Customs duty has been exempted on cotton imports until September 2022 as cotton prices have spiraled out of control in recent months. The cotton textile industry lobbied the government and textiles ministry about the urgent need to remove duty on cotton, which yielded this result. Export of cotton textiles like made-ups, fabrics and yarns have performed well, reaching $14.8 billion for 2021-2022, exceeding targets. However, the cotton crisis poses a threat to the $100 billion textile export target by 2030. The industry may increasingly adopt cotton blends as an alternative to pure cotton.

![26 TVC | APRIL 2022

OVERVIEW OF SMART FIBRES

Sakshi Khool

D.K.T.E’S Textile & Engineering Institute, Ichalkaranji

ABSTRACT

O

ver the past few years, smart fibres have seen tremendous growth, especially in terms of

research funding and development of start-ups. However, succeeding in reaching the con-

sumer market are a very few products. Indeed, one of the main challenges remains the lack

of standardised test methods to evaluate properties and performance of smart fibres. In this review

paper, we will talk about the history, applications, future readiness of smart fibres. Smart textiles

synonymously known as electronic textiles, e-textiles, intelligent textiles, and alike is a class of ma-

terials, where textiles play a vital role but where functionalities from other disciplines are added.

In technical textile area significant progresses have been achieved in last few years. There are many

separate and distinct fields of science and engineering. Considerable movement and convergence

has takes place between these fields of endeavour and results have been astonishing. One of these

results is Smart technology for materials and structures. Smart textiles are one of the exciting new

frontier technologies in engineering and manufacturing. Due advantages in many technologies cou-

pled with advances in textile materials and structures smart fibres are possible. Biotechnology, in-

formation technology, microelectronics, wearable computers, nanotechnology and micro electro-

mechanical machine are included in partial list.

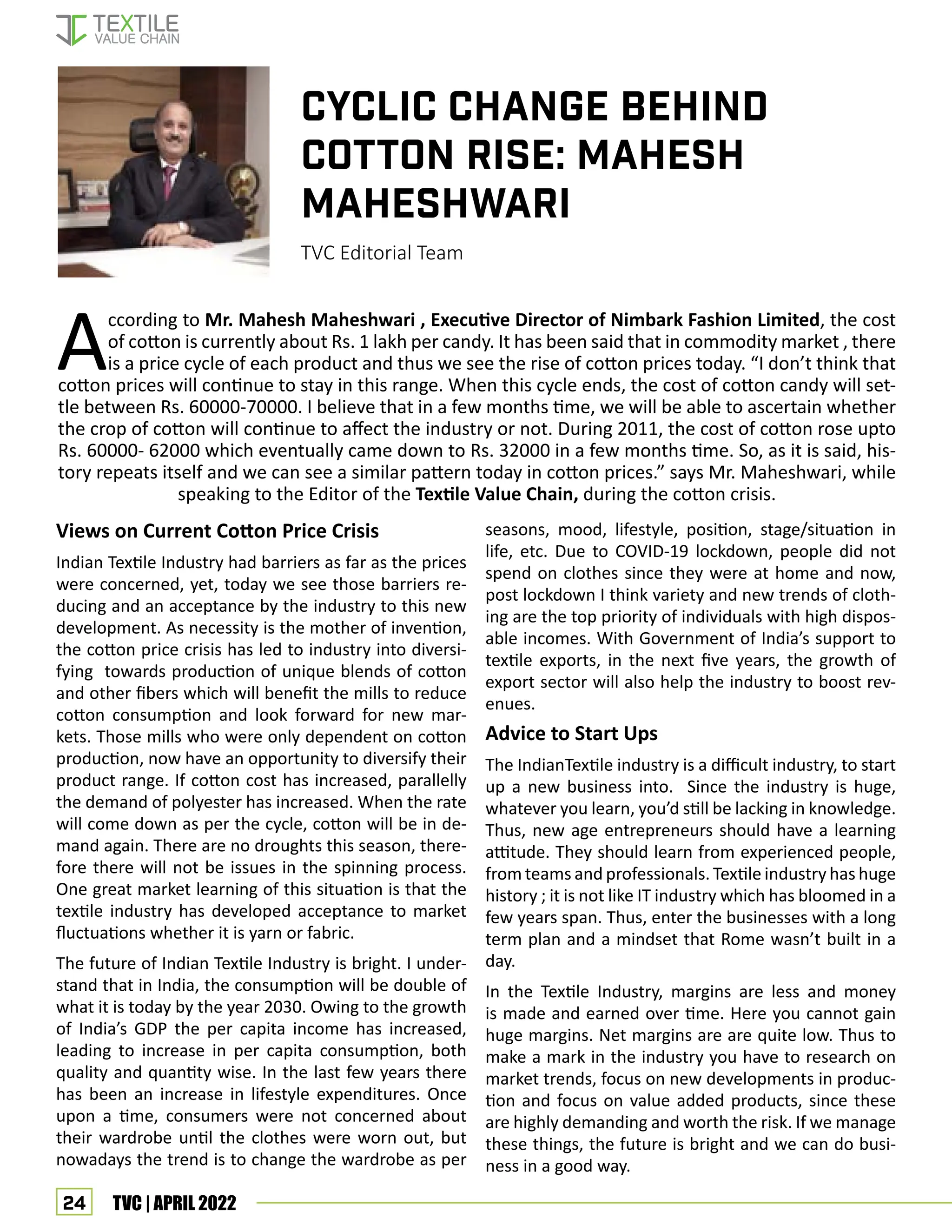

There are three categories in which smart fibres are classified according to their function. Results in

an outcome named as smart textiles are the amalgamation of electronic components and advanced

fibres with manmade textiles extend the field of material science and digital electronics. Often even

before we do the world of fashion knows what we want to wear. Be it the trending hemlines or the

latest accessories, designers around the world predict and often create the future when it comes to

preference. Smart fibres is one thing that has been picked up by a lot of such visionary designers.

Smart fibres are created by modified textile material and miniaturised electronic devices [3].

Definition

Smart fibres and structures can be defined as mate-

rials and structures that can sense and react to envi-

ronmental conditions or stimuli , such as those from

mechanical, thermal, chemical, electrical, magnetic

or other sources. Smart fabrics have been defined as

fabrics which are defined and manufactured to include

technologies that provide to the user increased func-

tionality.

Classification

Fibres can be divided into three materials according to

Smart Fibres](https://image.slidesharecdn.com/tvcapril2022-digital-231017111127-81362480/75/Textile-Value-Chain-April-2022-26-2048.jpg)

![29 TVC | APRIL 2022

of many of the smart technologies becomes achiev-

able. The demand for intelligent materials to develop

electric textiles (e-textiles) and smart apparel is rap-

idly growing up for industrial application such as sen-

sors, electrostatic discharge, steel corrosion, electro-

magnetic interference, shielding, dust free clothing,

monitoring, military application and data transfer in

clothing and all other field [3]. Smart textiles are not

yet ready for the market at large scale, even if smart

textiles are gained a certain level of maturity [5].

Numerous fields of applications including different

trends fields in leisure and sports, some lifesavings in

health care, security and military are new developing

sectors captured by smart fibres. Printed electronics

and energy harvesting technologies are evolving to

meet the demands of new, wearable formats. A lot

of work has been performed to make washable ready

to market smart textile products and wash ability of

smart textile has gained attention now days [5].

Risks involved in using smart fabric

The obvious flip side of using smart fibres is the po-

tential misuse of their capabilities. There is also per-

manent risk of unwanted or unintended body sur-

veillance and the erosion of any remaining sense of

privacy. One of challenges for manufacturing of smart

fabric is achieving seamless and invisible integration of

electronic into fabric. Consequently, researchers need

to provide fibres with desired electronic functionality

without compromising strength, comfort and aesthet-

ic apparel [4].

This technology gives uncomforted sensing of the

wearer, and a major challenge in wearable comput-

ing is how to interconnect these components with

soft textile, and find alternatives to silicon, metal, and

components with difficult to integrate them in textile.

However, the disadvantage of this kind of textile is that

the electric component must be removed before wash-

ing and it cannot be washed with an electric machine,

and so expensive. Both the textile and electronics field

should be compliant with requirement by commercial

smart textiles.

Conclusion

Advanced material, polymers, micro-electronics, com-

puters and information technology are the areas in

which number of researches and development are

conducting. These researches are done to develop and

advancement of new materials and better commu-

nication. Textiles are also changing day by day. There

are lots of developments which include lots of appli-

cations, which make the life easy and healthy. These

products are lifesaving, have protective clothing and

importance for medical and healthcare.

References

1. Ana M Grancaric, I. j. (2018): Conductive Polymers

for Smart Textile Application, Journal of Industrial

Textiles, 612-642.

2. Asis Patnaiik, S. P. (2020): Fibres to Smart Textiles .

CRC Press.

3. Meinander, H. (2014): Smart and Intelligent Textiles

and Fibres, Textiles in Sports , 120-133.

4. S. Lam Po Tang, G. S. (2006): An Overview of Smart

Technologies for Clothing Design and Engineering.

5. International Journal of Clothing Science and Tech-

nology .

6. SU Zaman, X. T. (2018): Market Readiness of Smart

Textile Structures--Reliability and Washability, Material

Science and Engineering.

7. Tang, S. L. (n.d.).

8. Tao, X.-M. (2001): Smart Fibres, Fabrics and Clothing:

Fundamentals and Application, Woodhead Publishing

Limited.

Figure 3: Shape memory fibres](https://image.slidesharecdn.com/tvcapril2022-digital-231017111127-81362480/75/Textile-Value-Chain-April-2022-29-2048.jpg)

![32 TVC | APRIL 2022

creased focus on production of speciality industrial

textiles to be end-used in hi-growth and strategic sec-

tors like the medical textiles, geotechnical textiles,

Aerospace and high-altitude end use where India is

very upbeat, the Indian Defence and civil infrastruc-

ture segments for creating high speed rail network,

new ports, new airports and tunnels and road in high

altitude areas like Kashmir, Ladakh and North East and

also including a string of new highways, etc.

It is now further endorsed that, with double the `de-

mand `growth rate versus the traditional T&C textiles,

the global textile recovery post Covid is to be led by this

new industrial textile sector led by increased availabil-

ity of MMF and synthetic fibres/filaments and growing

industrial use of `speciality` and advanced materials

based on new age fibres like Carbon, Aramide, Ceram-

ic and glass fibre, etc.

INDIA’s 4 Aces, that is 4 most impactful new policies to

help drive the production and use of technical textiles.

The Indian Government is now ready to provide to the

textile industry with its 4 new aces which will be the

key engines of growth for technical textile sector, as

also for pushing India’s global T&C share:

a. The TTDS scheme, with an outlay of Rs. 160,000

million is being launched to replace the 25-year-

old TUF scheme for incentivising the new invest-

ment in textile sector. However, the focus will be

advanced technology and such indigenous ma-

chinery development capabilities.

b. The NTTM scheme [that’s is National Technical

Textiles Mission spearheaded by Textile Ministry/

GOI] scheme, is being continued with a budget of

Rs.10,000 million for the textile industry to venture

into high tech projects in technical textiles arena.

c. The PLI or the production linked scheme is anoth-

er new mega investment scheme to rope in large

corporate and global investors into textile industry.

The PLI scheme will bring in large output produc-

tion and with focus on both MMF fibre use and

manufacturing of technical textiles. Already more

than 70 serious applications and project Intents

have been registered.

d. The launch of the MITRA scheme for development

and operations of large size or mega Textile Parks

to attract large global investment into such world

class `play n plug` manufacturing zones in different

corners of the country and ideally placed close to

the fibre production centres and seaports.

India’s competitive advantages v/s global

competitions

To be able to enhance India’s textile sector size to

US$100 billion plus by 2024, and slot itself with aver-

age of 8% share in global T&C/Tech textiles trade, India

has to emerge as leading China +1 global supplier and

lead from front using the competitive advantages such

as; Availability and access to all key raw materials and

MMF fibres,

2. However, India has to make a strong thrust into de-

velop and production of speciality fibres like carbon

fibres, Aramides, ceramic, glass and other fibres with

special focus on high tech textile end uses that are

based on `sustainability` and green issues.

3. India does have the advantage of competitive wag-

es, and yet needs to scale up for the production and

new markets.

India yet needs to address the deficiency and

critical gaps areas below

India needs to actively pursue free-trade agreements

(FTAs) with major export destinations like the EU ,and

the US to push apparel shipments amid increasing

competition from fast growing rivals like Vietnam,

Bangladesh, Turkey, Egypt, and Cambodia that enjoy

tariff concessions, under liberal duty free trade agree-

ments like GSP+ and TPT 11 and others.

India has traditionally enjoyed a comparative advan-

tage in the cotton-based textile sector, including ap-

parels, and they constitute a major chunk of India’s

export basket. However, India’s shift to MMF textiles

now has to be immediate and a serious call to enhance

its share in the global T&C trade to more than 5% and

also to take its rightful place as China+1.

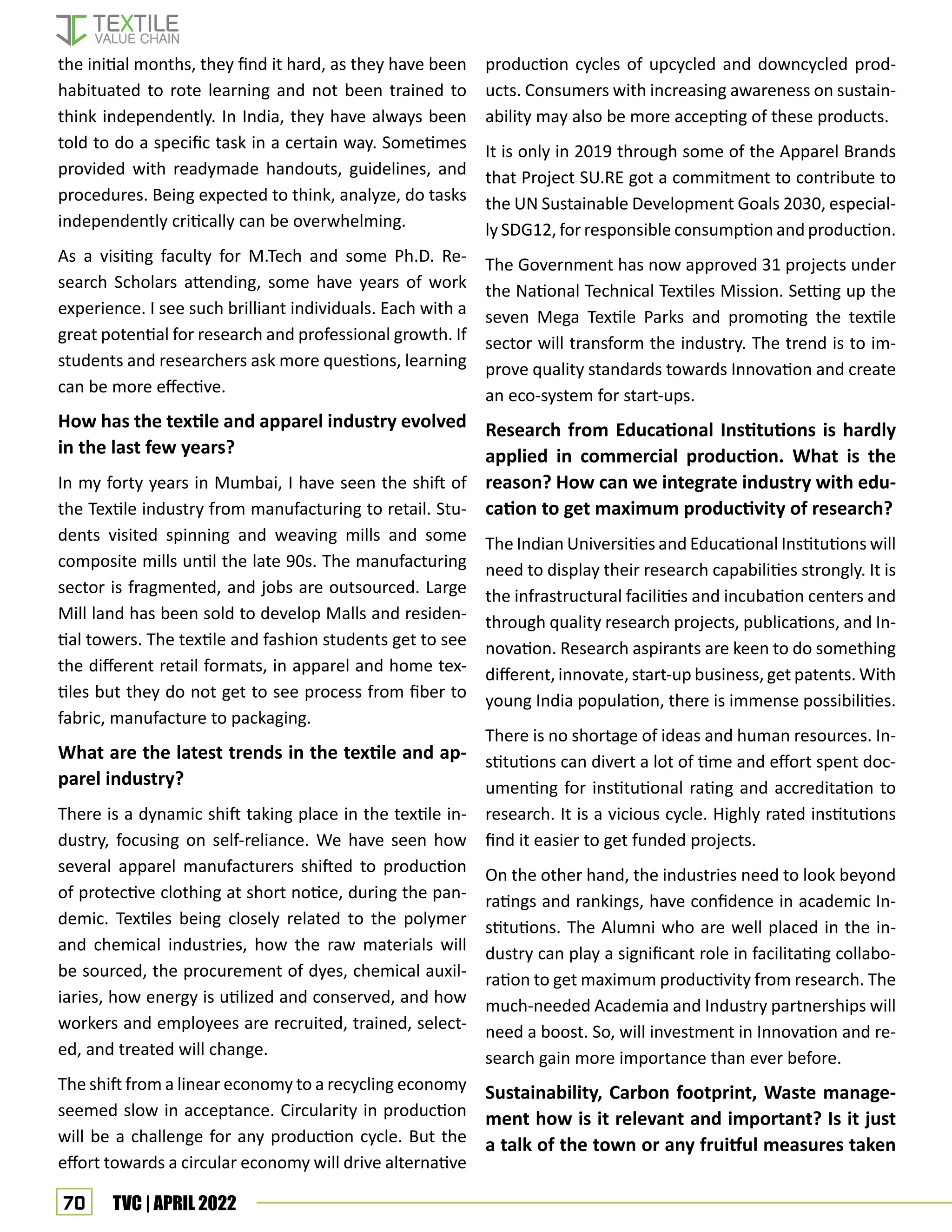

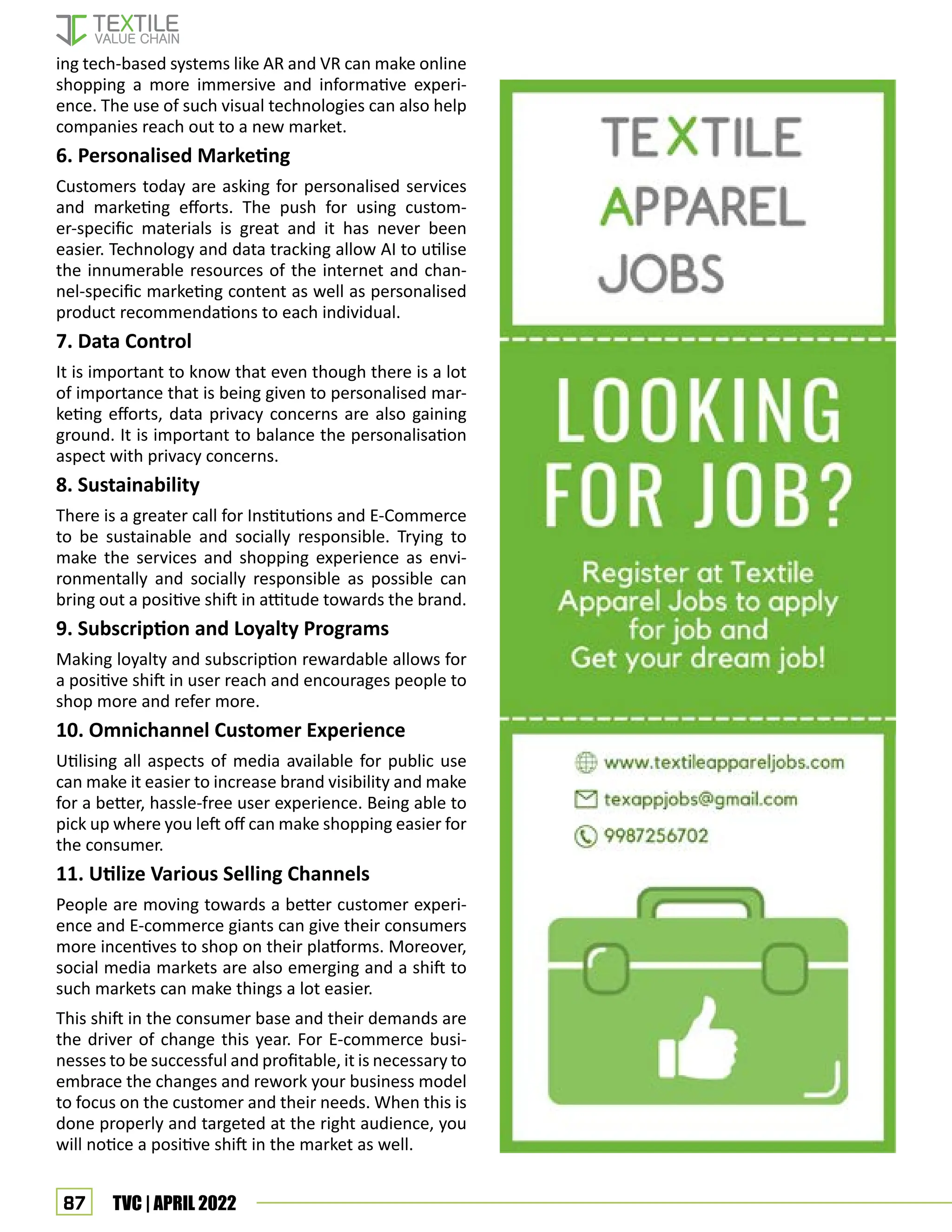

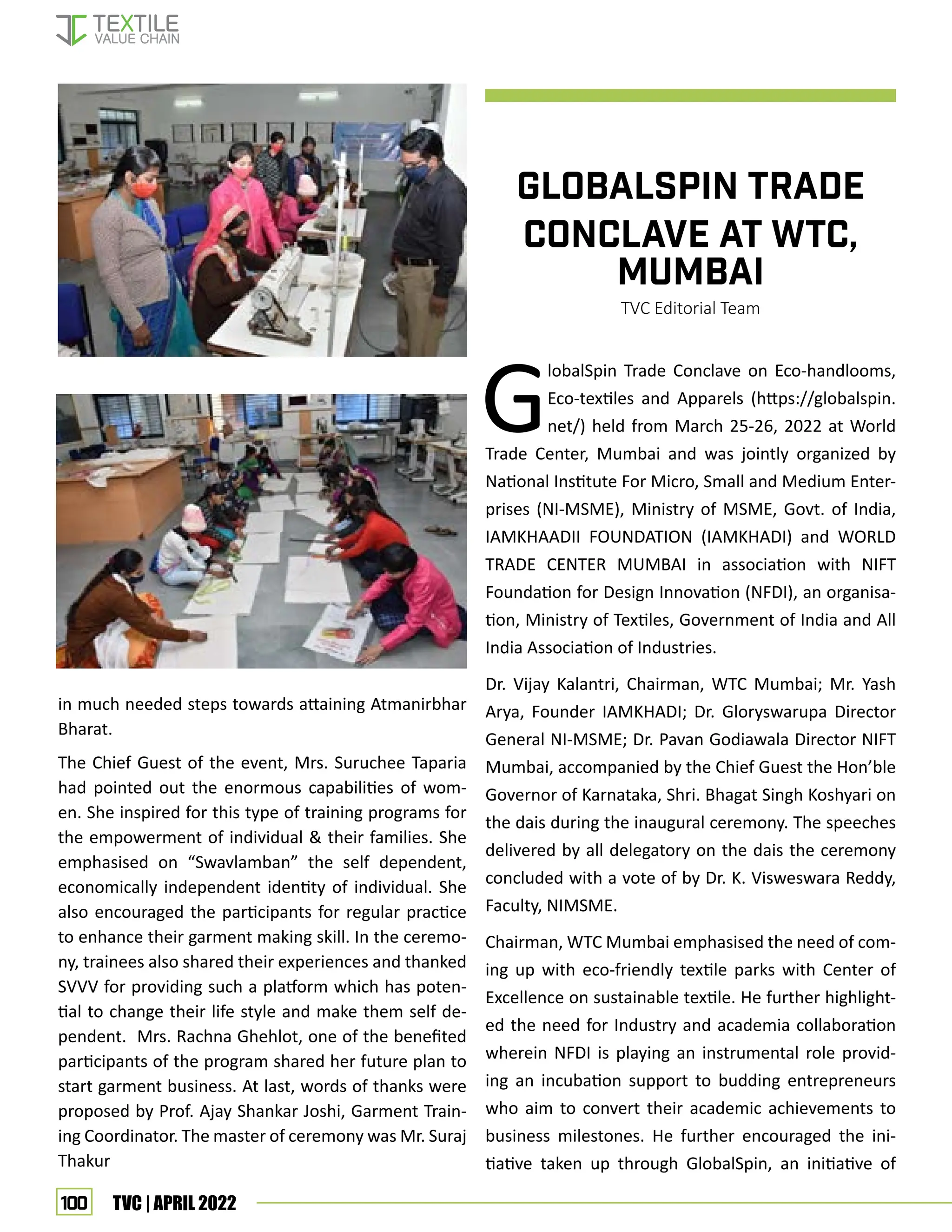

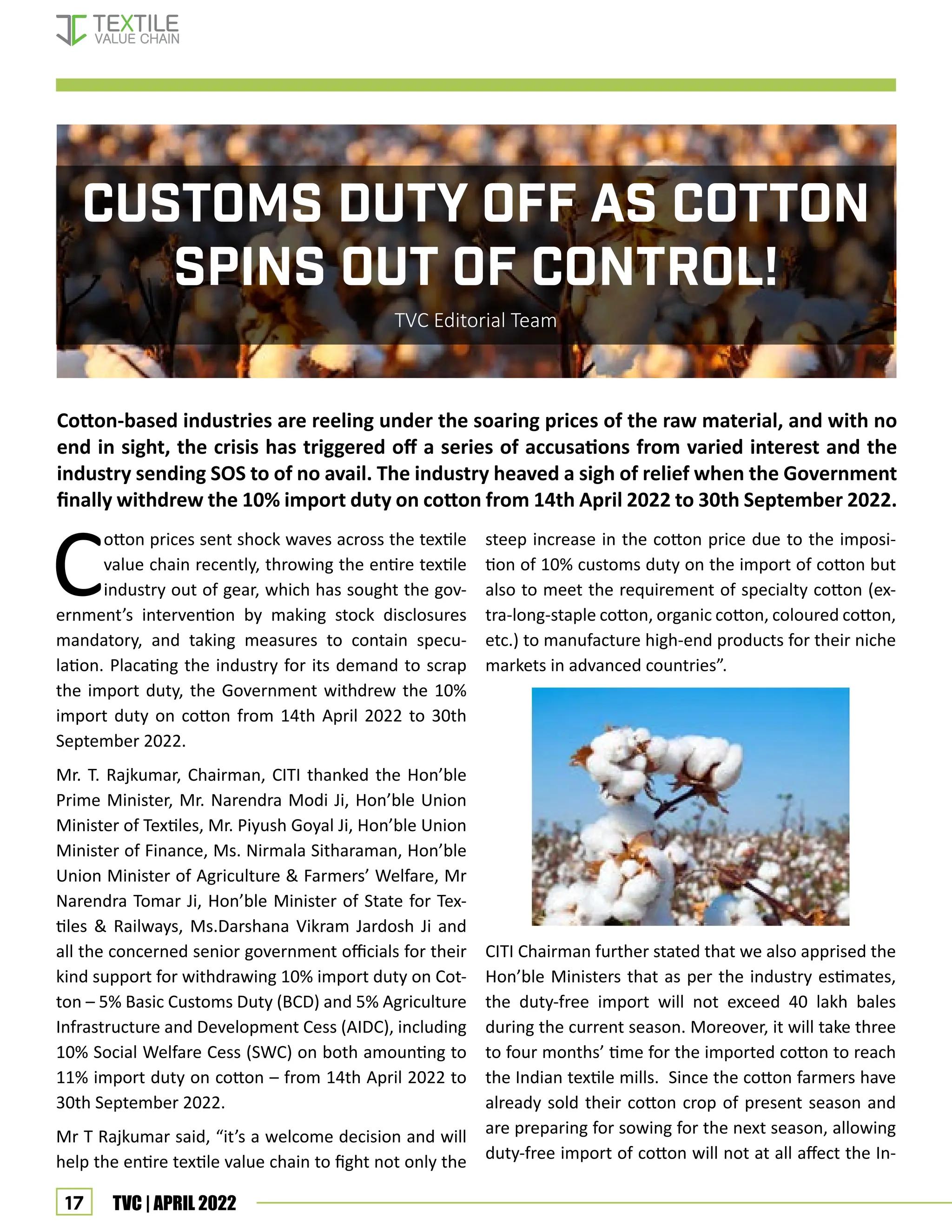

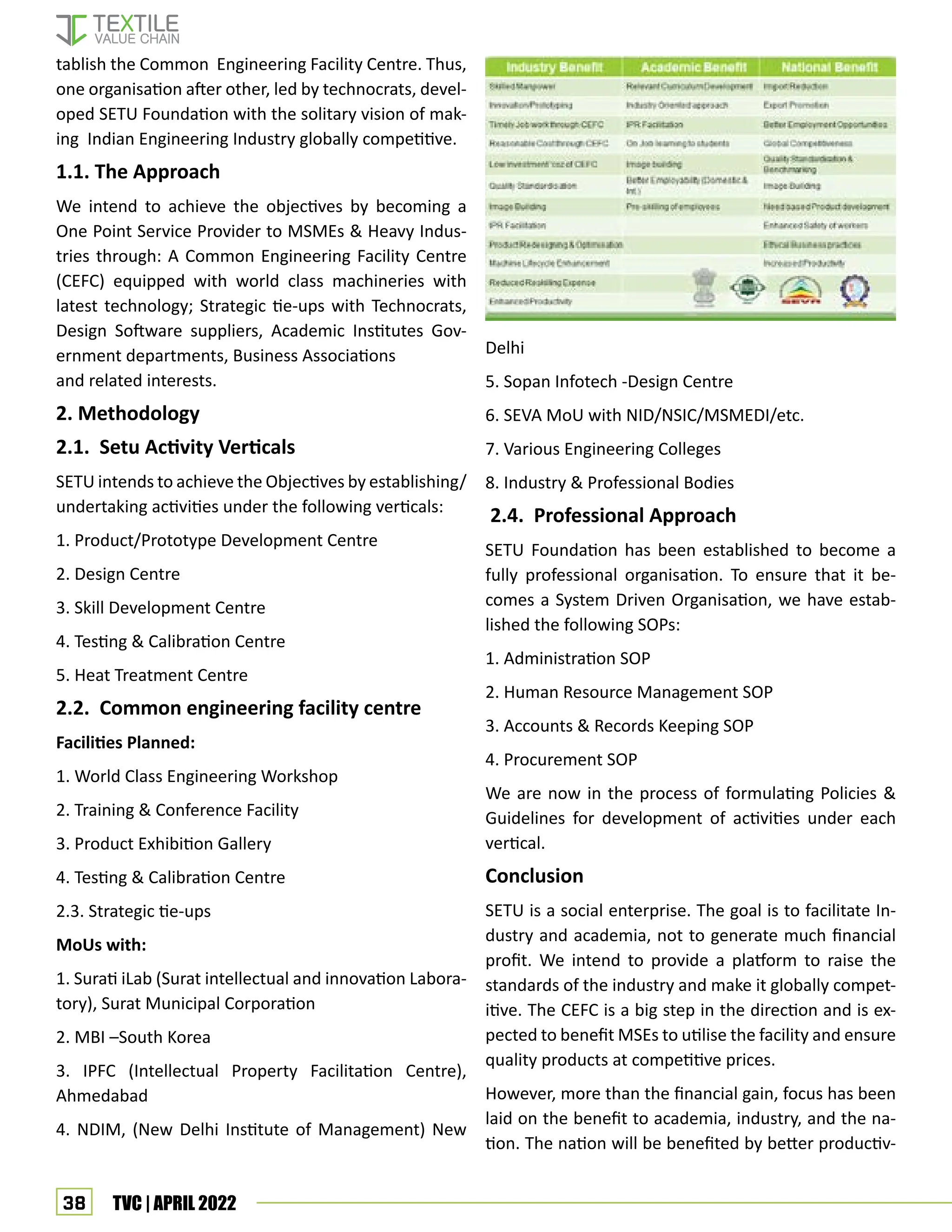

Project No. Project Title Project Capacity

1 Export focussed YARN SPG

MILLS,OF 25 K spdls,for BCI/

Organic yarns,for Knttg &wvg

Approx..20 TPD

2 Cotton Yarn Mill with Ring and

OE spg,withInhouse Knitting

unit

15 to 20 TP-

D,with 5TPD

knttg.

3 3.Integrated Yarn Spg.unit of

20 TPD Ring +OE yarns with

10TPD Terry Towelunit

15 to 20 TPD

New Textile Projects _3 Nos export oriented

*Mail us for Turnkey Proj. Execution.](https://image.slidesharecdn.com/tvcapril2022-digital-231017111127-81362480/75/Textile-Value-Chain-April-2022-32-2048.jpg)

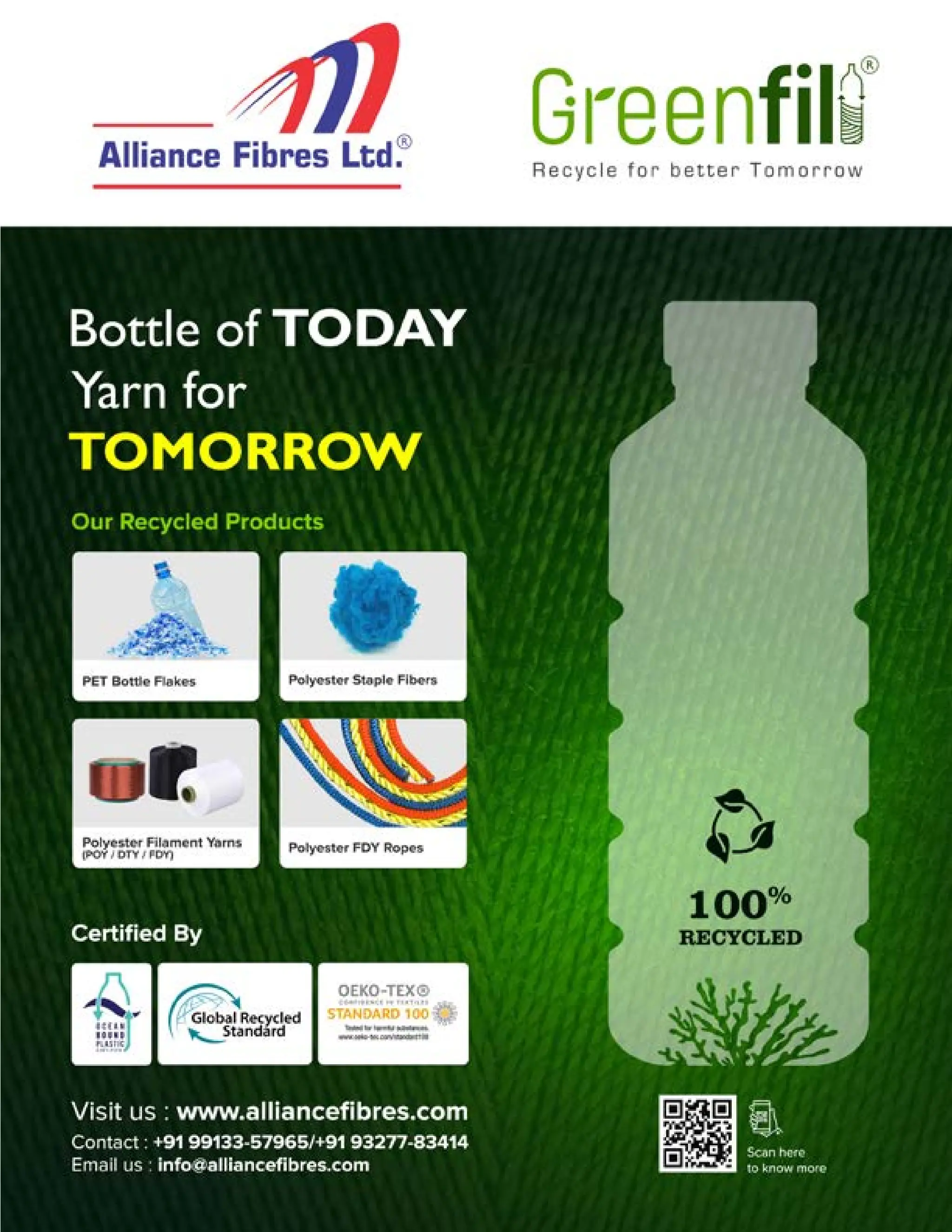

![46 TVC | APRIL 2022

“Gimatex ALWAYS FOCUSES

ON COTTON VALUE ADDITION”

TVC Editorial Team

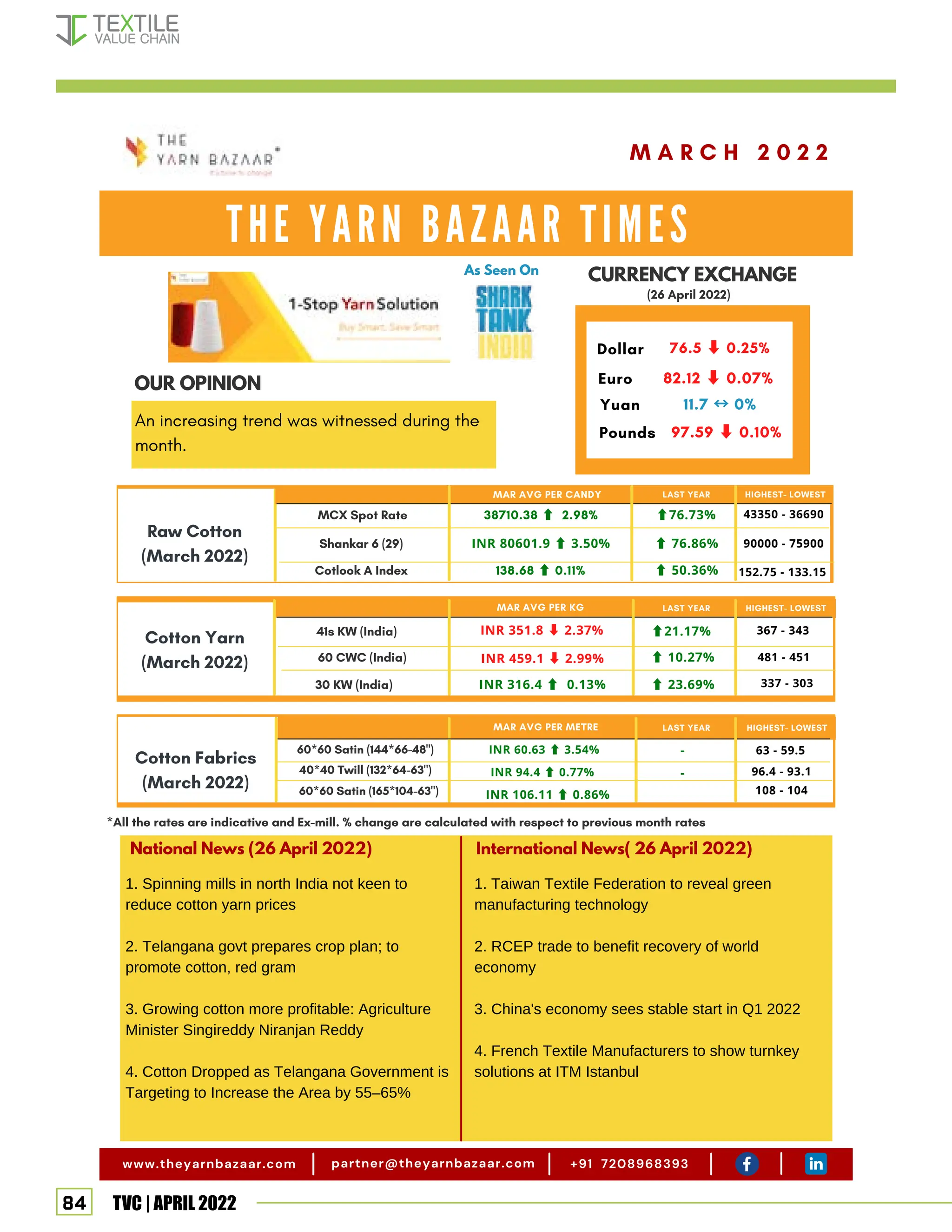

Gimatex replied to a TVC Questionnaire. Ex-

cerpts:

Mohota Group has a glorious history of over 125

years in the textile industry. Tell us about some

of the important highlights, achievements, mile-

stones during this journey. The Graph below

tells you the story so far…..

[From Left to Right: Vineet Kumar Mohota – Director (Finance),

Basant Kumar Mohota – Chairman, Prashant Kumar Mohota – MD,

Anurag Kumar Mohota – Director (Works)]

interview - Gimatex](https://image.slidesharecdn.com/tvcapril2022-digital-231017111127-81362480/75/Textile-Value-Chain-April-2022-46-2048.jpg)