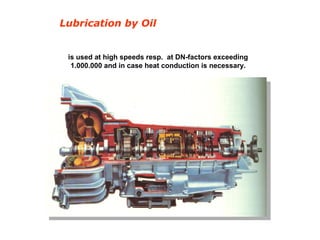

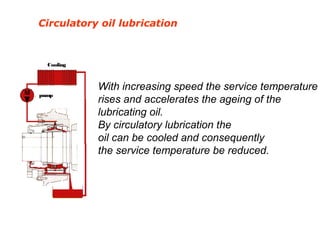

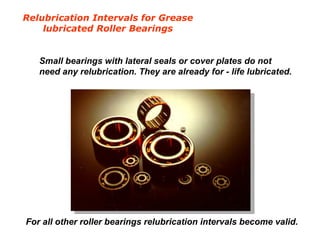

Lubricants are materials that are applied between moving parts to reduce friction and dissipate heat. They can be solid, semi-solid, or liquid. Greases are commonly used semi-solid lubricants that are applied between parts using grease guns. Oils are widely used liquid lubricants, with mineral oils being the most common. Solid lubricants like graphite are used in high temperature applications over 200°C. Relubrication intervals for grease lubricated roller bearings can range from 20 hours to over 20,000 hours depending on factors like bearing size, speed, and temperature.

![The most important Parameters for

selecting the suitable Lubricant

revolution or DN - factor

D = external bearing diameter [mm]

d = internal bearing diameter [mm]

n = revolution per minute [rpm]

dm= medium bearing diameter [mm] = ———

D + d

2

DN = ——— • nD + d

2

temperature range](https://image.slidesharecdn.com/lubrication2-150313052749-conversion-gate01/85/Lubrication-31-320.jpg)

![Guidelines for

Relubrication Intervalls

10 000

6 000

4 000

3 000

2 000

1 500

1 000

500

300

200

150

100

50

20 000

15 000

10 000

7 500

5 000

2 500

1 500

1 000

750

500

250

20 000

15 000

10 000

5 000

3 000

2 000

1 500

1 000

500

100 200 500 1 000 2 000 5 000 10 000

n [U/min]

tfa

tfb

tfcLubrication interval,

given by service hours

tfa = radial ball bearing

tfb = cylindrical roller bearing / needle bearing

tfc = self aligning roller bearing / taper rolling bearing / axial roller bearing

massive cylindrical roller bearing (0,2 tfc), axial cylindrical roller

bearing (0,5 tfc)

500 420 360 280 240 200 160 120 100 80 60

40

20

d=10

Example: A deep-groove ball bearing with an internal diameter

d= 100mm running at a speed of n = 1000 rpm. The operating

temperature lies between 60 and 70 °C.

Which is the expected relubrication interval?

The vertical in point n= 1000 rpm on the abscissa

cuts the curve for d= 100mm. From there the horizontal leads

to the outer left-hand scale (deep- groove ball bearings)

indicating a relubrication interval of 10000 service hours](https://image.slidesharecdn.com/lubrication2-150313052749-conversion-gate01/85/Lubrication-34-320.jpg)