Textile Value Chain- Jan 2023

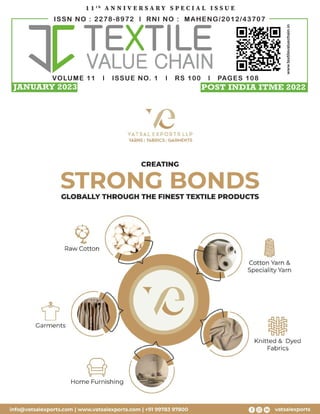

- 1. VOLUME 11 l ISSUE NO. 1 l RS 100 l PAGES 108 ISSN NO : 2278-8972 l RNI NO : MAHENG/2012/43707 www.textilevaluechain.in JANUARY 2023 POST INDIA ITME 2022 1 1 t h A N N I V E R S A R Y S P E C I A L I S S U E

- 2. Pranav Rathi - E-mail: pranav@bmhouse.in • pranav@rsbcottex.com • Mob.: +91 9986022878 Naresh Rathi - E-mail: naresh@rsbcottex.com • naresh@bmhouse.in • Mob: +91 9377924489 Web: www.rsbcottex.com | www.bmhouse.in For Enquiries For Enquiries SOUTH AMERICA PERU COLUMBIA GUATEMALA ASIA BANGLADESH CHINA SRI-LANKA MALAYSIA PHILIPPINES SOUTH KOREA VIETNAM AFRICA EGYPT MOROCCO TUNISIA MAURITIUS EUROPE PORTUGAL POLAND SPAIN TURKEY GERMANY ITALY NORTH AMERICA USA CANADA Markets Range Carded (Hosiery & Weaving) • Combed (Hosiery & Weaving) Slub • Core Spun • Core Spun Slub Elite Twist (Siro Compact) • Compact • TFOs TEX C I T N IL A E G S R T O A L N A D B A R O L D G GO S T ISO 9001:2015 & ISO 14001:2015 R O T P X H E O U R S A E T S R A E I C D O N I G F N O IS . E T D V O B G Y TEX C I T N IL A E G S R T O A L N A D B A R O L D G GO S T ISO 9001:2015 & ISO 14001:2015 R O T P X H E O U R S A E T S R A E I C D O N I G F N O IS . E T D V O B G Y TEX C I T N IL A E G S R T O A L N A D B A R O L D G GO S T ISO 9001:2015 & ISO 14001:2015 R O T P X H E O U R S A E T S R A E I C D O N I G F N O IS . E T D V O B G Y TEX C I T N IL A E G S R T O A L N A D B A R O L D G GO S T ISO 9001:2015 & ISO 14001:2015 R O T P X H E O U R S A E T S R A E I C D O N I G F N O IS . E T D V O B G Y R S B C O T T E X

- 3. PSCP Approved Supply Chain Vendors Truetzschler Blowroom Line LMW Ring Frame Uster AFIS - HVI UT-5 “A” RANK

- 4. High Tenacity Near Virgin Polyester Staple Fibre For Yarns & Non Wovens Denier 1 to 25 Cut 25 to 102 MM connect@jbecotex.com www.jbecotex.com India R 100% DYEING GUARANTEE

- 5. Barcode, Sample & Reports

- 6. JANUARY 2023 6 www.textilevaluechain.in CONTENT COVER STORY : Automation in Textile Industry - 10 LMW’s Mr. Sankar M on New Launches at India ITME ’22 - 13 Future of Textile Machinery Market: Mr. Anandkumar - 17 B-Tex’s Auto-Cut-Pack system by Mr. Bhupinder Singh – 20 Yamuna’s new launches at India ITME ’22 - 23 COVER: VATSAL EXPORTS - 1 GATE FOLD: RSB - 2-3 FRONT INSIDE: JB ECOTEX - 4 BACK INSIDE: RAYSIL - 107 BACK: RAYMOND - 108 EVENT CALENDAR - 90 ADVERTISER INDEX : SITEX 23 : Live saree jacquard weaving at Staubli’s booth - 43 INDUSTRY UPDATE : Texcom Invests in Bruckner power frame stenter - 44 Truetzschler card clothing expands its site in Neubulach - 47 KappAhl partners with TruceTrace - 49 Marzoli Announces Its ambitious roadmap - 50 REVIEW PAPER : Study on Health Problems of sewing machine operators - 69 Extraction and use of Natural Dyes – 75 GOVERNMENT INITIATIVES : Muzaffarpur Bag Cluster - 79 MARKET REPORT : Home Textile - 83 Natural, MMF, Nonwovens - 85 Textile and Apparels - 87 International Textile Industry Statistics - 88 A Glimpse of CEO Conclave - 26 SA Pharmachem : Best Initiatives in Pollution Control Technology - 29 Present & Future in Textile Printing: SPG Prints - 32 Empowering Textiles of India - 35 Check the Latest Innovations in ITME ’22 - 39 POST ITME 22 : Latest Trends for Spring Season by Reshamandi - 53 TREND FORECAST : Marketing: An Essential tool for successful business ventures - 61 INTERVIEW: EDUCATIONIST : PicConnect: Connecting the Textile Industry! - 55 Latest Innovation in Sustainable dyeing - 57 SpectraVision by Datacolor - 59 INNOVATION CORNER : How to become an apparel consultant - 64 SKILL DEVELOPMENT : Sustainability in Textile Industry and strategic innovation - 66 SUSTAINABLE DEVELOPMENT : Curtain Raiser for Technotex 2023 - 92 10th Intex India - 95 HGH India 2022 - 98 ISCMA Annual Get-together - 100 Sustainable Dynamics in Fashion: Dr. Ulhas Nimkar – 102 POST EVENT UPDATE : B-Tex - 5 Niva Exports - 7 Yash Machines – 9 Real Prince – 12 Zydex - 16 Balaji Santoni - 19 Yarn Fair - 22 DTG - 25 ITMA Milan – 28 Unitech Texmech – 31 Omax – 34 Uster - 38 TechTextil - 41 Wellknown – 42 D. Badami Fashion – 46 KEN India – 48 Texfab Industries – 54 Art Yarn - 56 Datacolor – 60 Saurer – 68 Cosmo – 74 Alliance Fibre – 78 ATE Processing – 82 Ramkrishna Cotspin – 86 Shahlon Silk – 91 Swissmem – 94 Staubli – 97 Chintamani Export – 99 GSCS – 101 SSPL - 103 Bhairav plant - 104 Domotex - 105 Technotex - 106

- 8. JANUARY 2023 8 www.textilevaluechain.in Automation in Textile Industry and a Review of India ITME 2022! Automation has become an increasingly important topic in the textile industry in recent years, as manufacturers look for ways to streamline their operations and increase efficiency. The use of advanced technology, such as robotics and artificial intelligence, has allowed companies to automate various tasks, from material handling to quality control. One key event that highlights the importance of automation in the textile industry is the India International Textile Machinery Exhibition (ITME), which is held every four years. The 2022 edition was special because it was happening after six years due to COVID-19. The use of automation in the textile industry has numerous benefits. For one, it can help to improve the accuracy and consistency of various processes, such as dyeing, printing, and finishing. This can lead to higher quality products and reduced waste, which is good for both the environment and the bottom line. In addition, automation can help to reduce the need for manual labour, which can be physically demanding and potentially hazardous. It can also help to improve working conditions, as employees are able to work with less strain and stress. However, it is important to note that automation also brings challenges, such as the potential for job displacement. It is important for companies to consider the impact on their workforce and to ensure that employees are trained in the skills needed for the jobs of the future. The use of automation in the textile industry has the potential to bring significant benefits, both for manufacturers and for the environment. As the industry continues to evolve, it will be important for companies to carefully consider the role of automation and how it can be used to enhance efficiency and sustainability. Hrushikesh Takbhate EDITORIAL TEAM EDITOR AND PUBLISHER Ms. Jigna Shah EDITORIAL ASSISTANT Ms. Gargi Dandegaonkar CREATIVE DESIGNER Mr. Adarsh JUNIOR EDITOR Hrushikesh Takbhate MARKETING AND ADVERTISING ENQUIRY Mohammad Tanweer +91-9167986305 sales@textilevaluechain.com REGISTERED OFFICE: TVC MEDIA AND PROMOTION PVT LTD. 504, Suchita Business Park, Patel Chowk, Pantnagar, Ghatkopar (East), Mumbai- 400075, Maharashtra, INDIA. Cell: +91-9769442239 Email: info@textilevaluechain.com Web: www.textilevaluechain.com Owner, Publisher, Printer and Editor - Ms. Jigna Shah Printed and Processed by her at, Impression Graphics, Gala no.13, Shivai Industrial Estate, Andheri Kurla Road, Sakinaka, Andheri(East), Mumbai 400072, Maharashtra, India. All rights reserved Worldwide; Reproduction of any of the content from this issue is prohibited without explicit written permission of the publisher. Every effort has been made to ensure and present factual and accurate information. The views expressed in the articles published in this magazine are that of the respective authors and not necessarily that of the publisher. Textile Value chain is not responsible for any unlikely errors that might occur or any steps taken based in the information provided herewith. Textile Value Chain EDITORIAL Ms. Vaibhavi Kokane +91-9869634305 marketing@textilevaluechain.com SUBSCRIPTION

- 9. www.yashtex.com sales@yashtex.com I +91 9167772065 I PRODUCTS Fabric Rewinding Machines Fabric Folding Machines Slitting & Cutting Solutions Batch Preparation Machines Roll Packing Machines Roll Handling & Sorting Systems Fully Automatic Packing Machine Open Width Knits Inspection Machine APPLICATION Knitted Fabrics Denim Bottom Weight Suiting & Shirting Home Furnishings Terry Towel Coated Fabrics and more....... M a d e in India Rewinding, Measuring & Packing Solutions

- 10. JANUARY 2023 10 www.textilevaluechain.in AUTOMATION In Textile Industry: A Comprehensive Overview Automation in textile machinery has been a topic of significant interest in India in recent years, as textile manufacturers seek to increase efficiency and reduce costs in a highly competitive industry. Automation in the textile industry refers to the use of technology and machines to perform tasks that were previously done by humans. This includes everything from spinning and weaving to finishing and packaging. Automation has brought about many changes to the textile industry, and there are both advantages and disadvantages to consider. One of the primary benefits of automation in the textile industry is increased efficiency. Automated systems are able to operate at a much faster pace than manual labour, which allows manufacturers to increase their production capacity and reduce the time required to complete tasks. This can lead to significant cost savings, as manufacturers can produce more goods in less time, while also reducing the need for labour. In addition to increased efficiency, automation can also improve the quality of textile products. Automated systems are able to operate with greater precision and consistency than manual labour, which can help to reduce defects and improve the overall quality of the finished product. This can be particularly beneficial in the textile industry, where even minor defects can have a significant impact on the quality of the final product. Another benefit of automation in the textile industry is improved safety. Automated systems can reduce the risk of injury to workers, as they are not required to perform tasks that may be physically demanding or hazardous. This can help to improve working conditions and create a safer environment for employees. There are several key technologies that are driving the adoption of automation in the textile industry in India. One of the most significant is robotic automation, which allows manufacturers to automate a wide range of tasks, including material handling, cutting, and sewing. Robotic automation can be particularly useful in the textile industry, as it allows manufacturers to handle large volumes of material and complete tasks with high levels of precision and consistency. Another important technology in the automation of the textile industry is machine learning, which allows machines to learn and adapt to new tasks and environments over time. This can help to improve the efficiency and effectiveness of automated systems, as they are able to learn from their mistakes and continually improve their performance. In addition to these technologies, there are also a number of other tools and systems that are being used to automate the textile industry in India. These include computer-aided design (CAD) systems, which allow manufacturers to design and test new products using computer simulations, and advanced sensors and monitoring systems, which can help to improve the efficiency and accuracy of automated systems. Overall, automation in the textile industry in India is providing a range of benefits to manufacturers, including increased efficiency, improved quality, and enhanced safety. With the continued development and adoption of new technologies, it is likely that automation will play an even larger role in the textile industry in the future. COVER STORY BY TVC TEAM

- 11. 11 JANUARY 2023 www.textilevaluechain.in However, there are also some disadvantages to automation in the textile industry. One of the main concerns is the potential for job loss. As machines take over certain tasks, there may be a need for fewer human workers. This can lead to unemployment and a decline in the number of jobs available in the industry. In addition, some workers may be concerned about the potential for machines to eventually replace them entirely. Another disadvantage of automation in the textile industry is the cost. While automation can lead to cost savings in the long run, the initial investment in technology and machinery can be expensive. This can be a barrier for smaller companies or those with limited financial resources. In addition, there may be ongoing costs associated with maintaining and repairing the machinery, as well as training workers to use it. Automation in the textile industry can also have negative environmental impacts. While some automation technologies can be more energy- efficient than their human counterparts, the production and disposal of machines can contribute to pollution and waste. In addition, automation may lead to a greater reliance on fossil fuels, as machines often require electricity to operate. Automation has brought about significant innovation in the textile industry, impacting every aspect of production from spinning and weaving to processing and garmenting. This has allowed manufacturers to increase efficiency, improve quality, and enhance safety in the industry. However, the fast fashion world has created a paradox for the textile industry as consumers demand both fast and high - quality products. In order to meet these demands, automation has become increasingly important in the textile industry. Automated systems are able to operate at a faster pace, with greater precision and consistency, which can help to produce high - quality products quickly. However, this also requires a shift towards a more tech-savvy workforce, as workers need to be able to handle and operate these automated machines. While automation can help to meet the demands of fast fashion consumers, it is important for companies to also consider the needs of those who prioritize quality over speed. This can be achieved through the use of advanced technologies such as machine learning, which allows machines to adapt and improve their performance over time, and through the implementation of strict quality control measures. In conclusion, automation in the textile industry has both advantages and disadvantages. On the one hand, it can increase efficiency and productivity, improve safety, and lead to improved working conditions for employees. On the other hand, it can lead to job loss, be expensive to implement, and have negative environmental impacts. Companies and policymakers must carefully consider the potential trade-offs of automation in order to make informed decisions about its use in the textile industry.

- 13. 13 JANUARY 2023 www.textilevaluechain.in Tell us something about the new innovations by LMW for the India ITME 2022 In the India ITME exhibition, which is being held after six years of gap. we have brought in new technology under the banner of 4S. 4S stands for Smart Solutions for Spinning Success, as all our machines are SMART and are built to ensure success and sustainability of our customers the products on the display include. Ringframe with RAP (Ringframe Auto Piecing), which is automatic piecing and connected to the link coner, which is indigenously developed by us in order to serve customers from start to end; i.e. from raw fibre processing to packaged yarn. What key areas you would recommend for start-ups to be successful in the industry? I would only recommend one or two key points. The first thing is the facility of inhouse R & D, and that’s going to play a critical role with respect to the start- ups and the inhouse R & D is the one which would be vital for success. Subsequently the modern manufacturing facility that would enable them to roll out the product with the complete ownership of process. If these two are right, I don’t see any reason for any start-ups to have any hiccup, and they would only prosper in the field whichever they embark on. I’m sure there are many examples of start-ups who have been successful this way. We’ve been successful. I think I would only like to advise all the start-ups to emulate this formula and that would enable them to be successful. Why LMW choose to showcase its new launches in India ITME 2022 and what are its plan for global market? At LMW, we are always striving to propel success and growth of Indian business ecosystem. Our global success does not steer our focus away from needs of Indian customers. The products which we have showcased are built on new technology indigenously developed by us and that’s why we would prefer all our new launches are done in India and some of the technology which are adaptable to the global market, we would take over there and then showcase it for our customers in the global market. In INDIA ITME 2022, LMW launched five new machines and one new user interface system and new service called LMW PACE for life cycle services, let’s have a look at each machinery and what are the features they came equipped with. The LMW Auto Leveller Draw Frame LDF3 2S is a high-performance machine that is designed to deliver maximum efficiency and productivity. One of its standout features is its impressive delivery speed of up to 1100 mpm, which ensures that the machine can keep up with even the most demanding production schedules. In addition to its speed, the LDF3 2S also boasts a 4 over 3 loaded drafting system with a pressure bar, which helps to ensure that the machine produces a consistent and high-quality output. The LMW Lakshmi Auto Winder LAW 60 is a highly advanced machine that is designed to deliver optimal efficiency and productivity in yarn processing applications. One of its standout features is its ability to process a wide range of counts, from 16’s to 10’s Ne, which makes it highly versatile and suitable for use in a variety of different settings. In addition, the LAW LMW Launches Five New Feature Packed Machines, IoT Enabled Real-Time Monitoring System And A New Customer Engagement Programme Called ‘PACE’ For Life Cycle Support At India ITME 2022 Mr. Sankar M., the President of Textile Machinery division of Lakshmi Machine Works Ltd, in the exclusive interview with Textile Value Chain at India ITME 2022, spoke at length on the new launches by LMW at the show and the tips to succeed for start-ups in the industry. Mr. Sankar M President Lakshmi Machine Works Ltd. COVER STORY JANUARY 2023 12 www.textilevaluechain.in

- 14. JANUARY 2023 14 www.textilevaluechain.in Tell us something about the new innovations by LMW for the India ITME 2022 In the India ITME exhibition, which is being held after six years of gap. we have brought in new technology under the banner of 4S. 4S stands for Smart Solutions for Spinning Success, as all our machines are SMART and are built to ensure success and sustainability of our customers the products on the display include. Ringframe with RAP (Ringframe Auto Piecing), which is automatic piecing and connected to the link coner, which is indigenously developed by us in order to serve customers from start to end; i.e. from raw fibre processing to packaged yarn. What key areas you would recommend for start-ups to be successful in the industry? I would only recommend one or two key points. The first thing is the facility of inhouse R & D, and that’s going to play a critical role with respect to the start- ups and the inhouse R & D is the one which would be vital for success. Subsequently the modern manufacturing facility that would enable them to roll out the product with the complete ownership of process. If these two are right, I don’t see any reason for any start-ups to have any hiccup, and they would only prosper in the field whichever they embark on. I’m sure there are many examples of start-ups who have been successful this way. We’ve been successful. I think I would only like to advise all the start-ups to emulate this formula and that would enable them to be successful. Why LMW choose to showcase its new launches in India ITME 2022 and what are its plan for global market? At LMW, we are always striving to propel success and growth of Indian business ecosystem. Our global success does not steer our focus away from needs of Indian customers. The products which we have showcased are built on new technology indigenously developed by us and that’s why we would prefer all our new launches are done in India and some of the technology which are adaptable to the global market, we would take over there and then showcase it for our customers in the global market. In INDIA ITME 2022, LMW launched five new machines and one new user interface system and new service called LMW PACE for life cycle services, let’s have a look at each machinery and what are the features they came equipped with. The LMW Auto Leveller Draw Frame LDF3 2S is a high-performance machine that is designed to deliver maximum efficiency and productivity. One of its standout features is its impressive delivery speed of up to 1100 mpm, which ensures that the machine can keep up with even the most demanding production schedules. In addition to its speed, the LDF3 2S also boasts a 4 over 3 loaded drafting system with a pressure bar, which helps to ensure that the machine produces a consistent and high-quality output. The LMW Lakshmi Auto Winder LAW 60 is a highly advanced machine that is designed to deliver optimal efficiency and productivity in yarn processing applications. One of its standout features is its ability to process a wide range of counts, from 16’s to 10’s Ne, which makes it highly versatile and suitable for use in a variety of different settings. In addition, the LAW 60 features a doffer with Fuzzy logic for efficient package removal, which helps to ensure that the machine produces a high-quality output with minimal waste. The winding head start feature is also a useful feature that helps to ensure that the machine gets up to speed quickly and smoothly, further enhancing its efficiency and performance. The CARD LC636 S CDS and FIX FIL CAN Changer is a highly advanced machine that is designed to deliver optimal efficiency and productivity in carding applications. One of its standout features is its impressive production rate, with the ability to produce up to 250kg/hr, making it an ideal choice for use in high-volume manufacturing environments. The machine also has a working width of 1500 mm, which allows it to handle a wide range of material sizes and types. In addition, the CARD LC636 S CDS and FIX FIL CAN Changer features a swingable delivery duct for

- 15. 15 JANUARY 2023 www.textilevaluechain.in easy access, which is a patented design that helps to improve the machine’s overall efficiency and ease of use. The brass clip with improved flat (patent applied) is another useful feature that helps to ensure that the machine produces a high-quality output with minimal waste. The Ring frame Auto Piecing (RAP) is a highly advanced machine that is designed to deliver optimal efficiency and productivity in ring spinning applications. One of its standout features is its impressive piecing cycle time, with an average time of just 35 seconds, which helps to ensure that the machine can keep up with even the most demanding production schedules. In addition, the RAP captures the broken end from the package in a unique way without lifting the package, thereby eliminating any contamination on the cop outer surface. This helps to enhance and retain the quality of the yarn, which is an important consideration for many yarn processing applications. The Lakshmi Jet Spinning - LJS9 is a highly advanced machine that is designed to deliver optimal efficiency and productivity in spinning and yarn processing applications. One of its standout features is its seed yarn piecing system, which helps to enhance the yarn joining quality and improve the overall consistency of the output. The LJS9 also has a lower footprint of up to 40% due to its double-sided concept, which makes it an ideal choice for use in environments where space is limited. In addition, the machine is easy to operate and maintain, with a user - friendly interface and simple maintenance requirements. Apart from the above-mentioned machines, LMW also launched SPIN CONNCET their new monitoring and control system. SPIN CONNECT is a revolutionary web-based monitoring and control system that is designed to provide an all-in-one solution for managing spinning mills. With its advanced digital capabilities, SPIN CONNECT connects all machinery and provides real - time information on production, quality, maintenance, and more, all in a single window. This allows the management team, technical team, and operators to monitor and manage the spinning mill with ease, optimizing processes and effectively utilizing resources to save costs and increase profits. The system’s comprehensive features make it an invaluable tool for improving the overall efficiency and performance of spinning mills. Overall, SPIN CONNECT is a reliable and effective system that is well-suited for use in a variety of spinning and yarn processing applications . The system also has a range of additional features, including Bale Management, Online Quality Module, Fancy Yarn Pattern Generation, and Condition Monitoring Module, which help to further optimize the performance and efficiency of spinning mills. One of the standout features of SPIN CONNECT is its ability to capture drive data, including KW, A, Nm, and Rpm, which can be used to identify and troubleshoot issues with the machinery. The system also includes periodic software updates and remote software diagnosis, which help to ensure that it stays up to date and performs at its best. Overall, SPIN CONNECT is a reliable and effective system that is well-suited for use in a variety of spinning and yarn processing applications. After the feature packed machines and latest monitoring system, LMW also launched the LMW PACE, the new life cycle services for hassle free ownership experience. The PACE stands for Professional Aftermarket Care for Excellence. LMW aims to achieve this excellence through three pathways, providing timely support on parts and components that ensure customer never loose out on productivity or quality, State of the art commissioning and technical solutions that ensure customer installation, commissioning and machine running experiences are always at the pinnacle of satisfaction, Life cycle services that ensure customer’s overall ownership experience is world class. Through these new machines, system and new promises, LMW is showing how they care for their customer with not just verbal promises but introducing new services and products that will benefit the customer for the long run.

- 17. 17 JANUARY 2023 www.textilevaluechain.in Can you tell us about the company and what new machines you are displaying? Kirloskar Toyota textile machinery (KTTM) is a joint venture between Kirloskar group India and Toyota Industries Corporation Japan, incorporated way back in 1995 and we started manufacturing in 1997 with Ring frame model RXi240. In the year 2014, we have started our new product RX 300 to serve global customers from India, and in last 8 years the machine is well accepted in the market. In this ITME we have launched a new product called Basket type Toyota Bobbin Changer an attachment to RX-300 wherever link coner is not viable, this will be supplied with machine. This will help spinners to reduce the manpower and nowadays all of us know the challenges associated in getting the required manpower. With reduced manpower in their mills the customers can achieve the optimised production from our machines. In this ITME - 2022 we have demonstrated the versatility of our product by focusing on MMF/PC blends. We are spinning Viscose in one side and the PC on other side with Toyota compact system. We have run the machine at industry benchmark speed levels of 24,000 to achieve 300 grams in Ne 30 count PC as well as Viscose. The machine is also working well with the slub. On our machine we can have various fancy options like slub on slub, thick slub, thin slub, negative slub, multi twist, multi count. All the provisions are available through soft keys on the machine. We have visitors beyond our expectations in this exhibition, more than 900 people have visited us. We had good inquiries from this exhibition. Even though the market is experiencing a challenging situation, all our customers felt that it’ll bounce back in a short time because India will have a bumper crop and the cotton price is getting stabilized and yarn price also, they hope will get stabilized in a few months. KTTM’s Mr. Anandkumar’s Views On Future Of Textile Machinery Market In India Mr. B. G. D. Anandkumar, Assistant General Manager, head of marketing for India, KTTM in the exclusive interview with Textile Value Chain at India ITME 2022, spoke at length on the new products by KTTM and future of textile machinery market in India. COVER STORY Mr. B. G. D. Anandkumar, Assistant General Manager KTTM

- 18. JANUARY 2023 18 www.textilevaluechain.in Like India ITME, will ITMA Milan also view any of your new innovations? Yeah, it’ll be there, we will be demonstrating the further updates on the present machine as well as future machines, we have exhibited all new spinning technology called Helix spinning in Barcelona, so we will have the updates on that as well in Milan. How do you compare your Japanese technology with European technology? Yeah see, Japanese technology always gives reliable machines with stable performance, committed delivery. So, what happens when a customer chooses our product, they get consistent performance for the long term. They achieve the highest productivity level on our machines. They also achieve the best quality with low maintenance. The machine is simple and also user-friendly. So once the customer experiences our machine, they come back for the repeat orders. So, we have been successfully selling this machine from 2014 onwards. I can say we are now in the desirable position w.r.t spinning machines. What are your observations of the industry? Now the industry is passing through challenging phase due to change in economic situation globally, owing to many factors such as Russia, Ukraine war, Covid, Scarcity of power, High inflation are few to mention but we are hopeful that turnaround will be around the corner due to many policies. Like PLI scheme, Mitra scheme and all are coming for the future., Government is supporting with all these schemes and India will surely consolidate its position even in Non cotton exports in coming days.

- 20. JANUARY 2023 20 www.textilevaluechain.in “B-Tex” Revolutionary Auto-Cut-Pack System With Italian Software Is All Set To Transform The Traditional Cutting And Packing Systems Excerpts from the exclusive interview held with Mr.Bhupinder Singh - CEO of B-Tex Textile Machinery after the recently concluded INDIA ITME 2022 at Noida, India. “B-Tex” began it’s journey around 2 decade ago and today they are a formidable player in the textile industry for Fabric Inspection, Rolling, Folding & Packing Systems in Collaboration with REALTIME Srl (Italy) for Defect Logging Software. Their machines are the physical manifestation of years of industry experience and it’s our constant endeavour to keep abreast with the latest technologies. “Nirvana” the latest and state of the art Auto- Cut-Pack system from the BTex stable is all set to transform traditional cutting. How has been the journey in manufacturing since the beginning? Well the journey has been long and exciting, two decades to be precise also one that has presented challenges and opportunities equally, while technology was constantly changing and developing. B-Tex witnessed frequent innovations in the industry and that meant we too had to adapt quickly and bring out novel automations to be relevant in the industry. We started with simple Inspection cum rolling machines with minimum infra and support but in a unique, customer-centric direction. Our Sales program includes, Fabric Inspection, Rolling, Folding Machines and all types of winders and Un-winders with PLC controls. Greige, Finish and Preparatory machines are our standard products. We are specialised in fully automatic LDPE and HDPE Packing Machines with Italian Know-How. B-Tex had delivered stretch less with Zero elongation KNITS Inspection and rolling machines and achieved commendable market-share in the segment. Along with Woven and Knits, B-Tex has expertise in NON - WOVEN and Specially TECHNICAL TEXTILE Machines for Winders, Un - Winders, Slitting and Packing systems. We have already delivered tailor-made machines to High quality manufacturers like M/s. Khosla Profile, SRF, Milliken, Wilhelm, Texport Syndicate, etc.. How was your experience at India ITME-22 and what new B-Tex has offered? INDIA ITME-22 has been a great success for B-Tex. We launched our all new Auto-Cut-Pack Machine - Model COVER STORY Bhupinder Singh CEO, B-Tex Textile Machinery At B-Tex, we design and deliver automation solutions for Inspection and Packing Dept. with Italian Know - How and Software to global standards of excellence with local support.

- 21. 21 JANUARY 2023 www.textilevaluechain.in NIRVANA with LDPE & HDPE packing at one go with Italian Software. It was an absolute honour to host industry leaders like Mr. Manmohan Singh, Mr. Updeep Singh, Mr. Alaaggapan R, and Mr. Gurudas Aras for the demonstration. Can you brief more about B-Tex Auto-Cut-Pack? There’s no denial of the fact that manpower crisis and space crunch poses a severe challenge to the textile industry, automation is the need of the hour in each and every process that obviously helps organizations to have optimal manpower, increase production and have quality MIS reports. Nirvana helps you to achieve all of these with Italian Know-how and Software. In B-Tex Auto-Cut-Pack System, we Inspect the fabric and log all the defect in IGS (Inspection & Grading Software) through Batch to Batch or Trolley to Trolley Mapping Machine and later on optimize as per the severity to generate beneficial Cut-Pan. Finally the data is transferred to B-Tex Auto-Cut-Pack machine model NIRVANA, where it rolls the fabric at high speed of 80 m/m and pack it with LDPE and HDPE film with lots of other benefits. What are the benefits of Auto-Cut-Pack? Nirvana is a boon to Inspection and Packing department . Due to optimised cut plan, 2-3% A-Grade fabric is saved and mind it, its lots of business and profit for quality and quantity fabric manufactures. Along with this, it reduces manpower up to 60% as their is bare minimum handling of fabric due to automatic packing with sorting and all the extra manpower is eliminated. All defect entries through touch screen in Italian software delivers lots of reports like shift-wise, sort-wise, operator-wise, production and department-wise to improve quality. 40% space is also saved as Auto-Cut-Pack singlehanded delivers 80,000 mtr/day with LDPE and HDPE packing with single operator. There are lots of other benefits like Auto-Samples, Folders, Barcode, Automatic labelling, etc. We have successfully delivered this system with software to some high quality fabric manufacturers in last few years. How B-Tex stand out against its competitors? B-Tex has 2 pillars Innovation and Automation and this keeps us ahead of competitors. At B-Tex, we design and deliver automation solutions for Inspection and Packing Dept. with Italian Know-How and Software to global standards of excellence with local support. With Italian know-How, our machines are famed to be at par with that of Italian standards in terms of inputs and performance, sold out at affordable price. We are with our customers right from conceptualisation to the final product, which helps us deliver tailor made solutions. We can proudly state that pre and post sales service is our hallmark and this always keeps us on our toes. What at the future plans for B-Tex? India is considered to be preferred supplier in recent times, due to in increase demand and widespread acceptance in our products, we are under expansion. We are sanguine about the over all scenario and are ready to face the new growth phase of Textile Industry. B-Tex is participating in ITMA 2023 in June at Milan, Italy along with our Italian partners to showcase the recent innovations and development on a global scale. Mr. Manmohan Singh, CMO - Aditya Birla And Mr. Bhupinder Singh, CEO - B-Tex Textile Machinery With Team At ITME

- 23. 23 JANUARY 2023 www.textilevaluechain.in COVER STORY Yamuna Machine Works Ltd’s First Indian Made Multilayer Stenter: Know The Features Yamuna Machine Works Ltd launched three new machines in the India ITME 2022. Prashant Mangukia, Director of the company shared his thoughts with the Textile Value Chain during the launch, “We are here at Yamuna Machine Booth in Hall three. We have had three new product launches this time. First of all was the Open Width Knit Compactor. Second was Open Width Knit Singeing Machine and the novel product of multilayer stenter. The multilayer stenter technology is from ALEA of Italy, and the compactor is first time Made in India. We have got very good response here to the show and we feel that this Made in India products will be a game changer for the textile industry.” Yamuna introduced three new machines namely, Open Width Knit Compactor, Open Width Knit Singeing Machine and ALEA-YAMUNA Multilayer Stenter. The feature packed machines were launched by the hands of leading textile industrialists. The Open Width Knit Compactor was launched by The Oster Group Director SHRI G. B. SINGH. The Open Width Knit Singeing Machine was launched by The Welspun Group Director SHRI RAJESH MANDAWEWALA.

- 24. The ALEA - YAMUNA Multilayer Stenter was launched by Bombay Rayon (BRFL) Managing Director SHRI PRASHANT AGARWAL. THE ALEA - YAMUNA Multilayer Stenter : The new ALEA-YAMUNA Multilayer Stenter, developed with the collaboration between ALEA and YAMUNA in India. The YAMUNA-ALEA Multi-Layer Stenter is a textile finishing machine that is designed to improve the quality and fineness of fabric. It is a 10-chamber machine that operates in a 3-chamber space, which means it can handle a larger volume of fabric in a smaller space. This can be beneficial for textile manufacturers who need to increase their production capacity but have limited space available. One of the main benefits of the YAMUNA-ALEA Multi-Layer Stenter is its ability to improve the finishing quality and fineness of fabric. This is achieved through the use of multiple chambers and a variety of finishing techniques, such as heat setting, shrinking, and drying. The machine is also energy- efficient, which can help reduce operating costs and improve the overall sustainability of the textile production process. In addition to these benefits, the YAMUNA-ALEA Multi-Layer Stenter can also increase productivity by allowing manufacturers to process more fabric in a shorter amount of time. This can be especially useful for businesses that need to meet tight deadlines or have high demand for their products. ALEA-YAMUNA is first Indian made multilayer stenter. YAMUNA has a strong market position in India as well as in the global markets such as the U.S.A, Europe, Brazil, Portugal, Argentina and many other countries. YAMUNA has been winning export awards consecutively for the last three years.

- 26. JANUARY 2023 26 www.textilevaluechain.in Symposium Of Great Minds… Transforming Ideas To Execution!!! : A Glimpse Of CEO Conclave India’s biggest Textile & Machinery Exhibition has set a new benchmark in this 2022 edition. The event that brings to the board only the best and most magnificent display of engineering technology & accessories expanded their horizon to enthrall the intriguing conclave. The theme of the conclave was bringing together the policymakers and the textile industry for chalking out a promising short-term & long-term technology strategy for the sustainable growth of the Textile Industry in India. It was a humble attempt to voice the textile & textile Engineering sector. The gathering began with a warm welcome from the Executive Director of India ITME Society Ms. Seema Srivastava to the guest of honor Shri P. Sathasivam Ex-Chief Justice of India & Former- Governor of Kerala, Mr. Rohit Kansal, Additional Secretary Ministry of Textiles, Ms. Prajakta Verma, Joint Secretary, Ministry of Textiles, GOI; Mr. Rajeev Saxena, Joint Secretary, Ministry of Textiles, GOI & Ms. Roop Rashi Mahapatra, Textile Commissioner, GOI. Mr. Hari Shankar & Mr. Ketan Sanghavi greeted the dignitaries with mementos & gifts. The event began with our national anthem as a salute to our incredible India. It was a visual display of India’s vibrant culture and musical symposium. The India ITME Chairman opened the forum with his welcome speech a crisp and precise amalgamation of the global CEO conclave theme with the ongoing football tournament. The Chief guest Shri P. Sathasivam Ji threw presented his guest of honor speech appreciating India’s ITME Society’s dedication towards the growth of Indian textile and engineering and as Albert Einsten said “The only source of knowledge is experience.” His speech was a sheer knowledge provider for new entrepreneurs and technology providers for their journey of growth and prosperity ahead. Shri. Rohit Kansal, Additional Secretary Ministry of Textiles delivered a stunning speech and a ray of hope for fellow industrialists by throwing light on the Indian government’s vision and investment assistance to promote the Textile as well as textile engineering sector. He also informed that the government goal for textiles and apparel is US$ 350 Bn, the export goal for textiles & apparel is US$ 250Bn whereas the goal of US$ 100Bn is for the domestic market. Mr. Avinash Mayekar, MD of Suvin then opened the forum with a splendid theme presentation by weaving different cultures of India with the textiles of India and formulating a pathway to our honorable Prime Minister, Sri Narendra Modi Ji’s vision of 5F strengthening (Farm, Fibre, Factory, Fashion & Foreign Trade). Focusing on the theme, Mr. T. Rajkumar Chairman of the Confederation of Indian Textile Industry represented the Textile Voice by delivering a remarkable view on “Indian Textile Industry; Need & Gaps - An Honest Review”. He informed the audience about the different policies and frameworks available for the industry’s growth. Mr. M. Sankar, President- Textile Machinery Division TMD (Operations), Lakshmi Machine Works Limited with his presentation formed an inspiration and mapped roadmap for the growth of India’s Textile Engineering and technology sector. The inspiration growth of textile engineering and technology in the spinning segment is a module well fit and replicable to all other segments of textile engineering and technology. So the Voice of The textile engineering & technology segment clearly POST ITME 2022

- 27. 27 JANUARY 2023 www.textilevaluechain.in encapsulated the investment for textile engineering in all the segments of textiles. It was time for the voice to be channeled, so Mr. Arun Kumar Garodia, Chairman of the Engineering Export Promotion Council took the stage and showcased the strength of our Engineering sector and congratulated the industry for having a growth rate of 16%. He has also informed of the plans of government for the engineering sector. It was time for the voice to be heard and reciprocated into action. Ms. Roop Rashi Mahapatra, Textile Commissioner, GOI assured the industry of the different plans of the ministry for increasing investments in India. She also informed of the continuous efforts of the government to formulate a plan for encapsulating the textiles and textile engineering and technology under one wing. Ms. Prajakta L. Verma, IAS, Joint Secretary, Ministry of Textiles, GOI then took the stage and educated the audience on the government reviews of the TUFS scheme and assured that the government is channeling all its efforts for policy framing of the TUFS or equivalent scheme. Mr. Rajeev Saxena, Joint Secretary, Ministry of Textiles, GOI delivered a short speech on the government’s future plans for increasing investment in the textile and textile engineering sector and promotional plans for the growth of Industry. The forum then witnessed the release of a “Compendium for the Ministry of Textiles- Textile & Textile Engineering Industry Voice” which contains compiled segment-wise industry snapshots on growth and trade, the details on key stakeholders, and policy currently operational. It also contains key concerns and suggestions from the industry with the details of the addressee along with industry highlights & some abstracts shared by industry experts. Post the knowledgeable gathering of minds, it was time for the celebration of the best of the best in the technology industry. A teaser of the technology awards containing the theme, the process, and the winner announcement was beautifully presented to the entire audience which checked all the parameters of enthusiasm within the audience. The technology awards were then presented. The ceremony began by presenting the Textile Maestro award to none other than “Mr. S P Oswal” and the quote of Mr. John C. Maxwell fits well in. A leader is one who knows the way, goes the way, and shows the way. “. The award on his behalf was received by Mr. Neeraj Jain, Joint Managing Director & Head - of Yarn Business, Vardhaman Group. The winners were presented with the award trophy and a cheque as a token of appreciation for their marvelous hard work and dedication. 1. Top Performance in Textile Engineering Industry a) Spinning - M/S Lakshmi Machine Works b) Weaving & Preparatory- Rabatex Industries c) Finishing - Texfab Engineers (India) Pvt. Ltd. d) Printing– ColorJet India Ltd. e) Accessories - Lakshmi Card Clothing Manufacturing Company Private Limited 2. Best Initiatives for Pollution Control Technology - S. A. Pharmachem Pvt. Ltd. 3. Category 3 – Special Award for Women a) Women Entrepreneur – Ms. Deepa A Kumar, Founder & CEO- Yashram Lifestyles b) Nurturing Women Empowerment – Ms. Neha Jhunjhun- wala, Director, Sarla Performance Fibers c) Woman Master Weaver - Ms. Santoshi Kewat d) Reviving Traditional Textiles - Ms. Kumari Raita 4. Category 4 – Award for Research Excellence - Dr. Rekha Ramakrishnan, SASMIRA All the speakers and jury members were presented with a memento and a gift of a token for their continuous support. The award concluded with a vote of thanks from Mr. Ketan Sanghavi, Treasures, India ITME Society, and acknowledgment to Mr. Avinash Mayekar, MD – Suvin, and his team as the knowledge partner for the event.

- 28. Show Owner CEMATEX Associations ACIMIT (Italy) AMEC AMTEX (Spain) BTMA (United Kingdom) GTM (Netherlands) SWISSMEM (Switzerland) SYMATEX (Belgium) TMAS (Sweden) UCMTF (France) VDMA (Germany) Show Organiser T: +65 6849 9368 E: info@itma.com Connect With Us @ ITMA2023 Scan for More Info Source, collaborate and future-proof your business at the world’s largest international textile and garment technology exhibition Visitor registration is now open! Scan the QR code to find out why you should visit. Source from some 1,500 leading manufacturers and see live machinery demonstrations Future-proof your business with best-in-class solutions to stay ahead of the competition Collaborate and grow your business with digital transformation and sustainability Access ITMAconnect - the year-round sourcing and knowledge hub for the global textile community

- 29. 29 JANUARY 2023 www.textilevaluechain.in ITME Society Awarded S. A. Pharmachem Pvt. Ltd. Best Initiatives for Pollution Control Technology Announcing India ITME Technology Awards: “Exceptions make rules Strong; Be the Exception”, This is the idea which drives India ITME Society’s search for talented, stand out leaders, innovators and determined perseverance in their field of work. To mark 4-decade old successful journey of India ITME Society an award was initiated. The 2nd edition of awards are Society’s humble attempt to recognize the exceptional & significant contributions that have influenced positive change in the textile engineering sector of our nation. These awards will set the tone for the start of the biggest textile engineering show which will have the presence of international & national delegates representing ambassadors, council members, various ministries, state ministers, textile & state commissioners and global investors. The renowned textile entrepreneurs and emerging textile investors will all be a part of this event. The winners will be felicitated with cash award, trophy & certificate in the format best suitable to the category. With the wide network of the India ITME Society, the recognition of the awards will not just be limited to the delegate present at the award function but will also be circulated to the wide database & the entire press & ministry associated with the India ITME Society. This 2nd edition of awards looks to recognize and felicitate awards in the following new categories: Category 1 - Award for Overall Best Performer in Engineering Industry presented in 8 Specific categories (Ginning | Spinning| Weaving & weaving preparatory |Processing & Finishing | Garmenting | Printing | Accessories for Textiles | Technical Textiles) Category 2 - Award for Best Innovative Technology for Pollution Control Category 3 -Women Leadership Award in Textile & Textile Engineering Category 4 -Award for Research Excellence Category 5 – Textile Maestro Society strongly believes that education is the foundation platform that has lifted this textile sector to such a glorious stage. So it has also introduced an award category specifically targeting youth, research & innovations. Mr. S Hari Shankar, Chairman, India ITME Society said, “The society & self strongly believes that the young minds of today are the colourful future of our Textiles, this is why in addition to the dedicated award category for our innovators in 2022 edition, we have always introduced knowledge programs for the learners. Our society over the years is initiating several constructive programs to recognize & empower knowledge to innovative researchers, and technical faculties as well as to act as an active connect between the knowledge hub -technical institutes & the ever-changing industry. I am sure, the success story of innovators recognized in our awards will attract more youths towards R & D in textiles”. To ensure fair practice and true unbiased nature towards the awards selection, the society has brought on board reputed textile technocrats from different sectors of textile. Mr. S. Hari Shankar, Chairman & Members of Steering Committee of India International Textile Machinery Exhibitions Society along with the Jury members announced the winners of Category 2 - Best Initiatives for Pollution Control Technology to S. A. Pharmachem Pvt. Ltd. “Sincere appreciation goes to the elite jury panel who took time out of their busy schedule to help us ensure smooth and unbiased decision making.” POST ITME 2022

- 30. JANUARY 2023 30 www.textilevaluechain.in Mr. Vinay D. Patil, Managing Director, S. A. Pharmachem Pvt. Ltd & his team working and offering Mr. Vinay D. Patil Managing Director a full proof system to reduce the pollution from textile waste water. S. A. Pharmachem is offering a solution which helps textile industries for competitiveness and it will be a game changer. Size Recovery System from desize wash liquor. Caustic Purification System from mercerization wash liquor Indigo Dye Recovery & Reuse. All the systems are built in India using KOCH membrane - USA. ITME Society has given recognition for these activities and awarded “Best Initiatives for Pollution Control Technology by giving Trophy, Certificate & Rs 1,00,000 Cash.

- 32. JANUARY 2023 32 www.textilevaluechain.in World Premiere Of The ‘Present & Future’ Of Textile Printing : SPG Prints From 8th to 13th December 2022, India’s largest textile machinery show ITME was held in Greater Noida, India. Stovec, a subsidiary of SPG Prints BV, The Netherlands, announced a successful show by introducing the latest innovations in both conventional and digital textile printing for the fashion and the home-furnishing industry. As the inventor of rotary screen technology in 1963 and the initiator of digital textile printing in 1991, SPG Prints has been playing a leading role in textile printing for over 60 years now. Our global brand ambition with focus on sustainability unveiled At ITME, SPG Prints proudly presented its global brand ambition with new slogan “Printing tomorrow.” to its customers worldwide. With this, SPG Prints highlights its ambition to be the reliable partner in the global textile and industrial printing market while taking care of our planet in a responsible way. Looking for a conventional or digital textile printing system, SPG Prints has always proven to be the total solution provider for all textile printing needs. World premiere of entry level digital printer DART with live demonstrations SPG Prints launched the new robust entry level digital printer - DART at ITME for its Indian customers who want to kick start their journey in digital textile printing. The ribbon cutting ceremony was done by two proud DART customers – Mr Akash Sharma (from Akash Fashions, Ahmedabad) & Mr Parthiban M (from Brindhaa Processing Mills, Tirupur). Supported by live demo sessions every hour, while also printing the varied customized needs of visitors on site, DART proved to be a perfect solution for start- ups to fulfill their need for a medium speed printer. With fast turnarounds and full application support, DART gained immense customer’s attraction during the show. The digital technology of this digital printer enables customers to print on demand at a top quality of 720 x 1080 dpi, using 8 colours. With an extra row of print heads, amounting to 16 print heads, it can print up to 150 square meters per hour in fast mode. The optimum drop size helps to produce clear images, vibrant colours and smooth gradations. The installation is plug & play and the latest colour management engine and colour processing tools are included in the preloaded RIP software. The machine is designed for continuous production, that offers immense creative opportunities to customers to print on even the most difficult fabrics. Mr Shailesh Wani (Managing Director, Stovec Industries Ltd.) SPG Prints | Stovec booth at India ITME, Dec’22 Launch of digital textile printer - DART POST ITME 2022

- 33. 33 JANUARY 2023 www.textilevaluechain.in Rose, Jasmine, and Magnolia: three new digital printers SPGPrints|Stovec also introduced the addition of 3 new digital printers in the portfolio - Rose, Jasmine, and Magnolia, that focused on maximum productivity at optimal print resolution. Rose is a roll-to-roll paper sublimation system with a peak productivity of up to 720 sqm/h. With variable ink drop - size and a maximum resolution of 1200dpi, the print quality offered is excellent. Jasmine and Magnolia are direct to fabric systems that will enable our customers to extend their offering in digital printing. Jasmine focuses on maximum productivity at the most optimal print resolution where Magnolia with its true 1200 dpi and Archer+ technology raises the bar to new levels of print quality.’ Introduction of Teak, our latest innovation in Rotary Textile Printing Through the years, our industrial roots have proven to be a solid platform for countless inspired innovations, that have put SPGPrints on the map as a global market leader for textile rotary screen printing technology. The company was proud to showcase our latest innovation in rotary portfolio Teak, a 2.45 meters wide rotary printing machine with Universal Repeat functionality. Teak is the latest generation of the Pegasus series, that has opened a wide - spectrum of applications for our customers worldwide, allowing them to print on woven and knitted fabrics for fashion and home textiles. All repeat sizes from 640 to 1018 mm can be printed in the same machine without any modification of parts. What is also unique to the Teak is that both squeegee types can be combined in a single position. This gives the utmost printing flexibility, and is ideal for optimising effects such as half tones, fine lines and blotches. The evolution of rotary screen technology With the introduction of two the new screen types Ortascreen and Randomscreen Eco together with rotary printing machine Teak and the latest BestLEN engraving technology, SPGPrints underlined its statement to the industry that the rotary printing market is still growing. The visitors could see print samples available at booth, made with OrtaScreen, a revolutionary screen based on the flatbed screen structure. The latest-paste saving screen RandomEco, that also helps to avoid Moiré, was also shown on the booth. N RICH technology: better inks for a better planet ‘Based on our know-how plus 30 years’ experience in ink development, SPGPrints inks offer optimal colour efficiency. They are made with the best available dyes and chemicals. For us quality has always been key, but sustainability is now even more important than ever. When selecting ink components, we consider all known and expected RSLs (restricted substance lists) for all major brands and meet guidelines such as REACH, OEKO-TEX® and ZDHC. We apply N RICH technology to develop and produce our benchmark quality digital printing inks for textiles in a sustainable way.’ says Daan de Kubber, Innovation & Development Manager at SPGPrints Boxmeer, The Netherlands. ‘We have created three different performance levels for our most used inks that you can mix and match to suit your digital textile printing applications: Pasha, Morpho and Alcon series. These are compatible with all major industrial print heads and fabrics. Our inks guarantee unattended printing without nozzle blockages or print head failures while adhering to the highest standards and legislation on sustainability’. Commercial success During the show SPG Prints signed contracts for several rotary printing machines, engraving systems, digital printers and also received highly potential enquiries for rotary screens and digital inks. This has made the ITME 2022 one of the most successful events in the recent history of SPG Prints, and also empowers us in creating a path to a sustainable future for our customers. Introduction of TEAK machine with universal repeat functionality

- 34. F A R M T O F A S H I O N F A R M I N G G I N N I N G K N I T T I N G D Y E I N G A N D P R I N T I N G G A R M E N T I N G S P I N N I N G 1800 - 889 - 6020 info@omaxcotspin.com www.omaxcotspin.com Sr. No. 842,843,845/1, Near. Petrol Pump, Village Rajsitapur , Ta. Dhrangadhra Dist. Surendranagar. Gujarat. (INDIA).

- 35. 35 JANUARY 2023 www.textilevaluechain.in Empowering Textiles Of India: India ITME 2022 India ITME 2022 a prestigious textile engineering and technology B2B Exhibition hosted in IEML, Greater Noida, U.P. showcased 1600 + Live machinery and unveiled 69 new products with participation from 68 countries. 11th edition of India ITME displayed a never before quality standard and success in terms of amenities for exhibitors and visitors setting new benchmark for exhibitions in India. 87,400 unique visitors totaling to 1,10,000 footfalls over 6 days enjoyed an array of activities at the venue. Concurrent programs included technical discussions, CEO conclave, industry awards, wildlife photo gallery, alumni meet and Government to industry interactions enhancing the experience and raising the excitement of participants. After a gap of six years, the event recorded a high flow of quality visitors which included industry members, technocrats, academicians, students and government officials apart from the delegations from 13 countries lead by senior officials of respective country who are looking to engage with India as sourcing and trade partner for developing their textile industry. 8th December 2022 the event was opened in accordance with Indian tradition of lamp lighting, Ganesh Vandhana & national anthem attended by Mr. S. Hari Shankar, Chairman, India ITME Society, Mr. Ketan Sanghvi, Hon. Treasurer, Mr. Sanjay Jayavarthanavelu, Chairman & Managing Director, Lakshmi Machine Works Ltd and Past Chairman, Mr. Sanjiv Lathia, Past Chairman Mr. Anuj Bhagwati, Chairman & Managing Director, ATE, Mr. Rakesh Kumar, Chairman, India Exposition Mart Ltd. along with other dignitaries who joined the simple ceremony. The high-profile technology & engineering exhibition for textiles witnessed participation from leading Indian institutes for textile engineering such as VJTI Mumbai, DKTE Ichalkaranji where MOU’s were signed for knowledge exchange with Swiss Textile Machinery Association and Italian Textile Machinery Association, paving way for collaboration not only in business but also in technical education. Eminent Panelists from Aachen University, Germany, Prof. Thomas Gries, Chairman, ITA, RWTH, Mr. Philipp Huber, RWTH Aachen, Mr. Kumar Jois, RWTH Aachen, Mr. Shantanu Bhat, RWTH Aachen, Ms. Gözdem Dittel, RWTH Aachen, Mr. Justin Kühn, RWTH Aachen, flew down to speak on latest technology topics. The other renowned speakers included Mr. Uday Gill, CSO, Indorama, Dr. PKC Bose, MD, Enercon Mr. Braz Costa, CITEVE, Portugal, Mr. Gurudas Aras, Strategic Consultant, Mr. Ranjit Sasi, India Head, Reverse Resources, Ms. Khusbhu Maheshwari, Mr. Anurag Gupta, MD, Usha Yarns, Dr. Asim Tewari, IIT B, Dr. Rajalakshmi Natarajan, IIT Dharwad, Saatchi Doshi, Programme, Devyani Hari, Director Centre for Responsible Business (CRB), Dr. Mohit Raina, Raina Industries Pvt Ltd, Dr. Asim Tewari, IIT Bombay & Mr. Prashant Agrawal, Wazir Advisors. The topics included by them included: • Transformation through Collaboration to achieve Sustainability. • Hydrogen Storage systems - Trends in Europe and India. • Role of Carbon in Fuel Cell Technology and Energy Conversion Devices. • Fibre based materials for future energy applications. • From fibres to component: What hydrogen storage POST ITME 2022

- 36. JANUARY 2023 36 www.textilevaluechain.in technology have to do with textile technology? • Composites & Technical textiles for Energy Efficient Building. • Multifunctional textile reinforced concrete structures for building applications. • Strategic Innovation in Textile Value Chain. • Need of Composites in the Energy Sector. • Learnings from the transformation in the Apparel & Textile Industry in Portugal. • Accelerating innovations for circular textiles. India ITME Society facilitated an interaction between industry and policy makers through CEO Conclave coordinated by Mr. Avinash Mayekar, Suvin. This session was attended by Shri Rohit Kansal, IAS, Additional Secretary, Ministry of Textiles, GoI, Shri P. Sathasivam, Ex-Chief Justice of India & Former Governor of Kerala, Ms. Prajakta L.Verma, IAS, Joint Secretary, Ministry of Textiles, GoI, Mr. Rajeev Saxena, Joint Secretary. Ministry of Textiles, GoI, Ms. Roop Rashi Mahapatra, Textile Commissioner, GoI. Industry sector were represented by Mr. T. Rajkumar, Chairman, Confederation of Indian Textile Industry, Mr. M. Sankar, President- Textile Machinery Division TMD (Operations), Lakshmi Machine Works Limited, Mr. Arun Kumar Garodia, Chairman Engineering Export Promotion Council of India (EEPC,). The six-day event carried forward its theme “Empowering Textile Through Technology” encouraging indigenously developed innovations and research by Indian companies. “Appreciating the best of the industry’ the 2nd edition of ITME awards felicitated companies like Lakshmi Machine Works Ltd. (LMW) , Rabatex Industries, Texfab Engineers (India) Pvt. Ltd., ColorJet India Ltd. Lakshmi Card Clothing Manufacturing Company Private Limited, S. A. Pharmachem Pvt Ltd for their outstanding products. Giving importance to gender equality women entrepreneurs were also lauded for their success in an industry dominated by men. Ms. Deepa A Kumar, Founder & Managing Director, Yashram Lifestyle Brands Pvt. Ltd. & Ms. Neha Jhunjhunwala, Director, Sarla Performance Fibers Ltd. were selected for women entrepreneurship award. Proving to be a responsible industry body, India ITME Society not only encouraged modern innovations and technology but also provided inspiration for traditional skills and artisans of the nation. Under the category of best Master Weaver, Ms. Santoshi Kewat, Master Weaver, Maheshwari Creations, Madhya Pradesh & under category of Restoring Traditional Skills Ms. Kumari Raita, Soura Development Agency, Odisha were felicitated. Under the Category of Research Excellence - Dr. Rekha Ramakrishnan, SASMIRA Institute was felicitated.

- 37. 37 JANUARY 2023 www.textilevaluechain.in The prestigious jury panel comprised of the stalwarts of Indian industry Mr. Uday Gill, Group Chief Strategy Officer, Indorama Ventures Ltd, Mr. Updeep Singh, President & CEO, Sutlej Textiles and Industries Ltd, Mr. Manohar Samuel, Advisor, R&D, Reliance Retail, Mr. Gurudas V Aras, India consultant to the ITA group, Germany, Mr. R. Anand, Partner, Eastern Engineering Company, Dr. Manisha Mathur, Joint Director, SASMIRA, Mr. Sanjiv Lathia, Past Chairman of India ITME Society, Mr. Ketan Sanghvi, Hon. Treasurer, Mr. Hari Shankar, Chairman unanimously recommended for Mr. S.P. Oswal for the honour of ‘Textile Maestro of industry’ of Indian textile industry. A Technical symposium by Veermata Jijabai Technological Institute, Mumbai on the theme of “Reduce-Reuse-Recycle State of the Art in Textile Sector” was well appreciated and well received by officials as well as industry. The organizer India ITME Society executed a seamless & flawless exhibition taking care of all round growth and progress of Indian textile industry creating opportunities for business, education, women, research etc. Amidst high voltage negotiations and discussions, art and culture also was given its due place whereby an evening of cultural Programme with dance, music and Fine Dine was organized for exhibitors. Once again working towards creating opportunities Pan India, North East folk art music and dance combined with fashion show and live music showcasing Maheshwari Sarees create using traditional handlooms by women Master Weavers of Madhya Pradesh were presented to global audience. The platform gave global exposure to our handicraft and traditional artisans especially women weavers from rural area of our Country. For those who enjoyed wildlife and photography as array of photographs captured by well-known photographer by Mr. Hari Santharam was on display which was enjoyed by one and all. The six - day marathon event definitely set the foundation for upgradation and modernization of the textile industry of India which is the 2nd largest employment generation sector after agriculture.It also has motivated and enhanced the confidence of Indian textile engineering industry in their capabilities to cater to the demand of domestic market as well as competing in the global market. India ITME 2022 opened the possibility and opportunities for overseas machinery manufacturers to tap the gaps in India and also connect with many buyers spread across 68 Countries. The 11th edition of India ITME truly proved that it is a business platform which empowers and motivates the industry to the next level. Showcasing the digital prowess of India, this edition of India ITME event digitalized all its services and provided event catalogues, visitor guide, help desk assistance, exhibitor manual etc. digitally reducing the print activity and thus saving quantum of paper usage. The mega event concluded on a high note of enthusiasm empowering all its participants, infusing vibrancy into the industry facing geo - political turbulence amidst other challenges.

- 38. www.uster.com/qbar2 Inspecting fabrics after weaving is old school. With USTER® Q-BAR 2, smart weavers can pinpoint defects during fabric formation. It’s the right way to reduce material losses and minimize manual checks. When it comes to fabric quality issues, prevention is better than cure. The whole fabric is automatically monitored – warp, weft, selvage and leno – and faults are identified immediately. LEDs signal defect locations to the weaver, with information shown on the control unit touchscreen. It’s automatic inspection, in-process and instant, so weavers can react to prevent long-running or repeating faults. USTER® Q-BAR 2 sets the future standard, controlling the weaving process instead of the output. USTER ® Q-BAR 2 Weave it right: spot defects on the loom

- 39. 39 JANUARY 2023 www.textilevaluechain.in India ITME (International Textile Machinery Exhibition) 2022 is a leading trade fair for the textile industry, showcasing the latest innovations and technologies in the field. This year, the event featured a range of new products and technologies in the sectors of spinning, weaving, processing, and digital printing. In the spinning sector, several companies displayed innovative machines that can produce high- quality yarn at high speeds and with improved efficiency. Meera Industries has developed a Twine Twister that is capable of completing S & Z twists in a single step. The ability to produce S & Z twists in one machine can significantly improve efficiency and productivity in the production process. Similarly, their other machine, that is capable of Twisting, Prying, and Reverse Twisting in a single step is also a valuable innovation. By reducing the number of steps required to produce twisted yarn, the TPRT machine can help to streamline the production process and save time and resources. ELGI Electrics launched their new cubical yarn conditioning machine, with capacity of 360Kg to 3000Kg per batch, you can also link the machine with automatic cone transport system. In the weaving sector, companies showcased new types of looms that can produce complex and intricate fabrics with greater precision and speed. These looms use advanced technologies such as lasers, robotics, and computer-aided design (CAD) to produce high-quality fabrics in a shorter time. Some of the new looms also have the ability to produce fabrics with multiple colours and patterns, allowing for greater design flexibility. Rabatex has developed an Advanced Sample Warping Machine with advanced features such as 18 axis control and the ability to produce 16 color patterns. The machine’s capacity to produce warp lengths of up to 700 meters is also noteworthy, as it allows for the production of longer lengths of warp yarn, which is essential for many textile applications. Prashant Industries has developed a new direct warper for cotton and filament yarns with a high capacity of 1200 meters per minute. The use of Industry 4.0 automation in the machine allows for greater efficiency and precision in the warping process, resulting in a more consistent and high- quality product. The processing sector saw the introduction of new machines that can improve the quality and efficiency From Spinning To Digital Printing: Check The Latest Innovations In India ITME 2022 POST ITME 2022

- 40. JANUARY 2023 40 www.textilevaluechain.in of fabric finishing processes. TexFab has displayed a Loops steamer with new features such as the ability to fix the colour of reactive prints. This added feature can improve the quality and durability of the finished fabric, as it helps to prevent fading or bleeding of the colours during washing or other processing steps. The fact that TexFab received an award in the finishing sector at India ITME 2022 further demonstrates the company’s commitment to innovation and the development of high-quality products. The Embee Group has developed printing machines, such as the ACUMEN and SIGNATURE, with advanced features such as individual drive heads and multi repeat printing heads with a precision of 0.1mm. These features allow for greater control and accuracy in the printing process, resulting in a more consistent and high-quality product. The ability of the machines to be used for both wider and narrow width fabrics adds value, as it allows for greater versatility and the production of a wider range of fabrics. The digital printing sector also saw a number of new innovations at India ITME 2022. Companies displayed new printers that can produce high-quality prints with a wide range of colours and patterns, using eco- friendly inks and processes. Some of the new printers also have the ability to print on a variety of fabrics and materials, including natural and synthetic fibres. COLORJET Group launched their sustainable Pigment printing solution – EARTH SERIES. ColorJet EARTH Series is an advanced sustainable printing solution in the Digital textile printing segment. This new process does not require additional equipment for pre and post treatment. By eliminating pre-& post treatment, this has led to huge saving of water and energy, and provides a competitive edge in the sustainable direct-to-fabric printing category. Tanya Enterprises displayed their digital printers, the printers have capacity to print at 15 sq. m per hour using nine different CMYK colours. The printers can also print using fluorescent colours. Their DTF (Direct to Fabric) printers comes with three heads, CMYK, white and neon. The printers can print on variety of fabrics from Polyester, Cotton and Denims. Overall, the innovations showcased at India ITME 2022 demonstrate the continued growth and development of the textile industry in India. With the adoption of new technologies and processes, the industry is poised to continue producing high-quality fabrics and garments that meet the needs and expectations of consumers.

- 41. 12 – 14 September 2023 Jio World Convention Centre (JWCC), Mumbai Exhibit at India’s foremost expo on technical textiles, nonwovens & composites Show Highlights • Special focus on product categories : Filtration, Masterbatches and Composites • Resume in-person interactions with international buyers on a large scale • Meet high quality buyers from 12+ industries like agriculture, automotive, textiles, medical, packaging etc • Display your latest innovations at a world class venue : Jio World Convention Centre, BKC, Mumbai Contact us. Priyanka Pawar +91 22 6144 5990 priyanka.pawar@india.messefrankfurt.com For bookings, scan the QR code

- 43. 43 JANUARY 2023 www.textilevaluechain.in Experience The Live Sari Jacquard Weaving At Stäubli’s Booth At SITEX SITEX trade fair will be held at the Surat International Exhibition and Convention Centre (SIECC) in Sarsana, Surat from January 7 - 9. The economic importance of the Surat region has been growing continuously and heavily, especially with the flouring textile industry. Today Surat is one of the textile hubs encompassing the entire supply chain of synthetic fibres. Around 60,000 weaving machines are in operation there, and an estimated half of them are running with waterjet weft insertion. Production equipment must be efficient, and purpose designed. The trade fair is an opportunity for the local players to discover Stäubli’s latest solutions for efficient weaving processes at Booth 243 and see several machines in operation. Stäubli is a leading supplier of Jacquard technology around the world. Indian mills rely on Stäubli solutions for weaving all sorts of Jacquard fabrics, from home textiles to technical fabrics, narrow to large- format applications, and apparel fabrics, particularly for saris. In fact, it’s difficult to imagine a Jacquard weaving mill without a solution by Stäubli. Stäubli Jacquard machines have become a central element in mills that demand high productivity and top quality because they deliver a broad range of decisive benefits: top energy efficiency, the highest production speeds, and minimum vibration thanks to optimally balanced kinematics. Weavers were introduced to the new LX PRO Jacquard machine at India ITME in December 2022. Featuring the TC8 controller, NOEMI electronics architecture for unmatched reliability in data transmission, and the MX PRO modules for energy savings, the machine boasts ultra-high weaving speeds with reliable hook selection for all kinds of woven fabrics. Live sari Jacquard weaving Visitors to the Stäubli booth will see a complete 380cm installation weaving sari fabric and featuring another reliable high-speed Jacquard solution : the LXM Jacquard machine, operating with 5,376 hooks. Available in two formats (2,688 and 5,376 hooks) this model meets the requirements of a wide range of applications and assures reliable operation at high weaving speeds. High - speed frame - weaving solutions for any application Whether running a weaving mill with rapier, air-jet, or water-jet weaving machines, weavers can choose from a wide range of Stäubli dobbies, including the S3000 / S3200 electronic rotary dobby series, and Stäubli cam motions like the S1600 / S1700 series. Visitors to the Stäubli booth will observe a renowned machine that is already operating in many mills around the globe, weaving a wide variety of applications : the S3260 electronic rotary dobby, offering a housing size for up to 16 lifting units. Seeing this machine gives one a very good idea of the operational performance and running speeds these machines achieve. This electronic rotary dobby can be operated with the latest generation of e32/33 transmissions, offering benefits such reduced maintenance cost and time due to maintenance-free bearings and other refined features. Both machine and transmission promise a long service life for many years of high-efficiency production. Automation solutions for the weaving preparation of filament warps Drawing in warps in the weaving preparation department is a crucial processing step. Proper drawing in plays an important role for the efficient downstream weaving process, ensuring instant S3260 electronic rotary dobby SITEX 2023