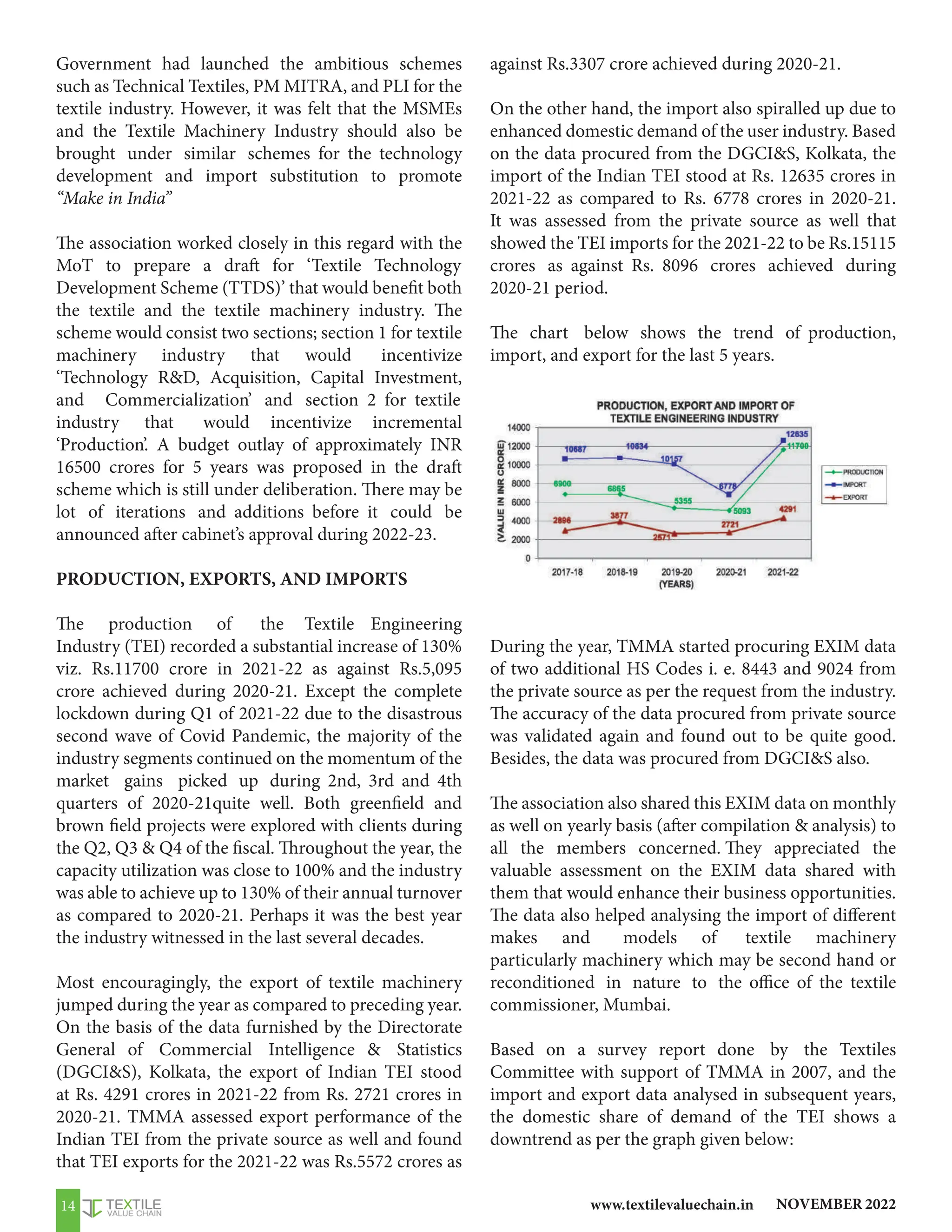

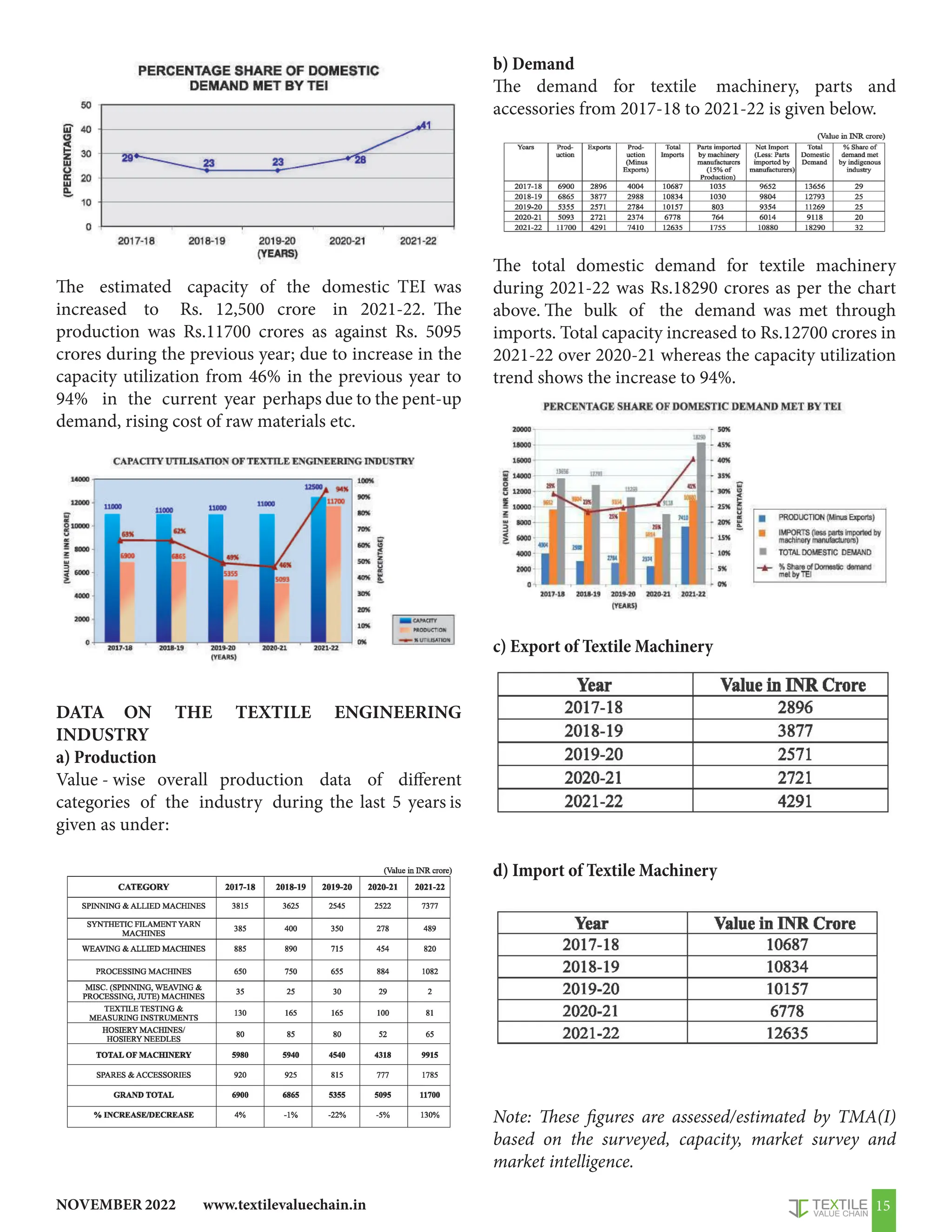

The textile engineering industry in India achieved significant growth in 2021-22, with production increasing 130% to Rs. 11,700 crore compared to Rs. 5,095 crore the previous year. Exports of textile machinery also rose over the previous year, with exports at Rs. 4,291 crore in 2021-22 versus Rs. 2,721 crore in 2020-21. The growth has been driven largely by increased demand and expansion of spinning machinery capacities in India. However, imports also increased substantially over the previous year. For the industry to strengthen further, it will need to absorb more foreign technologies while leveraging domestic expertise. The textile engineering industry has potential to become a major hub for text

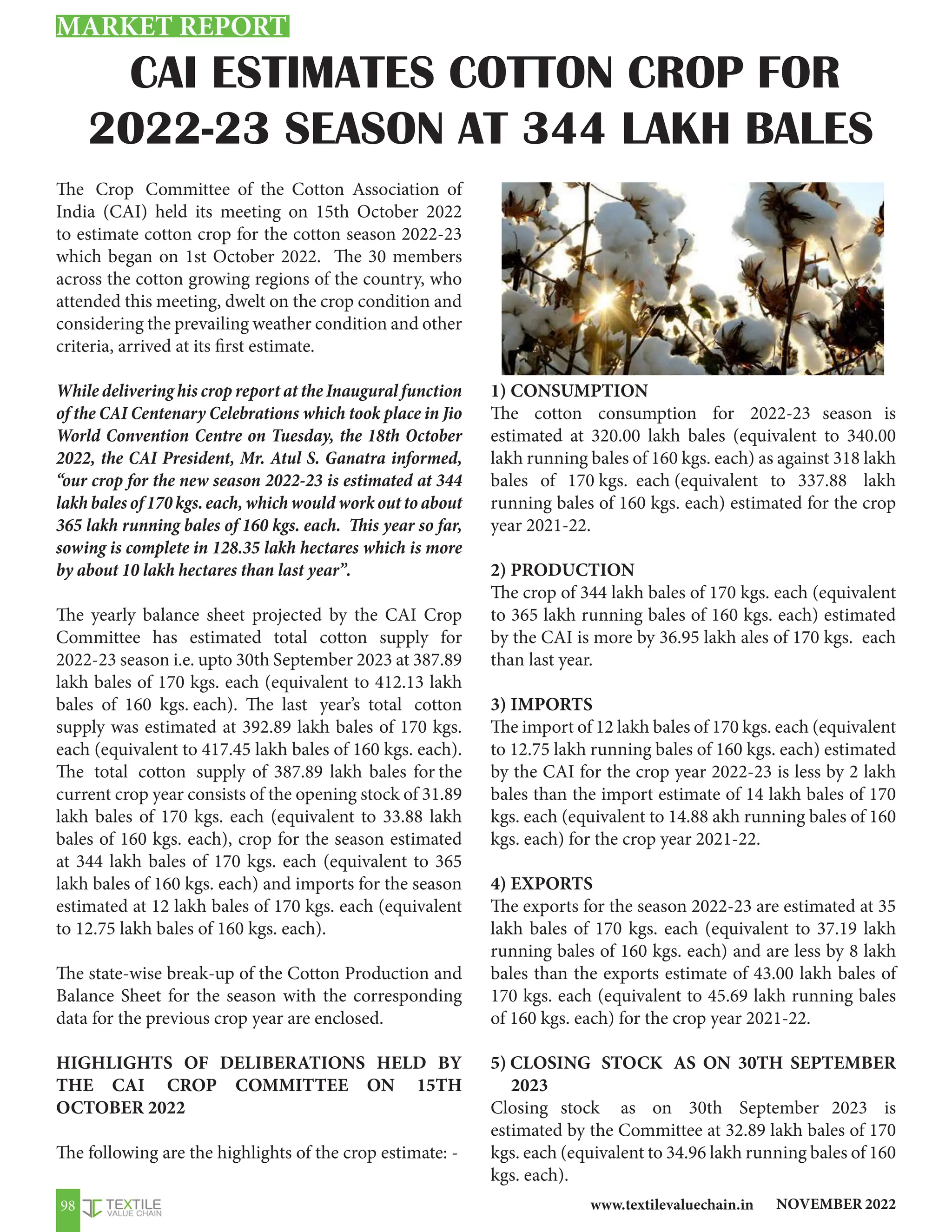

![www.textilevaluechain.in

NOVEMBER 2022 75

Textile Reinforced Concrete Composite

Material Pultrusion Products for

Modular Houses

Abstract

The paper presents the combination of aforesaid latest

technologies that are being implemented for making

road, pedestrian - Bridges for surface transportation

as well as low cost and High strength low weight

modular Housing on commercial scales under

Technical Textiles and Composites application.

Keywords : Textile Reinforced Composites, Pultursion,

Light weight Modular Houses

1. Introduction

A composite material is a combination of a

reinforcement material and a matrix. Reinforcement

forms include fibers, particles, and flakes it is

the main load-bearing component and contribute for

the strength and stiffness of the composite material.

Woven, Knitted or Braided structure are the

reinforcement material in the textile reinforced

composites are [1,2]. Textile reinforcement for

concrete is mesh like structures with fibers made

of alkali resistant glass or carbon. Its casting is easy

as it needs little machinery and manpower. TRC is a

composite material consisting of rich cement enriched

with chemicals, uniformly reinforced with one or

more layers of textiles. The cement absorbs the

compressive load and the textile reinforcement asorbs

the tensile and shear stresses. It differs from

conventional reinforced concrete or pre –stressed

concrete. It has low self weight, non-corrosive

reinforcement and formwork is avoided. Pultrusion

is a cost effective way of making high stiffness hollow

sections of composites. The advantages of pultrued

composite material in applications include their

lightweight, high strength, resistance to corrosion, and

fast, easy installation. These properties make them

competitive with standard bridge materials in

situations where access and construction present

difficulties. Pultruted materials can be designed

to provide a wide range of flexural, impact, tensile and

compressive strengths. They can be formed into any

shape and color can be added to allow the structures

to blend with most landscapes. Composites cost less

than stainless or high carbon alloy steel components

that might be used in highly corrosive environments

[3,4] .

2. Material Methods

2.1 Fabric Construction

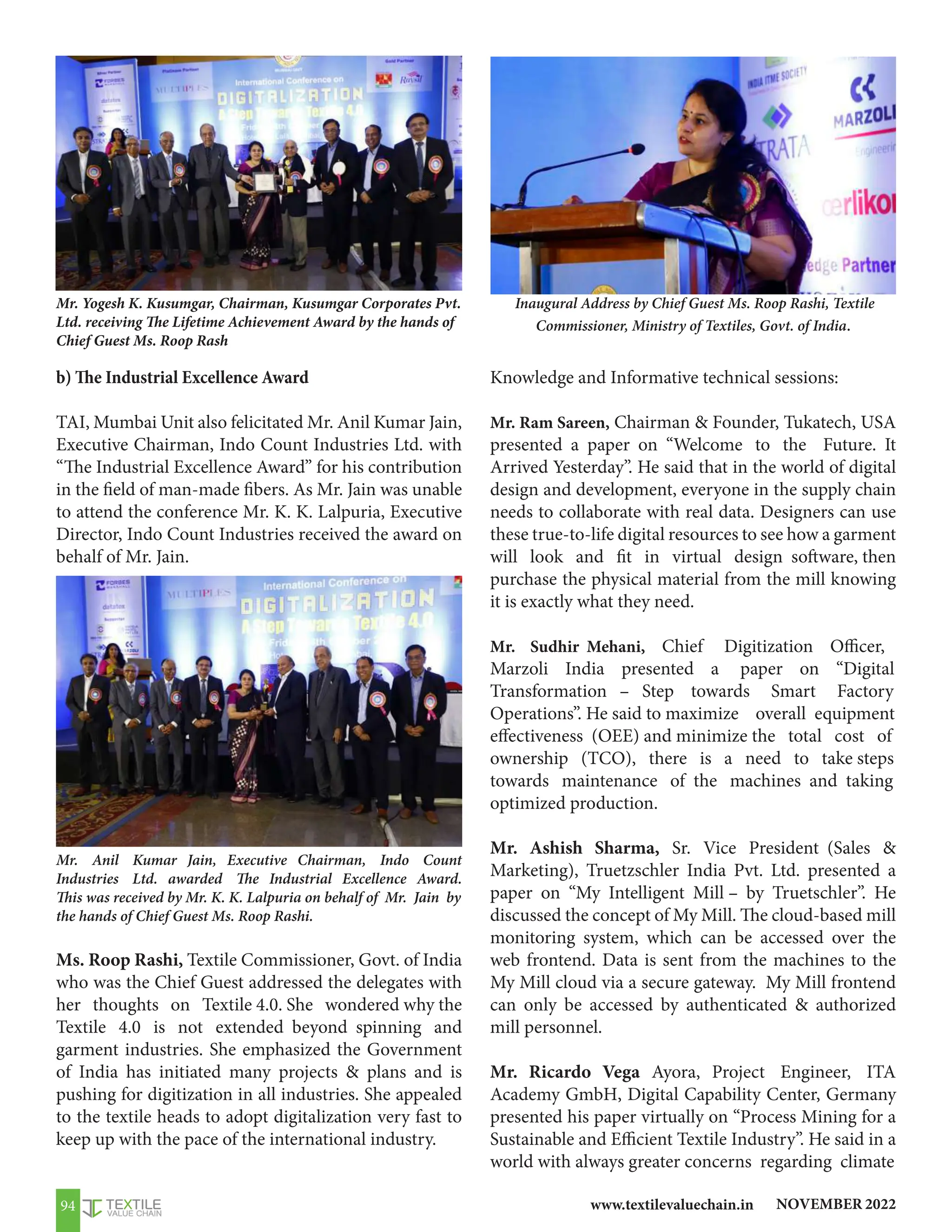

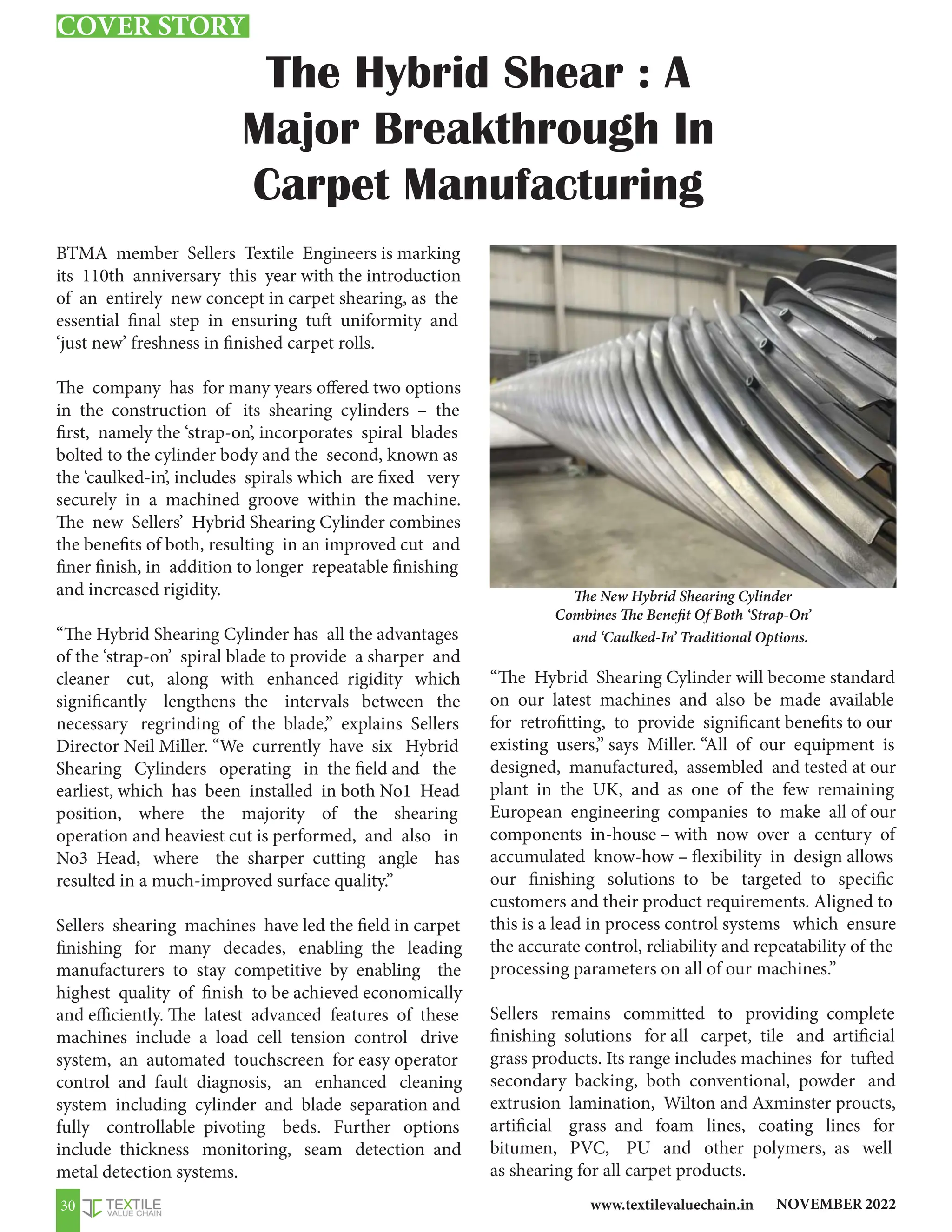

Glass Leno Fabric was developed on Rapier looms

having auxiliary attachment by Glass Roving. The

parameters are as illustrated in the table appended

below:

REVIEW PAPER

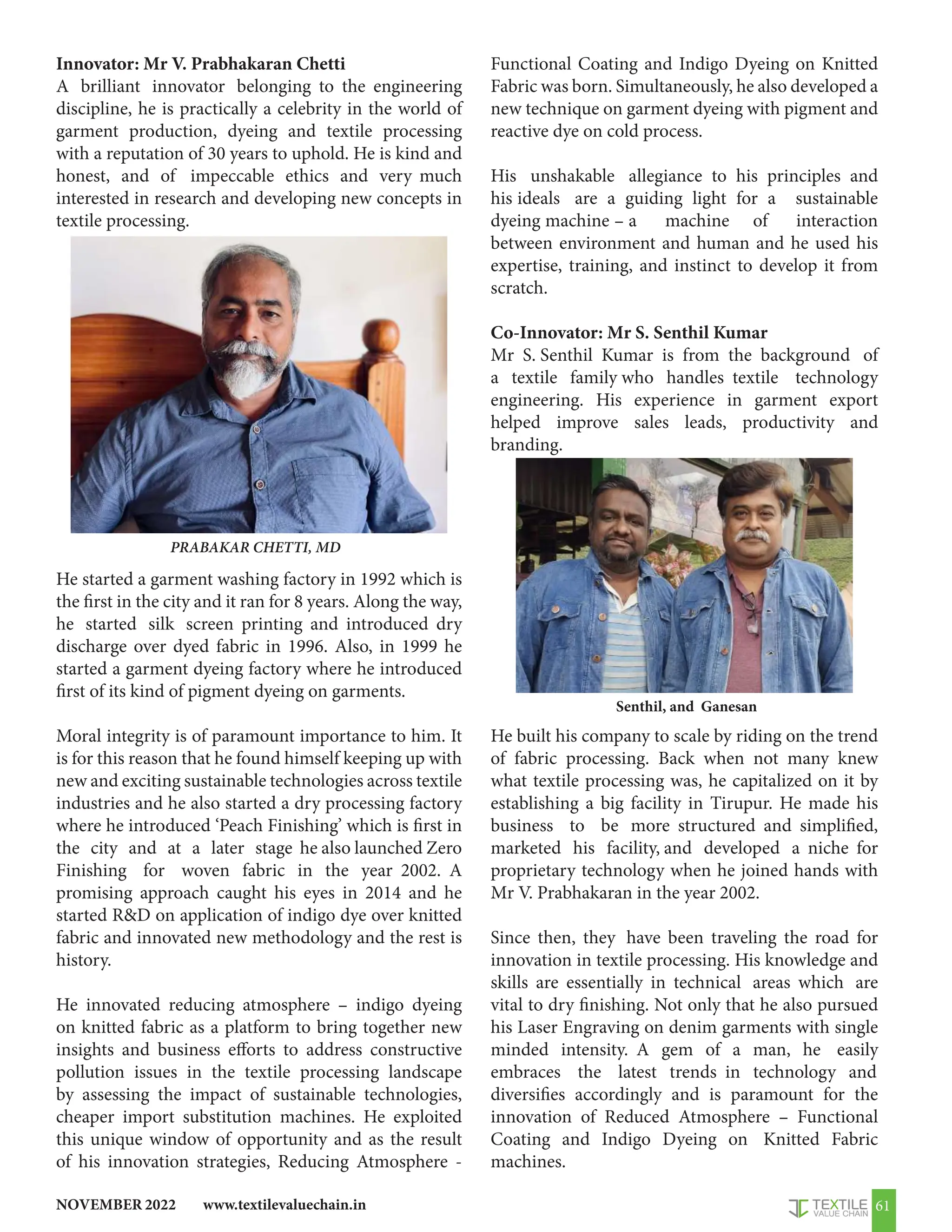

Pradeep Kulshrestha

Plant Head

United Fiber Composites Pvt Ltd

Mayur Basuk Shishir Tyagi

Deputy Director

Wool Research Association

K K Misra

Director (O) C.O.O

Wool Research Association](https://image.slidesharecdn.com/november2022digitalissue-231017112728-e6638550/75/Textile-Value-Chain-Nov-2022-75-2048.jpg)

![NOVEMBER 2022

www.textilevaluechain.in

76

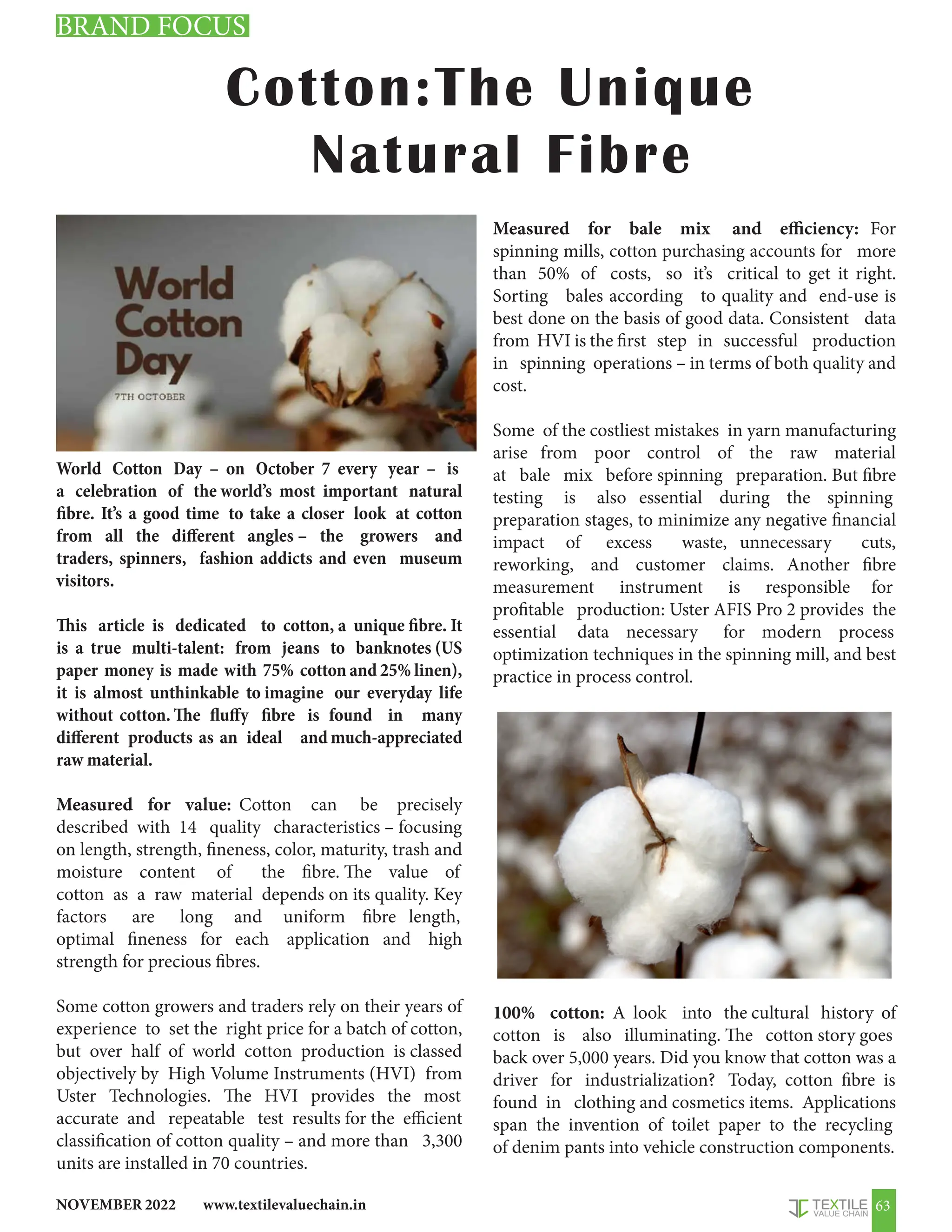

For cost effective Housing Wall can be made from

Glass Leno fabric by joining number of layers with

resin and doors by jute hybrid composites. Installation

of Textile Reinforced Concrete based modular toilet

takes just one day.

Basic Components of Toilets are given below:

• Toilet Pan

• Water Seal

• Superstructure

• Interconnecting pipe work

• Leach pits

• Light points

2.2 Size of the Toilet[5]

• Width : 914 mm

• Breadth: 1219 mm

• Height : Front 2215 mm / Back 1963 mm

Fabric Weaving Of Glass Leno Fabric

Process Flow of TRC For Modular Houses

This will be a U V resistant, Fire resistant,

Maintenance free lifelong Toilet.

For Construction of Modular Houses following

components required:

1. TRC Sheet 10 mm thick

2. Pultruded Square Profile

3. Pultruded L profile

4. Vent assembly

5. JRC Door 2.67 x 6.40 feet

6. Toilet Pan Standard Ceramic

7. Water Seal Standard Ceramic

8. Sock pit Circular Concrete

9. CLC Blocks

10. PCC RCC works

11. PVC albow

12. Cabling and Light point

Misc. Hardware

While Flooring Tiles

Installation

2.3 Work in Progress

TRC and Pultusion are being used for Godowns,

Building etc. There is lot of scope to bring these

composites for Sports like to make Modular Stadium,

Cricket Pitch with anti skid coatings on pitch and tiles

etc.

3. Features of Pultruded Products:

• Lightweight: Pultrusion products are 20 – 25% the

weight of steel and 70% the weight of aluminum.

• High Strength: Stronger than structural steel on

a Kg –for-basis.

• Corrosion Resistant: Pultruded products will

not rot and are impervious to a broad range of

corrosive elements.

• Dimensional Stability: The coefficient of thermal

expansion of pultruded products is slightly less than

steel even less than aluminum.

• Non – Conductive: Glass reinforced pultrusions

have low thermal conductivity so these are electrically

non-conductive.

• Electro-Magnetic Transparency: Pultruded proucts](https://image.slidesharecdn.com/november2022digitalissue-231017112728-e6638550/75/Textile-Value-Chain-Nov-2022-76-2048.jpg)

![www.textilevaluechain.in

NOVEMBER 2022 77

are transparent to radio waves, microwaves, and other

electromagnetic frequencies.

• Parts Consolidation: Custom-designed pultrusions

allow multiple parts to be designed and fabricated

into a single part thus reducing the need to join many

fabricated parts together.

• Low - Temperature Capabilities: Glass - fiber

reinforced pultrusions show significant mechanical

properties at very low temperatures (- 70F). Tensile

strength is greater at -21C while Impact Strength is

greater at +26C.

4. Other Advantages of Pultruded Composites

Pultrusion manufacturing allows for the production

of nearly any constant cross-sectional shape in almost

any size, enabling market penetration in a wide range

of markets. Pultruded products provide benefits to

some sectors that go beyond price competitiveness,

thanks to corollary advantages that typical competitor

materials can’t match.

1. Corrosion resistance: Fiberglass pultruded goods

that resist both acidic and alkaline corrosives

are appropriate for use in outdoor or harsh

settings, making them perfect for use in construction

verticals.

2. Telecoms and wireless industries can benefit from

the capacity of fiberglass pultrusion to be easily

pierced by radio waves for support of two-way radios,

cell phones, WiFi, or Bluetooth connections.

3. Electrical shock is reduced in charged surroundings

because of nonconductive pultruded fiberglass-

handled equipment and fiberglass pultrusion ladders

that provide insulation.

4. Thermal insulation: Fiberglass pultrusion’s reduced

thermal transmittance reduces condensation and

supports feature installations that require thermal

characteristics to be retained through a wall cavity

or on a surface.

Pultruded composite materials are ideal for projects

that require high dimensional stability, ease of

transportation and installation, near tolerance to

specified criteria, and little maintenance over a long

period of time. It’s a long-term, cost-effective solution.

5. Conclusion

Textiles reinforced concrete and Pultrusion product

enables the production of robust, durable, long-lasing,

and lightweight structural profiles and components in

a high-volume, cost-effective manner. Pultruded items

are simple to transport and assemble, and they align

perfectly with global sustainability goals.

Aside from the cost-effectiveness of manufacturing,

transportation, and asset management, one of the

most appealing features of pultruded items is their

long - term viability. Pultruded composites are

exceptionally durable, have a long service life and

low maintenance requirements, and use less energy

throughout a product’s life cycle, after which many can

be recycled. In the face of tariffs and rising shipping

costs, the ability of pultrusion composites to

substitute steel and aluminum is more important than

ever. Composite pultrusion goods account for only 5%

of all reinforced plastics manufactured, while

aluminum extrusion items account for roughly 15% of

all aluminum consumed. This opens the door to

tremendous market growth for pultruded items,

which can help to promote global sustainability.

Acknowledgement

The authors of this article are thankful to the

Management of Wool Research Association United

Fiber Composites Private Limited for their continuous

support, valuable guidance inputs.

Conflict of Interest

Author declares no conflict of interest.

References:

1. B. Kumar, S. Thakur (Eds.) Textiles for Advanced

Applications. London, United Kingdom, IntechOpen, 2017

[Online]. Available from : https://www.intechopen.com/

books/5921 DOI: 10.5772/66015

2. Stepan V. Lomov and Ignaas Verpoest, Encyclopedia of

Aerospace Engineeing in 2010 by John Wiley Sons,

Ltd. DOI:10.1002/9780470686652.eae203

3. Fairuz, A.M., Sapuan, S.M., Zainudin, E.S., Jaafar,

C.N.A. (2015). Pultrusion Process of Natural Fibre-

Reinforced Polymer Composites . In: Salit, M., Jawaid,

M., Yusoff, N., Hoque, M. (eds) Manufacturing of

Natural Fibre Reinforced Polymer Composites. Springer,

Cham. https://doi.org/10.1007/978-3-319-07944-8_11

4. Fairuz, A. M., Sapuan, S. M., Zainudin, E. S. Jaafar, C.

N. (2014). POLYMER COMPOSITE MANUFACTURING

USING A PULTRUSION PROCESS : A REVIEW.

American Journal of Applied Sciences, 11(10), 1798-1810.

https://doi.org/10.3844/ajassp.2014.1798.1810

5. K K Misra Pradeep Kulshrestha, ATIRA TRC Modular

Toilets prepared under Prime Minister Scheme in 2015](https://image.slidesharecdn.com/november2022digitalissue-231017112728-e6638550/75/Textile-Value-Chain-Nov-2022-77-2048.jpg)