches body, but it can be widely used in Shoes, many global brands like NIKE, Decathlon, many more started using recycled fabrics. Recycled Fabrics with good finishes are making it look and feel of like natural fabrics. Nonwoven Fabrics, for Technical tex le with addi on of fashion, color, design aspects make this fabrics also interes ng and vibrant, lot more research and innova on need to be done in this sector. Nonwoven is compressed material of co on or synthe c yarns; widely used in medical, FMCG, automobile, Agriculture industry. Simple test to see whether its natural or synthe c fabrics, just rub fabrics for 2 minutes, if heat produced during fric on between fingers and fabrics then its synthe c fabrics, if not heat, then its natural and sustainable fibre fabric. EDITORIAL TEAM EDITOR AND PUBLISHER Jigna Shah EDITORIAL ASSISTANT Gargi Dandegaonkar CREATIVE DESIGNER Asif Khan MARKETING AND ADVERTISING ENQUIRY Mohammad Tanweer +91-9167986305 sales@tex levaluechain.com REGISTERED OFFICE: TVC MEDIA AND PROMOTION PVT LTD. 504, Suchita Business Park, Patel Chowk, Pantnagar, Ghatkopar (East), Mumbai- 400075, Maharashtra, INDIA. Cell: +91-9769442239 Email: info@tex levaluechain.com Web: www.tex levaluechain.com Owner, Publisher, Printer and Editor Ms. Jigna Shah Printed and Processed by her at, Impression Graphics, Gala no.13, Shivai Industrial Estate, Andheri Kurla Road, Sakinaka, Andheri(East), Mumbai 400072, Maharashtra, India. All rights reserved Worldwide; Reproduc on of any of the content from this issue is prohibited without explicit wri en permission of the publisher. Every effort has been made to ensure and present factual and accurate informa on. The views expressed in the ar cles published in this magazine are that of the respec ve authors and not necessarily that of the publisher. Tex le Value chain is not responsible for any unlikely errors that might occur or any steps taken based in the informa on provided herewith. Editorial +91-9869634305 marke ng@tex levaluechain.com Jigna Shah I

- 12. OCTOBER 2023 10 www.textilevaluechain.in Event Calender UPCOMING EVENTS EVENTS November 2023 1st-7th Nov 47TH EDITION OF BAGHDAD INTERNATIONAL FAIR Baghdad, Iraq h ps://fieo.org 2nd-3rd Nov 24TH INTERNATIONAL CONFERENCE INDIAN PETROCHEM – 2023 Mumbai, India h ps://www.eliteconferences.com/home/indianpet- rochem-2023/ 2nd-3rd Nov AUTOEV TECH-VISION SUMMIT 2023 Bengaluru, India h ps://www.autoevexpo.com/book-a- cket/ 6th-8th Nov Yarn Expo Shenzhen Shenzhen, China h ps://yarnexpo-shenzhen.hk.messefrankfurt.com/ shenzhen/en.html 6th-9th Nov 10TH IME 2023 Kolkata,India h ps://miningexpoindia.com/ 6th-9th Nov AFEV 2023 Kolkata,India h ps://www.alternateenergyexpo.com/ 6th-9th Nov ISME 2023 Kolkata, India h ps://www.steelandmetallurgyexpo.com/ 6th-9th Nov INTERNATIONAL CONSTRUCTION, EQUIPMENT MATERIALS EXHIBITION Kolkata, India h ps://www.cemindiaexpo.com/ 6th-11th Nov FIHAV 2023 CUBA, Carribbean. h ps://www.belize.org/events/39th-edi- on-of-the-havana-interna onal-fair-fihav-2023/ 15th-17th Nov Morocco FashionTex Style OFEC Casablanca/ Morocco h ps://moroccofashiontex.net/ 19th-23rd Nov ITMA ASIA + CITME 2022 Shanghai, China h ps://www.itmaasia.com/ 21st-23rd Nov FAST TEXTILE 2023 Poland, Europe. h ps://fas ex le.com/en/ 27th-29th Nov 16TH INTERNATIONAL APPAREL TEXTILE FAIR Dubai, UAE. h ps://www.interna onalapparelandtex lefair.com/ 30th-2nd Dec ITME AFRICA M.E. 2023 Nairobi, Kenya h ps://www.itme-africa.com/

- 15. 13 OCTOBER 2023 Market Report: Fabric Imports Units : USD Million

- 17. A novel product for pretreatment Scouring and bleaching at low temperature 57, Maha Gujarat Industrial Estate, Sarkhej Bavla Road, Opp. Sarvoday Hotel, Moraiya, Ahmedabad-382 213 INDIA Website: www.microchem.co E-mail: info@microchem.co Mobile: +91 98251 23800 57, Maha Gujarat Industrial Estate, Sarkhej Bavla Road, Opp. Sarvoday Hotel, Moraiya, Ahmedabad-382 213 INDIA Website: www.microchem.co E-mail: info@microchem.co Mobile: +91 98251 23800 Scouring and bleaching at lower temperature of 80 °C Minimize weight loss to a great extent Higher CSP, RKM, tensile and bursting strength Crease formation is greatly reduced for knits Saves time and energy, increases productivity Chemistry with Vision... 100 90 80 70 60 50 40 30 20 30 40 50 60 70 80 100 90 Time / min. Temp ºC Conventional process 98 ºC Low temperature process 80 ºC Ultratreat

- 18. OCTOBER 2023 16 www.textilevaluechain.in Market Report: Fabric Export Units : USD Million

- 20. ƌƚͲzĂƌŶdžƉŽƌƚƐ;/ŶĚŝĂͿWǀƚ͘ƚĚ͘ WƌŽĚƵĐƚDŝdž ‡ ŽƚƚŽŶ zĂƌŶƐ ͗ ĂƌĚĞĚ͕ ŽŵďĞĚ͕ ŽŵƉĂĐƚ͕ ŽƉĞŶ ŶĚ ‡ ŽƚƚŽŶ ǁĂƐƚĞ ͗ ŽŵďĞƌ EŽŝů͕ ƌĞĂŬ ŽŵďĞƌ͕ ůĞĂĐŚĞĚ EŽŝů͕ ŝĐŬĞƌŝŶ ǁĂƐƚĞ͕ ůĂƚ ǁĂƐƚĞ͕ WƌŽĐĞƐƐ ŽƚƚŽŶ ‡ WŽůLJĞƐƚĞƌ zĂƌŶ ‡ sŝƐĐŽƐĞ zĂƌŶ ‡ WŽůLJĞƐƚĞƌͬ ŽƚƚŽŶ zĂƌŶ ‡ WŽůLJĞƐƚĞƌͬsŝƐĐŽƐĞ zĂƌŶ ‡ ŝůĂŵĞŶƚ LJĂƌŶƐ ϵƚŚůŽŽƌ͕ͲtŝŶŐ͕'ŽĚƌĞũŽůŝƐĞƵŵĞŚŝŶĚǀĞƌĂƌĚEĂŐĂƌ͕ ^ŝŽŶͲdƌŽŵďĂLJ ZŽĂĚ͕^ŝŽŶ;ĂƐƚͿDƵŵďĂŝʹ ϰϬϬϬϮϮ͕/ŶĚŝĂ dĞů͗нϵϭϵϬϬϰϱϲϮϱϴϴͬĂdž͗ϬϮϮϰϬϬϭϮϲϳϵtĞďƐŝƚĞ͗ ǁǁǁ͘ĂƌƚLJĂƌŶŝŶĚŝĂ͘ĐŽŵ ͲŵĂŝů͗ĂƌƚLJĂƌŶΛĂƌƚLJĂƌŶŝŶĚŝĂ͘ĐŽŵ ďŽƵƚhƐ ‡ ƌƚͲzĂƌŶŝƐĂůĞĂĚŝŶŐƐƵƉƉůŝĞƌŽĨLJĂƌŶƐŝŶƚŚĞŐůŽďĂů ŵĂƌŬĞƚ͕^ƵĐĐĞƐƐĨƵůůLJƐƵƉƉůLJŝŶŐďĞƐƚƋƵĂůŝƚLJLJĂƌŶƐĂŶĚ ƐĞƌǀŝĐĞƚŽŽƵƌƉĂƌƚŶĞƌƐĂŶĚĂƐƐŽĐŝĂƚĞƐĂůůŽǀĞƌƚŚĞǁŽƌůĚ ĨƌŽŵƉĂƐƚ ƚǁŽĚĞĐĂĚĞƐ͘ ^ƚƌĞŶŐƚŚƐ ‡ ƵůĨŝůůŝŶŐ ƚŚĞ ŶĞĞĚƐ ŽĨ ĐůŝĞŶƚƐ ďLJ ƐĞůůŝŶŐ ϭϰϬϬϬн ƚŽŶŶĞƐ ŽĨ LJĂƌŶ ĂŶŶƵĂůůLJ͘ ‡ zĂƌŶ ƐƵƉƉůŝĞĚ ĨŽƌ ĞŶĚ ƵƐĞ ŽĨ ŬŶŝƚǁĞĂƌ͕ ƐŚŝƌƚŝŶŐ Θ ^ƵŝƚŝŶŐ͕ dĞƌƌLJ dŽǁĞů͕ ,ŽŵĞ dĞdžƚŝůĞƐ͕ ƐŽĐŬƐ͕ /ŶŶĞƌ tĞĂƌ͕ ĞŶŝŵ͕ hƉŚŽůƐƚĞƌLJ͕ ĂƌƉĞƚƐ͕ ĞƚĐ͘ ‡ ůŝĞŶƚ ďĂƐĞ ŝŶ ŵŽƌĞ ƚŚĂŶ Ϯϱ ĐŽƵŶƚƌŝĞƐ ‡ /^K͕ 'Kd^͕ 'Z^͕ KKͲdy͕ / ĐĞƌƚŝĨŝĞĚ

- 21. www.textilevaluechain.in 19 OCTOBER 2023 Cover Story By Susmita Ghosh uch advancements are extremely crucial as they have not only revolu onised the industry and tex le produc on but also carved a be er way for the use of func onal, sustainable and not-to-men on aesthe cally appealing materials. Before delving into the key breakthroughs of fabric and finishes, it is important to understand what helped India achieve a 4.6% share of the global trade in tex les and apparel. Sustainability Ini a ves: Considering the growing focus of the Indian Tex le Industry on sustainability, adop ng eco-friendly processes, water conserva on techniques, sustainable and organic materials along with reduced energy consump on have helped manufacturers incorporate new ways of innova on in the related field. Technical Tex les: The growth of the technical tex le sector has also served as a helping hand. With increased demand in industries like healthcare, automo ve and agriculture, innova ons in fabric and finishes were seen. Fabrics with fire resistance, UV protec on and fabrics with an microbial proper es are a few such examples. Digital Prin ng: The demand for digital prin ng tex les has grown exponen ally in the past few years, allowing more intricate and precise designs on fabrics. Apart from that, minimised waste, and compara vely reduced water consump on are a few other benefits. Innova ve Finishes: As the demands grew in the areas such as sports and hard-core industries, many innova ve fabric finishes were introduced. Fabrics with moisture-wicking, odour-resistant and stain-repellent finishes are a few such examples. Smart Tex les: Integra on of electronics into tex les became an emerging trend. The usage of sensors, LEDs and other electronic components transformed a normal fabric Fabric and Finishes Innovation: Redefining Textile Industry Standards In recent years, the tex le industry has witnessed a remarkable surge in innova on, par cularly in the realm of fabric and finishes. S

- 22. OCTOBER 2023 20 www.textilevaluechain.in into a smart tex le. Usage of such fabrics is evident in sports, fashion and healthcare. Handloom Revival: The revival of India’s tradi onal handloom fabrics was a considerable step. Driven by consumer demand for sustainable and authen c tex les, many weavers and ar sans started adop ng contemporary styles while preserving the conven onal methods. Government Ini a ves: The Indian government launched several ini a ves to promoteinnova onintex les.TechnologyUpgrada on Fund Scheme (TUFS) to encourage modernisa on and research and development in the sector is one such example. In 2022, the government issued a Quality Control Order (QCO) on the import of Viscose Staple Fibre (VSF), a sustainable alterna ve to co on. India, being one of the world’s largest exporters of tex les and garments, innova ons in fabrics and finishes were a much-needed step to maintain and expand its market share. Presently, India is the second largest producer of Man-made Fibre (MMF). Even though the focus was majorly on co on exports, India’s export of MMF tex les and apparel was recorded at USD 9.56 billion for the financial year 2021-22. Owing to India’s poten al, the Ministry of Tex le formed a Tex le Advisory Group on MMF in January 2023 to increase focus on the area. Here are a few innova ons that can be witnessed in the tex le industry: One of the most significant strides is the emergence of smart fabrics. Such tex les are integrated with conduc ve materials or electronic components or wastes like mangoes, mushrooms and apple peels. Such fabrics help judiciously interact with their environment. From moisture-wicking workout gear, and self-hea ng jackets to Pinatex and Leaf Leather, smart fabrics are transforming the apparel industry both in terms of limited wastage and enhanced comfort and func onality. Nanotechnology has found a promising applica on in tex les. The use of metal and metal oxide nanopar cle proper es to interact with light and microorganisms is one such recent innova on. Dispersing organic embedded metal oxide and zinc oxide nanopar cles in a soluble starch matrix to improve an bacterial proper es and manage UV radia on is another example. Addi onally, nanotechnology helps in the development of self-cleaning tex les. It reduces the need for harsh chemicals in laundry. Plasma technology uses electricity to turn gases into ‘cold plasma’ which can change the fabric surface without deteriora ng the quality. It can also be used on materials like polypropylene and polyethylene which have a very low mel ng point. Plasma technology helps get rid of any stuff on the fabric and prepares it to have new things added to its surface. Microencapsula on is a process where a con nuous film of polymeric material is coated into very ny droplets of liquid par cles or solid material, forming Microencapsulos. These capsules help fragrance-emit- ng fabrics retain their odour for a longer dura on. Currently, microencapsula on can be done in two methods - Padding and Exhaus ng. The usage of clay finishing and composite fibres has been widely accepted due to its low cost. The micro- structural layer proper es in clay materials are used. In an experiment, where polymers were infused with 2-5% nanoclays, significant improvement was observed in barrier proper es, flame retardant capacity and dimensionalstability.Thisinnova onisusedprimarilyin synthe c polymers such as polypropylene, polyamide, polyethylene terephthalate, and polyethylene fibres. Fabric and finishes Innova on has significantly developed the tex le industry and is con nuing to do so by pushing the boundaries at a faster pace. From sustainable materials to fragrance-emi ng fabrics, these advancements are transforming the way we approach tex les. As technology con nues to advance, we can expect more upgrades in technology and material, further revolu onising the world of fabrics and finishes. Cover Story

- 24. Presently we are selling to more than 40 countries, our major business comes from countries like – Bangladesh, China, Portugal, Sri lanka, , Vietnam, USA, Chile, Peru,Thailand, Poland, Korea. We also have a domestic division, which suppliesyarn to our clients within India. We are facilitating approx 18~20 containers per month in Exports and approx 400 tons per month in our domestic business. sumitsinghal.sspl@gmail.com +91 98370 94847 Soft Yarn for Blankets, Bath Mats Hand Knitting: Ne 6/2/3, Ne 6/2/4, Ne 4/2,Ne 4/4, Ne 6/2 133-A NAND NAGAR, INDUSTRIAL ESTATE, PHASE - II, KASHIPUR DESTT. UDHAM SINGH NAGAR, UTTRAKHAND - 244713 PRODUCT RANGE We are working with brands like HM, IKEA, INDITEX and many more 100% Cotton Open End Knitting Yarn: Ne 8/1, 10/1, 12/1, 14/1, 16/1, 20/1, 24/1, 26/1, 30/1 Open End for Weaving / Denim: Ne 4/1, 6/1, 7/1, 8/1, 10/1, 12/1, 16/1, 20/1 Industrial yarns: Ne 20/4, 12/4, 6/6, 10/8 Double OE Yarn for Weaving: Ne 4/2, 4/4, 6/2, 6/3, 8/2, 10/2, 10/3,12/2 16/2 Cotton/Polyester Open End yarn: Ne 6/1, 7/1, 8/1, 10/1, 12/1, 16/1, 20/1, 24/1, 30/1 Cotton/Viscose Open End yarn: Ne 6/1, 7/1, 8/1, 10/1, 12/1, 16/1, 20/1 Cotton/Bamboo Open End yarn: Ne 6/1, 7/1, 8/1, 10/1, 12/1, 16/1, 20/1 Cotton/Excel(Lyocell) Open End yarn: Ne 6/1, to Ne 26/1

- 25. www.textilevaluechain.in 23 OCTOBER 2023 t is the promising me to dig through the enchan ng world of fabrics, be it tex le, color, or designs. What 2023 has in store? What are the new fabric trends that will set the tone for joyful celebra ons? Let’s have a look! The Classic linen is an all- me favorite among the fashion enthusiasts. The come-back is strong and perfect for the present climate scenarios. The natural sheen and refinement ensure an enduring elegance that lasts as long as you desire. The possibili es for ou its are limitless, from sophis cated formals to trendy dresses, striking a perfect balance between style and comfort. Shimmering sequins and metallic fabrics have been a go-to choice among those in the limelight. Be it a metallic-threaded saree or a sequined cocktail dress like materials reflect an aura of celebra on. “Trends are moving away from stereotypical bling into a more subtle, muted, tone on tone look and feel. This is the Neo Metallic for the fes ve season,” suggested Pankaj Kapoor, Founder Partner, BMS Fashion when asked if diverse metallic hues are redefining celebratory fashion. Gold and silver are meless classics, however, the contemporary fes ve season has witnessed enthusiasts embracing a wide spectrum of shades like copper, rose gold, bronze, so on and so forth. Synonymous with grandeur and luxury, silk has been a staple choice, especially in the western, eastern, and southern corners of India. Be it the tradi onal sarees or the modern drapes, the natural sheen and so ness of the fabric are the top quali es that have made it so popular, especially during the fes ve seasons. The fusion of conven onal and modern design elements, crea ng eye-catching and unique ensembles celebra ng heritage and innova on, is what we have seen in the recent past! While asking his envision on sustainable materials contribu ng to a more environmentally conscious approach to celebra ng, Pankaj Kapoor asserted, “There is definitely a demand and awareness for more sustainable fabrics like recycled polyester, organic co ons, etc. The market cap is growing slowly, crea ng a niche. However, the cost disparity coupled with rising infla on is an obstacle for the cause.” The fes ve season is the best me to highlight its importance.Therehasbeenashi towardseco-friendly fabrics among conscious customers and the fes ve season is no excep on. Sustainable fabrics like organic Fabric Trends in the Festive Season: A Feast for the Senses By Susmita Ghosh In India, ‘September’ blows the trumpet marking the beginning of the fes ve season. A span of joy and celebra on! Fabrics are an integral element that highlights these moments of joy. Even though the world is transcending towards a ‘hep’ culture, a mix of contemporary and cultural influences emerges a new wave of fabric trends during the fes ve seasons. I Cover Story

- 26. OCTOBER 2023 24 www.textilevaluechain.in co on, bamboo linen, Cashmere, and Econyl are a few examples that we expect to see this year. Embracing natural hues, minimalist designs, and earthy textures while reducing the environmental footprint of our celebra ons, is a celebra on in itself! Organza, a delicate and translucent fabric, has gained popularity as a choice for fes ve a re. With a touch of romance and sophis ca on, this ethereal fabric is perfect for gowns, blouses, and the six-yard beauty! The minimalist floral designs with a metallic touch on the fabric have become a signature style. Considering its mul -purpose proper es, this fabric is perfect for the fes ve weather and gives its se ngs a dreamy and whimsical ambiance. The fes ve season provides an ideal canvas for showcasing the ar stry of embroidery and handwork, given the Indian fes ve environment. FromintricatezardoziandmirrorworkinIndiana reto delicate beading and lace in Western fashion, the detail and cra smanship in fes ve fabrics are awe-inspiring. Such adornments not only add a personalized glimmer to apparel and decor but also make every piece a work of art. Nostalgia o en plays a role in fes ve style. Brocade and Jacquard are fabrics inspired by vintage fashions that exude an insight of meless refinement. Be it jacquard suits or brocade sarees, such fabrics bring a touch of old-charm to contemporary celebra ons. Moreover, such fabrics are known for their intricate pa erns and textured surfaces. “This fes ve season, we are pushing a range of embroidered fabrics, structures, jacquard’s and dobbys. People are gravita ng towards ethnic and Indo-Western ensembles. There is also a fresher take on metallics like tone on tone Lurex,” said Pankaj Kapoor. While solids and tradi onal pa erns have their place in fes ve fashion, playful and unconven onal prints are gaining momentum. Bold florals, geometric designs, whimsical mo fs, abstract art are more in demand as the fes ve celebra ons approach. Such fes ve a re with prints and pa erns is taking on a more diverse and individualis c character. Fashion forward approaches like mixing and matching different prints has allowed individuals to ar culate their phenomenal style during the joyous season. Whether it’s a tasseled hemline on a dress, fringe-trimmedcurtains,ortassel-adornedaccessories, tassel and fringe embellishments sway and dance with movement, crea ng an element of fun and fes vity. Vibrant, mul -colored tassels are par cularly popular, injec ng a burst of energy into the fes vi es. They add a playful and bohemian touch not only in fes ve fashion but also in case of fes ve decor. Velvet is one such fabric that is a perennial favorite. Jewel tones like emerald green, royal blue, and deep burgundy are currently trending and adorned during the fes ve seasons. Moreover, velvet has experienced a revival in vogue in recent years. Being a meless fabric that never goes out of style, the deep style, lush texture, and inherent opulence make it the perfect choice among fashion enthusiasts. Velvet suits, dresses add an air of sophis ca on to fes ve gatherings. Such fabrics also look good on home decor items like throw pillows and tablecloths. The fes ve seasons open up all the routes to express one’s individuality and crea vity through the fabrics be it welcoming tradi on or blazing a new fashion trail. The fes ve fashion serves as a deligh ul feast for the senses. As the fes ve season approaches, the world of fabrics unlocks a new array of fashion lines. Catering to every taste and sensibility, be it the meless allure of linens, the eco-consciousness of sustainable fabric, or the shimmering sequins, the fabrics celebrate fes vals in their unique ways.

- 28. LC636 SX LC636 SX +LJKHU(ɝFLHQFDQG 3URGXFWLYLWXSWR 250 Kg/hr ΖPSUHVVLYHDFWLYHFDUGLQJ DUHDEHWZHHQFOLQGHU DQGPRYLQJȵDWV +LJKHUUHDOLVDWLRQRIXS WRLQUDZPDWHULDOV DQGVXSHULRUTXDOLW 3RZHUVDYLQJVRI XSWR W DQ 'ULYLQJ3URGXFWLYLW4XDOLWb 6XVWDLQDELOLWbWKURXJKΖQQRYDWLRQ SUSTAINABLE SMART INNOVATING VERSATILITY, RELIABILITY, AND SUSTAINABILITY ACROSS APPLICATIONS

- 29. he tex le and apparel industry is a vital sector of India’s economy, contribu ng significantly to employment genera on and export earnings. The trends in imports and exports of fabrics in India play a crucial role in shaping the dynamics of this industry. India’s export value for 2022-23 was Rs 362,063,094.86, compared to Rs 314,702,149.28 in 2021-22. Similarly, for imports India’s total value stands at Rs 573,395,859.64 in 2022-23 compared to Rs 457,277,458.91 in 2021-22. The value of India’s exports and imports in 2023-24(Apr-Jun) stands at Rs 113,836,644.90 and Rs 175,229,305.66, respec vely. Having said that, let’s have a look at the country’s posi on in exports and imports related to fabrics. India’s Fabric Export Trend Fig 1.1: India’s Fabric Export Data (Graph Format) * Source: Trade Sta s cs, Ministry of Commerce, GOI Commodity 2021-2022 (Rs) 2022-2023(Rs) 2023-2024(Apr-Jun) Co on 8,043,453.61 4,534,888.93 1,735,180.43 Furskins and Ar ficial Fur (Manufactures) 17,826.02 11,869.24 3,058.26 Impregnated, Coated, Covered or Laminated Tex le Fabrics; Tex le Ar cles for industrial use. 330,335.88 312,899.32 130,822.05 Kni ed or Crocheted Fabrics. 633,974.89 461,096.15 113,003.30 Other Vegetable Tex le Fibres; Paper Yarn and Woven Fabrics of Paper Yarn. 503,460.56 374,063.05 115,257.87 Raw Hides and Skins (Other Than Furskins) and Leather 340,743.00 346,836.56 124,618.37 Silk 86,703.59 81,168.05 30,750.64 Special Woven Fabrics; Tu ed Tex le Fabrics; Lace; Tapestries; Trimmings; Embroidery. 275,892.50 278,403.40 111,229.16 Fig 1.2: India’s Fabric Export Data (Tabular Format) * Unraveling the Fabric Trade: Exploring Trends in Imports and Exports and Their Industry Implications By Susmita Ghosh T Cover Story www.textilevaluechain.in 27 OCTOBER 2023

- 30. OCTOBER 2023 28 www.textilevaluechain.in Cover Story Source: Trade Sta s cs, Ministry of Commerce, GOI Fig 1.3: India’s Fabric Export % Share (Graph Format) * Source: Trade Sta s cs, Ministry of Commerce, GOI India’s Fabric Import Trend Fig 2.1: India’s Fabric Import Data(Graph Format) * Source: Trade Sta s cs, Ministry of Commerce, GOI Commodity 2021-2022 (Rs) 2022-2023(Rs) 2023-2024 (Apr-Jun) Raw Hides and Skins (Other Than Furskins) and Leather 316,488.17 386,928.34 116,110.95 Furskins and Ar ficial Fur (Manufactures) 4,011.16 4,794.05 2,857.57 Silk 110,486.66 217,381.74 61,154.09 Wool, Fine Or Coarse Animal Hair, Horsehair Yarn and Woven Fabric. 208,429.17 255,919.62 95,566.09 Co on 550,826.59 1,362,869.42 289,143.10 Other Vegetable Tex le Fibres; Paper Yarn and Woven Fabrics of Paper Yarn. 313,563.38 419,930.96 151,869.22 Special Woven Fabrics; Tu ed Tex le Fabrics; Lace; Tapestries; Trimmings; Embroidery. 184,017.53 174,419.13 57,119.27 Impregnated, Coated, Covered or Laminated Tex le Fabrics; Tex le Ar cles suitable for industrial use. 636,871.89 690,095.96 227,122.50 Kni ed or Crocheted Fabrics. 502,222.64 607,397.14 200,670.57 Other Made Up Tex le Ar cles; Sets; Worn Clothing and Worn Tex le Ar cles; Rags 463,300.08 506,014.45 165,915.08 Footwear, Gaiters and The Like; Parts of Such Ar cles. 479,751.01 739,771.13 246,458.64 Fig 2.2: India’s Fabric Import Data (Tabular Format) * Source: Trade Sta s cs, Ministry of Commerce, GOI Fig 2.3: India’s Fabric Import % Share (Graph Format) * Source: Trade Sta s cs, Ministry of Commerce, GOI India’s Fabric Export and Import Growth Trends Fig 3.1: India’s Fabric Export % Growth (Graph Format) * Source: Trade Sta s cs, Ministry of Commerce, GOI

- 31. www.textilevaluechain.in 29 OCTOBER 2023 Fig 3.2: India’s Fabric Import % Growth (Graph Format) * Source: Trade Sta s cs, Ministry of Commerce, GOI Fig 3.2: India’s Fabric Export and Import % Growth 2023-24 from April to June (Graph Format) * Source: Trade Sta s cs, Ministry of Commerce, GOI Commodity %Share (Export) %Share (Import) Co on. 1.5243 0.165 Furskins And Ar ficial Fur, Manufactures Thereof. 0.0027 0.0016 Impregnated, Coated, Covered Or Laminated Tex le Fabrics; Tex le Ar cles Of A Kind Suitable For Industrial Use. 0.1149 0.1296 Kni ed Or Crocheted Fabrics. 0.0993 0.1145 Other Vegetable Tex le Fibres; Paper Yarn And Woven Fabrics Of Paper Yarn. 0.1012 0.0867 Raw Hides And Skins (Other Than Furskins) And Leather 0.1095 0.0663 Silk 0.027 0.0349 Special Woven Fabrics; Tu ed Tex le Fabrics; Lace; Tapestries; Trimmings; Embroidery. 0.0977 0.0326 Fig 3.4: India’s Fabric Export and Import % Growth 2023-24 from April to June (Tabular Format) * Source: Trade Sta s cs, Ministry of Commerce, GOI Takeaway The trends in imports and exports of fabrics have far-reaching implica ons for India’s tex le industry. Staying informed about these trends and adap ng to changing market dynamics are essen al for businesses to remain compe ve and contribute to the growth of the tex le sector in India. * The fabric-related commodi es are within the Top 100 2-level commodi es as men oned in the Ministry of Commerce website, Government of India, as of September 2023. The values are given in Indian Rupees (Rs).

- 32. www.fashionvaluechain.com TVC MEDIA AND PROMOTION PVT. LTD. www.textilevaluechain.in TEXTILE VALUE CHAIN (TVC) is an Indian Trade Media serving the Indian and Global Textile industry with Monthly Print Magazine, E-Magazine, Online Global Information Platform. FASHION VALUE CHAIN (FVC) is the integrated Media with Bi monthly magazine on digital platforms. TECHNICAL TEXTILE VALUE CHAIN is an Indian Global Media with quarterly magazine with digital Platform. www.textileappareljobs.com TEXTILE APPAREL JOBS is the Indian Global Online Employment Platform for both Organization who needs an Efficient Human Resource to build strong team and for people who are seeking Dream Jobs with Meaningful Career. Contact Us: +91 9167986305 / sales@textilevaluechain.com www.technicaltextiles.in

- 33. Home of Flooring DOMOTEX FLOORED BY NATURE Hannover · Germany domotex.de 11 – 14 JANUARY 2024

- 35. Technical Article Index Terms- Indigo Fabric dyeing, Ultra Rapid Indigo Dyeing, Zero trade effluent, ZLD, Eco-friendly Dyeing, Sustainability 1 Introduc on Indigo yarn dyed fabrics are the most popular and fashionable woven wear for all genera ons. The global jeans business is increasing in a dras c way because of its comfort-ability, trend, and performance. Till today majority of the indigo yarn dyeing produc on is done in the conven onal way using slasher, rope dyeing machines. There have been advancements in these conven onal technologies for achieving specific goals like super dark shades, mul ple color dyeing, precise e controls for be er workability, adaptability for running various processes, also modifica ons to achieve sustainability etc. A Sustainable future can be achieved if usage of less energy, less chemicals and less water is emphasized. Various Pad-Fixa on dyeing processes with a sustainable approach are • Pad-roll-batch • Pad-dry-cure Continuous Fabric Dyeing with Ultra Rapid Indigo Dyeing(PG) with Sustainable approach Abstract: Denim is a unisex fashionable warp dyed woven wear for all genera ons. The global jeans business is increasing steadily because of its comfort-ability, trend, and performance. Denim yarn indigo dyeing produc on is done in the conven onal way using slasher, rope dyeing machines. Till today fabric dyeing using indigo color is challenging due to technological limita ons. Many a empts have been made to dye indigo in fabric form with few excep ons but could not be commercialized. Looking at the conven onal Indigo yarn dyeing process which requires pretreatment, washing, ba ery of (dip, nip air) indigo dyeing followed by washing, drying and sizing beaming or batching seems to be too lengthy for fabric which may need utmost care in every step to ensure that the fabric is dyed evenly. Hence to dye Indigo in fabric form, a new approach is made in a sustainable way by using the Ultra-Rapid dyeing technology. This technology primarily focuses on the concept of Ultra-Rapid indigo dyeing. Here the substan vely of the indigo solu on is tremendously increased by achieving the required physico-chemical parameters in an inert atmosphere. This enables the super substan ve leuco indigo to instantaneously penetrate with a decreasing gradient in the core of the fiber. Thus giving darker shades at minimal contact me. This evolved technology has been successfully tested on various fabrics of different blends, weaves, gsm and lengths. This technology is being developed for achieving sustainability in indigo dyeing. Notably this technology enables near- zero water denim dyeing, contribu ng to environmental conserva on. By Bhushan Chaudhari, Jaydeep Umalkar – Atharvaved Impex, Maharashtra, India, By Pradeep Pillai - WFB Baird Co India Pvt. Ltd. Kochi, Kerala, India www.textilevaluechain.in 33 OCTOBER 2023

- 36. OCTOBER 2023 34 www.textilevaluechain.in • Pad-steam Fix • Pad-dry-bake • Pad-Air-Dry • Eco-control dyeing • Pad-Ox processes Ultra rapid dyeing technology [PG] has been developed using the pad dry bake method of dye applica ons. Pad dyeing’s are be er than exhaust dyeing’s from a sustainability perspec ve [1]. Because these offer the following benefits. - Faster dye applica on - Minimum liquor to material ra o - Electrolyte free exhaus on - Lower quan es of le -over dye liquor - Easier dyeing control for dye levelness on the fabric Exhaustdyeingmachinesfacilitatedyeing’sasminimum as 3:1 liquor to material ra os, whereas pad dyeing’s are carried out at much lower liquor ra os between 1:1 and 0.5:1 resul ng in increased dye uptake at low liquor ra os. Thus deeper shades can be dyed with op mum quan es of dyes, chemicals and water. Low liquor ra os also reduces the amount of dye, chemicals and water discharged to treatment plants. Widthwise, lengthwise uniformity and depth of shade depends on below factors. • Machine factors - dwell me, mangle expression, temperature, pressure, dye liquor turnover ra o, agita on mechanism, circula on, effec ve interac on of dye liquor and fabric • Substrate Factors – fiber proper es, fiber type composi on, yarn twist structure, type of pretreatment, evenness in pretreatment, absorbency, construc on of fabric, moisture content, residual chemicals, overall dye affinity for the substrate. • Other factors – dye concentra on, dye bath ra o, dye bath addi ves, dye bath pH control, dye stability, dye aggrega on, preferen al dye uptake, dye reac on me, fixa on me, possible impuri es from fabric prepara on to dye bath. A erpaddingfixa onofdyesiseitherdonebysteaming or curing in specially designed con nuously operated chambers. At the end of the pad dyeing process, all the dye liquor in its concentrated form remaining in the trough, piping and pumps is drained [2]. The volume of le over dye liquor drained depends upon the design and capacity of the trough. Many machine manufacturers have introduced low capacity of troughs volumes as 10 to 15 L, such low trough volumes has improved dyeing efficiency and reduced the wastages [3] here ver cal pad systems are used. Where as in horizontal pad designs the dye liquor volumes are s ll low where the trough is formed in the nip between the squeezing rollers. Such pad designs are regarded as the best available equipment’s for reducing the dye bath le over wastages [2] Keeping sustainability in focus i.e. (environment, economicandsocial)[4]variousemergingtechnologies are con nuously worked upon by scien sts and industrialists to reduce consump on of water, energy and chemicals, and waste water pollu on from dyeing processes. Many new technologies are been tested such as ultrasonic energy, electrochemical technology, microwave, UV radia on, RF, PEF, plasma and supercri cal carbon dioxide. Some of them are finding their way towards commercializa on. Ultrasonic energy in wet processing have shown promising results and have opened an opportunity to increase the process effec veness and reduce the process dura on for many cri cal wet tex le processes. It has shown reduc on in consump on of energy, water and chemical, with improvement in colour yields and reduc on in wastewater pollu on [5,6]. The use of ultrasonic energy on a produc on scale, mostly for exhaust and some pad-batch dyeing’s of cellulose fabrics with reac ve dyes, has also been tested and reported [7]. UV irradia on can be successfully applied to enhance the colour strength as well as colour fastness proper es of colored silk and flax fabrics by improving their we ability [8]. The use of Ultraviolet curable dyeing liquors and finishing chemicals could has place in order to save both energy and me, and to create “new tex le products” [9]. Reduc on and oxida on of sulphur dyes and vat dyes, Technical Article

- 37. www.textilevaluechain.in 35 OCTOBER 2023 using electrochemical methods, is an emerging area. So far, electrochemical reduc on and oxida on have been shown to reduce wastewater pollu on [10]. Microwave hea ng can improve the dye uptake and dye fixa on [11, 12], however, efforts are laid to make it viable on a produc on scale. Supercri cal carbon dioxide and plasma have been reported as ways to carry out waterless dyeing [13, 14]. Indigo a prehistoric color documented was dyed on tex le materials in wooden pots or vats in the early days and are water-insoluble colored compounds [15]. Indigo is insoluble in water and cannot be directly dyed. To make this dye soluble, two steps of reac on is required. First, reduc on of vat dye into leuco vat dye by sodium hydrosulphite. Second, neutraliza on of leuco vat dye with caus c soda to give soluble sodium salt of leuco vat dye. Indigo dyeing in the conven onal con nuous process involving pretreatment with caus c followed by washing followed by dyeing in a 4 to 16 ba ery of dip in indigo bath nip to extract excess color and aera on to oxidize the indigo color followed by rinsing at ambient temperatures in 2-3 rinsing baths a er oxida on is normally adequate to remove alkali and unfixed oxidized leuco compounds [16]. Denim is a co on warp facing twill fabric where the we passes below two or more warp threads [16]. Conven onal denim manufacturing process involve warping, dyeing, sizing, weaving, finishing, and inspec on. Denim is always warp dyed where warp is dyed a er warping and we is mostly white co on yarn but as per trends these can be dyed co on, blended white/dyed, synthe c white /dyed, regenerated white /dyed. Indigo solids are in trend where the warp and we both are indigo dyed. Here indigo dyed sized warp is prepared as per the conven onal slasher or rope process.Forwe theIndigodyedyarnispreparedasper the conven onal indigo rope dyeing process followed by conver ng the re-beamed dyed yarn in cone form using the beam to cone conversion machine. There are always several produc on and environmental challenges associated with this conven onal process for producing consistent indigo solids. Produc on challenges in Tradi onal Dyeing – Produc on challenges involves physical and chemical wear and tear of the material in process due to long passage lengths, limita ons in usage of minimum lot length, consistent and even depth of shade in warp and we , challenges related to maintaining the physical proper es, limita ons in use of blends, construc on, weave gsm. Environmental challenges in Tradi onal Dyeing – Tradi onal Indigo dyeing is a heavy natural resource consuming process. High amounts of water flow in pre-wash boxes are required to rinse out caus c soda and other auxiliaries completely from the substrate. Con nuous rinsing also reduces the yarn temperature thereby preparing the substrate for indigo dyeing at room temperature. In Post-wash boxes to rinse out unfix dyes and chemicals from dyed yarn surface. Huge amount of other resources like steam, compressed air and power is also consumed in running the tradi onal indigodyeingmachineswhichalsoaddstothecostsand various environmental factors. As per the Greenpeace report for producing two billion jeans pants every year, it takes a total of 1.7 million tons of chemicals and water consump on can reach as much as 7,000 liters per one pair [17]. Consump on of large quan es of chemicals and freshwater ends up in increased product cost and larger volume of chemically loaded effluents; par cularly high pH and high quan ty of sulfate salts due to sodium dithionite followed by unfixed indigo dye and their byproducts [18]. Considera on all the associated drawbacks for indigo solids fabric manufacturing using tradi onal indigo colora on process, Ultra Rapid Indigo dyeing technology[PG] has been developed. Thus achieving the most required sustainability. In this evolved dyeing method the substan vety of the leuco indigo is exponen ally increased by maintaining the required physico-chemical parameters in an inert atmosphere. This enables the super substan ve leuco indigo to in- stantaneously penetrate with a decreasing gradient in the core of the fiber. Thus giving darker shades at minimalcontact me.Thisevolvedtechnologyhasbeen successfully tested on co on, bast and regenerated yarns with certain precondi ons. Here near zero water indigo dyeing has been made possible using the Ultra-Rapid indigo dyeing technology [PG] ul mately achieving the most sustainable indigo dyeing. Linen yarn is very difficult to run on conven onal indigo dyeing machines and dyed linen yarn is difficult to

- 40. OCTOBER 2023 38 www.textilevaluechain.in Technical Article weave due to many known reasons. Grey or RFD linen fabric of any gsm, construc on, weave and type can be easily woven in fabric form. These linen fabrics can be easily dyed from few meters to thousands of meters in this con nuous Ultra Rapid Indigo fabric dyeing machine. 2 Materials and Ultra Rapid dyeing Method[PG] 2.1: Linen Fabric. 2.2 Chemicals –Ready premix of liquid indigo solu on. 2.3: Ultra rapid Indigo dyeing[PG] method 2.3.1: Ready premix of Liquid Indigo Dye solu on – Here ready premix of liquid indigo solu on is taken of a known concentra on for dyeing 3.5% shade, this solu on is a mix of liquid indigo, dispersant, ecofriendly reducing aid and a catalyst. This solu on is made in an inert atmosphere of 99.9% nitrogen at a predetermined pressure. 2.3.2: Prepara on of the fabric dyeing assembly – Horizontal padding assembly modified as per the Ultra rapid dyeing principle is used. This assembly ensures contact me of the dye liquor with the fabric in milli seconds with a dye liquor capacity of 1.8 liters only. This assembly or the modified nip trough is equipped with an inert atmosphere of nitrogen. Here the desired temperature, level and ultrasonic ac vity is maintained throughout the dyeing process. 2.3.3: The prepared dyeing solu on is dosed in the indigenously designed dyeing apparatus at a specified me, temperature, pressure and ultrasonic ac vity making the leuco dye highly substan ve. The fabric is traversed through the guides, expander rolls, crease remover rolls and selvedge guide into the nip trough encapsula on over the horizontal padding mangle. The fabric is dyed at the speed of 30 mpm. Thus facilita ng the super substan ve leuco indigo to instantaneously penetrate with a decreasing gradient in the core of the fabric. Followed by superficial extrac on by squeezing at 3 bar pressure, drying and batching. In this CLP (i.e. Closed Loop Porcess) color pick up was 1 liters per kg of fabric is achieved which is eventually evaporated in the process. Thus there is as such no genera on of any trade effluent during the ultra-rapid indigo dyeing [PG] process. Here the dyed fabric can be dried using both electric hea ng chambers or gas fired chambers thus ensuring near zero emissions. This can be further extended to carbon neutral system by using solar and wind energy. 2.3.4: This indigo dyed fabric is further neutralized and dye-fixed over the stenter for retaining the darker shade depth. If washdown shades are desired then the fabric can be washed in an con nuous soaper followed by dyefixing on stenter. 2.3.5: This dyed fabric is further finished for the desirable shrinkage and so ness. 2.3.6: Using the dyed fabric leg mocks and garments were manufacture for wash down analysis shown in pictures 1 2. Picture 1. Dyed Linen fabric leg mock Picture 2. Washed Linen leg mocks

- 41. www.textilevaluechain.in 39 OCTOBER 2023 2.4: Evalua on of Dyed Material 2.4.1: Colour measurement - Colour strength of the dyed fabrics was es mated from the reflectance measurements using spectrophotometer at standard illuminate D65 (LAV/Spec. Incl., d/8, D65/10°). The colour was evaluated by CIELAB colour values (L*a*b*) and colour strength (K/S) was calculated using the Kubelka–Munk equa on: K/S = (1-R2 )/R WhereRisthereflectanceofthefibreatthewavelength of maximum absorp on (630 nm). 2.4.2: Determina on perspira on fastness using Standard tes ng method AATCC15. 2.4.3: Determina on of washing fastness using Standard tes ng method AATCC 61 2A. 2.4.4: Determina on of rubbing fastness using Standard tes ng method AATCC8. 2.4.5: Microscopic analysis between dyed and wash samples. 3. Results and Discussion The plo ng on the Chart 1 shows the K/s values vs. the wavelength here the graph profile is similar for all the samples. Chart 1. K/S vs wave length The color values and color strength results obtained are presented in Chart 2. Overall figures of L*, a*, b*, C* and h values are consistent with minimal varia ons. K/s (630nm) values of all the samples are comparable with the standard 9347T and show less varia ons. The appearance strength is comparable with the standard. The dE* figures shows that the varia ons are well below the tolerable range. Chart 2. Color values and strength of indigo dyed linen fabric samples. Name Light source / angle L* a* b* C* h K/S (630nm) Appearance Strength dE*ab 9347 T D65/10° 28.76 -0.20 -16.55 16.55 269.32 13.72 0 9348 D65/10° 28.44 -0.50 -16.09 16.10 268.21 13.99 102.% 0.64 93472 D65/10° 28.89 -0.80 -16.00 16.02 267.15 13.51 99.% 0.82 93461 D65/10° 28.65 -0.66 -15.89 15.91 267.62 13.72 101.% 0.81 9345 D65/10° 28.89 -0.68 -16.24 16.26 267.62 13.68 100.% 0.58 9344 D65/10° 28.58 -0.34 -15.92 15.93 268.79 13.39 101.% 0.67 93481 D65/10° 28.58 -0.34 -15.92 15.92 268.78 13.39 101.% 0.67 9350 D65/10° 28.39 -0.73 -15.92 15.93 267.38 14.12 103.% 0.9 93501 D65/10° 28.90 -0.68 -16.23 16.24 267.60 13.64 100.% 0.59 9351 D65/10° 28.66 -0.42 -16.27 16.27 268.52 13.59 101.% 0.37 93511 D65/10° 28.58 -0.60 -16.29 16.30 267.90 13.99 102.% 0.51 9353 D65/10° 28.88 -0.63 -16.18 16.19 267.76 13.64 100.% 0.58 93531 D65/10° 28.80 -0.38 -16.22 16.22 268.66 13.34 99.% 0.38

- 42. OCTOBER 2023 40 www.textilevaluechain.in Technical Article The fastness proper es for the dyed samples are presented in Chart 3. When comparing the fastness proper es of water fastness and perspira on fastness are good. The rub fastness values are somewhat manageable considering the solid indigo dyed fabric. The wash fastness to color change and staining are below the mark and thus requires to be strengthened in the further processing of these indigo dyed fabrics. Chart 3. Color fastness of indigo dyed linen fabric samples. Sam- ple Water Fastness Washing fastness Wet Rubbing Dry Rub- bing Perspira on Fastness Colour Change Staining CA CO PA PES PAN WO Acid Alkali 9347 T 4 2 2 2 2 2.5 3 2.5 2 3 4 4 9348 4 2 2 3 2 3 3.5 2.5 1.5 3 4 5 93461 4 2.5 3 3 2 2.5 3 3 2 3 4 4 9345 4 2 2 2.5 3 3 3 2.5 2 4 4.5 4 9344 4.5 2.5 2.5 3 3 3 3 2 2 3 4 4 9350 4 2 3 3 2 3 3 2 1.5 3 4 4.5 9351 4.5 2 2 2 2 2.5 4 2.5 2 3 5 4 9353 4.5 2.5 3 3 2.5 2.5 3 2.5 2 3 4 4.5 93531 4 2.5 2.5 3 2 3 3 3 1.5 3 4 4 From the picture 2 represen ng the washed samples we can see the signatory puckering effect in the seams which is largely associated with the indigo fading effect. Observa ons about the microscopic analysis of indigo-dyed fabric picture 3 and its washing in picture 4, behavior is largely accurate and aligns with the well-known phenomenon of “ring dyeing” associated with tradi onal indigo dyeing process. In tradi onal indigo dyeing, the dye molecules do not penetrate deep into the fiber but instead adhere to the outer layers of the fabric. This is due to the nature of indigo dye. The “ring dyeing effect” is a term used to describe the uneven distribu on of indigo dye on the fabric surface. It creates a characteris c appearance where the outermost layers of fibers, those most exposed to the dye bath, take on a darker color compared to the inner layers. This effect is visible under a microscope, where the concentra on of dye on the fabric’s surface can be observed. A erwashing,theindigodye’slackofdeeppenetra on becomes apparent as the surface dye begins to fade or wear off. This fading a hallmark of indigo-dyed tex les and contributes to the unique and desirable pa na associated with indigo-dyed denim. It’s an excellent illustra on of how the structure of the dye molecules and their interac on with the tex le fibers result in the dis nct appearance and behavior of indigo-dyed tex les. Picture 3. Indigo Dyed Linen fabric microscopic view Picture 4. Washed Indigo dyed linen fabric microscopic view

- 45. www.textilevaluechain.in 43 OCTOBER 2023 4. Conclusion The Ultra Rapid Dyeing Technology [PG] represents an innova ve approach that combines various emerging technologies to achieve efficient dye applica on using the pad dry bake method. This process u lizes thermo sonic energy to significantly enhance dye substan vity, crea ng a conducive environment for dye molecules to penetrate fabric fibres. Mechanical padding is then employed to ensure rapid dye fixa on on the fabric within an inert atmosphere. This method consistently delivers results for both short and long produc on runs. Further microscopic analysis reveal the presence of surface-dyed indigo and that washing leads to the fading of this surface dye is consistent with the behavior of indigo-dyed fabrics and the ring dyeing phenomenon. The applica on of this technology has enabled the successful dyeing of fabric in indigo color, revolu- onizing the tradi onal indigo dyeing process. This advancement promotes sustainability by reducing water consump on, energy usage, and the need for harmful chemicals. A typical indigo yarn dyeing process consumes around 150 litres of water per kilogram of fabric [17], while the Ultra Rapid Indigo Dyeing technology achieves this with just 1.0 litre of water per kilogram of fabric. This remarkable reduc on in water usage represents approximately 1% of the water required by conven onal methods. One of the significant advantages of this technology is its minimal capacity of standing dye liquor, resul ng in negligibleeffluentgenera on.Thisnotonlycontributes to environmental conserva on but also leads to cost savings in machinery, wastewater treatment, energy, and raw materials and chemicals used in the dyeing process. Consequently, this technology reduces the overall investment required. The applica on of indigo dye in fabric dyeing has expanded the possibili es across various fabric types, including different construc ons, weaves, GSM (grams per square meter), fiber blends, yarn blends, and even yarn-dyed fabrics. This departure from the no on that indigo is solely for yarn dyeing has paved the way for versa le and crea ve applica ons. With an increasing focus on environmental awareness, sustainability, and ethical sourcing, contemporary customers are more conscious of the environmental impact of their choices. Retailers are responding by seeking sustainable produc on methods. The eco-friendly nature of the ultra-rapid indigo dyeing processalignswellwiththistrend,makingitapromising concept for fostering a sustainable dyeing business. References [1] W. Schramm and J. Jantschgi, “Compara ve assessment of tex le dyeing technologies from a preven ve environmental protec on point of view,” Colora on Technology, vol. 115, no. 4, pp. 130-135, 1999. [2] E. Commission, “Reference Document on Best Available Techniques for the Tex les Industry,” European Integrated Pollu on Preven on and Control Bureau, Ins tute for Prospec ve Technological Studies, Spain, vol. BREF TXT 07, 2003. [3] D. Phillips, “Environmentally friendly produc ve and reliable: priori es for co on dyes and dyeing processes,” Journal of the Society of Dyers and Colourists, vol.112, no. 7-8, pp. 183-186, 1996. [4] h ps://en.wikipedia.org/wiki/Sustainability. [5] E. Oner, I. Baser, and K. Acar, “Use of ultrasonic energy in reac ve dyeing of cellulosic fabrics,” Journal of the Society of Dyers Colourists, vol. 111, no. 9, pp.279-281, 1995. [6] Z. Khatri, M. H. Memon, A. Khatri, and A. Tanwari, “Cold Pad-Batch dyeing method for co on fabric dyeing with reac ve dyes using ultrasonic energy,” Ultrasonics Sonochemistry, vol. 18, no. 6, pp. 1301-1307, 2011. [7] K. A. Thakore, “Ultrasound treatment in exhaust and pad-batch dyeing,” AATCC Review, vol. 11, no. 4, pp. 66-74, 2011. [8] Egyp an Pharmaceu cal Journal, Vol. 16 No. 3, September-December 2017. [9] Dyes and Pigments 134 (2016) 442-447. [10] M. Božič and V. Kokol, “Ecological alterna ves to the reduc on and oxida on processes in dyeing with vat and sulphur dyes,” Dyes and Pigments, vol. 76, no. 2, pp. 299-309, 2008. [11] N. Lei, D. Gong, X. Ling, and Y. Shi, “Researches on microwave dyeing co on fabrics,” vol. 627, pp. 343-347, 2013. [12] M. R. Badrossamay and S. H. Amirshahi, “Effect of microwave hea ng on dyeing of co on fabrics,” pp. 414-416, 2001. [13] A. Schmidt, E. Bach, and E. Schollmeyer, “The dyeing of natural fibres with reac ve disperse dyes in supercri cal carbon dioxide,” Dyes and Pigments, vol. 56, no. 1, pp. 27-35, 2003. [14] M. V. Fernandez Cid, J. van Spronsen, M. van der Kraan, W. J. T. Veugelers, G. F. Woerlee, and G. J. Witkamp, “A significant approach to dye co on in supercri cal carbon dioxide with fluorotriazine reac ve dyes,” The Journal of Supercri cal Fluids, vol. 40, no. 3, pp. 477-484, 2007. [15] V. A. Shenai, Chemistry of Dyes and Principles of Dyeing, Third. Mumbai: Sevak Publica ons, 1997. [16] E. Csanák, “Denim Fi ng Finishing : Challenges on High-Quality,” in Interna onal Joint Conference on Environmental and Light Industry Technologies, 2015, no. November, p. 10. [17] B. Jiby., “The Indian Denim Industry In a Market Driven Environment,” Int. J. Adv. Res., vol. 5, no. 6, pp. 2088–2095, Jun. 2017. [18] S. Meraj, A. Qayoom, and A. S. N., “Effec ve Process Op miza on of Indigo Rope Dyeing : A Case Study,” J. New Technol. Mater., vol. 6, no. 2, pp. 33–37, 2016.

- 47. www.textilevaluechain.in 45 OCTOBER 2023 ww www. w.te tex xtilev ev v valuecha ain. .i in 4 45 5 5 5 5 5 5 5 5 5 5 5 OC C C C C C C C C C C C C C C C C C C CT T T T T TO TO T T BE ER 20 2023

- 48. OCTOBER 2023 46 www.textilevaluechain.in Sustainable Fiber Birla Cellulose, the pioneering pulp and fibre business of the Aditya Birla Group, has once again redefined the world of sustainable fashion by introducing its latest crea on–Birla EcoSo . This revolu onary variant, bamboo viscose fibre, is set to transform how we perceive fashion, blending style seamlessly with environmental consciousness. The story behind Birla EcoSo is one of dedica on to quality, sustainability, and the pursuit of perfec on. With a deep-rooted respect for the environment and a vision for a more sustainable future, Birla Cellulose embarked on a journey to harness the untapped poten alofbamboointhe world of tex les. Result? The crea on of Birla EcoSo , an innova ve bamboo rayon fabric, epitomizes the seamless fusionofnature’swonders and human ingenuity. Derived from lush, sustainably managed bamboo forests and for fied with FSC cer fica on, Birla EcoSo blends responsibility with innova on, preserving nature’s rhythm while cra ing a fabric that caters to modern-day demands. One of the defining features of Birla EcoSo is its excep onal breathability and moisture management, which will undoubtedly redefine comfort in the fashion world. The resul ng fabric boasts unparalleled comfort and a velvety drape, ensuring that every piece created with Birla EcoSo resonates with luxury and elegance. And that’s not even the best part! What dis nguishes Birla EcoSo from other fabrics is the molecular tracer technology. Each Birla EcoSo crea on comes with a molecular tracer transac on cer ficate, assuring consumers and trust they deserve. This intelligent addi on enhances the fabric’s authen city and reflects the company’s unwavering commitment to transparency. Mr. ManMohan Singh, Chief Marke ng Officer at Birla Cellulose, said, “It’s a proud moment for Birla Cellulose to introduce a made-in-India bamboo variant of viscose, Birla EcoSo . Birla Cellulose is commi ed to providing our customers with the highest quality bamboo variant viscose in India and worldwide.” With its blend of luxury, comfort, and sustainability, Bamboo viscose fabric is more than just a fabric. It’s an insight into the poten al of responsible fashion. By introducing this bamboo viscose fabric, Birla Cellulose redefines what fashion can be and charts a path towards a more harmonious coexistence with our planet. BirlaCellulose’sdedica on to sustainable prac ces extendsfarbeyondthecrea onofBirlaEcoSo .Withan impressivetrackrecordofenvironmentalresponsibility, Birla Cellulose operates 12 manufacturing sites that employ closed-loop technologies, leveraging recycled materials and enhanced resource conserva on. Their fiber offerings, including Livaeco viscose, Livaeco Modal, Excel™ (lyocell), and Spunshades™ Eco-Enhanced, showcase their dedica on to delivering performance and sustainability. This commitment to sustainability has earned Birla Cellulose recogni on, topping the Hot Bu on Ranking andreceivingthepres gious‘darkgreenshirt’accolade from the Canopy Planet Society. Empowering Style With Sustainability: Birla Cellulose Expands Portfolio With Innovative Bamboo Rayon Fabric

- 51. www.textilevaluechain.in 49 OCTOBER 2023 he company aims to diversify its product offerings further into the weaving and garment sectors. They boast world-class equipment from Uster Technologies including a high-volume instrument tes ng machine for raw co on and state- of-the-art machinery for quality checks on co on yarns. In an industry characterized by both organized and unorganized players, they value buyers who operate in a streamlined and organized manner. From deal nego a ons to execu on and post-sales processes like transporta on, they seek buyers who priori ze a structured approach. Digitaliza on is another key criterion, as it’s considered essen al for staying compe ve in today’s business landscape. Amid these challenges, Shivkrupa Cotspin found a reliable partner in The Yarn Bazaar. In a conversa on, Aditya Agarwal shared their The Yarn Bazaar’s Role in Shivkrupa Cotspin’s Market Expansion In the world of tex le manufacturing, where quality and reliability are paramount, Shivkrupa Cotspin has emerged as a noteworthy player. This family-owned business, deeply rooted in the co on ginning and pressing industry for over 25 years, has recently made significant strides in co on yarn manufacturing. Their journey is marked by a commitment to excellence and a forward-looking approach. T Interview

- 52. OCTOBER 2023 50 www.textilevaluechain.in Interview successful collabora on journey with The Yarn Bazaar. Ini ally focused on the Malegaon market, Shivkrupa Cotspin aimed to expand into Ichalkaranji, and TYB played a crucial role in this expansion. TYB introduced Shivkrupa Cotspin’s combed weaving counts to the Ichalkaranji market, a significant milestone. However, some poten al buyers hesitated due to unfamiliarity with the yarn quality. TYB stepped in, helping in the yarn sales with 100% advance payment and building trust in the product’s quality. They also assisted in logis cs management, a cri cal but o en overlooked aspect. “What truly sets TYB apart is their unwavering commitment to their partners. Unlike many traders who tend to disengage a er nego a ons, TYB remained ac vely engaged throughout the en re process, from start to finish. They provided con nuous updates on each development, extending their support beyond the deal-making stage, and ensuring seamless progression un l the payment and delivery were completed” quoted Mr. Aditya Agarwal. For Shivkrupa Cotspin, this partnership with TYB transcended a typical business transac on; it became a source of trust, reliability, and peace of mind throughout their journey. Interview Tell us about your journey with Shivkrupa Cotspin? We have had a family business we are in cotton ginning and pressing for the last 25 years so just immediately after completing my education in Pune I came back and joined my family business of jining and pressing. looking good and extensive experience incottonginningandspinningwearenowintocotton yarn. So in 2017, we incorporated our company, and in 2019 we started with the commercial operations. Since July 2019 we have been manufacturing cotton yarn, the unit is 14892, and we have already completed four years of operations. in these 4 years, we could see all the phases in our business. like in the COVID period, post covid. being a beginner in the industry was somewhat challenging. We enjoyed it and now we are planning for the expansion of the 21888 spindle. so that expansion is already going on the machinery process so we are expecting our production by December this year for the new unit. Other than the expansion what are the things you’re looking forward to for the next year? Initially, we had our vision from farm to fiber. We were in cotton ginning and pressing Rather we are very close to farmers. After having the vision of a farm to fibre we look forward to fibre-to-Fashion. it’s too early like we are in spinning only but after this expansion, we are planning for some more of the forward integrations going in the weaving and garmenting sector. What are the criteria you have while choosing a yarn buyer for your business? If we see there are many unorganized players in the industry but our business is under very unorganized things so if we get some buyer or some purchaser who is working in a very channelized method or completely organized way it will help a lot. it starts from the deals to the execution phase. it may be the transportation, contract, or some issues which come after sales. thankfully we have not faced any customercomplaintstodatebutifmyyarnpurchaser likes having all the things streamlined or proper methodology is fixed. and if everything is getting worked in a properly organized manner. It helps a lot. One most important things is Digitalisation. There should be complete digitalization. It’s the need of the hour. Most businesses are adopting it but still, some things are not under data analyzation thing and those should come in. What are the biggest pain points and challenges you face while finding these suppliers? we always believe in quality over quantity even if I talk about our gaining business. though we can manufacture more than 50000 bales per annum we manufacture only 9000 to 10000 bales, not more than that. it’s not because cotton is not available but it is the case that quality cotton is available in little quantity. we take quality very seriously and it is the reason we keep very stringent quality checks and we follow proper SOP for all the quality parameters. Moreover, the issue we face is skilled manpower. Many times even if we have instructed people to do things in a particular manner they might miss some things. They might miss some points. Then the pain part comes in, because even if you’ve kept everythingproperlyandyou’veinstructedeverything

- 53. www.textilevaluechain.in 51 OCTOBER 2023 properly if they are not meeting your needs then it disturbs the thing. The important to do things in a particular manner something there might be some points everything properly everything HowdidTheYarnBazaarmethosecriteria?Andatthat me, what were the problems you were facing, and did The Yarn Bazaar help you solve those problems? Iwouldliketomakeabigcomment.Myyarnwasfirst introduced in the Ichalkaranji market by The Yarn Bazaar. I was already having a good market share. I was aggressively working in the Malegaon market. initially, when I started with the carded counts I was only focusing on the Malegoan market. Though I was looking for some good suppliers who could help to cater in Ichalkaranji at that time The Yarn Bazaar came in and Mr Vishal Darak who was in the initial phaseofthecompany.sohehelpedmealotandwith TYB we started our journey in Ichalkaranji market for 30s combed weaving. So my combed weaving count in the domestic market was first introduced by TYB. In the Ichalkaranji market, some buyers were not ready to buy on the advance payment terms because they were not aware of the supreme quality of yarns that we were manufacturing. so TYB helped me there also. They purchased each slot from the advance payment terms. also supported me in arranging the vehicles. Many times buyers just book the orders and at the time of lifting, they just put it on suppliers to arrange and manage the logistics. If the mill is unable to arrange for the logistics it delays the lifting and as a result the payment also gets delayed. But in this case, TYB helped a lot. They also arranged the vehicle on time. Many traders in the industry put effort only till the bargaining, but till the execution of the order TYB supports us as a Miller I feel relieved from that part. Expansion For quality things, as we all are aware, we see, that the world’s best lab is from Uster Technologies, Switzerland if we are targeting quality consumers to sell quality products at a premium rate we have we have installed the labs from Uster only. so right now I am having the HVI1000 from Uster for checking of raw material or cotton bales. And even for cotton yarn, I have having latest UT6 machine from Uster. so definitely it; ‘s helping us a lot in a lot of processes. Moreover, if we see this HVI1000 for raw cotton, rather than for raw materials like bales and UT6 for cotton yarn, one thing missing in my mill was the machine that checks the material during the process. we have machines each for raw materials and finished goods. but there was nothing that could check the quality flaws in the process. So we have also ordered the Uster AFIS which will be delivered next month. It will also strengthen our quality supply part. SUBSCRIPTION FORM Name Email Id Mobile Number Landline / Alternate Number Address Company Name Designation Payment Method Print 1 year 12 issues Rs. 800/- Digital Rs. 500/- Print 2 years 24 issues Rs. 1500/- Digital Rs. 1000/- TEXTILE VALUE CHAIN 504, Suchita Business Park, Pantnagar, Ghatkopar (East), Mumbai - 400075, Maharashtra, INDIA. website : www.textilevaluechain.in, email : sales@textilevaluechain.com, Call/ Whats App : +91 9167986305

- 56. OCTOBER 2023 54 www.textilevaluechain.in Textile Education Introduc on Tex le is one of the most ancient engineering disciplines [1]. It started alongside the first industrial revolu on (1750–1840) which saw the inven on of the flying shu le loom in 1747 and spinning jenny in 1770. The first co on mill in India was established in 1832 in Kolkata (Fort Gloster Estate). This was followed by another one in Mumbai in 1854. The tex le educa on in India was inherited from the Bri sh with the objec ve to produce qualified manpower to oversee the tex- le manufacturing processes. Therefore, the tex le educa on was process-centric and to a great extent devoid of elementsneeded to nurture crea vity and innova on. In recent years, with the advent of electronically controlled machines and incorpora on of intelligent systems, the role of tex le engi- neers has changed significantly. Emergence of new fibres, novel characterisa on techniques and use of tex le materials in non-apparel applica ons (filters, ropes, geotex les, agro- tex les, bulletproof jackets, etc.) have added further com- plexity to the problem of tex le curriculum design. It is a taddisappoin ng that Rejuvenating the Textile Engineering Education in Indian and South-Asian Universities Abhijit Majumdar Department of Tex le and Fibre Engineering, Indian Ins tute of Technology Delhi, New Delhi 110016, India Abstract: Dinosaurs were massive and powerful. Yet the lack of adaptability led to their ex nc on. Evolu on of engineering to a great extent started with tex les. However,tex le as an academic discipline is s ll nebulous. There aremajor flaws in the structure of the curriculum and serious weakness in the pedagogical approaches. Through this ar -cle, I argue that tex le educa on in South-Asian countries needs major transforma on in terms of principles, content and delivery. With the dynamic environment, we need to make the curriculum relevant and interes ng coupled with the crea on of teachers who can intellectually entertain thestudents. If this course correc on, along with the augmen- ta on in pay structure and nature of job, does not happen, then the tex le educa on may slowly move towards virtualex nc on. Keywords Educa on · Fabric manufacturing · Tex le engineering · Yarn manufacturing · Fibre science · Tex le chemical processing

- 57. www.textilevaluechain.in 55 OCTOBER 2023 tex le curriculum has not received enough a en on from the Indian and South-Asian academia to makeit contemporary. Old-fashioned curriculum and delivery s llrule the roost. The objec ve of this ar cle is to highlightthe deficiencies of tex le curriculum from two perspec ves(intellectual value and employment value) and propose some strategic pathways to overcome thesedeficiencies.Thoughtsexpressed in this ar cle are expected to be useful for the Indian and South-Asian universi es as well for the statutorybodies entrusted with technical educa on. Evolu on of Tex le Educa on Science-driven tex le educa on started in the UK during the first industrial revolu on. The University of Manchester was at the forefront and tex le was one of its original depart-ments when the Mechanics Ins tu on was created in 1824.The‘EngineeringDesign Culture’ in tex les was introducedby Prof. John Hearle, a physicist by training, who had a long career in the University of Manchester. Table 1 shows someof the landmark events that transformed the tex le industry and educa on. Table 1 Major landmarks of tex le engineering innova on Year Event 1914 First patent on air-jet weaving 1922 Rapier loom (Gabler loop transfer) 1926 Publica on of Peirce’s weak-link theory 1937 Publica on of Peirce’s geometry of cloth structure 1941 Discovery of polyester (Terylene) fibre 1946 Publica on of van Wyk’s theory of compression of fibrous materials 1955 Publica on of Leaf and Glaskin’s geometry of a plain kni ed loop 1963 Inven on of Rotor spinning machine 1965 Discovery of Kevlar® fibre 1980s Air-jet spinning 1990s Air-jet weaving with profile reed and relay nozzles However, things started to change dras cally in the 1990s primarily due to economic reasons. When a country shi s from an agriculture-based economy to an industrial economy, it starts with the tex le and clothing industry as it has a low entry barrier and provides jobs to a huge num- ber of unskilled and semi-skilled workers. In the next step, the country moves into steel and chemical industries whichrequire more sophis cated technologies and skills than tex- les. This industrial progression con nues with gradua on to automobile and electronics industries and finally to bio- tech and other high-tech industries. During the 1990s, pro- duc on of commodity tex le and clothing shi ed to Asian countries largely due to the low labour cost and abolishment of Mul -Fibre Agreement. This resulted in gradual closure of tex le industries in the western world including the USAand UK. As a consequence, the tex le programmes of vari- ous universi es in the USA and UK were either closed or merged with either materials science or design as shown in Table 2. In the last few decades, the tex le industry worldwide has gone through many transforma ons changing its focus from low-cost and high-volume produc on (lean) to value-added produc on (agile). The produc on of high-volume commodity tex les is providing spaces to value-added func- onal tex les and clothing. Being the second most pollu ng industry, fulfilment of circularity and sustainable develop- ment goals (SDGs) have become extremely important for thetex le and clothing industry. Therefore, green technologies involving reduced water and energy consump on, energy recovery, recycling, etc., have become crucial for the com- pe veness of tex le industry. Some of the manufacturing process-related skillsets which were useful in the past have become redundant due to the development of automated machines which have eliminated the manual interven ons to a great extent. On the other hand, tex le graduates are supposed to possess some new skill sets to cope with the challenges posed by new tex le manufacturing systems and business models. Tex le Educa on in India It was soon followed by establishment of tex le colleges at Serampore (Government Weaving Ins tute) and Berhampore (Govern- ment Silk Weaving and Dyeing Ins tute) in 1909 and 1927, respec vely. At present, there are around 40 colleges and universi es offering tex le degree programmes in India [2].Tex le undergraduate (UG) degree programmes are offeredin

- 58. OCTOBER 2023 56 www.textilevaluechain.in Textile Education India under various names as given below. o Tex le Technology p Tex le Engineering/ Tex le Plant Engineering q Tex le Cchemistry r Manmade Fibre Technology Table 2 Restructuring of tex le departments in various universi es Old name New name Country School of Tex le and Fibre Engineering, Georgia Tech. University School of Materials Science and Engineering USA College of Tex les, Clemson University Department of Materials Science and Engineering USA Department of Tex les, The University of Manchester Department of Materials UK Department of Tex le Industries, University of Leeds Department of Design UK Department of Tex les and Light Industries, Budapest University Department of Polymer Engineering Hungary s Apparel Engineering/ Apparel Produc on Managementt t Fashion Technology u Carpet and Tex le Technology v Handloom and Tex le Technologyw w Silk Technology x Jute and Fibre Technology Though the total sanc oned intake in the aforesaid pro- grammes is around 3000, over the past few years, there isa dras c reduc on in students’ intake in many tex le ins - tutes across India. Students are op ng for computer science-related programmes and core engineering programmes are languishing behind. A problem o en faced by these tex le departments is that the machines used in the laboratories are of industrial scale, and therefore, they require huge invest- ment, space and running cost. Interes ngly, a large propor- on of these tex le ins tutes are run by the state or central governments. While most of the engineering disciplineshave a meagre 5–6% seats in government colleges, in con- trast,tex lehasahopping share of 42%. The data imply thattex le engineering educa on is not a lucra ve proposi on for the private ins tutes. It also underlines that the input quality of the students, especially in public funded ins tutes,may not be as bad as it is perceived. For example, the closing rank in the year 2021 for one such government college in West Bengal was~9200 and~15,200 for Mechanical Engi- neering and Tex le Technology, respec vely. Considering that around 100 thousand students appeared in the entranceexamina on, tex le a racted students from top 15% percen- le, and therefore, they cannot be considered as bad based on any yards ck (Fig. 1). So, where does the problem lie? Problems of Tex le Educa on There is an inherent percep on in the tex le fraternity thattex le educa on is fundamentally different from other engineering disciplines. This may stem from the fact some of the legacy tex le colleges in India and other South-Asian countries were established standalone and they were not part of mul disciplinary engineering ins tutes. This might have precluded free exchange of knowledge with other engi-neering fields and learning from them. There is no other engineering discipline which offers so many programmes at the UG level like tex le does. Most of the engineering disciplines offer a large number of specialisa ons at the post-graduate (PG) level but s ll have only one or two uni- fied undergraduate programmes. Electrical engineering andCivil engineering are the best examples. IIT Delhi offers sixspecialisa ons at the PG (M.Tech) level while offering onlytwo UG programmes in Electrical Engineering and Electri- cal Engineering Power and Automa on. IIT Delhi and IIT Roorkee offer eight and six PG programmes, respec vely, with only one UG programme in Civil Engineering. UG edu-ca on in engineering should focus on the basics and fun- damentals of the domain without being too specific about par cular products, processes or industries. Therefore, it is important to look at the tex le