Textile value Chain- Sep 2023

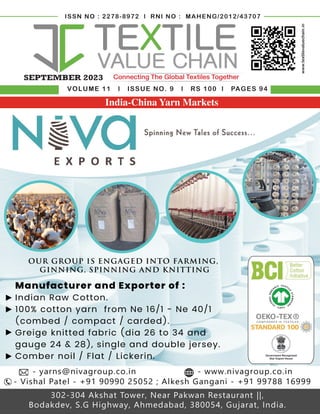

- 1. OUR GROUP IS ENGAGED INTO FARMING, GINNING, SPINNING AND KNITTING Manufacturer and Exporter of : Indian Raw Cotton. 100% cotton yarn from Ne 16/1 - Ne 40/1 (combed / compact / carded). Greige knitted fabric (dia 26 to 34 and gauge 24 & 28), single and double jersey. Comber noil / Flat / Lickerin. - Vishal Patel - +91 90990 25052 ; Alkesh Gangani - +91 99788 16999 302-304 Akshat Tower, Near Pakwan Restaurant ||, Bodakdev, S.G Highway, Ahmedabad, 380054, Gujarat, India. - yarns@nivagroup.co.in - www.nivagroup.co.in ISSN NO : 2278-8972 l RNI NO : MAHENG/2012/43707 www.textilevaluechain.in SEPTEMBER 2023 VOLUME 11 l ISSUE NO. 9 l RS 100 l PAGES 94 India-China Yarn Markets

- 4. Grasim Industries Limited (VFY - Fashion Yarn Business) www.raysil.co.in | raysil@adityabirla.com For trade inquiries, please contact: (Mumbai): +91 22 22027570-77 (Surat): +91 261 4003361/62/66 LUXURIOUS ELEGANCE for Made with premium wood pulp, Raysil® , of 100% natural origin, gives fabrics a rich lustre, vivid colour, superior drape and a feather-light feel.

- 5. 100% Cotton RAW WHITE Combed and Carded yarns for Knitting & Weaving OPEN END RW YARNS in 100% Cotton and Polyester / Cotton Blends Cotton / Polyester Yarns Cotton / Viscose Yarns, Cotton / Modal Yarns Cotton / Tencel Yarns, Cotton / Acrylic Blended Yarns, Cotton / Nylon Yarns Count Range NE 16s to NE 40s - Single and Double RAW WHITE YARNS 100% Cotton, Multi-Fiber Blends, Tencel Blends, Polyester / Viscose Polyester / Cotton, Cotton / Nylon, Cotton / Viscose, 100% Viscose 100% Polyester, Acrylic / Cotton, Acrylic / Viscose, Modal / Cotton 100% Polyester Dope Dyed yarns in Black and various shades: NE 8s to NE 18s Count Range NE 16s to NE 40s - Single and Double Melange yarns and Fancy yarn MELANGE YARN AND DYED YARNS Jaspe /Siro Yarn, Cotton / Viscose / Nylon Cotton / Silk, Cotton / Wool, Cotton / Hemp SPECIALTY YARNS 100% Organic Cotton & Organic Blends, BCI Cotton & Cotton Blends GRS Certified Recycled Polyester Blends, Eco-Friendly Viscose Blends Recycled Cotton Blends Sustainable yarns with Recycled Cotton, Recycled Polyester, Organic Cotton, BCI Cotton, and Liva Eco Viscose SUSTAINABLE PRODUCTS Dyeing– Fibre and Yarn Dyeing Plant with the Capacity to Dye 15 MT / Day WE OFFER RAW-WHITE & MELANGE YARNS IN COTTON, PC & MANY MORE BLENDS.... MARKETING OFFICE INDIA BANGLADESH OFFICE House No/. 2nd Floor, Road No. 8, Baridhara DOHS, Dhaka Bangladesh FACTORY ADDRESS Village Akbarpur, Ahmedgarh, Dist. Sangrur Near Ludhiana, Punjab – 148021, India +91 – 98200 60227 / +91- 98112 82258 rm@cedaartextile.com www.cedaartextile.com Cedaar Textile Pvt. Ltd. YARN RANGE FOR SWEATERS Cotton / Acrylic, 100% Cotton, Acrylic Viscose Cotton / Viscose, 100% Viscose, Cotton Polyester Count Range 2/20 NE to 2/40 NE Office No. 413, 4th Floor, Eros City Square Mall, Rosewood City Road, Sector-49, Gurugram - 122018, Haryana, India Office No. 411, Prime Mall, Plot No. D-66, Sector 12, Kharghar, Navi Mumbai-410 210, Mumbai, India

- 6. CORPORATE SPEAKS DIGITIZATION HOME TEXTIELS CORPORATE VIEWS REVIEW PAPER POST EVENT STARTUP & MSMES MARKET REPORT Unveiling the Evolu on of India and China Yarn Markets 10 Upcoming Events October 2023 08 Jay Bharat’s new plant for rPET chips 18 ‘We Believe in Quality’ 20 Pifron: High Performance Air-Jet Looms and Roving machines 24 The Journey of Astra Tech India 30 Digital connec vity for Indian Manufacturers; Interac on with Capximize 34 The Impact of 3D Digital Fabric Material Crea on On Driving Business Growth 40 Global Market Opportunity in Rugs and Carpet 43 Company Culture at The Yarn Bazaar: Promo ng Collabora on and Crea vity in Our Workplace 48 A compara ve study of Crosrol card Mk5d versus modified card Mk6 for ul mate effect on sliver and yarn quality 58 Nano-Tex les: Applica ons and challenges 74 BITTex les: Pla orm for Industry Networking 78 HGH India puts Indian home market in global context 87 HGH India a racted over 41,000 visitors across all four days at its 13th edi on that culminated in Mumbai 88 India’s Startup Fundraising in 2023 - Analysis & Insight 81 Man Made Fibres 14 Natural Fibres 16 EU Apparel Import 54 RSB COTTEX GATEFOLD NIVA EXPORTS FRONT COVER RAYSIL FRONT INSIDE CEDAAR TEXTILE 3 RAMESWAR 5 SAMBANDAM 7 SALONA GROUP 9 GOKUL YARNS 11 RADHESHYAM SPINNING 13 FIOTEX 15 KEWALRAM TEXTILES 17 PASHUPATI 19 GLOSSY 21 CAIRO FASHIONTEX 22 JOLLY SPINNERS 23 REAL PRINCE 27 SAURER 28 OMAX COTSPIN 29 ASTRATECH 31 TECHTEXTILE 32 LUWA 33 MOROCCO FASHIONTEX 36 ART YARN 37 CEMS 38 INDOSPUN LLP 39 AMBICA COTSEEDS PVT LTD 45 NONWOVEN TECH 46 BRUCKNER 47 ASSOCHAM 50 NEEVA TRADELINK 51 ITMA ASIA 52 ALLIANCE 53 RIMTEX 55 ITMACH 56 SSPL 57 MEERA INDUSTRIES 59 USTER TECHNOLOGIES 61 YARN EXPO ICHALKARANJI 63 UNIFORM & SPORTSWEAR EXPO 64 GSCS 65 ZYDEX 67 YAMUNA 69 SPG PRINTS 71 DOMOTEX 72 D BADAMI FASHION 73 SITEX 76 SHREEJI 77 GOKULANAND TEXTURISER 79 TUREL 80 PAMEX 83 UNITECH TEXMECH 84 ITM 85 SHIDHANATH COTEX 86 WEAVEKNITT 89 THE X AXIS 90 SAUDI STITCH 91 EXCEL 92 JB ECOTEX BACK INSIDE RAYMOND BACK COVER ADVERTISER INDEX COVER STORY EVENT CALENDER CONTENT SEPTEMBER 2023 4 www.textilevaluechain.in

- 7. Super Combed Compact Yarn (Ne 10s to Ne 80s) Combed Yarn (Ne 10s to Ne 50s) Carded Yarn (Ne 10s to Ne 40s) Open End Yarns (Ne 6s to Ne 20s) TFO Doubled Yarns All Yarns for Knitting and Weaving purpose RAMESWAR UDYOG PRIVATE LIMITED 404 BALLESWAR SQUARE, 4TH FLOOR, S. G. ROAD, OPP ISCON TEMPLE, AHMEDABAD 380015, INDIA +919998007171 +91 79-40215500 www.rameswar.com ruchi@rameswar.com

- 8. SEPTEMBER 2023 6 www.textilevaluechain.in Evolving Landscape of Indian and Chinese Yarn Markets heyarnmarketsofIndiaandChinahavebeenundergoing significant changes, reflec ng the dynamic nature of the global tex le industry. Bangladesh’s ascent as the largest export market for Indian co on yarn, surpassing China, marks a noteworthy shi in demand. This trend, along with rising co on yarn and home tex le export orders, paints a posi ve picture for India’s yarn market. The projec on of expor ng tex le products worth US$ 18 billion underscores India’s growth trajectory. Emphasizing market diversifica on, par cularly towards countries with less than 20% of India’s yarn imports, showcases the industry’s proac ve approach. In the Chinese context, as the world’s primary co on yarn importer, China’s influence remains substan al. The transi on of China’s co on produc on to the distant Xinjiang region has reshaped global trade pa erns and supply chains, symbolizing a new equilibrium. A significant development is China’s replacement by Vietnam and Indonesia as the top co on yarn importers due to their duty-free access, highligh ng the impact of trade policies. The global co on yarn market’s projected growth and China’s strategic posi oning within it reflect its enduring significance. Contribu ng factors in both markets intertwine to shape their trajectories. Bangladesh’s ascendancy signifies changing demand dynamics, while increased demand from China and Bangladesh elevates prices within the Indian market. The projec on of the global co on yarn market’s growth underscores the industry’s vibrancy, propelled by rising demand, sustainability awareness, and government support. These dynamics resonate in the strategic shi of China’s co on produc on, influencing global trade pa erns and supply chains. In conclusion, the Indian and Chinese yarn markets exemplify adaptability and innova on within the tex le industry. As these markets respond to shi ing demand, embrace diversifica on, and navigate changing produc on landscapes, they carve paths toward promising futures in the world of tex les. EDITORIAL TEAM EDITOR AND PUBLISHER Jigna Shah EDITORIAL ASSISTANT Gargi Dandegaonkar CREATIVE DESIGNER Asif Khan JUNIOR EDITOR Hrushikesh Takbhate MARKETING AND ADVERTISING ENQUIRY Mohammad Tanweer +91-9167986305 sales@tex levaluechain.com REGISTERED OFFICE: TVC MEDIA AND PROMOTION PVT LTD. 504, Suchita Business Park, Patel Chowk, Pantnagar, Ghatkopar (East), Mumbai- 400075, Maharashtra, INDIA. Cell: +91-9769442239 Email: info@tex levaluechain.com Web: www.tex levaluechain.com Owner, Publisher, Printer and Editor Ms. Jigna Shah Printed and Processed by her at, Impression Graphics, Gala no.13, Shivai Industrial Estate, Andheri Kurla Road, Sakinaka, Andheri(East), Mumbai 400072, Maharashtra, India. All rights reserved Worldwide; Reproduc on of any of the content from this issue is prohibited without explicit wri en permission of the publisher. Every effort has been made to ensure and present factual and accurate informa on. The views expressed in the ar cles published in this magazine are that of the respec ve authors and not necessarily that of the publisher. Tex le Value chain is not responsible for any unlikely errors that might occur or any steps taken based in the informa on provided herewith. Editorial +91-9869634305 marke ng@tex levaluechain.com Hrushikesh Takbhate T

- 10. SEPTEMBER 2023 8 www.textilevaluechain.in Event Calender UPCOMING EVENTS EVENTS October 2023 28th – 01st oct IBIA EXPO 2023 Istanbul, Turkey h ps://ibiaexpo.com/en/ 03rd – 10th Oct UGANDA INTL TRADE FAIR Uganda, Africa h ps://tradefair.uma.or.ug 04th - 05th oct PERFORMANCE DAYS FUNCTIONAL FABRIC FAIR Online Event h ps://www.performancedays.com/loop.html 05th -08th Oct GENOVAJEANS 2023 Genova, Italy h ps://genovajeans.it/ 05th - 07th Oct THE CAIRO FASHION & TEX Cairo, Egypt h ps://www.cairofashiontex.com/ 06th Oct NATIONAL CONCLAVE ON AGROTECH New Delhi, India h p://www.i aindia.org/ 07th -09th Oct GARMENTECH INDIA Mumbai, india h ps://garmentecindia.com 10th - 12th Oct FILTXPO™ 2023 Chicago, USA h ps://www.filtxpo.com/ 11th - 13th Oct MANUFACTURER EXPO IN THAILAND Bangkok, Thailand. h p://m4expo.com/ 18th – 19th Oct MANUFACTURING LEADERS INDIA SUMMIT Mumbai, India h ps://manufacturingleadersummit.com/Home.aspx 19th - 21st Oct INTERTEX Tunisia h ps://www.intertextunisia.com/index.php 24th - 27th Oct INTERMEDIATE NONWOVENS TRAINING COURSE Online Course h ps://imisw.inda.org 25th - 27th Oct HANOITEX 2023 Vietnam h p://vhanoitex.com/en/ 26th - 28th Oct GARMENT & TEXTILE INDUSTRY EXHIBITION Dhaka, Bangaladesh www.bigtex.exp

- 12. SEPTEMBER 2023 10 www.textilevaluechain.in India Yarn Market: Weaving Success Amid Challenges In the intricate tapestry of India’s tex le industry, the yarnmarketholdsacrucialthread.Bangladeshemerges as the leading des na on for Indian co on yarn exports in terms of value, while the combined force of China and Bangladesh accounts for a substan al 50% of India’s yarn exports in quan ty. A surge in Indian co on yarn and home tex le export orders serves as a beacon of hope, signifying a posi ve upswing in the market. Envisioning a bold future, the Indian tex le industry an cipates expor ng tex le goods worth a staggering US$ 18 billion in the upcoming fiscal year. A tale of resurgence unfolds as the Indian spun yarn market breaks free from a nine-year declining trend, soaring to new heights in 2019. However, challenges persist, echoing the need for diversifica on across markets where India’s yarn import shares remain under 20%. This adap ve strategy promises to unlock fresh avenues of growth. China Yarn Market: A Revolu on Unravelled The heartbeat of China’s tex le prowess lies within its yarn market. Claiming the tle of the world’s largest co on yarn importer, China’s influence reverberates across the global landscape. As the global co on yarn market charts an impressive trajectory, poised to grow from USD 82.81 billion in 2023 to a projected USD 100.68 billion by 2028, China stands firmly at the helm. A seismic shi is underway, tracing China’s reloca on of co on produc on to the distant Xinjiang region. This move, though marked by geographic hurdles, has ignited a domino effect that reshapes trade pa erns and supply chains. A notable change emerges as China gracefully bows to Vietnam and Indonesia, entrus ng them with the tle of the largest importers of co on yarn. Their duty-free access sets them apart, whereas Indian yarn carries a 3.5% import duty. Impact on the Global Tex le Fabric: Unravelling the Threads of Influence The ripples from India and China’s yarn markets reach far beyond their borders, touching the global tex le industry. The Indian tex le domain faces challenges as discerning consumers in Europe, the US, and other key markets cut back on clothing expenditure. Yet, the global co on yarn market’s projected growth reflects a promising narra ve, driven by heightened demand, a growing consciousness of sustainability in fashion, and unwavering government support. China’s strategic shi in co on produc on wields transforma ve power, redefining trade pa erns and Unveiling the Evolution of India and China Yarn Markets By Hrushikesh Takbhate The world of tex les is witnessing a dynamic transforma on, and at its forefront are the yarn markets of India and China. These two na ons, known for their rapid economic growth, have become pivotal players in the global tex le arena, marked by challenges and promising opportuni es that paint a vivid picture of their journeys. Cover Story

- 14. SEPTEMBER 2023 12 www.textilevaluechain.in Cover Story supply chains. This metamorphosis echoes across the fabric of the global market, leading to amplified demand for co on yarn in China and Bangladesh. The outcome? Elevated prices in the Indian market. AresilientspiritcharacterizestheIndiantex leindustry, as it strives to extend its market reach in countries where its yarn imports are less than 20%. This adap ve approach, rooted in diversifica on, is poised to for fy India’s presence on the global stage. In the realm of tex les, the threads of India and China are woven into a rich tapestry of evolu on. As challenges intertwine with opportuni es, these yarn markets stand as prime exemplars of adaptability, resilience, and innova on in a dynamic industry poised for a vibrant future. Performance of Indian and Chinese Yarn Markets: A Deeper Look In the backdrop of the ever-evolving global tex le industry, the performance of the Indian and Chinese yarn markets in the last year unfolds as a compelling narra ve of shi ing dynamics and influen al factors. The yarn markets of these two economic giants have experienced significant changes, propelled by various contribu ng factors. Indian Yarn Market: Naviga ng New Horizons The recent surge of Bangladesh as the largest export market for Indian co on yarn has ignited a paradigm shi , dethroning China from its long-held posi on. This noteworthy transi on not only underscores changing demand pa erns but also highlights India’s adaptability in catering to emerging markets. A remarkable up ck in Indian co on yarn export orders and home tex le export orders further tes fies to the market’s resilience and evolving trends. The projec on of expor ng tex le products worth a substan al US$ 18 billion in the fiscal year 2013-14 unveils a determined trajectory of growth, bolstered by a surge in demand. A call for market diversifica on resonates through the industry, advoca ng a strategic focus on countries where India’s share of yarn imports stands below 20%. This prudent approach speaks volumes about the industry’s intent to embrace new opportuni es while safeguarding against dependence on specific markets. Chinese Yarn Market: A New Equilibrium As the largest global importer of co on yarn, China has tradi onally wielded significant influence. However, a pivotal transforma on has unfolded, marked by China relinquishing its posi on to Vietnam and Indonesia as the largest importers of co on yarn. This power shi is a result of their favorable duty-free access, while Indian yarn grapples with a 3.5% import duty. The projec on of the global co on yarn market’s exponen al growth from USD 82.81 billion in 2023 to a staggeringUSD100.68billionby2028,exhibi ngaCAGR of 4.0%, accentuates China’s strategic posi oning. This foresight into market trends showcases China’s intent to stay at the forefront of global tex le dynamics. Yet, the seismic shi in China’s co on produc on landscape, gravita ng toward the distant Xinjiang region, has reverberated throughout the industry. This ripple effect has reshaped trade pa erns and disrupted established supply chains, yielding a new equilibrium that carries far-reaching implica ons. Contribu ng Factors: A Tapestry of Influence Several interconnected factors underpin the trajectory of both markets. The rise of Bangladesh as a dominant export des na on for Indian co on yarn illuminates the evolving demand landscape, while rising demand from China and Bangladesh has li ed prices within the Indian market, triggering significant industry shi s. The global co on yarn market’s projected growth underscores the sector’s buoyancy, driven by heightened demand, sustainability concerns in the fashion realm, and robust government backing for the expansion of domes c tex le endeavours. Addi onally, the pivotal shi in China’s co on produc on, coupled with its consequen al impact on trade pa erns and supply chains, reverberates globally. The subs tu on of India by Vietnam and Indonesia in thelistoftopco onyarnimportersfurtherunderscores the strategic significance of duty-free access in shaping trade dynamics. As the yarn markets of India and China con nue to traverse uncharted territories, this intricate interplay of factors paints a vivid picture of adapta on, innova on, and strategic foresight, paving the way for an exci ng future in the world of tex les.

- 16. SEPTEMBER 2023 14 www.textilevaluechain.in Market Report Man Made Fibres (Import) Man Made Fibres (Export) Natural Fibres (Import)

- 18. SEPTEMBER 2023 16 www.textilevaluechain.in Natural Fibres (Export) Market Report

- 20. SEPTEMBER 2023 18 www.textilevaluechain.in Corporate Speaks Can you tell us about Jay Bharat rPET? We are coming up with a new plant, this plant will be making chemically recycled rPET chips, these chips will beusedinbothfilamentand OPET grade applications. We already have a plant by the name of JB Ecotex. We make yarn there. The issue everyone faces currently in mechanical recycling is that many people wanted finer yarns. But that was not being able to reproduce the finer yarns. That’s why we have come up with this latest technology. Which is ourpatentedtechnologythatwedevelopedin-house. This will help customers make finer filament-grade yarns and be used in BoPET applications. WhoarethetargetcustomersofJB?Andwhatbenefits will they be receiving with this new ini a ve? Our target customers are Decathlon, Zara, Adidas, and all the other major brands across the deals. In India a lot of exports are happening, so everyone who is dealing in filament grade, and weaving are our target customer. Those who are exporting BoPET to European countries have major benefits as plastic taxes are levied in European countries. If you get it at chips level you will have great savings. We are currently coming with 70 tons of total output capacity per day and we hope to expand it soon with the help of our valuable customers. d l d y t r r r r r t Jay Bharat’s new plant for rPET chips Tex le Value Chain Talked with Mr. Samarth Arya, Director, JB rPET Industries Pvt. Ltd.

- 22. SEPTEMBER 2023 20 www.textilevaluechain.in Corporate Speaks Can you tell us about Wampum Syntex? We are into Polyester, Nylon, Sorona, and all synthetic and specialty yarn dying. We are offering polyester texturized twisted yarn, then air textured yarn, spurn yarn, along with virgin and recycled. In Nylon, we are doing crimp yarn, dying, virgin, and recycled. Then FDY twisted, then specialty yarn we are making in nylon that is Jari covering yarn, specially made for elastic tapes. We are making acrylic tape yarns, then Sorona, which is a DuPont product, is a bi-component yarn, which is sustainable yarn. We are offering 50 deniers to 150 deniers and multiple ply in that. So, we have a wide range of yarns to tackle all types of markets. Right from narrow woven to bigger elastic markets. We are making high-tenacity nylon also which is used for technical textile products. What are your product segments? We are supplying pan India with export also, we are doing good business with different countries, like Egypt, Vietnam, Peru, Morocco, and Singapore. We are supplying yarns to elastic tapes, solid tapes, narrow woven labels, sarees, dress materials, shirting and suiting, then home furnishing products, and knitted fabrics. What is your produc on capacity? We have a capacity of around 700 tones, Nylon we are having 50 tones, and we are making high bulk yarn also, which is loose for elastic tapes. How are your promo ng sustainability? We are now promoting recycled and sustainable yarns. In recycled we are doing in polyester and nylon and sustainable like micro Sorona for good volume. We are also the first, who made it successful in yarn dying. Sorona was earlier used in the raw white stage, but now we have made it successful in yarn dying and after dying it gives more than 2.5 times stretch in the yarn. Are there any plans for expansion in the near future? We are in the process, we are increasing specialty yarn products more and more. We are into new product developments like different types of blends for different applications. We are into major quality segments. We are not focusing on volume, we believe in quality. ‘We Believe in Quality’ Tex le Value Chain talks with Mr. Sandeep Ostwal, Director, Wampum Syntex Pvt. Ltd. at Yarn Expo 2023. Get Updates on Jobs by following our social media pages ie... Linkedin, Facebook, Instagram, Twitter Register Free : www.textileappareljobs.com texappjobs@gmail.com +91 9987256702

- 24. 05 - 06 - 07 OCTOBER 2023 CAIRO INTERNATIONAL CONVENTION CENTER “The Biggest Textile Fair in Mena Region” www.cairofashiontex.com ORGANIZER

- 26. SEPTEMBER 2023 24 www.textilevaluechain.in Corporate Speaks Can you provide an overview of Pifron’s specializa on and its posi on in the tex le machinery industry? Pifron’s specialization lies in the import of textile machinery. We have established ourselves as a trusted player in the textile machinery industry, particularly in the field of air-jet looms. Our partnership with Red Flag Textile Machinery Co., Ltd., the largest air-jet loom production company in China, positions us as a reliable importer and supplier of high-quality textile machinery. What are the key areas of focus for Pifron in terms of research, development, produc on, and sales? Pifron focuses on several key areas in research, development, production, and sales. Our primary focus is on sourcing and importing cutting-edge textile machinery that meets the highest standards of performance and quality. We constantly research market trends, technological advancements, and customer needs to ensure that we offer the most innovative and efficient machinery to our clients. Our production and sales processes are streamlined to deliver these products to customers in a timely and efficient manner. Could you elaborate on the achievements and collabora ons of Pifron, such as the establishment of the technology canter, tex le research ins tute, and dynamic lab? Pifron (REDFLAG) has achieved notable milestones and collaborations in the industry. We have established a technology center that serves as a hub for research and development activities. Additionally, we have collaborated with Qingdao University to establish the “Qingdao University Tianyi Group - Red Flag Textile Research Institute,” which further enhances our research capabilities. Furthermore, we have pioneered the establishment of a “textile machinery dynamic lab” in cooperation with the Xi’an Engineering Institute of Technology, which is the first of its kind in China. How does Pifron ensure the high performance and quality of its products, par cularly in the air-jet looms and roving categories? Pifron places utmost importance on ensuring the high performance and quality of our products, especially in the air-jet looms and roving categories. We achieve this by partnering with renowned manufacturers like Red Flag Textile Machinery Co., Ltd., which has a proven track record of producing top-notch machinery. We conduct rigorous quality control processes and adhere to international standards. Our products undergo thorough testing and inspections to guarantee their performance and durability before they reach our customers. Can you discuss Pifron’s status as a na onal high-tech enterprise and its recogni on through patents and na onal new product designa ons? Pifron(REDFLAG) holds the esteemed status of a national high-tech enterprise. This recognition highlights our commitment to technological innovationandadvancementinthetextilemachinery industry. We have been granted numerous patents, showcasing our dedication to developing unique and inventive solutions. Additionally, we have several products that have received national new product designations, further solidifying our position as a leader in innovation. How does Pifron emphasize technical innova on and maintain a strong quality assurance system, including cer fica ons like ISO9001:2000, UL, CE, PIFRON: High Performance Air-Jet Looms and Roving machines Tex le Value Chain Talked with Mr. Vinod Gigani, Director, Pifron,

- 27. www.textilevaluechain.in 25 SEPTEMBER 2023 and TUV? Technical innovation and maintaining a strong quality assurance system are fundamental principles at Pifron. We continuously invest in research and development to stay at the forefront of technological advancements. We have implemented a comprehensive quality assurance system and obtained certifications such as ISO9001:2000, UL, CE, and TUV. These certifications validate our adherence to international quality standards and demonstrate our commitment to delivering reliable and high-quality products to our customers. What is the extent of Pifron’s interna onal presence and reputa on, par cularly in countries like India, Bangladesh, Pakistan, and Southeast Asian regions? PIFRON (RDFLAG) has a strong international presence and a solid reputation in various countries, includingIndia,Bangladesh,Pakistan,andSoutheast Asian regions. Our products are exported to these countries, and we have established long-term relationships with clients in these markets. Our dedication to quality, reliability, and customer satisfaction has contributed to our positive reputation and continued success in these regions. How does Pifron approach customer coopera on and uphold the principle of win-win rela onships? At Pifron, we approach customer cooperation with a focus on establishing win-win relationships. We value the importance of understanding our customers’ needs and strive to meet their requirements effectively. Our team works closely with clients, providing personalized support and guidance throughout the entire process. We aim to foster long-term partnerships based on trust, mutual benefits, and shared success. Can you describe the company’s enterprise style and spirit, emphasizing prac cality, effec veness, and con nuous improvement? The enterprise style and spirit at Pifron emphasize practicality, effectiveness, and continuous improvement. We adopt a proactive and results-driven approach in all aspects of our operations. Our company culture encourages teamwork, innovation, and efficiency. We constantly seek opportunities for growth and enhancement, ensuring that we remain adaptable and responsive to evolving market demands. How does Pifron align its quality objec ves with customer needs and expecta ons, ensuring that users’ standards and market standards serve as the highest quality benchmarks? Pifron takes a holistic approach to balance quality, service,andinnovationinitsmanagementapproach. We recognize that all three elements are crucial to the success of our business and the satisfaction of our customers. To ensure quality, we have implemented rigorous quality control processes at every stage, from selecting reputable manufacturers to conducting thorough inspections before delivering products to our customers. We prioritize sourcing high-per- formance and reliable machinery that meets international standards. Additionally, our adherence to certifications such as ISO9001:2000, UL, CE, and TUV further demonstrates our commitment to maintaining quality. In terms of service, we prioritize customer satisfaction and strive to provide exceptional service experiences. Our dedicated customer support team is readily available to handle inquiries, provide guidance, and address any concerns promptly. We understand the importance of clear communication, timely delivery, and after-sales support to ensure a positive customer experience. Regarding innovation, Pifron continuously invests in research and development to stay ahead of market trendsandtechnologicaladvancements.Weactively seek out innovative solutions and collaborate with industry partners to enhance our product offerings. By staying at the forefront of innovation, we aim to provide our customers with cutting-edge machinery that improves productivity and efficiency.

- 28. SEPTEMBER 2023 26 www.textilevaluechain.in Corporate Speaks How does Pifron balance quality, service, and innova on in its management approach? We take a holistic approach in balancing quality, service, and innovation by prioritizing quality, focusing on customer/market needs, empowering employees, and continuously improvement How does Pifron handle customer inquiries and ensure mely responses while maintaining a focus on quality and con nuous improvement? Overall, our management approach involves striking a balance between quality, service, and innovation. We believe that by prioritizing all three aspects, we can deliver superior value to our customers and maintain a competitive edge in the textile machinery industry. Handling customer inquiries and ensuring timely responses while maintaining a focus on quality and continuous improvement is a key priority for Pifron. We understand the importance of promptly addressing customer queries and providing accurate information. To achieve this, we have established a dedicated customer support team that is trained to handle inquiries efficiently. We emphasize effective communication and actively listen to our customer’s needs and concerns. Our team is equipped with comprehensive product knowledge, enabling them to provide detailed and accurate responses to customer inquiries. To ensure timely responses, we have implemented streamlined processes and communication channels. We prioritize prompt communication with our customers, whether through phone, email, or online platforms. Our goal is to address customer inquiries within the shortest possible time frame, typically within 24-48 hours. At Pifron, we believe that timely responses go hand in hand with maintaining quality and continuous improvement. We value customer feedback and consider it a valuable source of information for enhancing our products and services. We constantly evaluate and optimize our processes to ensure efficient handling of inquiries while upholding our commitment to quality standards. By continuously improving our response mechanisms, we aim to provide an excellent customer experience that aligns with our focus on quality and continuous improvement. ISFMA – An Ichalkaranji based fabrics manufacturers associa on once again takes a lead to Organise its 2 nd Edi on of Yarn Expo 2023 – The Trade Bridge on 10 th amp; 11 th October 2023 at Ichalkaranji. LENZING FIBERS INDIA PRIVATE LIMITED is the main sponsor for the event. Leading Spinners, Fibre Manufacturers, Fancy yarn producers, Online Yarn Portals, Importers, Traders etc. around the country are par cipants to this show. Ichalkaranji - One of the fastest growing Tex le Hub of the country, has more than 22000 shu leless weaving machines in and around the town and with the promise of doubling the capacity – this area is just unstoppable. Yarn remains the raw material to the manufacturing of fabrics and hence there is fantas c demand of yarn in this market. Looking at this scenario ISFMA last year orgainsed its first YARN EXPO 2022 which was a super hit and hence ini ated ahead for its second edi on. DKTE is the knowledge partner and TAIMU (Students Chapter) is the event coordinator for the show. A very big foot fall is expected for this event by the Organisers and Par cipants of the show. Ichalkaranji Shuttleless Fabrics Manufacturers Association (ISFMA) To Organise YARN EXPO 2023 IN ICHALKARANJI

- 29. Yarn Noil Combed Yarn NE 16’s to 40’s Combed Compact Yarn NE 16’s to 40’s Carded Yarn NE 12’ to 30’s (for Knitting Weaving) Comber noil Flat strip Licker-in 19.HIN.92143 Hohenstein HTTI Inquiry: +91-9979240389, +919815004417 | sarjil@realprincegroup.com | munish@realprincegroup.com 3 Star Export House Fabric Knitted Fabric Single Jersey Single Jersey With Spandex/Rib/Interlock We, vertically integrated manufacturing Units established in Gujarat, one of the most progressive states and the cotton hub of INDIA. I N D I T E X Supplying quality worldwide

- 32. SEPTEMBER 2023 30 www.textilevaluechain.in Corporate Speaks The Journey of Astra Tech India Tex le Value Chin talked with Mr. Hemant Dantkale, Astra Tech India to understand the journey of star ng a new company in India’s vast Tex le Machinery landscape. Can you tell us about your experience working with DEECO Mechatron for over three decades? I consider myself fortunate to get the opportunity to serve in DEECO group for 34 years. Working under the highly qualified, talented, and very courteous management team of DEECO. It was a great experience. What were some of the most memorable moments or accomplishments during your tenure at DEECO Mechatron? There are many memorable moments and ac- complishments. Just a few I wish to narrate-- Mr. Manek Daver, elder brother of our Chairman, sent me a letter of appreciation from his Japan office when a 1st new high-speed Combing Machine I sold to a spun silk unit in 1998. When I sold the first set of Tubular Knit processing machines, our Chairman Dr. Minoo Daver came to my cabin and handed over a cash reward which was a pleasant surprise. Ethics in business was their prime principle. One of our principals wanted to bill the customer for a courtesy visit extended by their technician. On realizing the rigid view of the Principal, management decided to terminate the agency despite good business opportunities for their product. How has the tex le machinery industry changed over the course of your career? Machinery manufacturing has transformed a lot with the inclusion of automation, invertors, touch screen Human-machine interface, high speed, fault identification and diagnosis, and most important minimized human intervention. This all has made machines of high production capacity and improved quality Can you describe the process of star ng ASTRA TECH INDIA? ASTRA TECH INDIA is derived from carving a huge list representation of DN Associates for smooth and ease of operations. So, our firm, DN Associates now exclusively works for machines and accessories for long-fibre spinning. In fact, DN Associates was formed with kind support and guidance from the management of DEECO Mechatron, for the continuity of services to most of their representa- tions, as DEECO wanted to opt out of this business. What are the core strengths and exper se that ASTRA TECH INDIA brings to the market? One-- Only top makers of textile machinery and accessories and only from Europe. Two-- Our team of highly experienced and dedicated technocrats is our core strength. How do you see ASTRA TECH INDIA fi ng into the larger tex le machinery industry landscape? Though ASTRA TECH INDIA is a small and new entity, the reputation of our world-known Principals and our efforts to extend excellent services has made space for itself. What are some of the biggest challenges you have faced in your career, and how did you overcome them? Born and brought up in the remotest village and started my career as a Service Engineer in City of Dreams—Mumbai, had challenges in every aspect. Tried my best to work with sincerity and honesty made me overcome those challenges. How has your previous experience at DEECO Mechatron prepared you for your role as CEO of ASTRA TECH INDIA? My erstwhile employer --DEECO Directors, their family members, and the management team were kind to offer opportunities, caring, and respecting human beings. Their trust, confidence, and responsibilities reposed in me have helped me immensely to work as CEO of ASTRA TECH INDIA.

- 33. For QUALITY Products from Europe and EFFICIENT Services in India ------------------------------------------------------------------------------------------------------------------------------------------------------ We represent in India the following Textile Machinery Accessories manufacturers for Technical Textiles : LACOM GmbH, Germany : Hotmelt Laminating and Coating Systems – Multi Purpose, Multi Roller, Gravure Roller and Slot Die for complete range of Technical Textiles (Website: www.lacom-online.de) MORCHEM S.A.U., Spain : PUR Hotmelt Adhesives for Technical Textiles, Solvent Based, Water Based adhesives, cleaners and primers. (Website: https://www.morchem.com/markets-and-solutions/textile-lamination/ ) Fibres, Waste Recycling Nonwovens : Margasa, Spain: Textile Hard Waste Recycling Lines -complete with preparation, cutting, Storage, feeding, tearing, filtration and fiber packing. Peripheral equipment, for nonwovens waste. Complete lines for “Airlay Nonwovens” with thermo or resin bonding. Cotton Waste Cleaning Lines. (Website: http://www.margasa.com) FARE' S.p.A., Italy : Complete Lines for Spunbond / Meltblown nonwoven products /complete line to produce all type of fibers including mono and bicomponent including PET and PET fibers. Machines for producing Tapes and Rafia (website : www.farespa.com) Conventional : Mariplast Spa, Italy : All type of Yarn Carriers for spun and filament yarns - Cylindrical Tubes, Roving Bobbins, Ring Frame Bobbins, Cones and one time use and Reusable Dye Tubes (Website: www.mariplast.com) C + L Textilmaschinen GmbH, Germany : Reeling (Yarn Hank Forming) Machines, steaming, Bulking and Banding Machines for yarns ( Rep.for Western and Southern India) (Website: www.croon-lucke.com) Contact : ASTRA TECH INDIA E-mail : Website: www.astratechindia.co.in Contact :Mr. Hemant Dantkale / Mobile : 98201 06018 / E-mail:hdantkale@astratech.co.in :Mr.Gaurav Dantkale / Mobile : 8451031732 / Email : info@astratech.co.in HEAD OFFICE: 709, Rajhans Helix 3, L.B.S. Road, Ghatkopar (West), MUMBAI – 400 086 Regd.Office: C-801, Ashok Odyssey, Near Damodar Park, L.B.S Road, Ghatkopar (West), MUMBAI – 400 086 Branch Office: Coimbatore: Mr.Karthik Babu /9043016560 mail: Coimbatore@astratech.co.in

- 34. China Germany India France Korea Taiwan Italy 160+ brands from *Registrations are free of charge 12 – 14 September 2023 Jio World Convention Centre (JWCC), Mumbai MEDITEX™ – a dedicatedpavilion and conference on medical textiles will be co-organised by The South India Textile Research Association (SITRA) Techtextil India Symposium’s will bring forth a conference on Geotextiles and India’s infrastructure : Paving insights for a better tomorrow Knowledge seminars A power-packed expo with Scan the QR code to register Contact us. Anurag Bakhle +91 22 6144 5971 anurag.bakhle@india.messefrankfurt.com India’s most focused expo for Technical textiles, nonwovens and composites Must visit for 12+ indistries Supported by

- 35. Come Visit Us at Techtextil India Pavilion 23, L14 12-14 September Mumbai, India Swiss Quality since 1935 AIR CONDITIONING | HUMIDIFICATION | FILTRATION | CLEANING J Highest filtration efficiency in the industry J Maintain the right conditions for your process 24/7 J Up to ~70% space savings over traditional drum filters with the Luwa MCV filter while maintaining the same efficiency. luwa.com MultiCell Filter (MCV) ~70% Luwa India Pvt. Ltd. — # 3P-5P, Gangadharanapalya — Kasaba Hobli, Off Tumkur Road — Nelamangala, Bangalore North — 562 123, India

- 36. SEPTEMBER 2023 34 www.textilevaluechain.in Corporate Speaks Can you tell us about Capximize? Capximize is a global digital platform for manufacturing companies. At Capximize we are connecting manufacturing companies with each other. We help Indian manufacturing companies utilize their manufacturing capacities in a better way. We enlist their capacities in our platform, then with our proprietary algorithm, we recommend the right manufacturing partners to our registered members. We have manufacturing capacity providers who are Indian Manufacturers but the seekers are worldwide, global companies. So large multinational organizations who need Indian vendors can use our platform. Currently, we are covering five sectors, textile, pharma, electronics, auto components and chemicals. Apart from that we are also actively working to generate enquiries for our members. That way we are providing them additional business opportunities. Also, as this is a global platform we are also providing global visibility to MSME sectors of India. How can companies register on your pla orm? Both entities which are on the platform, the first Indian manufacturers, who are providing their capacities, have to register on the website (www. capximize.com) and log in as Capximizer, which is our own term which we use for capacity providers. They have to provide their capacities and additional requirements like any certifications, ISO in case of the pharma sector, they have WHO certificate, all these things they can upload on the platform. Also, the second kind of entity is seekers. So, seekers are the global companies, which can be MNCs, MSMEs or even startups who do not want to invest in a manufacturing setup. They also have to register on the website and register themselves. For both of these entities to register they only need three things: Email ID, Phone Number and GST. How do you verify the companies to avoid any complica ons in the future? For the verification process, using our proprietary algorithm, we use its inbuild mechanism to verify GST, email ID and phone number through the OTP process. Also, our platform is hosted on AWS servers, which are one of the world’s most secure servers which ensures our data security 24x7. Also, the data is not shared with anyone, it is 100% confidential and encrypted data. Also, for security purposes for our members, we have a two-step authentication process, one is password and the other is OTP. So, no one can hack and use their data. For GST verification we use the GST portal. For large-scale companies or in the case of major deals, we have tie-up with certain validation agencies, so these agencies sometimes go and physically validate plants also, through that we ensure that the deals, plants and production capacities are genuine. Seekers are also verified the same way, if they are international seekers, in that case, our members can use one of the validation agencies to verify them. Their payment capabilities and other things. Also, Capximize is not involved in any deals, we are just connecting the seekers and manufacturers. After Digital connectivity for Indian Manufacturers; Interaction with Capximize Tex le Value Chain talks with Mr Sanjeev Pandey, Zonal Head and Marke ng, Capximize at Yarn Expo Surat 2023.

- 37. www.textilevaluechain.in 35 SEPTEMBER 2023 that all the deals happen between two parties, even the owners are verifying each other. But we still help them with our agencies. Currently how many companies have partnered with you? We started last year around January-February 2022, so now in 18-20 months, we have already more than 5200 manufacturing companies with us. Out of which 4500 are the Indian manufacturers. As I mentioned we are a very new platform, but in this short span of time, we have got more than 100 enquiries currently going on. These are the large size enquiries, the average enquiry size on our platform will be more than a crore. And we have concluded more than dozens of deals as of now which are multi-crore deals. So, we are adding a lot of value to our manufacturers now. A lot of enquiries have come into the pharma sector and textile sector, few of them are in chemicals, electronics and auto parts. Are there any plans for expansions in the near future? We have our plans, as I mentioned we are currently in only five sectors, so one plan is to move into other sectors through sector expansions. So, we are going into consumer goods and food products. that’s one way. The second plan in 2-3 years is to offer manufacturing capacities from out of India as well. Currently, we are offering from India only, but in the future, even foreign companies will also be able to offer their capacities. Are you partnering with any associa ons? This has been our plan from the beginning, we take a lot of support and help from not only Indian associations but also foreign and Indian chambers also. We have taken membership in more than twenty chambers and associations. Some of them may be the Indo-France Chamber of Commerce, New India Chamber, Indo-German Chamber, and Indian associations like ITMA, Drug Manufacturing Association, Indian Textile Association, and CMAI, so these are some of them. We do a lot of seminars, and webinars with them, we also sponsor their events and we also do our own events with these associations and through that we connect with our members. SUBSCRIPTION FORM Name Email Id Mobile Number Landline / Alternate Number Address Company Name Designation Payment Method Print 1 year 12 issues Rs. 800/- Digital Rs. 500/- Print 2 years 24 issues Rs. 1500/- Digital Rs. 1000/- TEXTILE VALUE CHAIN 504, Suchita Business Park, Pantnagar, Ghatkopar (East), Mumbai - 400075, Maharashtra, INDIA. website : www.textilevaluechain.in, email : sales@textilevaluechain.com, Call/ Whats App : +91 9167986305

- 39. ƌƚͲzĂƌŶdžƉŽƌƚƐ;/ŶĚŝĂͿWǀƚ͘ƚĚ͘ WƌŽĚƵĐƚDŝdž ‡ ŽƚƚŽŶ zĂƌŶƐ ͗ ĂƌĚĞĚ͕ ŽŵďĞĚ͕ ŽŵƉĂĐƚ͕ ŽƉĞŶ ŶĚ ‡ ŽƚƚŽŶ ǁĂƐƚĞ ͗ ŽŵďĞƌ EŽŝů͕ ƌĞĂŬ ŽŵďĞƌ͕ ůĞĂĐŚĞĚ EŽŝů͕ ŝĐŬĞƌŝŶ ǁĂƐƚĞ͕ ůĂƚ ǁĂƐƚĞ͕ WƌŽĐĞƐƐ ŽƚƚŽŶ ‡ WŽůLJĞƐƚĞƌ zĂƌŶ ‡ sŝƐĐŽƐĞ zĂƌŶ ‡ WŽůLJĞƐƚĞƌͬ ŽƚƚŽŶ zĂƌŶ ‡ WŽůLJĞƐƚĞƌͬsŝƐĐŽƐĞ zĂƌŶ ‡ ŝůĂŵĞŶƚ LJĂƌŶƐ ϵƚŚůŽŽƌ͕ͲtŝŶŐ͕'ŽĚƌĞũŽůŝƐĞƵŵĞŚŝŶĚǀĞƌĂƌĚEĂŐĂƌ͕ ^ŝŽŶͲdƌŽŵďĂLJ ZŽĂĚ͕^ŝŽŶ;ĂƐƚͿDƵŵďĂŝʹ ϰϬϬϬϮϮ͕/ŶĚŝĂ dĞů͗нϵϭϵϬϬϰϱϲϮϱϴϴͬĂdž͗ϬϮϮϰϬϬϭϮϲϳϵtĞďƐŝƚĞ͗ ǁǁǁ͘ĂƌƚLJĂƌŶŝŶĚŝĂ͘ĐŽŵ ͲŵĂŝů͗ĂƌƚLJĂƌŶΛĂƌƚLJĂƌŶŝŶĚŝĂ͘ĐŽŵ ďŽƵƚhƐ ‡ ƌƚͲzĂƌŶŝƐĂůĞĂĚŝŶŐƐƵƉƉůŝĞƌŽĨLJĂƌŶƐŝŶƚŚĞŐůŽďĂů ŵĂƌŬĞƚ͕^ƵĐĐĞƐƐĨƵůůLJƐƵƉƉůLJŝŶŐďĞƐƚƋƵĂůŝƚLJLJĂƌŶƐĂŶĚ ƐĞƌǀŝĐĞƚŽŽƵƌƉĂƌƚŶĞƌƐĂŶĚĂƐƐŽĐŝĂƚĞƐĂůůŽǀĞƌƚŚĞǁŽƌůĚ ĨƌŽŵƉĂƐƚ ƚǁŽĚĞĐĂĚĞƐ͘ ^ƚƌĞŶŐƚŚƐ ‡ ƵůĨŝůůŝŶŐ ƚŚĞ ŶĞĞĚƐ ŽĨ ĐůŝĞŶƚƐ ďLJ ƐĞůůŝŶŐ ϭϰϬϬϬн ƚŽŶŶĞƐ ŽĨ LJĂƌŶ ĂŶŶƵĂůůLJ͘ ‡ zĂƌŶ ƐƵƉƉůŝĞĚ ĨŽƌ ĞŶĚ ƵƐĞ ŽĨ ŬŶŝƚǁĞĂƌ͕ ƐŚŝƌƚŝŶŐ Θ ^ƵŝƚŝŶŐ͕ dĞƌƌLJ dŽǁĞů͕ ,ŽŵĞ dĞdžƚŝůĞƐ͕ ƐŽĐŬƐ͕ /ŶŶĞƌ tĞĂƌ͕ ĞŶŝŵ͕ hƉŚŽůƐƚĞƌLJ͕ ĂƌƉĞƚƐ͕ ĞƚĐ͘ ‡ ůŝĞŶƚ ďĂƐĞ ŝŶ ŵŽƌĞ ƚŚĂŶ Ϯϱ ĐŽƵŶƚƌŝĞƐ ‡ /^K͕ 'Kd^͕ 'Z^͕ KKͲdy͕ / ĐĞƌƚŝĨŝĞĚ

- 41. Growing Exporter of Polypropylene Multifilament Yarn from INDIA 100% Export Oriented Unit Production Capacity 5000 Tonnes per Annum Proximity from NHAVA SHEVA PORT, Mumbai Indospun LLP 1008, Embassy Centre, Nariman Point, Mumbai -400021 Mr. Suresh Pimpale s.pimpale@indospun.com INDOSPUN Manufacturer of High Tenacity PPMF Indospun LLP was formed in 2017 with the idea of providing the best quality polypropylene multifilament yarn to the Market. About US : www.indospun.com

- 42. SEPTEMBER 2023 40 www.textilevaluechain.in Digitization Expanded Product Offerings With digital fabrics, tex le businesses can expand their product offerings without the need for significant physical inventory. The ability to showcase a wide range of virtual fabric op onsand the commercial data of each fabric with a digital library enables the crea on of diverse collec ons and personalized products, catering to a broader customer base and capturing new market segments. Accessto Global Markets Embracing digital fabrics opens up opportuni estocatertoglobalmarkets. With virtual fabric samples and online digital libraries, tex le businesses can reach a broader audience without geographical limita ons. This expanded market reach can lead to increased sales and revenue streams, fostering interna onal businessgrowth. Reducing Costsand Saving Time Tradi onal tex le material crea on and sampling processes are o en laborious and resource-intensive. However, with 3D digital fabric material crea on, the need for physicalproto- types is eliminated. This reduc on in physical sampling not only minimizes raw materialwaste but also significantly lowers produc on costs. By virtually visualizing fabric swatches and material combina ons, tex le manufacturers canmake informed decisions early in the design phase, mi ga ng the risk of expensive modifica ons during later stages of produc on. As a result, the technology saves both me and money, providing tex le businesses with improved cost-efficiency and enhanced profit margins. The Impact of 3D Digital Fabric Material Creation On Driving Business Growth The tex le industry is no stranger to innova on, con nuously seeking ways to improve efficiency, crea vity, and sustainability. Among the latest technological breakthroughs, 3D digital fabric material crea on stands out as a game-changer that has revolu onized the tex le landscape. This cu ng-edge process empowers tex le manufacturers and designers to create highly realis c virtual fabric materials, offering a plethora of advantages that directly impact business growth.

- 43. www.textilevaluechain.in 41 SEPTEMBER 2023 Embracing Sustainable Prac ces Sustainability has emerged as a driving force in today’s tex le industry, with brands and consumers increasingly seeking eco-friendly products. Embracing 3D digital fabric material crea on aligns with this growing demand for sustainability. By reducing the reliance onphysical samples, tex le manufacturers ac vely contribute to minimizing fabric waste and conserving valuable natural resources. Promo ng sustainable prac ces not only strengthens a tex le company’s reputa on but also appeals to envi- ronmentally conscious brands and consumers, crea ng new opportuni es forgrowth. As the industry shi s towards more sustainable approaches, businesses that adopt 3D digital fabric material crea on can posi on themselves as leaders in responsible tex le manufacturing. Strengthening Collabora on and Supply Chain Efficiency In the tex le industry, collabora on and supply chain efficiency are essen al for seamless opera ons. 3D digital fabric material crea on facilitates real- me sharing of virtual fabric samples and designs between designers, manufacturers, and suppliers, regardless of their geographic loca ons. Improved collabora on ensures that everyone involved in the produc on process has a clear understanding of the design intent, minimizing errors and discrepancies. The result is a more streamlined supply chain with reduced lead mes, enabling tex le manufacturers to seize market opportuni es swi ly and drive business growth. Introducing Fron er.cool: A Fabric Digi za on Real- me Collabora on Pla orm —Powered by AI Fron er.cool provides the world’s first AI-powered fabric digi za on real- me collabora on pla orm, helping suppliers, manufacturers, and designers digi ze their fabrics at scale within just 5 minutes— saving me and money through out the en re fabric- digi za on journey. Already trusted by hundreds of APAC suppliers and vendors, world-renowned fashion brands, and global designers, Fron er.cool enables anyone to digi ze fabric materials usinga regular flatbed scanner by themselves. Scanning can be performed by the user on-site, elimina ng the wastage of me, money, resources, effort, and shipping. Fron er.cool’s cu ng-edge AI and machine learning technology transforms a fabric image into a digitalma- terial which includes: ● The fabrics pecifica ons. ● AI-generated metadata (or maps) to ensure the digital material looks realis c. ● The material’s physical proper es which enable the digital material to move naturally when placed on a 3D model. ● Environmental impact data and much, much more. Once the digital material has been generated, suppliers can showcase their materials digitally, making it easy for brands to choose fabrics. Brands and their designers can select fabric and plan collec ons in real- me —with team members involved —to reduce the cost and me associated with tradi onal fabric shipping processes. There lease ofnew product lines can be executed in afrac on of the me.

- 44. SEPTEMBER 2023 42 www.textilevaluechain.in Digitization Sustainability Ma ers As sustainability takes center stage, transparency becomes paramount for brands. Mee ng the demands of regulators, investors, and customers means enhancing traceability throughout the supply chain. Unfortunately, the lack of readily available, scien fically- backed data has hindered brands from achieving their sustainability goals. Enter Fron er.cool — the world’s first material digi za on solu on to provide interna onally verified environmental impact data es ma ons. Say goodbye to uncertain es, as Fron er.cool’s cu ng-edge technology now enables the delivery of material-level impact measurements with utmost accuracy. From CO2 emissions to water consump on and even land use, the environmental impact data is not just comprehensive but also en rely trust worthy. Every piece of fabric scanned and uploaded to Fron er. cool’s Tex leCloud™ pla orm displays the es mated impact that it has had on the environment. This informa on is crucial for informed decision-making right from thevery start. The Bo om Line Asthetex leindustryevolves,businessesthatembrace 3Ddigitalfabricmaterialcrea oncangainacompe ve advantage, cater to changing buyer preferences, and fuel business growth in an ever- compe ve market. Join us in embracing this transforma ve technology and take the lead in driving sustainable change. Together, we can create a world where fashion meets responsibility — let’s shape a brighter and greener future for the tex le industry. Visit www.fron er.cool for more informa on or get in touch at vijay@fron er.cool to schedule a demo. Alterna vely, scan the QR code below. Dr. Vijay Gotmare, Ph.D.(Tech.), Hon. FTA Representa ve Director (India) Fron er.cool Inc., Taiwan E-mail: Vijay@fron er.cool Mob:+919833721022 he global rugs and carpet market is valued at US$ 77 billion in 2021 and has been witnessing a growth at a CAGR of 4% over the past decade. The market is expected to reach US$ 95 billion by 2025 at a CAGR of 5% from 2020 to 20251. Global Rugs Carpets Market Scenario Growth of rugs and carpets sector is highly dependent on the increasing demand for home décor products, recogni on of carpet as a necessary product instead of luxury, growth in end- user segments such as The rug and carpet market is a significant segment of the tex le industry, growing at a steady pace fuelled by various factors such as changing consumer preferences, rising disposable incomes, technological advancements, and rapid urbaniza on. In addi on, the use of innova ve materials and technology, along with the popularity of e-commerce pla orms and online sales channels, are also contribu ng to the growth of the market. Global Market Opportunity in Rugs and Carpet T HomeTextiels

- 45. www.textilevaluechain.in 43 SEPTEMBER 2023 hospitality, corporate, retail, entertainment, avia on, etc. Figure 1:Global Rugs Carpets Market Size (US$ bn.) Source: Tex le Focus, Floor Covering Weekly, Carpet Research Ins tute and Wazir Analysis As of 2021, the global rug market comprises 30% of the overall market, valued at US$ 27 billion, with carpets accoun ng for the remaining 70%, valued at US$ 50 billion2 . The largest segments within the global rug and carpet market are bath rugs and wall-to-wall carpets. The global trade of rugs and carpets have stood at US$ 17 billion in 2021, with tu ed category holding the highest share of 43%, followed by woven 32%.3 The synthe c fiber segment dominates the market with 56% share, which is a ributed to its economical prices, durability, and low maintenance requirements4 . The USA is the largest market accoun ng for US$ 22 billion in 2021 having 29% market share, followed by Europe accoun ng for US$ 14 billion for the same period having 18% share5 . The synthe c fiber segment dominates the market with 56% share, which is a ributed to its economical prices, durability, and low maintenance requirements. Figure 2: Global Market Size (2021) Markets Value(US$bn.) Share USA 22 29% EU 14 18% Turkey 9 12% China 7 8% Japan 4 6% India 4 6% Australia 4 5% ROW 12 16% Total 77 Source: Wazir Analysis More than 85% of the demand for carpets and rugs in the US is met by domes c manufacturing, with the remaining 20% being fulfilled through imports. According to the Carpet Rug Ins tute (CRI), the state of Georgia alone accounts for over 45% of the world's carpet supply. Interes ngly, the top four countries that produce carpets are also the top four markets for carpets in the world. India Rugs Carpets Market Scenario The growth of Indian market of rugs and carpets is steadily accelera ng over last 10 years and the trend is expected to con nue. Rugs and Carpets market of India stands at US$ 1.2 billion in 2021, growing at a CAGR of 3% since 2011, with rugs having a largest share of US$ 900 million and carpets holding a value of US$ 280 million6 . Carpet market is yet to fully develop as majority of households do not use wall to wall carpets. Their usage is concentrated in corporate, hospitality, avia on and entertainment industry. Most of the demand is concentrated in low and economy segment with very low product prices. The demand across segments is growing but India remains a price sensi ve market. An important character of Indian market is that almost 80-85% demand is catered to by unorganized, unbranded segment. Figure 3:Indian Market of Rugs Carpets (US$ Mn) Source: Sta sta and Wazir Analysis The market is segmented by product type into tu ed, woven, needle-punched, kno ed, and others. The tu ed and woven rug segments are the most popular types of rugs and carpets, accoun ng for a significant share of India's exports. Wool-based carpets are also highly sought a er with India having a rich tradi on of producing beau ful and durable woolen carpets. India’s export India’s rugs carpets export stood at

- 46. SEPTEMBER 2023 44 www.textilevaluechain.in HomeTextiels US$ 2.2 billion in 2021, growing at a CAGR of 6% since 2011. Natural fibre based rugs carpets such as of wool, co on, jute, etc. are majorly exported from India. India’s exports of tu ed carpets is gretaer compared to other rugs and carpets segments. Industry Dynamics The global market for rugs and carpets is undergoing a rapid evolu on, providing companies with the chance tobroadentheircustomerbaseandenternewmarkets. In order to seize the immense opportunity available in the global rugs and carpets market, companies must priori ze product innova on, quality, and design. They must also adopt modern manufacturing processes and technologies to enhance their compe veness and efficiency in the global market, and focus on sustainability and eco-friendliness to keep up with changing customer demands. Addi onally, there are several trends observed in the industry that can be leveraged are: • Increasing demand for eco-friendly and sustainable products Sustainability concerns is causing shi towards envi- ronmentally friendly and circular fibres like recycled pet, nylon, PP. Rugs made out of nylon wool are losing their market share to polyester PP rugs, respec vely due to price considera ons. • Increasing demand for customized rugs and carpets Customers are becoming more interested in personalized products, and this presents an opportunity in the rug and carpet industry. Customizedrugsandcarpetscancatertothegrowing demand. Customers can choose the size, colour, and design of the rug or carpet they want, and a product that meets their specific requirements can be created. This can help market players differen ate themselves from their compe tors and increase customer loyalty. • Growing demand in emerging markets Emerging markets, such as India present a massive opportunity in the rug and carpet industry. The middle class in these countries is growing, and with it, the demand for home decor products, including rugs and carpets. Industry can leverage this opportunity by entering these markets and offering their products to the growing customer base. • Technological Advancements Due to price considera on, there has been a shi from handmade rugs to machine made rugs. Conven onal dyeing processes are being replaced withdopedyed/solu ondyedyarndyeingprocesses saving water. In conclusion, the global market opportunity for rugs and carpets is a promising one, with increasing demand from both residen al and commercial sectors. As the world becomes more conscious of the need for sustainable and eco-friendly products, the rug and carpet industry has responded by innova ng and producing environmentally conscious materials. With the rising demand of stylish and func onal floor coverings and growth of the global economy, manufacturers have the chance to expand their reach beyond their tradi onal markets and cater to a wider audience. It is clear that the rug and carpet industry is poised for con nued growth and success, as long as it stays a uned to changing consumer needs and preferences. Source: 1 Tex le Focus, Floor Covering Weekly, Carpet Research Ins tute and Wazir Analysis 2 Wazir Analysis based on published reports, global trade data and primary research 3 UN Comtrade and Wazir Analysis 4 Source: UN Comtrade and Wazir Analysis 5 Source: Wazir Analysis 6 Sta sta and Wazir Analysis

- 47. More Than Years of EXPERIENCE 25,536 SPINDLES Manufacturing Vivekanand Industries Vivekanand Industries 56 DR 56 DR Capacity 60,000 Bales Capacity 60,000 Bales [165 Kgs/Bale] [165 Kgs/Bale] Vivekanand Cotspin LLP Vivekanand Cotspin LLP 32 DR 32 DR Capacity 35,000 Bales Capacity 35,000 Bales [165 Kgs/Bale] [165 Kgs/Bale] Raw Cotton : S-6, J34, MECH-1, MCU-5 DCH-32 We can also supply Raw Cotton from Australia, Africa (East West), Brazil and USA. Cotton Waste : Comber Noil, Flat Strips, Licker-In, Sweeping, Roving and Hard Waste. Raw Cotton : Cotton Waste : S-6, J34, MECH-1, MCU-5 DCH-32 We can also supply Raw Cotton from Australia, Africa (East West), Brazil and USA. Comber Noil, Flat Strips, Licker-In, Sweeping, Roving and Hard Waste. Cotton Yarn Manufacturing from our Spinning Unit –Vivekanand Cotspin LLP with 25,536 Spindles. • Our inclination towards supreme quality production is reflected in all our practices, right from procurement of raw materials up to production and delivery of the products. • Blow room to Ring frame from LMW with 100% Compact. • Link Coner: Muratec qpro plus, all made in 2016. • Our spinning unit is equipped with world class facilities and our machinery has been secured from reputed suppliers in India, Japan and Switzerland. • We have our Yarn Production Capacity of 25-30MT/Day. Certifications Products Range Open End Counts NE 6's to NE 24's with 1600/1700/1800 CLSP. Ring Spun Combed and Carded Compact Single/Double (TFO) Yarn for Hosiery Weaving. Counts: 12's to 100's 100% Cotton Yarn. Survey No. 185/1, Thol Road, Kadi, Rangpurda, Dist. Mehsana-382715, Gujarat, India. 702, 7th Floor, Fortune Business Hub, Science City Road, Sola, Ahmedabad-380060. Gujarat, India. C O T S P I N (3★ Export House) (Spinning Mill) Bangladesh Malaysia Hong-Kong Japan Indonesia China Egypt Italy UAE Thailand S. Korea Vietnam Pakistan Taiwan Sri Lanka Portugal With an industry experience of more than 25 years, we understand client's interest and requirements locally and internationally, which itself is a reason for making us one of the leading exports business entity to deal with the overseas clientele. Currently the company is exporting to its best quality products and our overseas markets stand right from Japan in the East to Latin America in the West. We are also exporting across the following countries like. Exports Trading Our Group of Companies : VIVEKANAND INDUSTRIES AMBICA COTSEEDS LTD. VIVEKANAND COTSPIN LLP AVADH COTTON INDUSTRIES BALAJI OIL MILL GINNING PRESSING FACTORY AMBICA INTERNATIONAL LLC (USA) Overseas Offices : Australia Benin Sudan UAE USA

- 49. www.brueckner-textile.com FASCINATING TEXTILE MACHINERY ACHI IN N N N N N NE E E E E E ER R RY Digitize your processes! Visit us in Mumbai TECHTEXTIL INDIA 12 – 14 September '23 Pavillon 3 · Booth M34

- 50. SEPTEMBER 2023 48 www.textilevaluechain.in CorporateViews t The Yarn Bazaar, we recognise the immense value of a nurturing company culture, where employees are encouraged to thrive and discover their own unique paths to success. Our progressive policies ac vely foster an environment that cherishes individuality, unlocks crea vity, and empowers every team member to unleash their full poten al without the constraints of excessive conformity. For starters, we believe that crea ng a posi ve and welcoming first impression for new employees is crucial. That’s why, unlike most companies, we schedule the first day of work on Saturdays instead of Mondays. We want our newcomers to have the weekend to reflect on their ini al experience and to share their excitement with their loved ones at a company-sponsored dinner on the same day. To help new employees quickly bond with their colleagues, our HR department has a though ul tradi on in place. On their first day, each new team member receives a box of chocolates, which they distribute while introducing themselves to the rest of the office! This sweet gesture not only fosters connec ons but also sets the stage for a warm and inclusive work atmosphere. Company Culture at The Yarn Bazaar: Promoting Collaboration and Creativity in Our Workplace By: Pra k Gadia, Founder and CEO, The Yarn Bazaar In today’s ever-evolving corporate landscape, company culture has long been dismissed as a so and secondary aspect of business, o en overshadowed by the more tangible metrics such as profit and loss. However, the post-covid world has brought about a profound shi in thinking, promp ng a reevalua on of these conven onal no ons. We have come to realise that what was once considered a mere a erthought is, in fact, a crucial element that significantly impacts an organisa on’s success. The belief that there is a ‘one size fits all’ approach is slowly losing its sheen, making room for a more enlightened perspec ve—one that champions flexibility and places trust in our employees’ agency. A

- 51. www.textilevaluechain.in 49 SEPTEMBER 2023 To further strengthen our team’s camaraderie and build a robust company culture, we organise regular game nights featuring sports like football and badminton. Addi onally, our weekly tribe sessions offer opportuni es to engage in insigh ul discussions on compelling case studies and other educa onal topics, fostering con nuous learning and growth. And to tackle the dreaded “Monday Blues,” we host fortnightly movie mornings, ensuring our team starts their week with high energy and mo va on. Recently, we screened the inspiring movie ‘Air’ on Ne lix, which tells the story of Nike’s partnership with the legendary basketball player Michael Jordan. Also, we try to ensure that team bonding isn’t just limited to the office; we recently organised an overnight camping trip where we played various team sports and games like paintball and cricket. During office hours, we encourage the team to eat lunch together, promo ng a sense of unity and encouraging cross-team interac ons. We even have spontaneous jam sessions that bring out the hidden musical talents among us, making our workplace vibrant and enjoyable. Most importantly, flexibility is at the core of our work environment. Employees have the freedom to clock in and out at their convenience, as long as they fulfil their daily working hours. Our flexible work hours are complemented by a one-hour lunch break, providing ample me for relaxa on and rejuvena on. We also have other features in our office such as a state-of-the- art, fully automa c full-body massage chair to ease muscle tension and provide relaxa on during work hours. When it comes to work-life balance, we offer work-from-home each month, ensuring our team members can balance personal and professional commitments effec vely. More importantly, we also understand the importance of taking care of our team’s well-being. That’s why we have an excellent leave policy, fully paid maternity leave and paternity leave. Employees can carry forward or even encash their unu lised leaves, encouraging them to take much-needed breaks when required. Finally, we believe in recognising and rewarding our team’s dedica on and commitment. To align our employees’ interests with the company’s success, we offer ESOPs (Employee Stock Ownership Plans) to all teammembers,givingthemastakeintheorganisa on’s growth. Overall, our commitment to fostering a posi ve and empowering company culture extends beyond words to tangible ac ons that nurture our team members’ well-being and inspire them to reach their fullest poten al.

- 52. ,QWHUQDWLRQDO7H[WLOH9DOXH KDLQ ,79 ([SR 6HSWHPEHU_6XUDW,QWHUQDWLRQDO ([KLELWLRQ RQYHQWLRQHQWUH 6,( )RUPRUHLQIRUPDWLRQSOHDVHFRQWDFW 0RKG1DKLG$ODP -RLQW'LUHFWRUDQG+HDGRI$662+$07H[WLOHV$QG7HFKQLFDO7H[WLOHVFRXQFLO (QDKLGDODP#DVVRFKDPFRP 7+($662,$7('+$0%(562)200(5($1',1'8675 0UV6LPPL3DUDVKDU (VLPPLSDUDVKDU#DVVRFKDPFRP 0 0U*DXUDYKRXGKDU (JDXUDYFKDXGKDDU#DVVRFKDPFRP 0 0U'HHSDQVKX6KRNHHQ (GHHSDQVKXVKRNHHQ#DVVRFKDPFRP 0 0UDVKSDO (DVKSDO#DVVRFKDPFRP 0 .H)RFXV$UHDV 2'23 3DYLOLRQ 7HFKQRORJ 6KRZFDVH )DVKLRQ6KRZ 3URGXFW /DXQFK 7HFKQLFDO 7H[WLOH 6XVWDLQDEOH 7H[WLOH 6XSSRUWLQJ 3DUWQHUV 3DUWLFLSDWLRQ RXQWULHV 7HFKQLFDO 6HVVLRQV VTP *URVV([KLELWLRQ 6SDFH 9LVLWRUVKLSV ([KLELWRUV 6SHDNHUV 7UDGLWLRQDO 7H[WLOH %60%* %%0HHWLQJ

- 56. SEPTEMBER 2023 54 www.textilevaluechain.in Market Report Value in Million US$ Country Jan-Apr 2022 Jan-Apr 2023 Growth World 32296.62 29835.41 -7.62% China 8554.75 7094.59 -17.07% Bangladesh 7535.44 7064.53 -6.25% Turkey 4164.93 3594.96 -13.68% India 1802.13 1810.16 0.45% Cambodia 1121.15 1058.48 -5.59% Vietnam 1291.00 1335.05 3.41% Pakistan 1255.42 1161.06 -7.52% Morocco 1065.42 888.41 -16.61% Sri Lanka 531.18 440.05 -17.16% Indonesia 425.72 391.73 -7.99% Quantity in Million KG Country Jan-Apr 2022 Jan-Apr 2023 Growth World 1420.14 1200.73 -15.45% China 352.73 278.48 -21.05% Bangladesh 443.83 388.43 -12.48% Turkey 157.57 118.70 -24.66% India 74.64 68.55 -8.17% Cambodia 51.54 44.31 -14.04% Vietnam 43.30 40.16 -7.26% Pakistan 86.13 75.93 -11.84% Morocco 34.64 27.35 -21.04% Sri Lanka 18.64 14.28 -23.43% Indonesia 14.97 11.34 -24.23% Unit Price (USD value/KG) In US$ Country Jan-Apr 2022 Jan-Apr 2023 Growth World 22.74 24.85 9.26% China 24.25 25.48 5.04% Bangladesh 16.98 18.19 7.12% Turkey 26.43 30.28 14.57% India 24.14 26.41 9.38% Cambodia 21.75 23.89 9.83% Vietnam 29.81 33.24 11.50% Pakistan 14.58 15.29 4.90% Morocco 30.76 32.48 5.61% Sri Lanka 28.49 30.82 8.19% Indonesia 28.44 34.54 21.44% Source: eurostat EU Apparel Import

- 59. Presently we are selling to more than 40 countries, our major business comes from countries like – Bangladesh, China, Portugal, Sri lanka, , Vietnam, USA, Chile, Peru,Thailand, Poland, Korea. We also have a domestic division, which suppliesyarn to our clients within India. We are facilitating approx 18~20 containers per month in Exports and approx 400 tons per month in our domestic business. sumitsinghal.sspl@gmail.com +91 98370 94847 Soft Yarn for Blankets, Bath Mats Hand Knitting: Ne 6/2/3, Ne 6/2/4, Ne 4/2,Ne 4/4, Ne 6/2 133-A NAND NAGAR, INDUSTRIAL ESTATE, PHASE - II, KASHIPUR DESTT. UDHAM SINGH NAGAR, UTTRAKHAND - 244713 PRODUCT RANGE We are working with brands like HM, IKEA, INDITEX and many more 100% Cotton Open End Knitting Yarn: Ne 8/1, 10/1, 12/1, 14/1, 16/1, 20/1, 24/1, 26/1, 30/1 Open End for Weaving / Denim: Ne 4/1, 6/1, 7/1, 8/1, 10/1, 12/1, 16/1, 20/1 Industrial yarns: Ne 20/4, 12/4, 6/6, 10/8 Double OE Yarn for Weaving: Ne 4/2, 4/4, 6/2, 6/3, 8/2, 10/2, 10/3,12/2 16/2 Cotton/Polyester Open End yarn: Ne 6/1, 7/1, 8/1, 10/1, 12/1, 16/1, 20/1, 24/1, 30/1 Cotton/Viscose Open End yarn: Ne 6/1, 7/1, 8/1, 10/1, 12/1, 16/1, 20/1 Cotton/Bamboo Open End yarn: Ne 6/1, 7/1, 8/1, 10/1, 12/1, 16/1, 20/1 Cotton/Excel(Lyocell) Open End yarn: Ne 6/1, to Ne 26/1

- 60. SEPTEMBER 2023 58 www.textilevaluechain.in Review Paper By *Muhammad Imran-ul-Haq, **Nisar Ahmed Jamil, ***Nasir Mahmood MATERIAL AND METHOD The present research study “ compara ve study of crosrol card MK5D versus modified card MK6 for ul mate effect on sliver and yarn quality” was conducted in the Department of Fibre Technology, University of Agriculture, Faisalabad and at the Shams Tex le Mills Limted Chiniot, during the year 2005. The process details and methods applied to record the effect of different number of sta onary flats at front and back carding zones with changing the cylinder speed. The raw co on MNH-93 samples were condi oned in the standard atmosphere before actual physical tes ng. Co on used for this inves ga on was of the following physical characteris cs. Staple length = 27.17mm Uniformity ra o = 46.72percent Fineness = 4.73 micrograms/inch Short fibre content = 19.47% Trash content = 7.5 percent The following changes were made at card and record its effect on sliver and yarn quality No of back (pre) sta onary flats No of front (post) sta onary flats Cylinder speeds (rpm) B1 = 5 F1 = 5 C1 = 500 B2 = 4 F2 = 4 C2 = 600 B3 = 3 F3 = 3 C3 = 700 Sliver specimen of 72 grains/yard thus prepared at the MK5D and MK6 (Crosrol) cards were fed to the breaker and finisher draw frames (TOYDA-DYH-500, JAPAN, 1989) and then fed to the simplex machine (FL-16, Japan, 1989) and ul mate to the China AGM-128 ring frame, for the prepara on of yarn samples keeping the en re machine se ng constants. Finally the PC blended yarn with blend ra o (52:48) of 30’s carded was spun with T.M 4.3 from 0.85 hank roving. YARN CHARCTERISTICS The yarn of 30s prepared at each se ng was subjected to the following physical tests. Yarn Count Yarn count was determined through Uster Digital Auto Sorter-III linked with computer system IBM, which gives direct reading. A lea of 120 yards was fed to the computer to determine English count according to instruc ons laid down in its opera onal manual recommended by ASTM (1997a). Yarn Lea Strength Lea strength tester was used to find the yarn lea strength in pounds. The lea of 120 yards was fed to the instrument according to the method recommended by ASTM (1997b). Count Lea Strength Product (CLSP) The product of count and lea strength was calculated by mul plying the count value with the respec ve lea strength value of yarn. CLSP = Yarn count x Lea strength A comparative study of Crosrol card Mk5d versus modified card Mk6 for ultimate effect on sliver and yarn quality ABSTRACT: The carding segments prior to the revolving flats exert a large impact upon sliver yarn quality. It ensures opening, thinning out, spreading out uniform distribu on of fibre flocks over the total surface area of the cylinder. Thus using these addi onal carding segments reduces the number of imperfec ons. Hence an inves ga ve study has been planed to evaluate the sliver and yarn characteris cs

- 62. SEPTEMBER 2023 60 www.textilevaluechain.in Yarn Single End Strength Yarn single end strength calculated with Uster Tensojet, whichappliestheprincipleofconstantrateofextension (CRE) for tes ng. CRE describes the simple fact that the moving clamp is displaced at the constant velocity. As a result the specimen between the sta onary and moving clamp extended by a constant distance per unit me and the force required to do so is measured. The breaking tenacity is calculated from the peak force, which occurs any where between the beginning of the test and the final rupture of the specimen. The procedure adopted is given in detail ASTM Standard (1997a). Sta s cal Analysis The data thus obtained was analyzed sta s cally as suggested by Steel and Torrie 1980) using M-Stat microcomputer sta s cal program as devised by Freed (1992). Atmospheric Condi ons All the tests of card sliver and yarn were performed under standard atmospheric condi ons which were maintained at 65 + 2 percent rela ve humidity and 20 +2°C temperature. RESUTLS AND DISSCUSSION Yarn lea strength The analysis of variance of data regarding yarn lea strength is shown in Table-1.This table shows the highly significant effect of back (B) and front (F) sta onary flats upon yarn lea strength while significant effect of cylinder speed (C). The B x F also generates highly significant effect upon the data while all other possible interac ons i.e B x C, F x C and B x F x C remained non-significant. The mean values pertaining to the lea strength at B1, B2, B3 are 111.88 lbs, 109.64 lbs, 109.00 lbs respec vely. These results shows highly-sig- nificant difference with each other and fully correlated by Anonymous (1986) who found that the system with some fixed flats improved fibre transfer from main cylinder to doffer and thereby leads to improve in yarn quality. Similarly Cha ah (1994) stated that the system with fixed flats improved the lea strength value of yarn. Likewise Rusca (1970) reported that increase in short fibre degrade yarn strength, uniformity and appearance. In general yarn strength decreased about 1.0 percent for each 1.0 percent increase in short fibre. The individual comparison of treatment means for mean lea strength of front sta onary flats (F) for different numbers are recorded as 110.65 lbs at F1, 110.27 lbs at F2 and 109.59 lbs at F3 shows in Table-1(a) . These values show a highly significant difference to each other, and fully correlated by Cha ah (1994) who stated that the system with fixed flats improved the lea strength value of yarn. Sasser (1991) found that Table-1. Analysis of variance for yarn lea strength S.O.V D.f S.S M.S F. Value Prob. Back sta onary flats (B) 2 205.409 102.704 47.2176 0.0000** Front sta onary flats (F) 2 26.062 13.031 5.9909 0.0034** Cylinder speed (C) 2 14.033 7.017 3.2259 0.0436* B x F 4 93.888 23.472 10.7911 0.0000** B x C 4 9.569 2.392 1.0999 0.3605 NS F x C 4 16.384 4.096 1.8831 B x F x C 8 39.771 4.971 2.2856 Error 108 234.914 2.1775 Total 134 640.03 Table-1(a) Comparison of individual treatment means for yarn lea strength B Mean F Mean C Mean B1 = 111.88 a F1 = 110.65 a C1 = 110.14 b B2 = 109.64 b F2 = 110.27 b C2 = 110.58 a B3 = 109.00 c F3 = 109.59 c C3 = 109.79 c Note: Any two values not sharing a le er in common differ significantly at µ=0.05 level of probability Table-1(b) Comparison for the Interac on B x F for yarn lea strength F1 F2 F3 B1 = 112.38 a 111.81 b 111.44 c B2 = 110.71 d 110.64 e 107.55 I B3 = 108.87 g 108.36 h 109.78 f ** = Highly Significant * = Significant NS = Non-Significant Review Paper