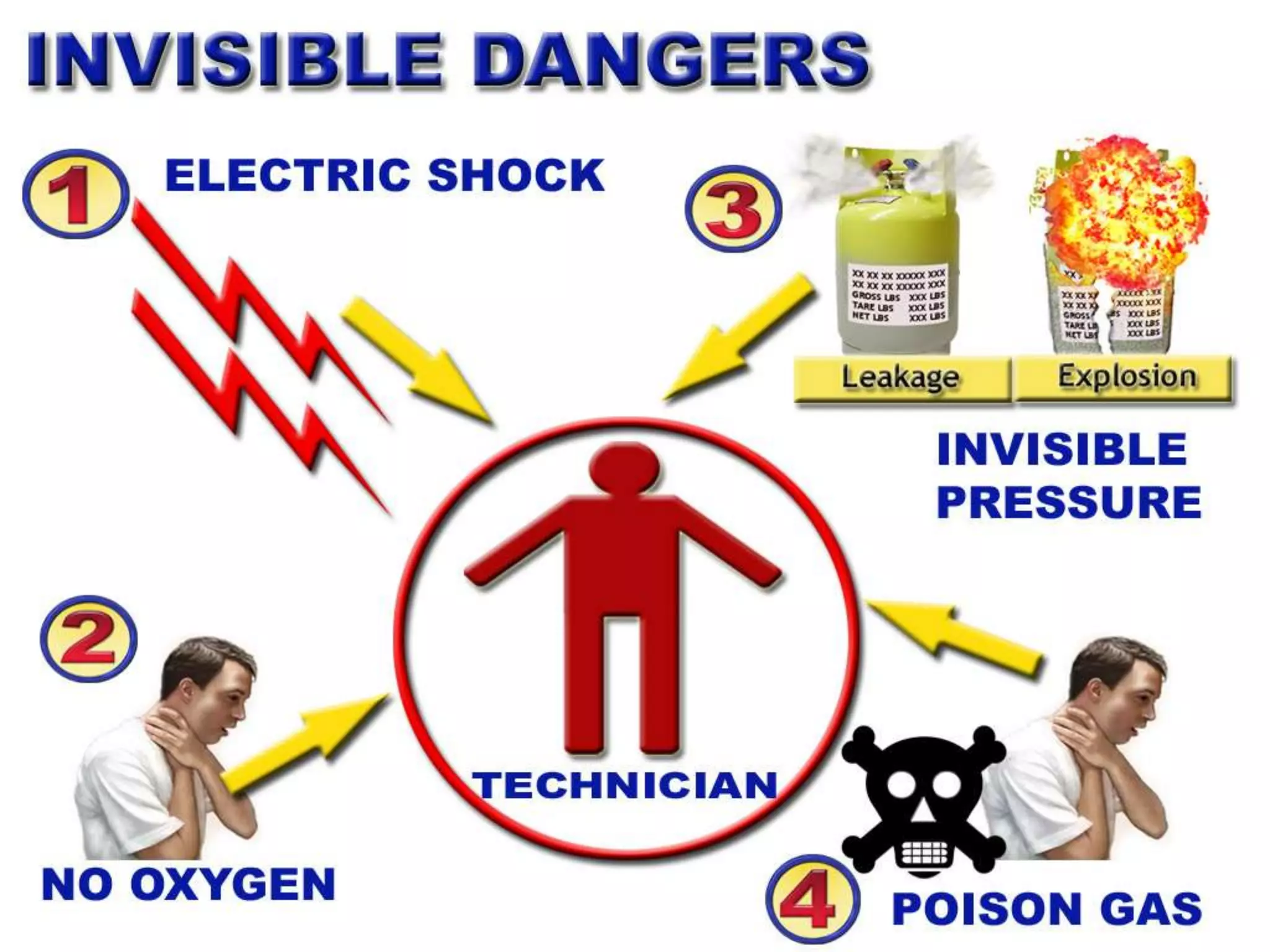

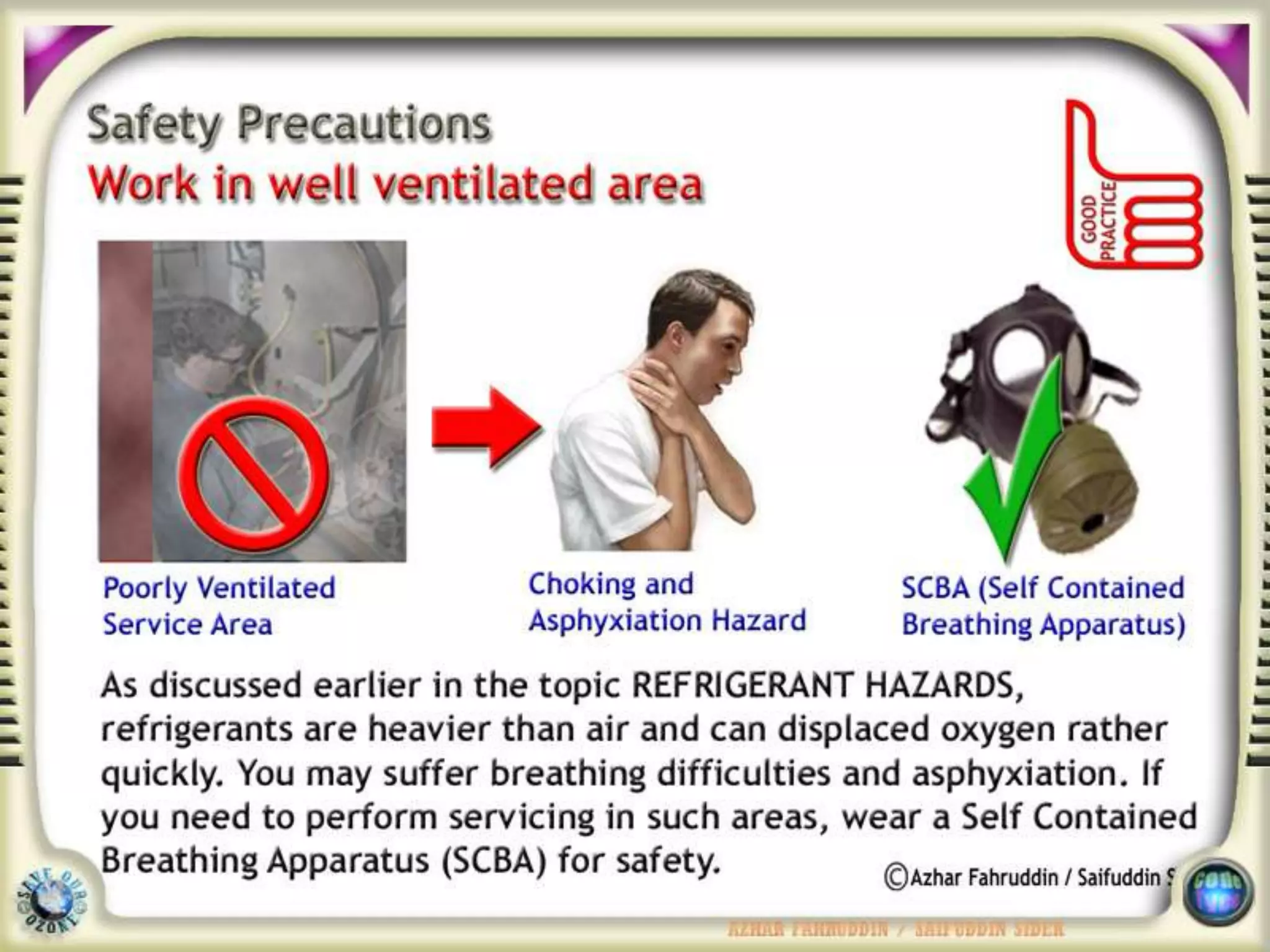

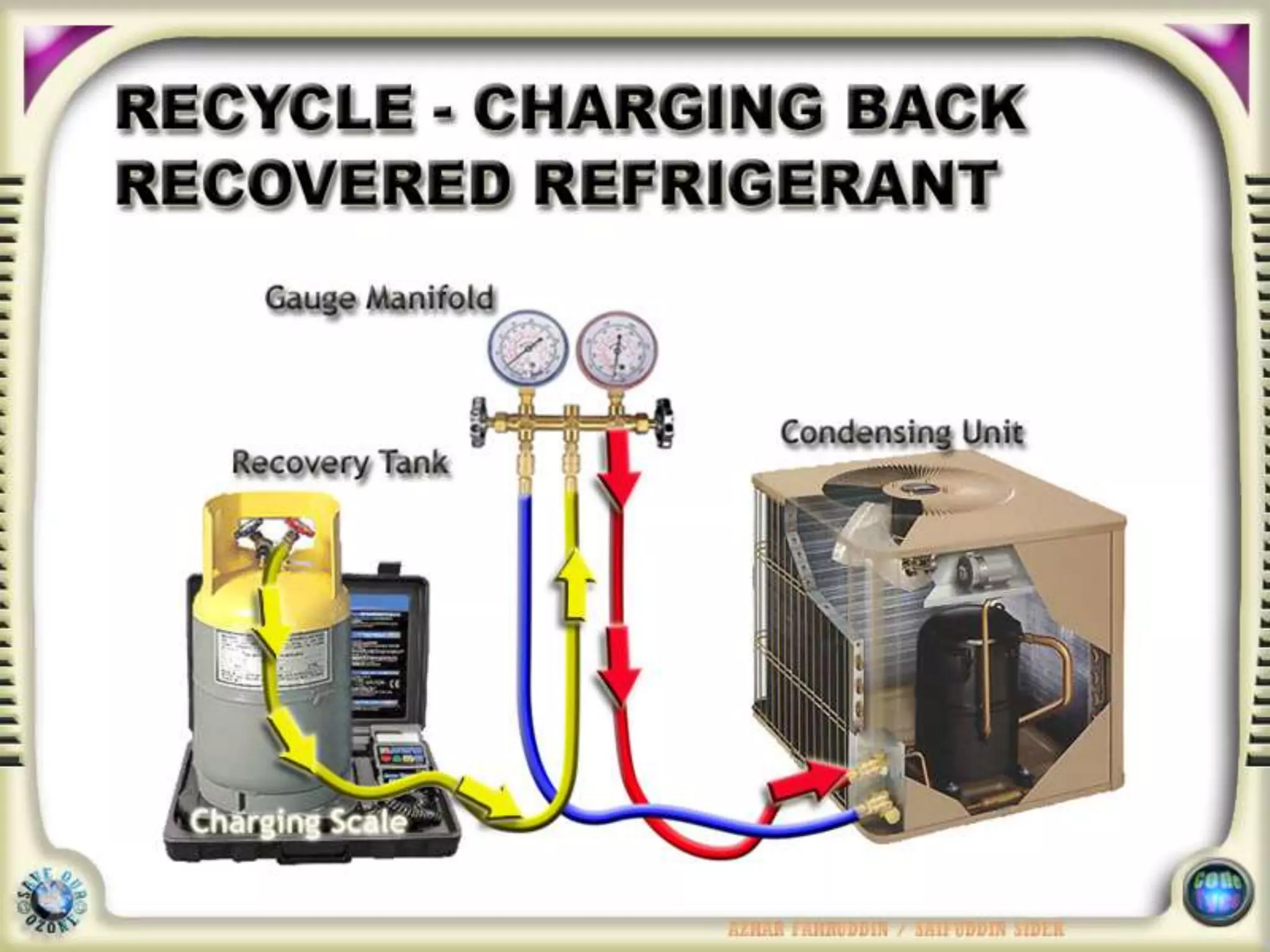

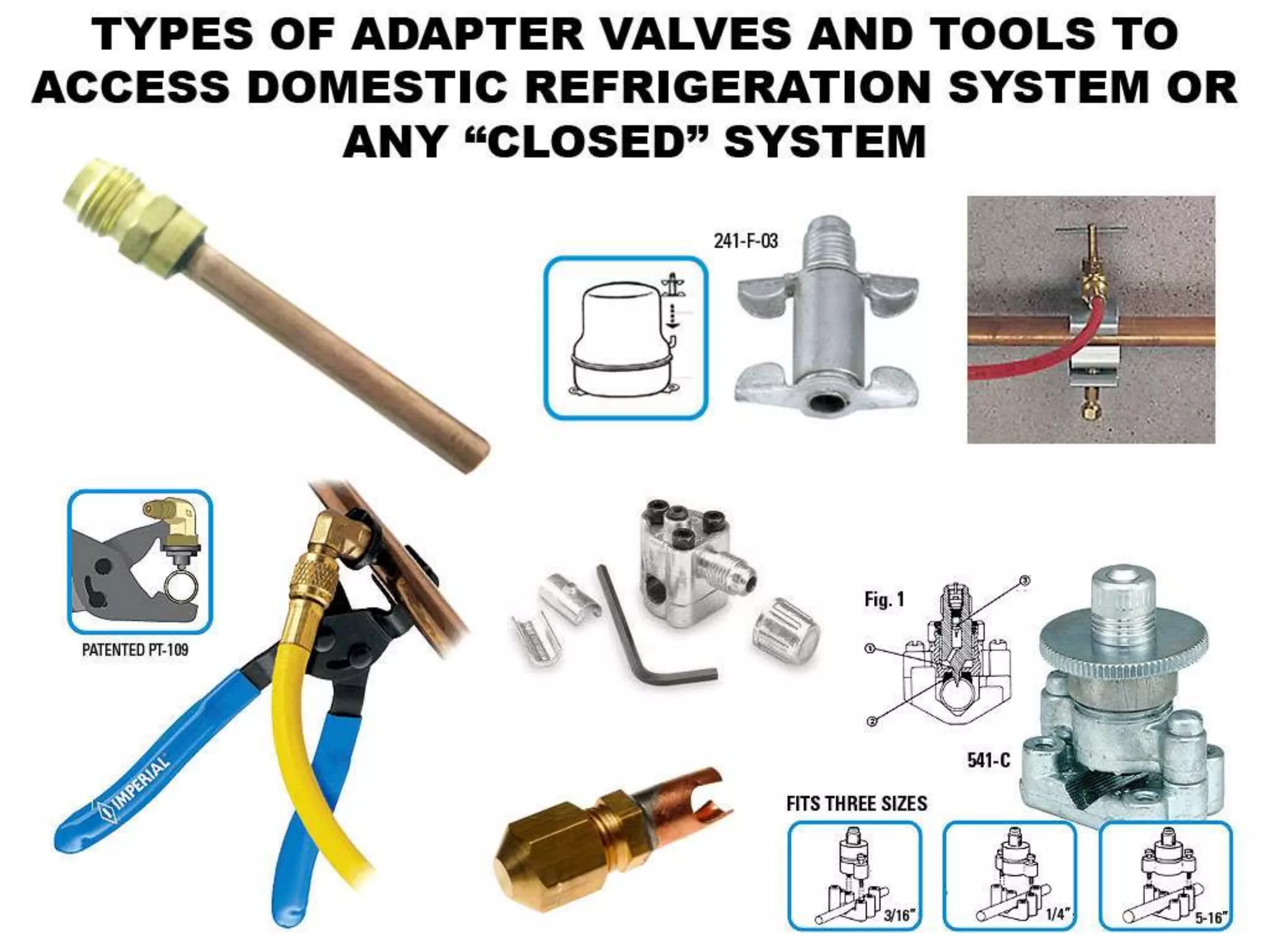

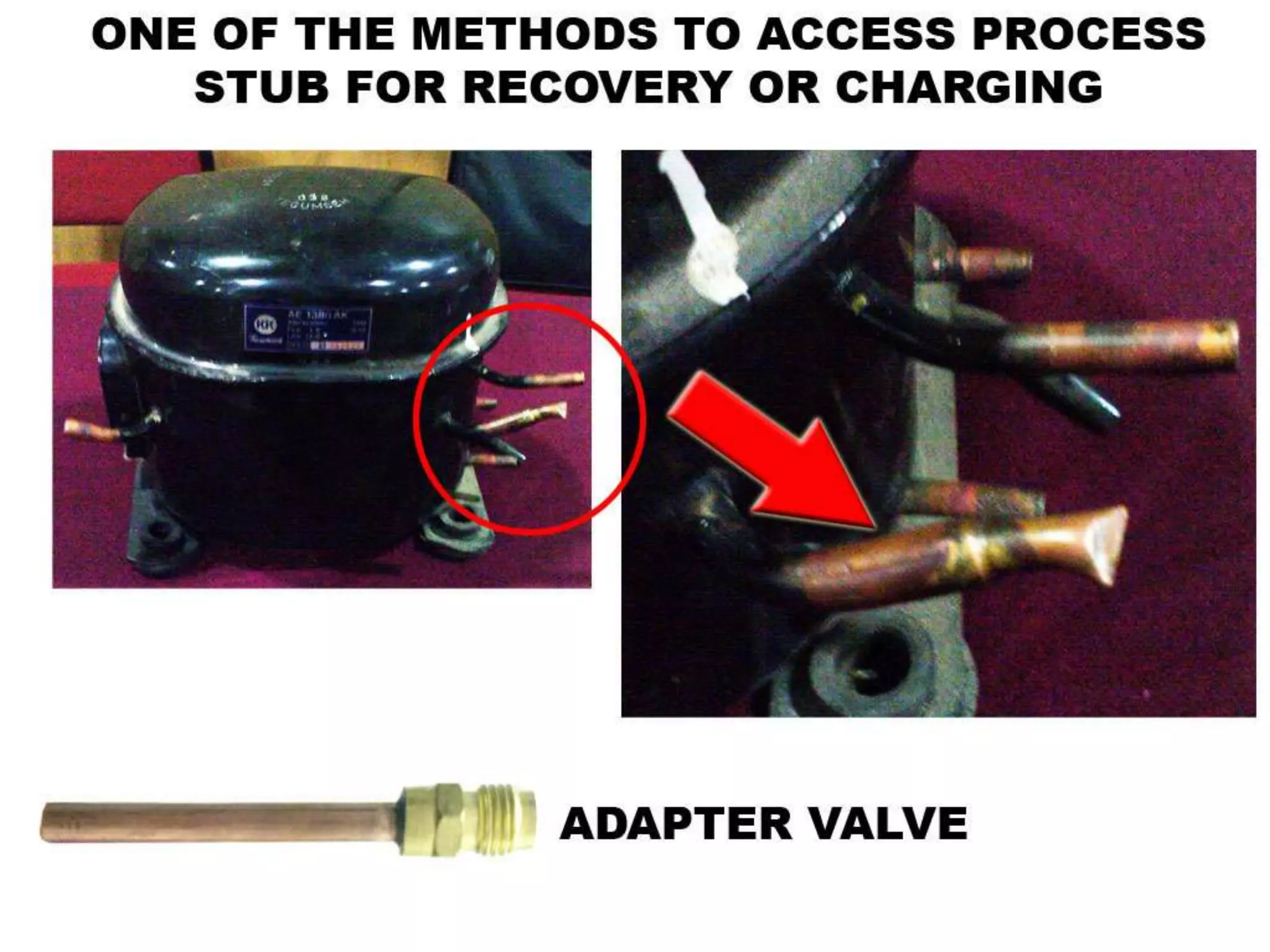

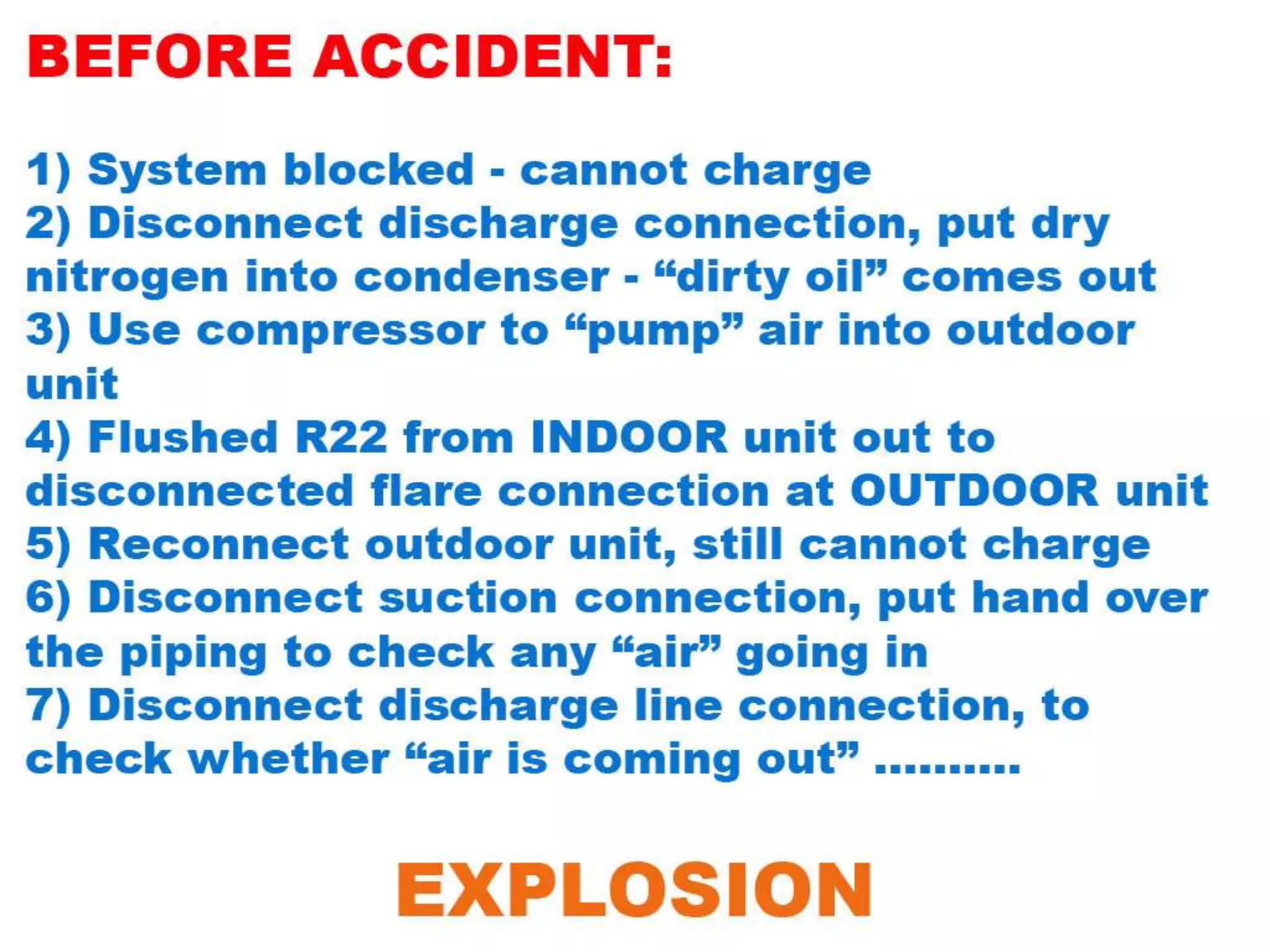

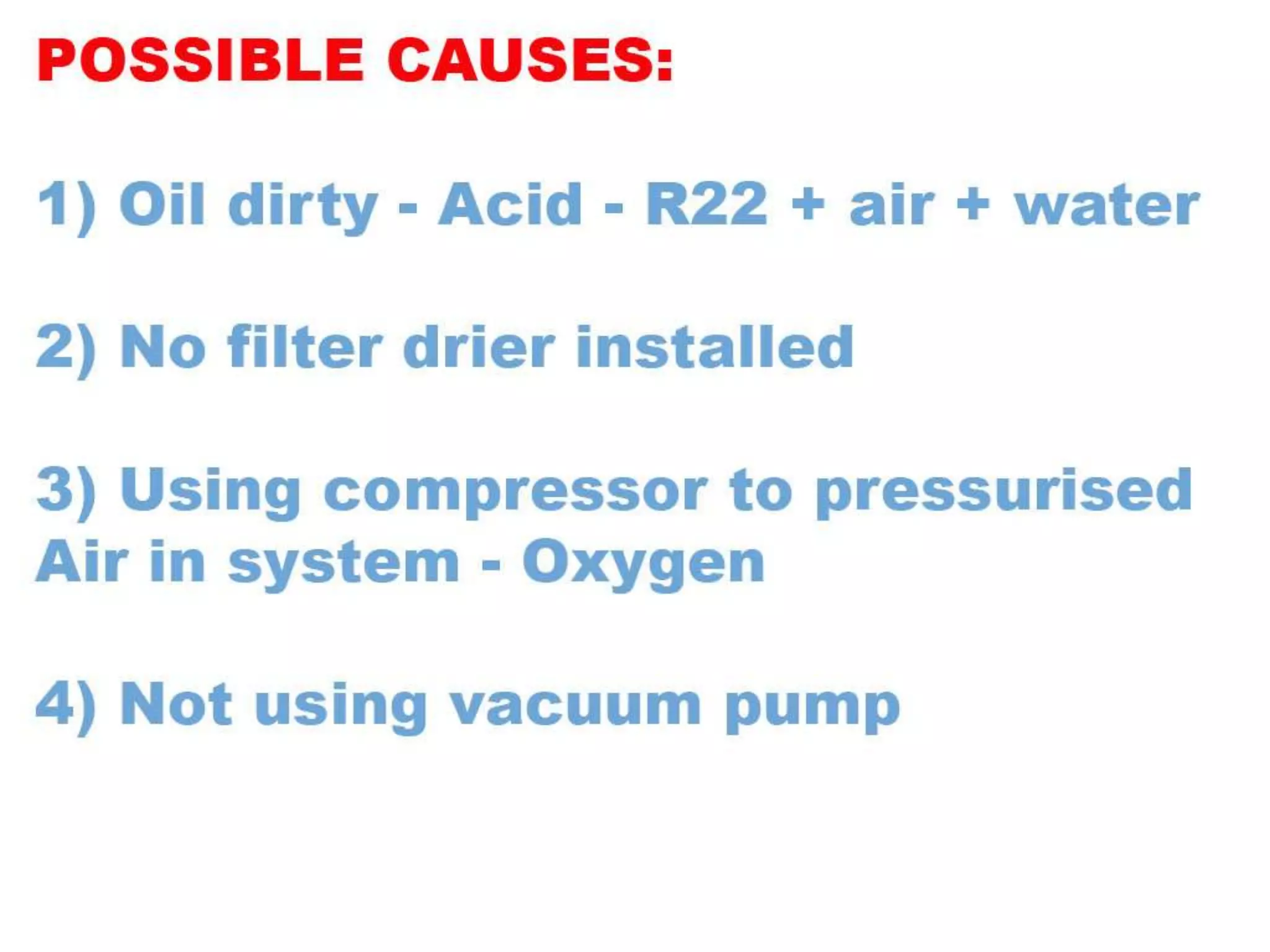

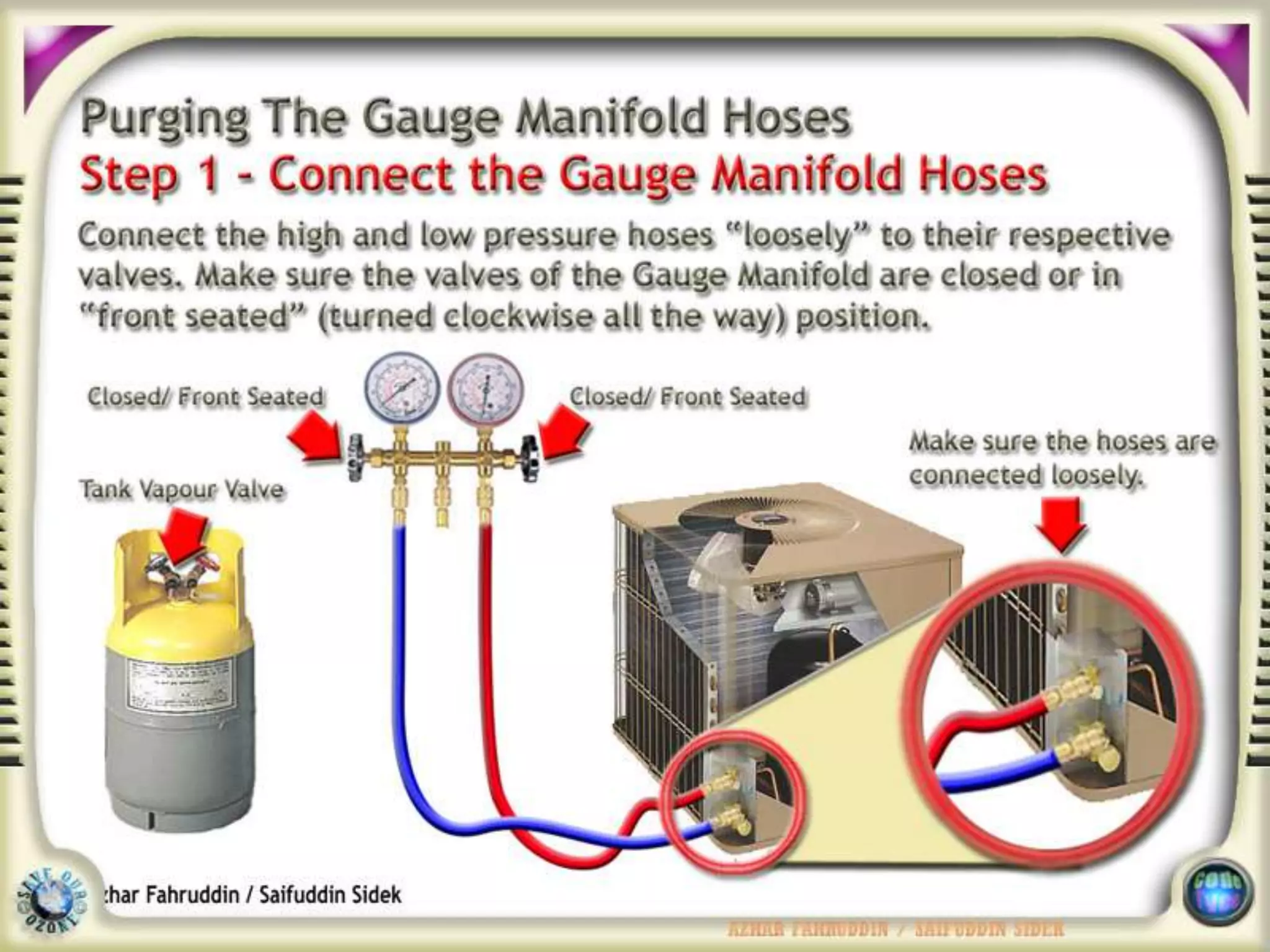

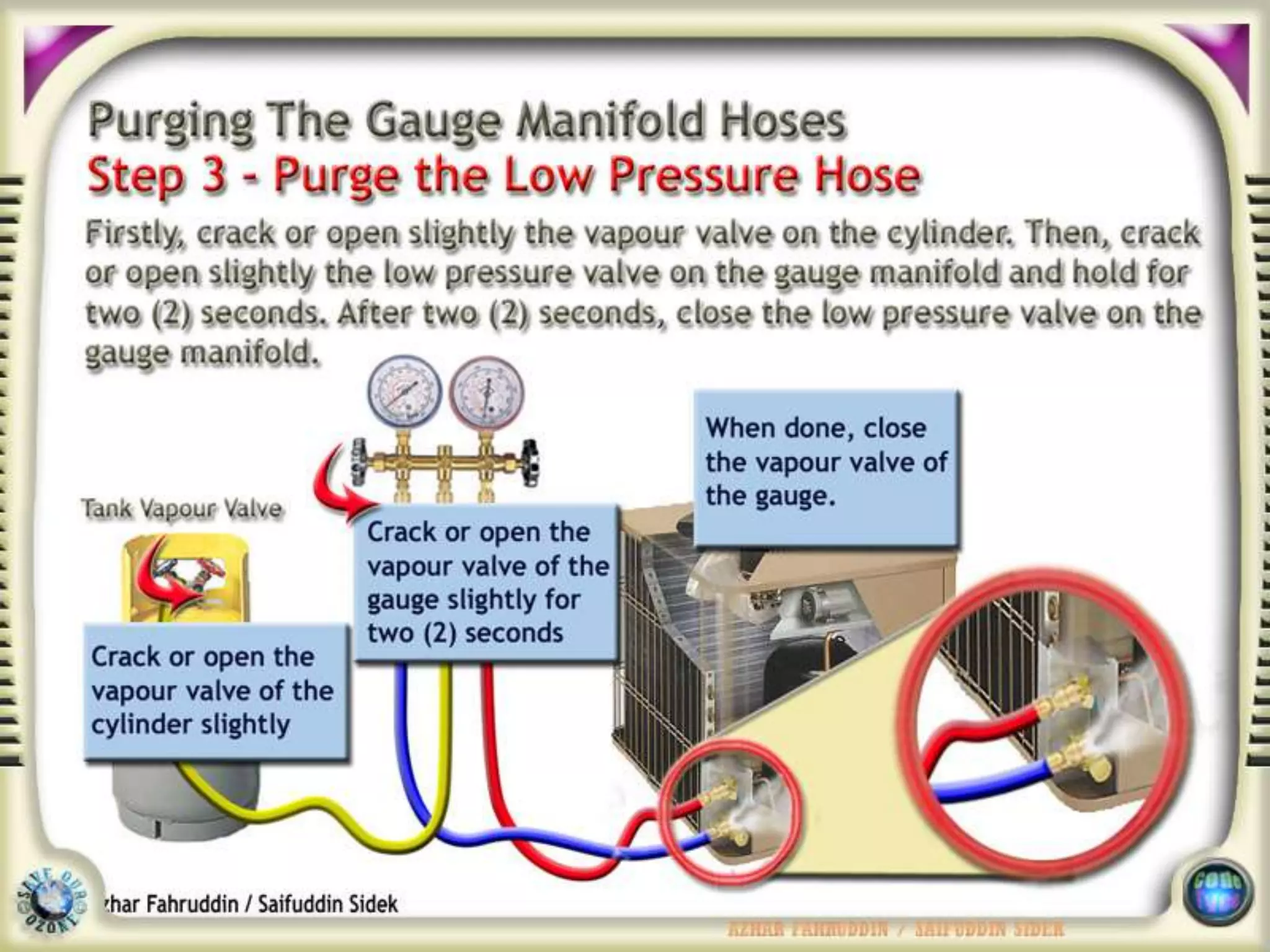

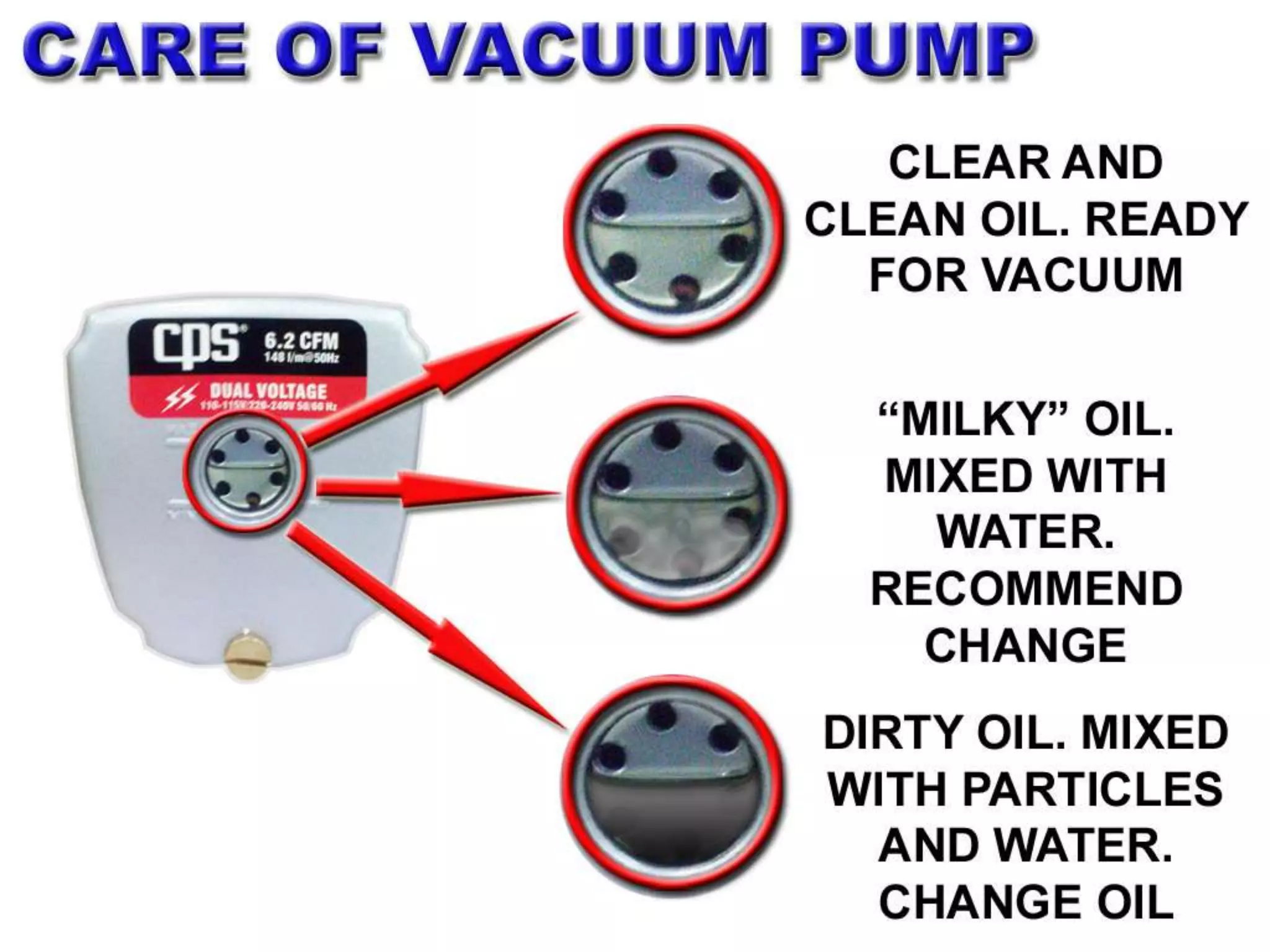

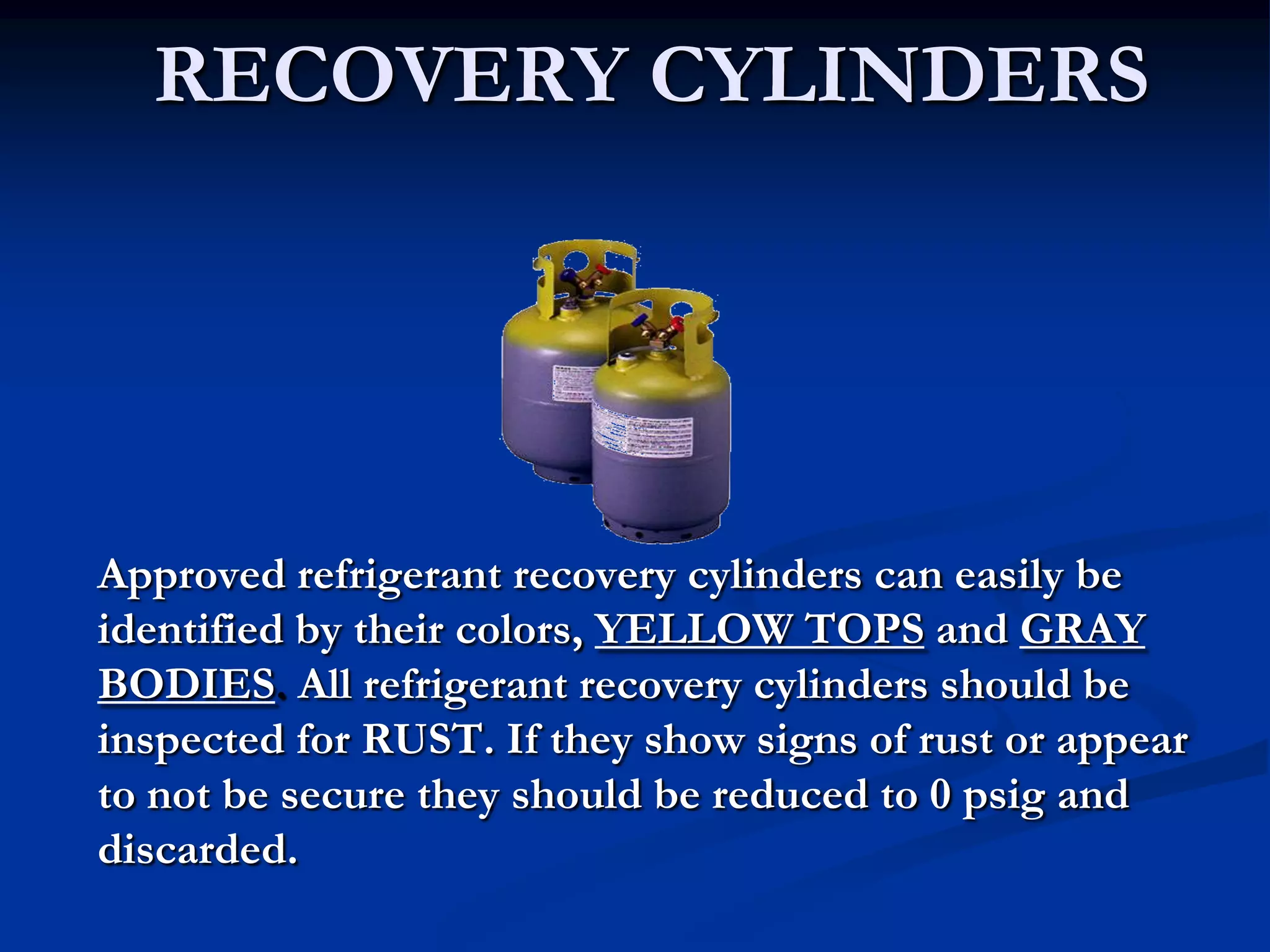

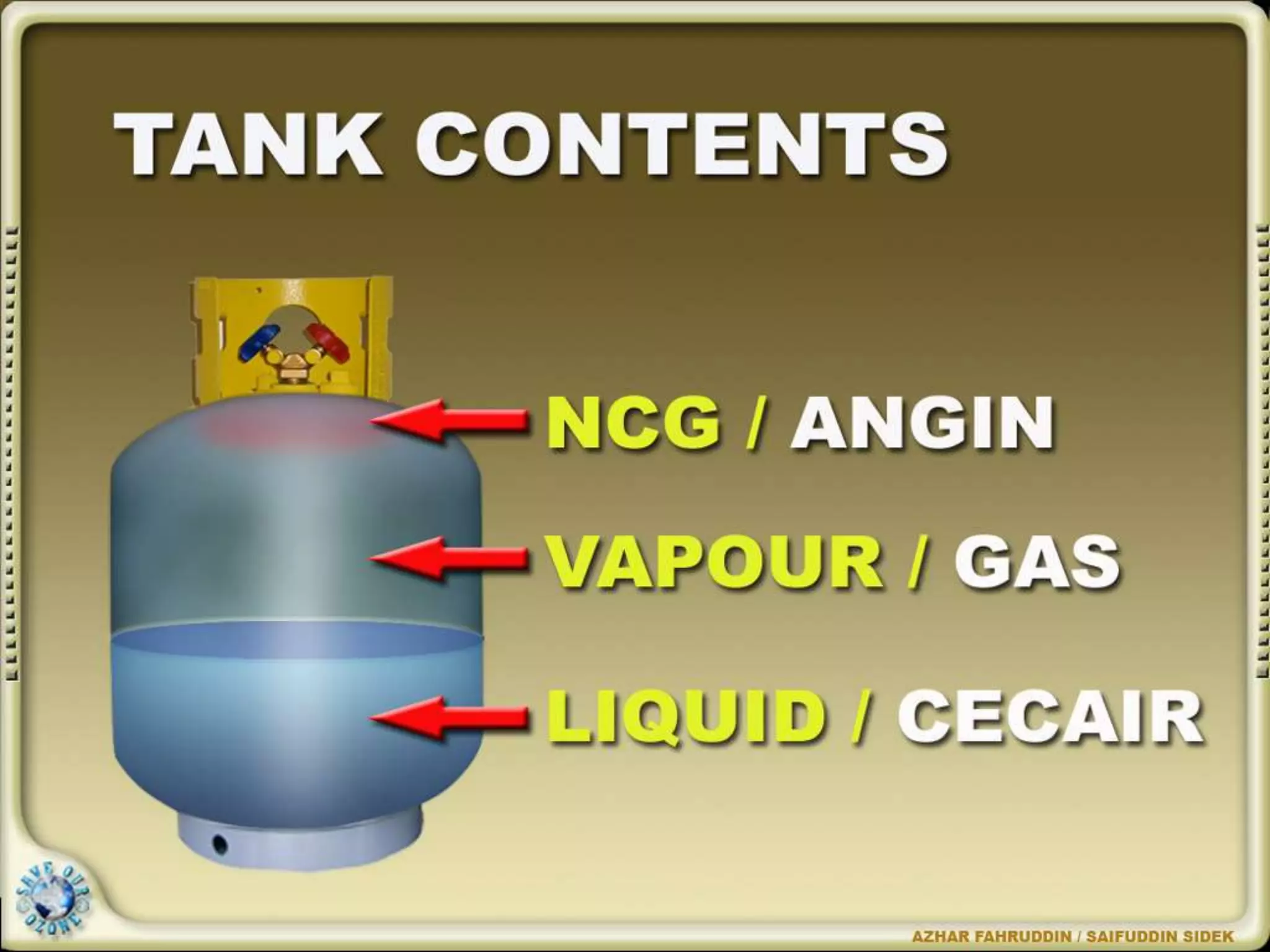

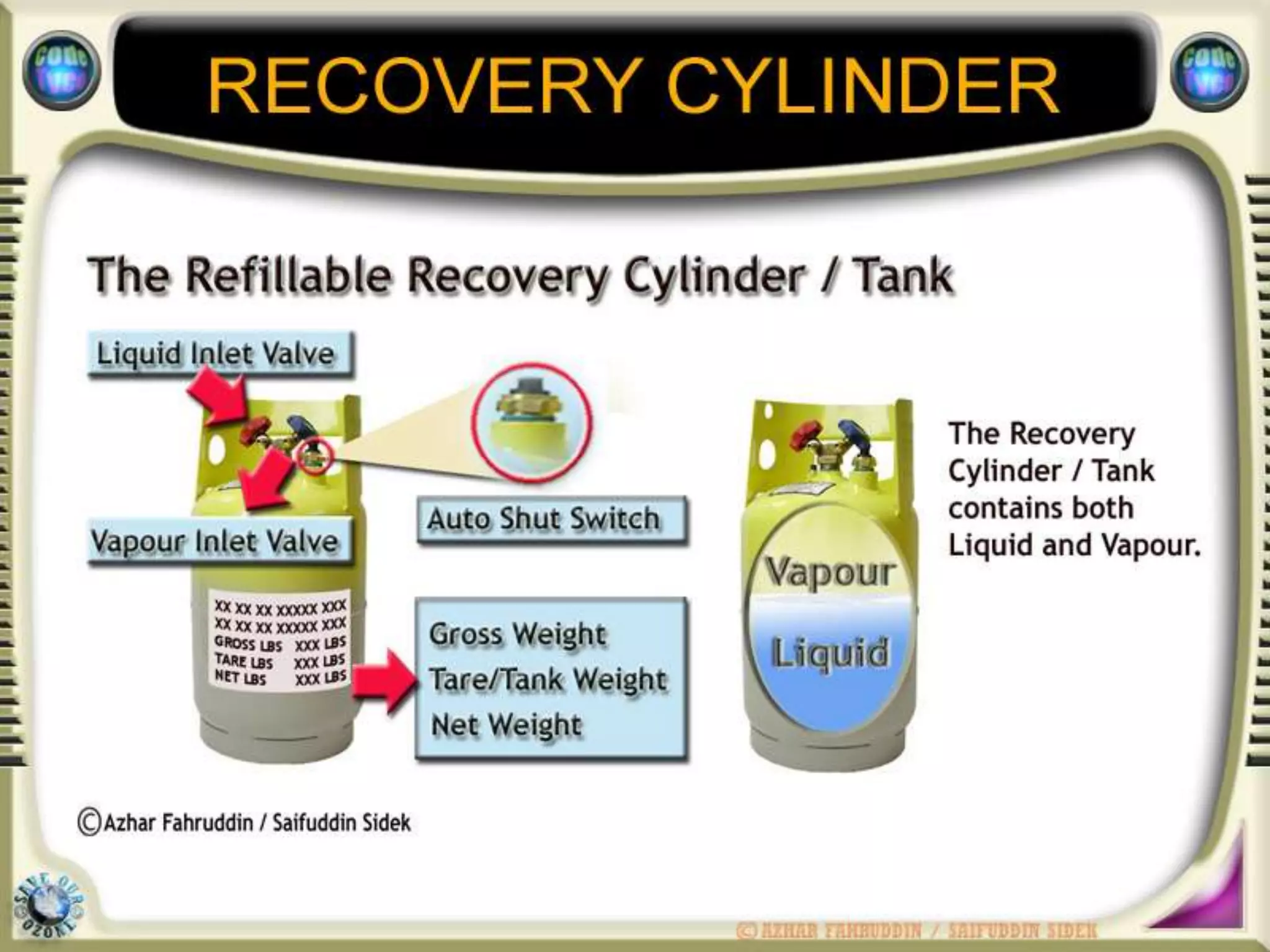

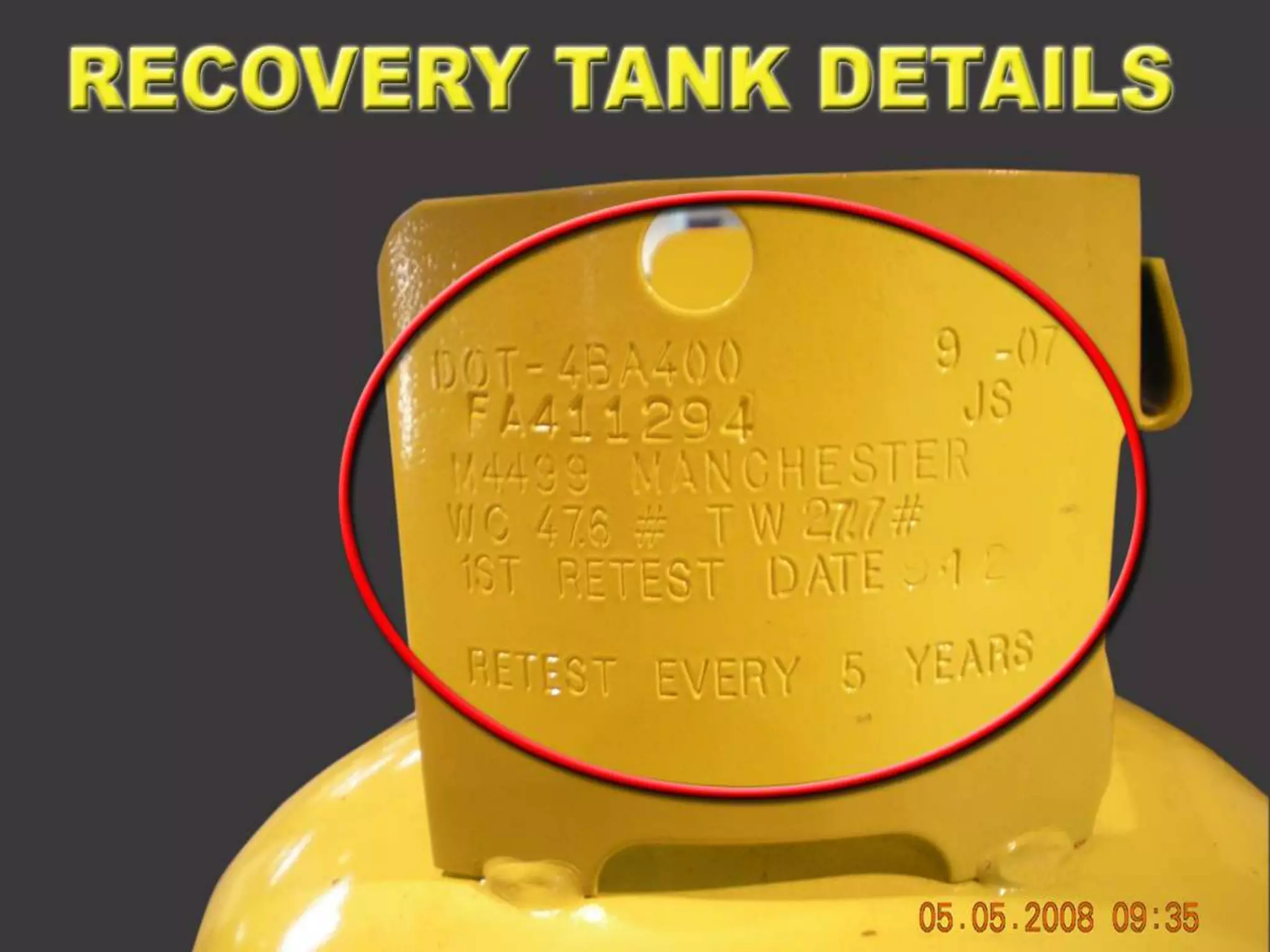

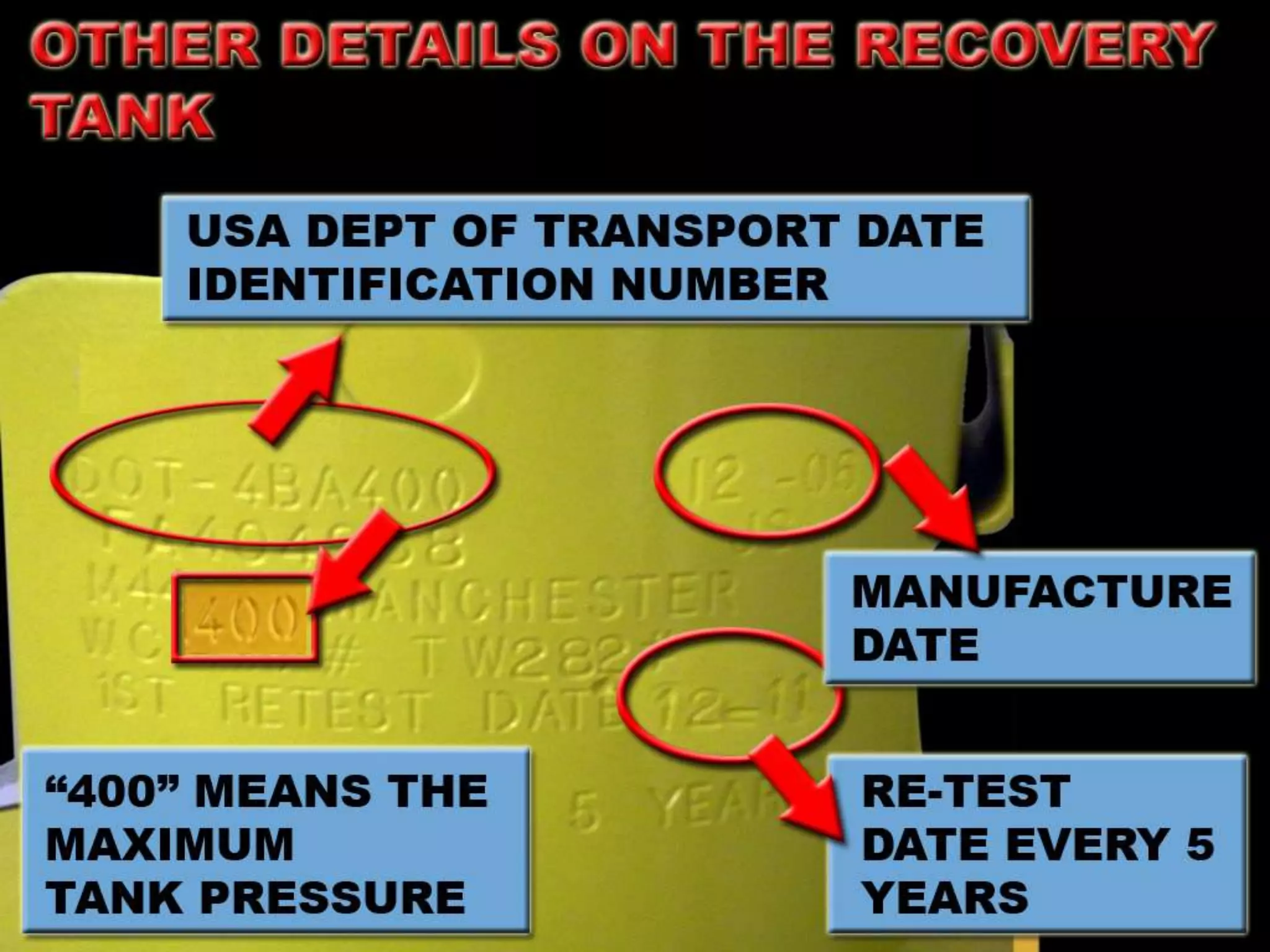

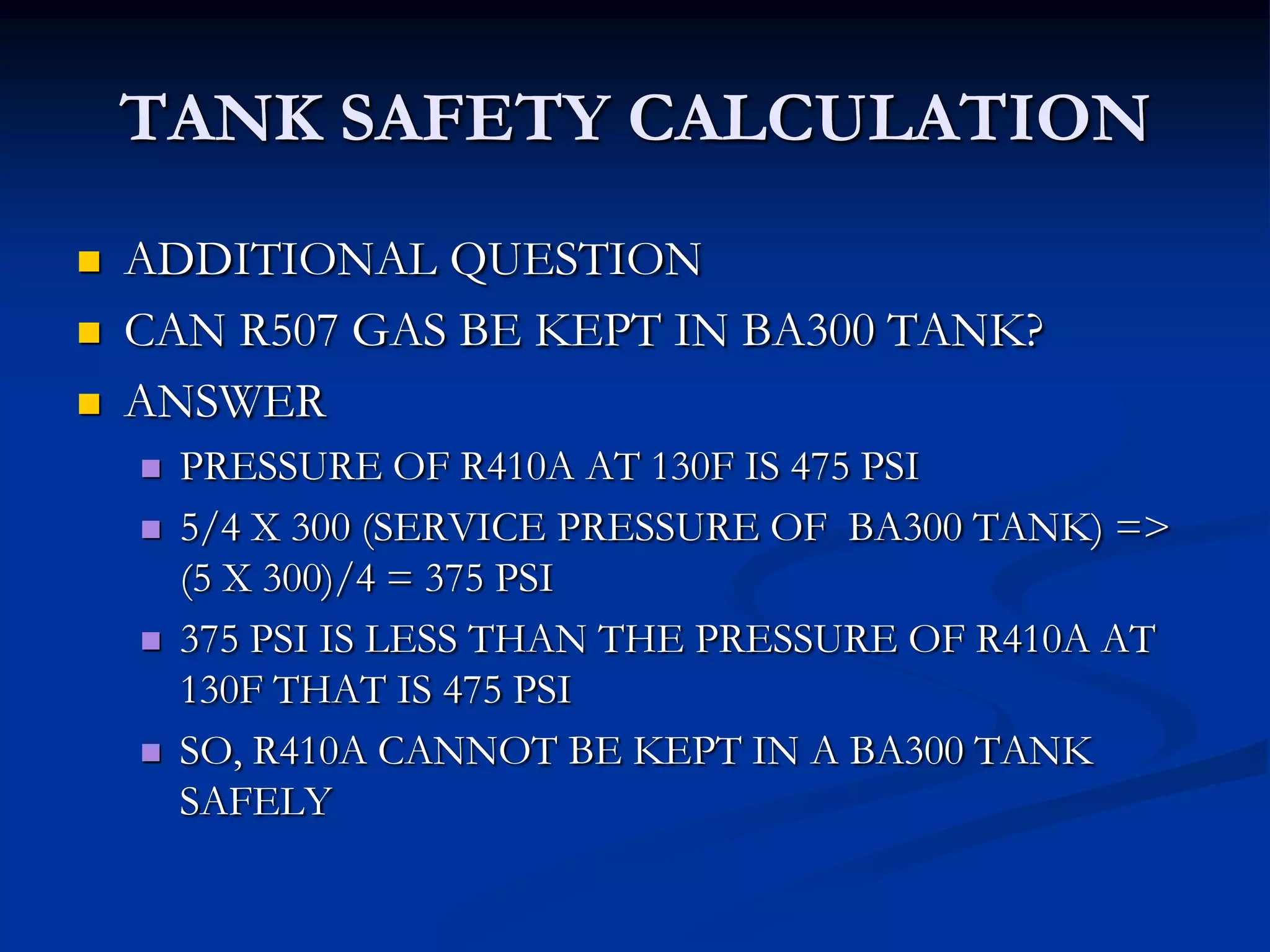

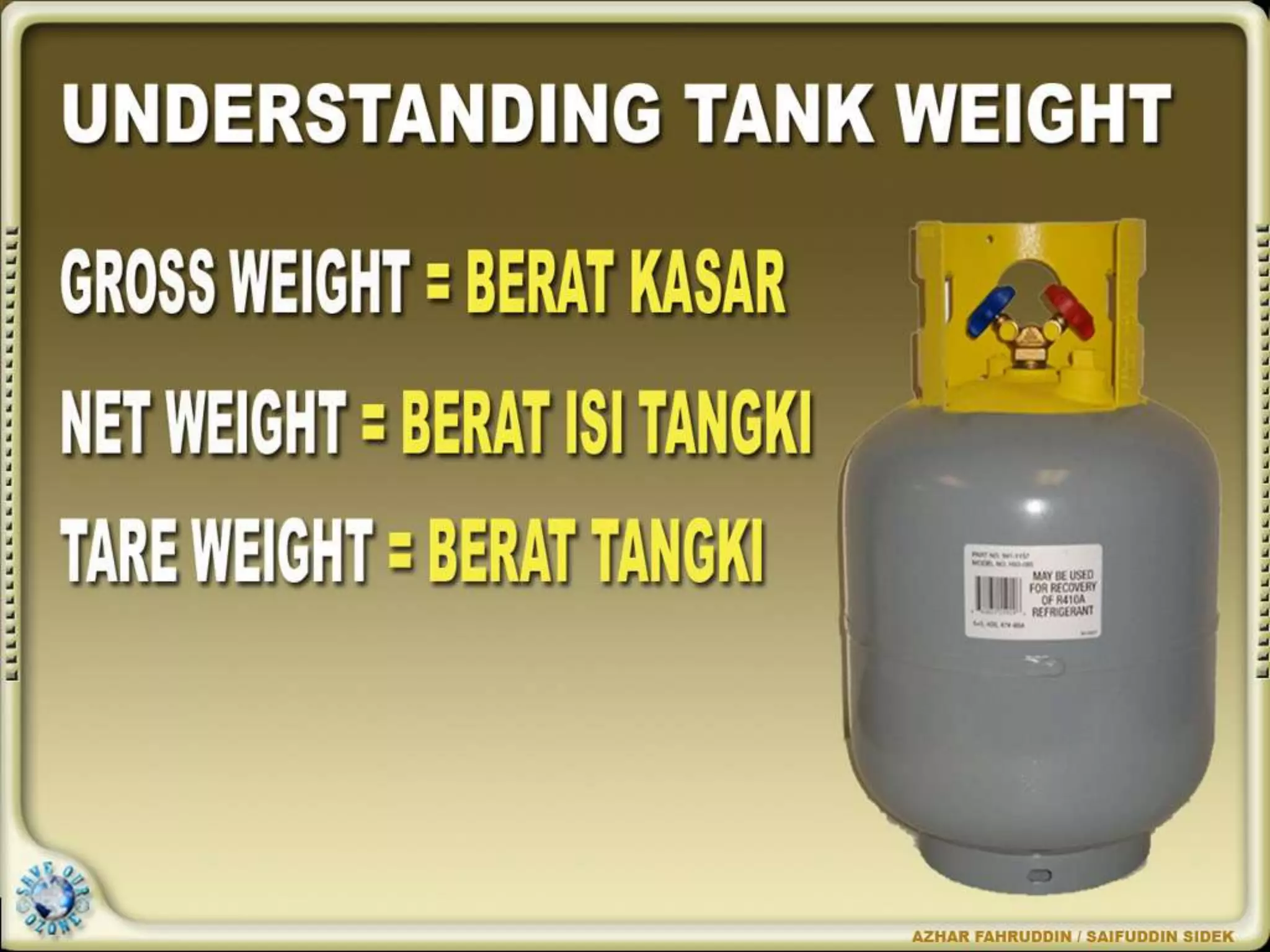

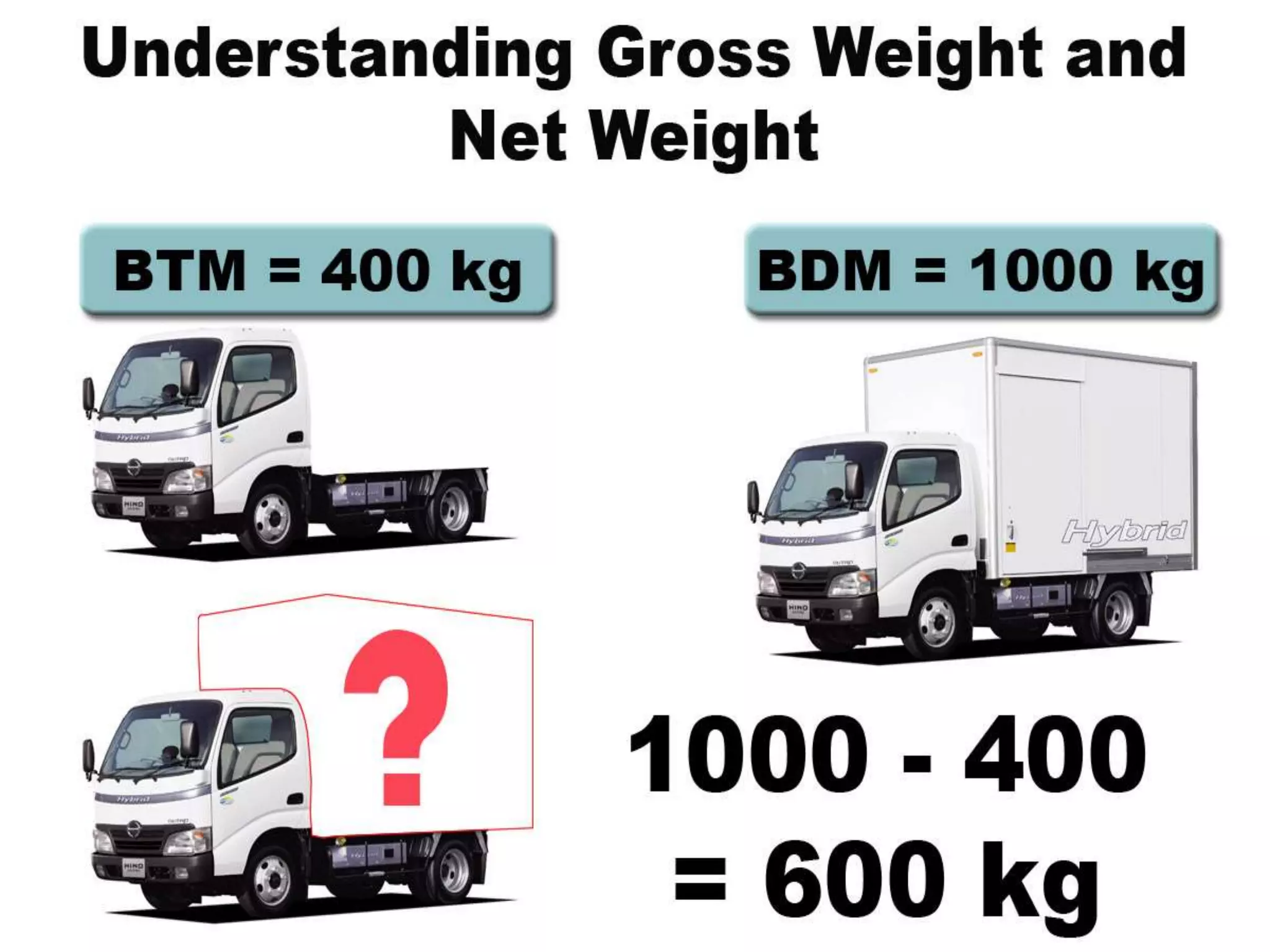

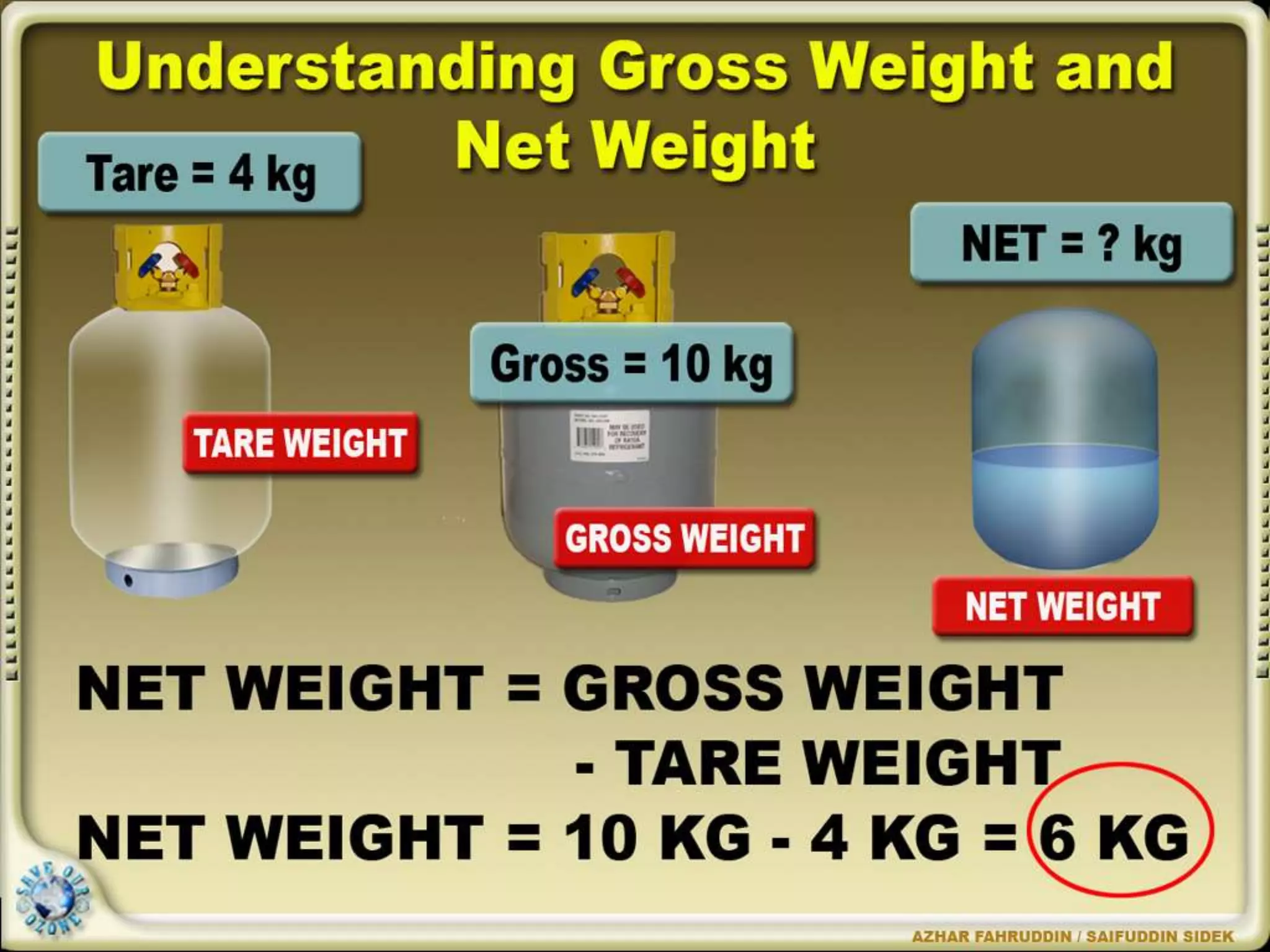

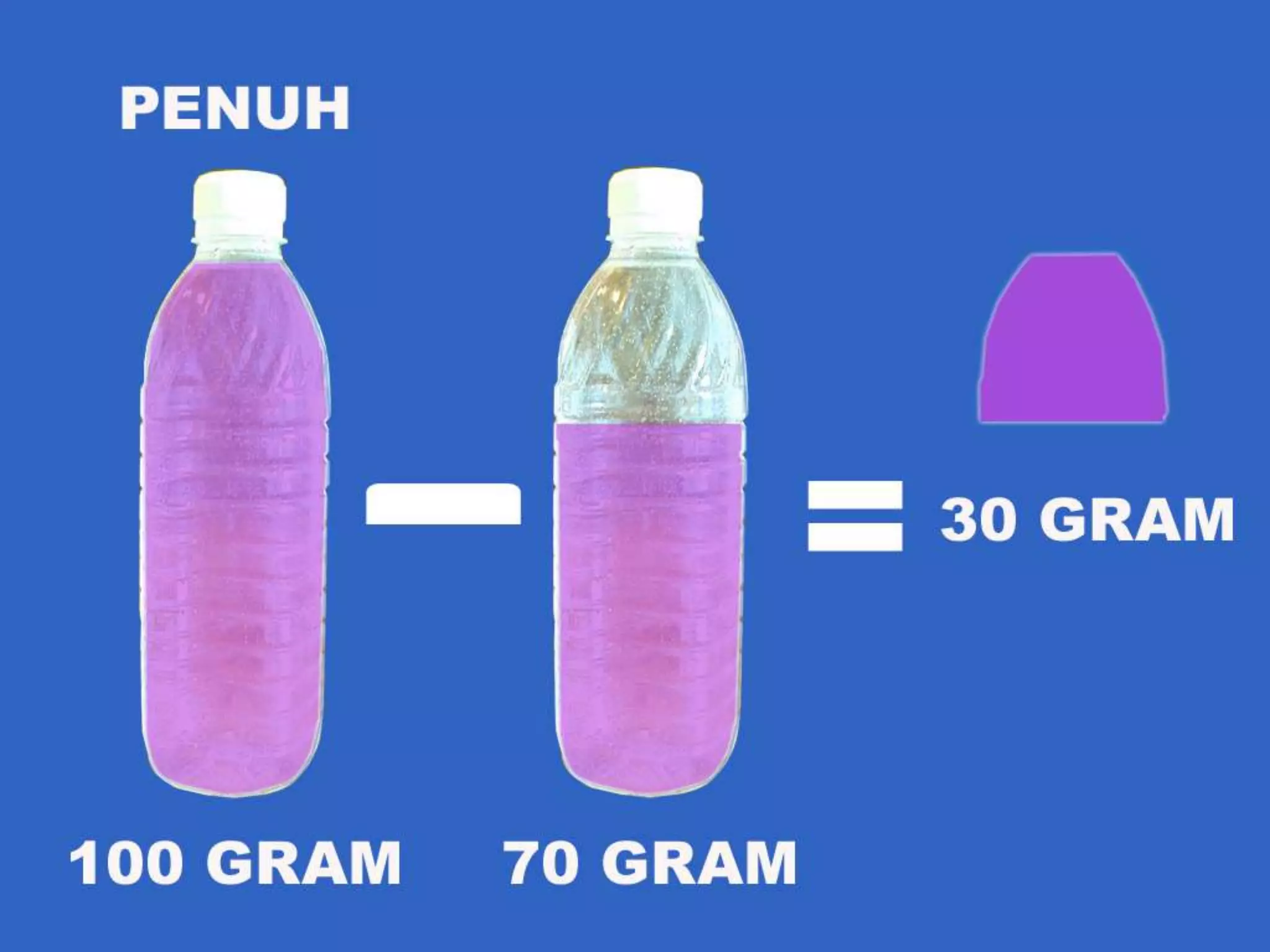

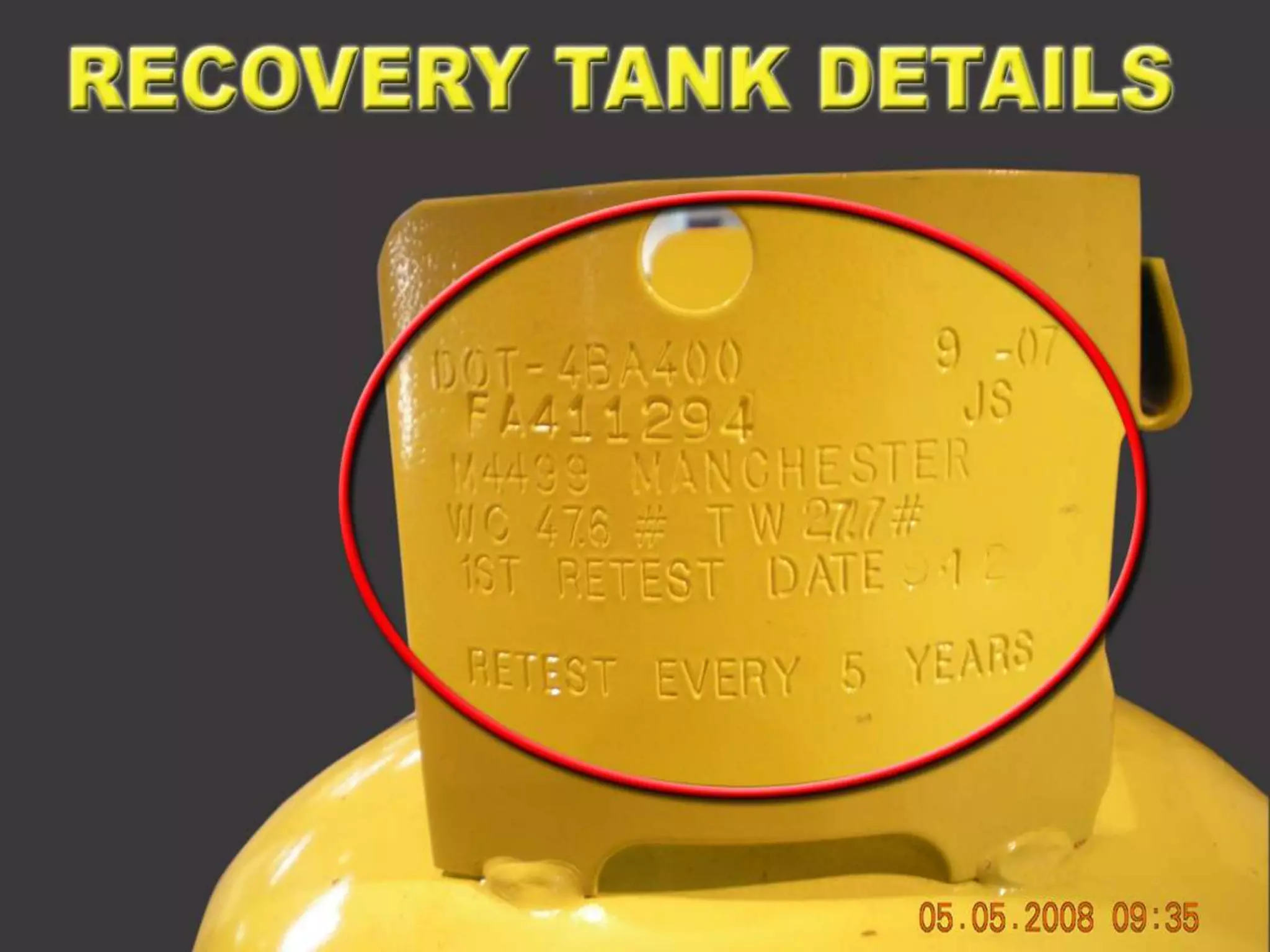

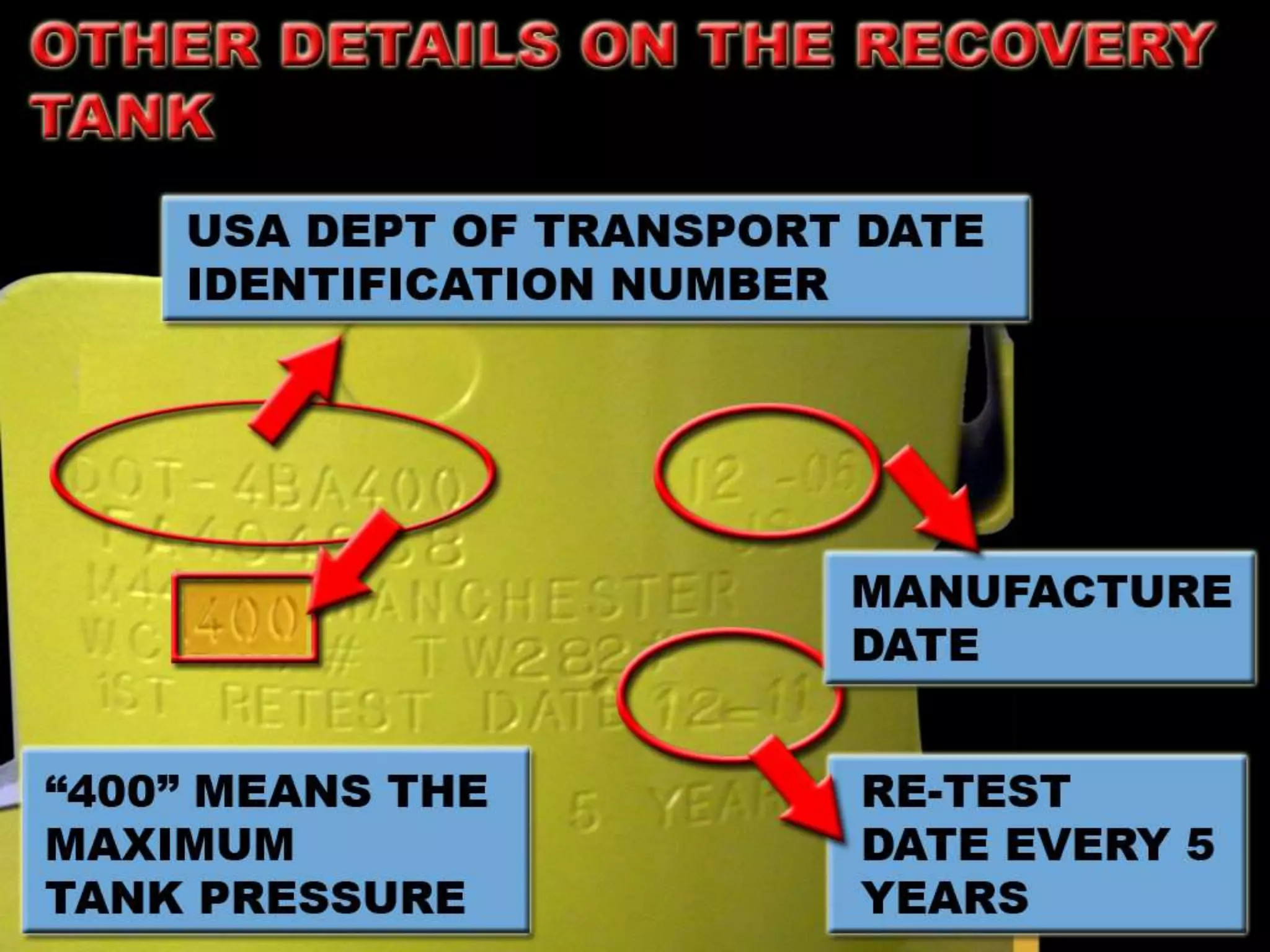

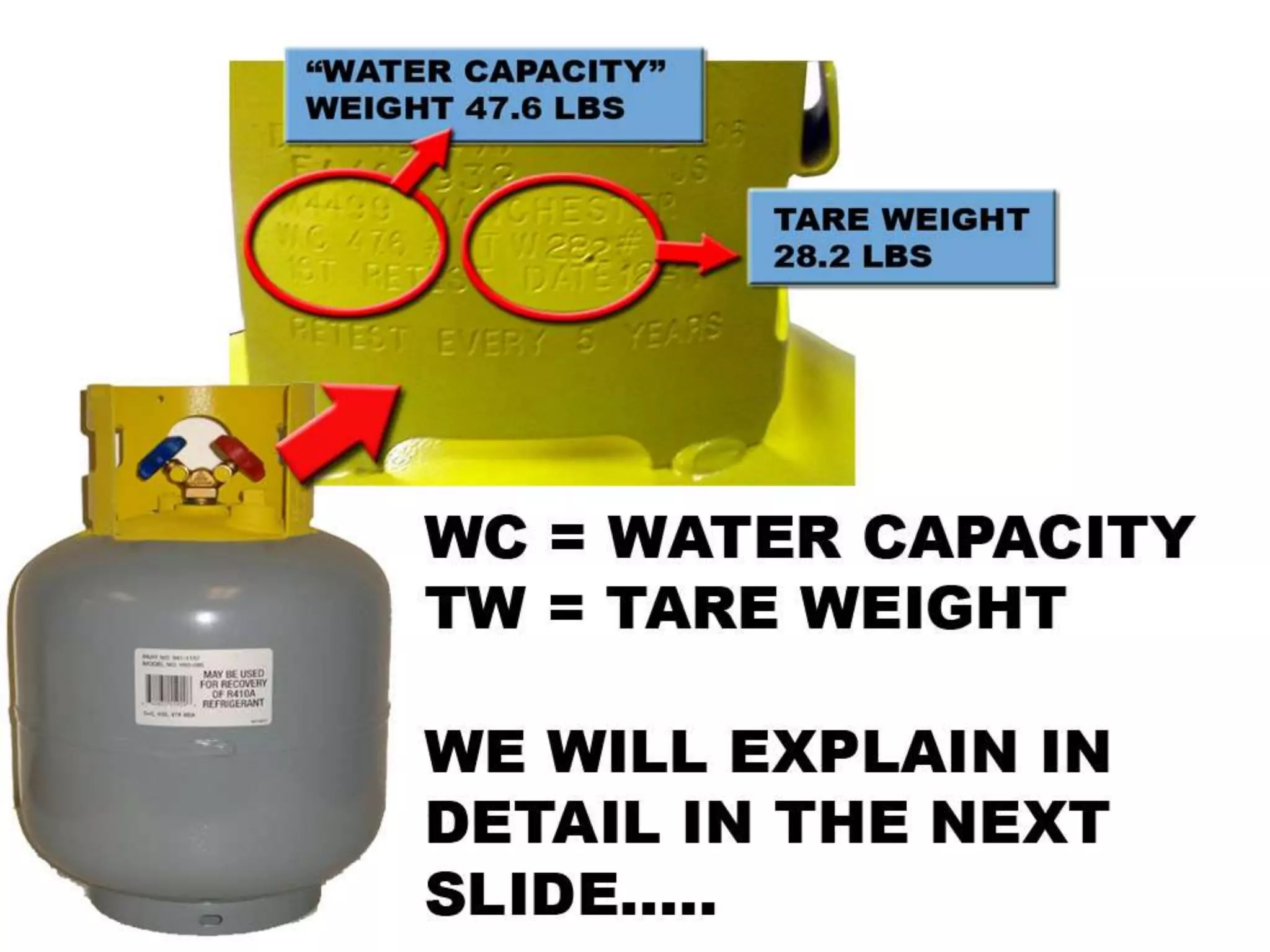

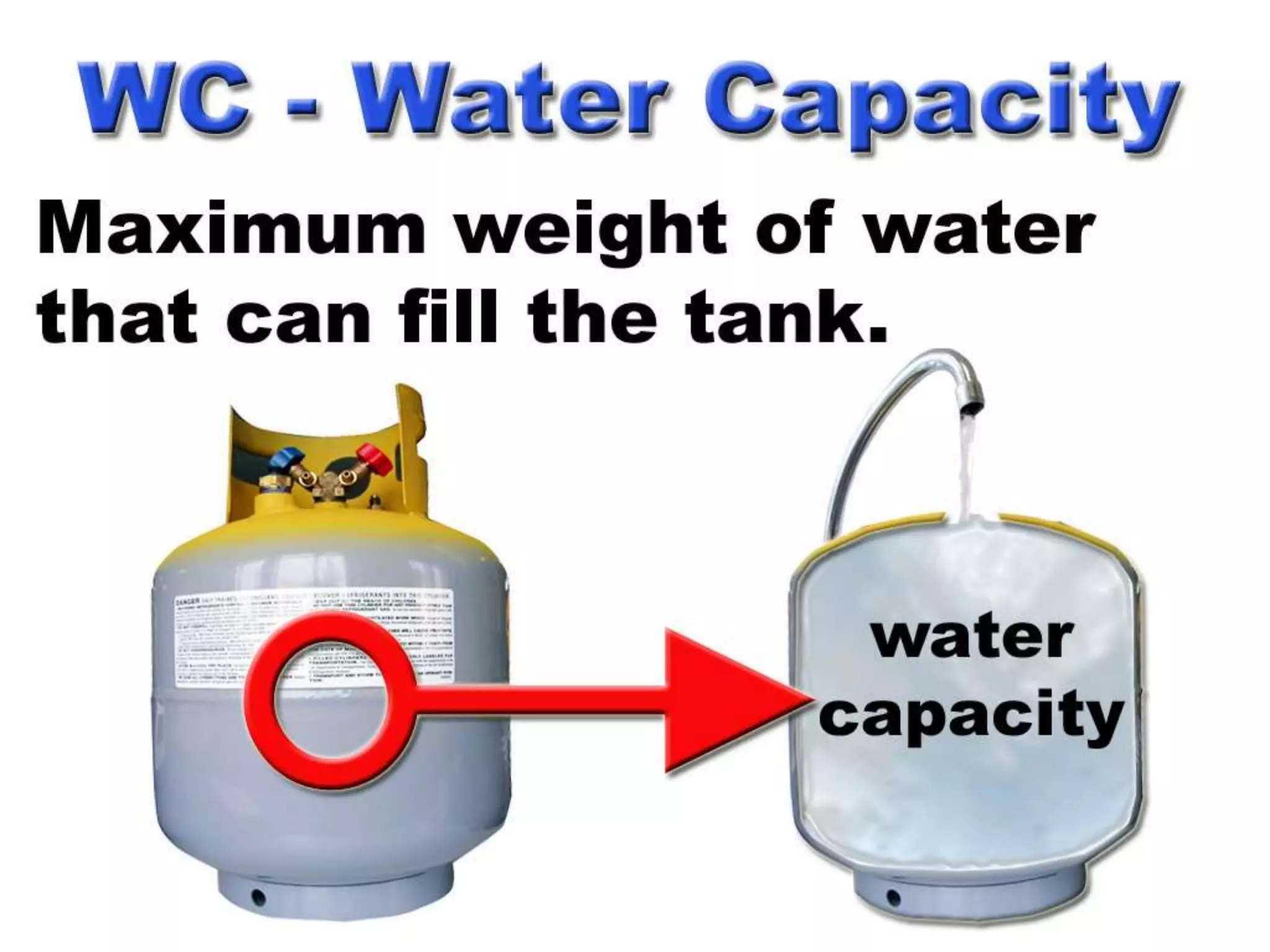

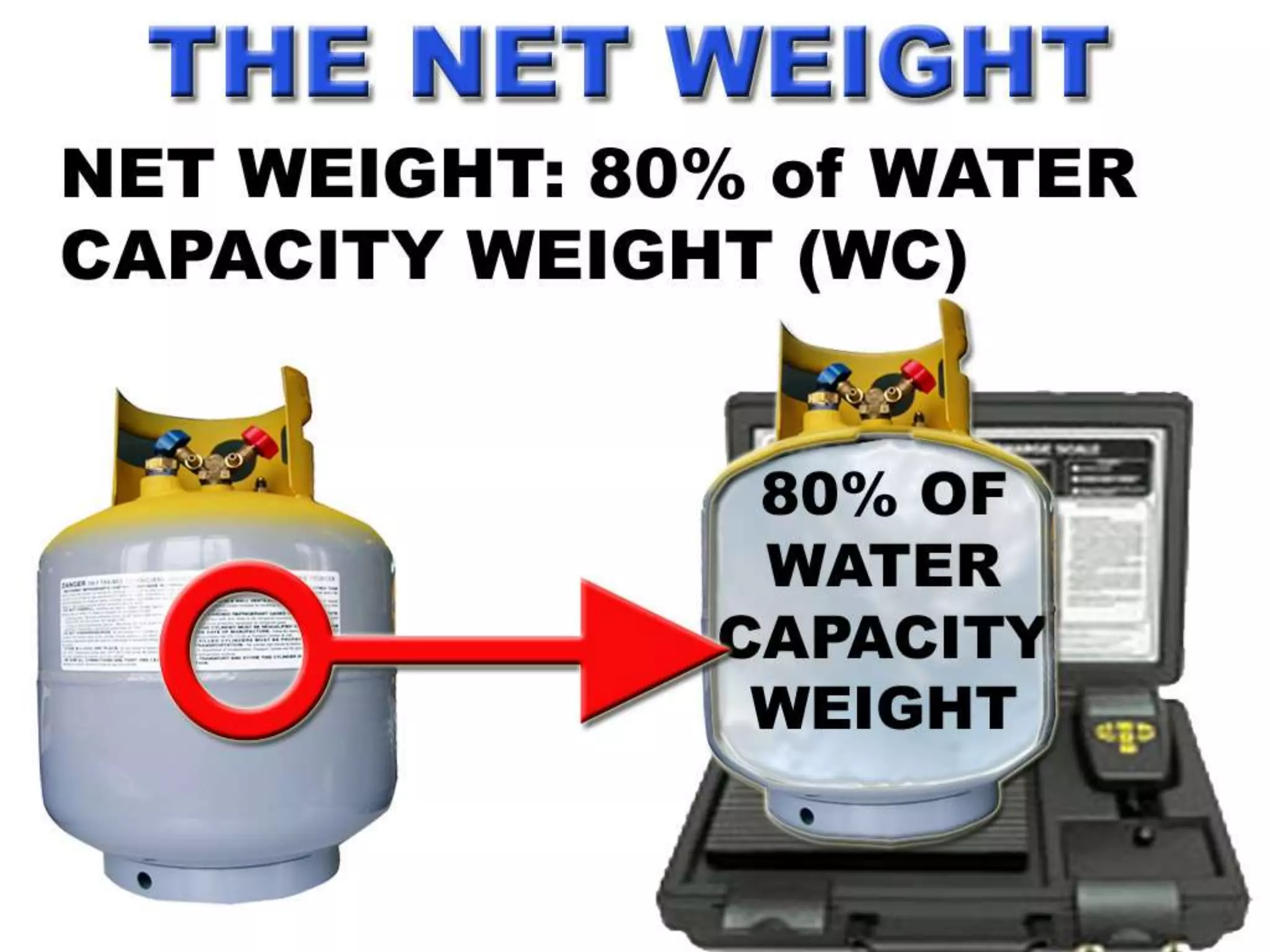

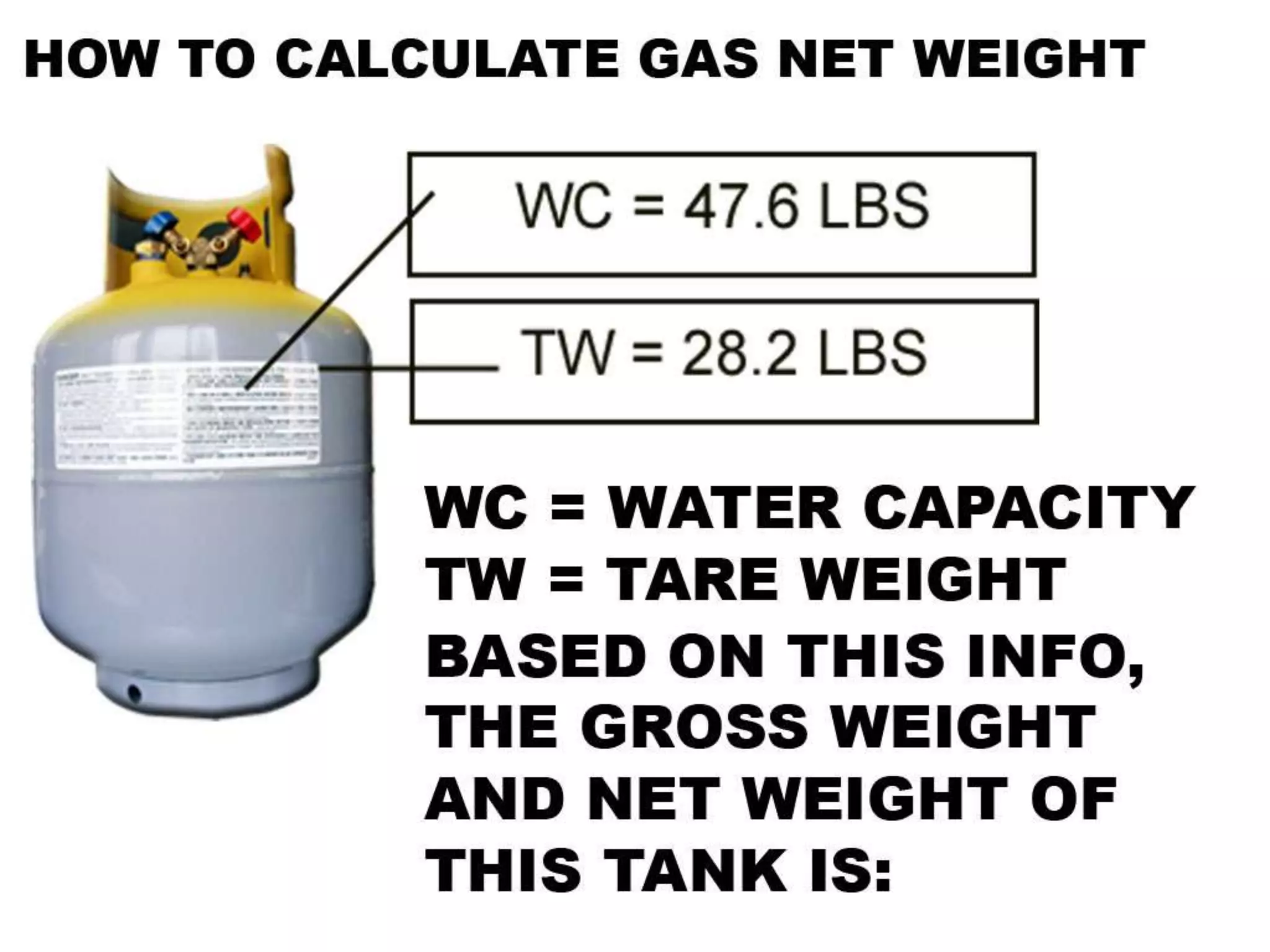

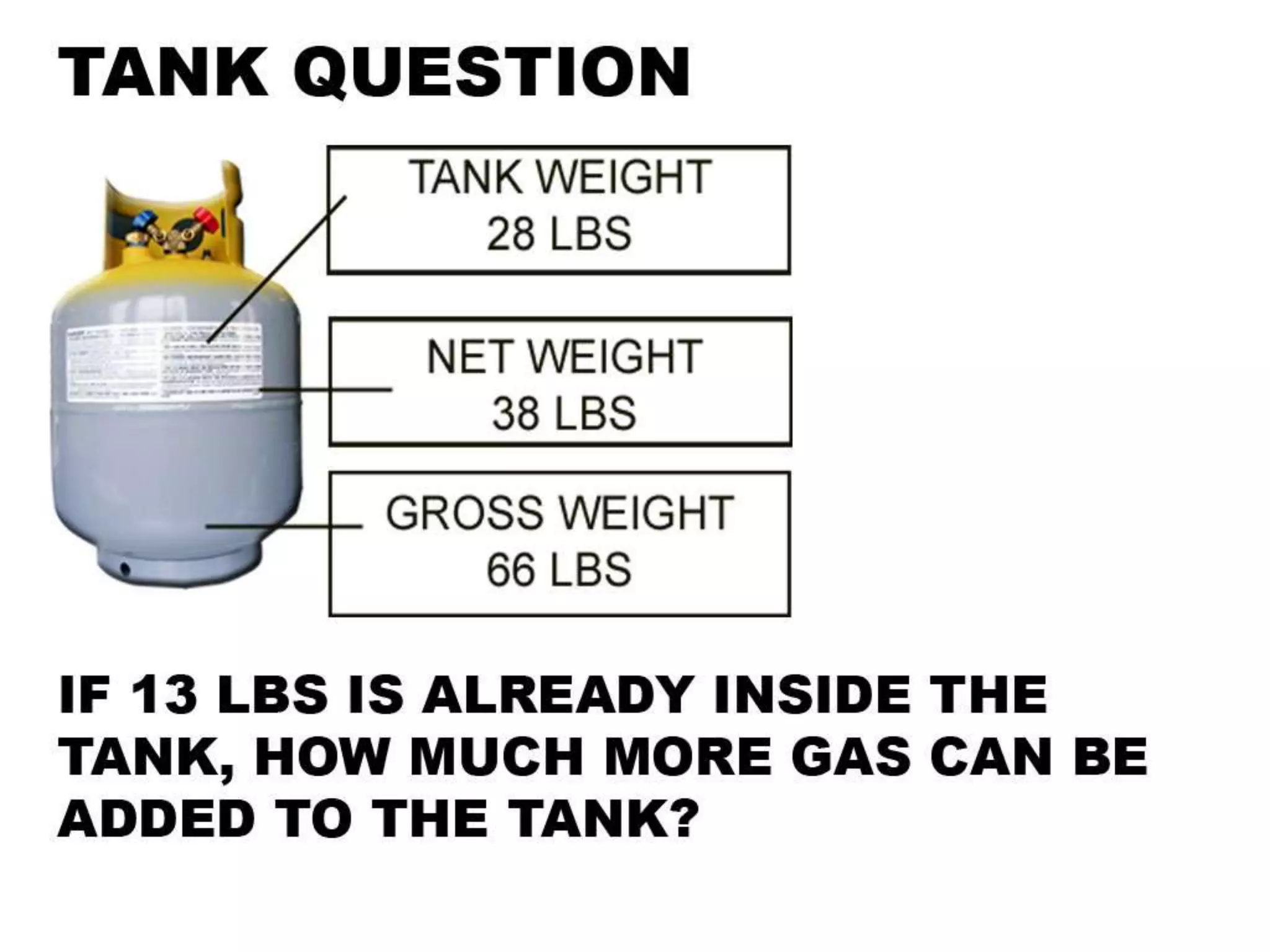

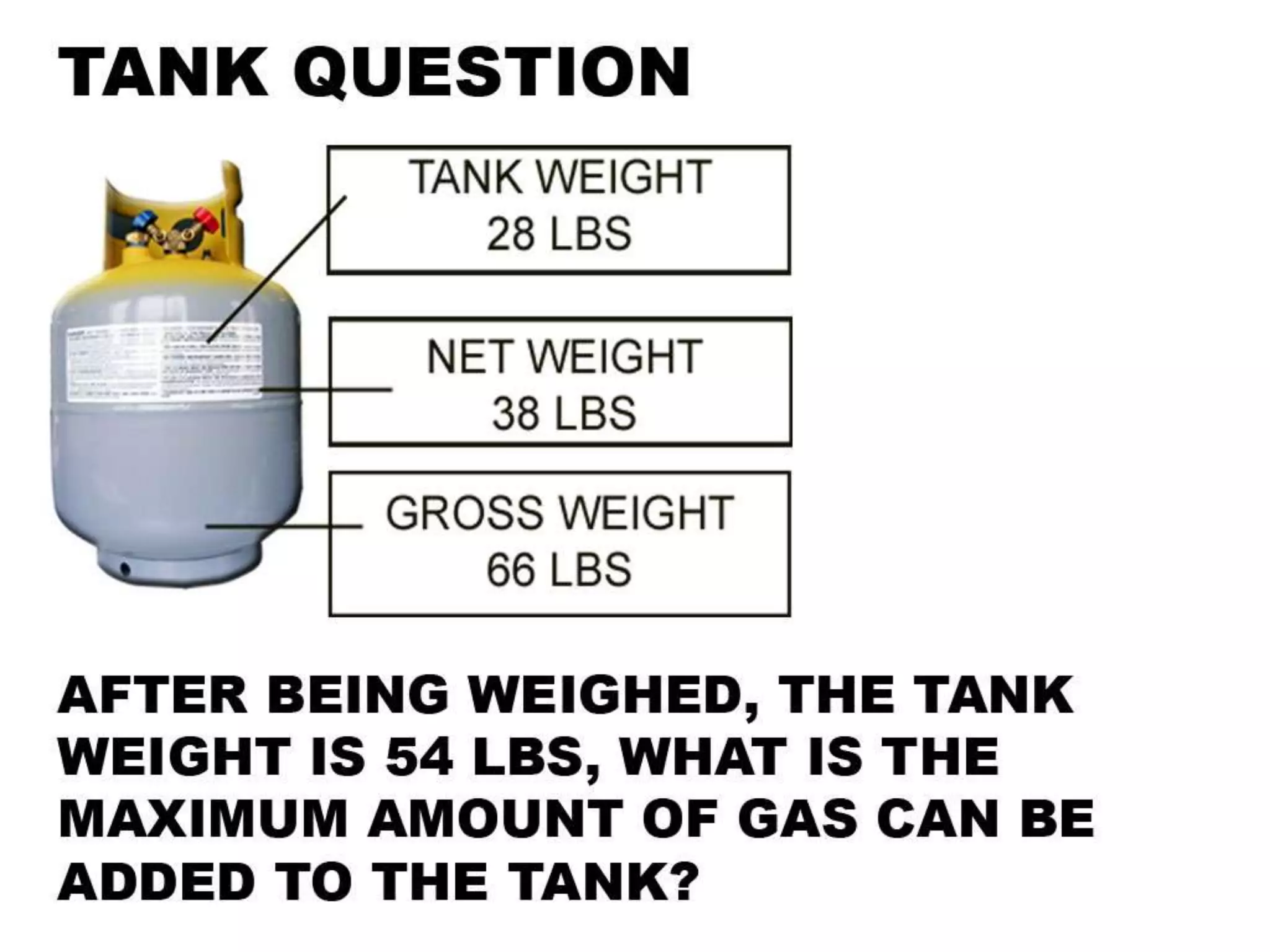

The document discusses the importance and functions of lubricants in refrigeration systems, emphasizing the need for chemical stability and resistance to contamination. It examines various types of refrigerant contamination and the effects on system efficiency, as well as safety and recovery procedures for refrigerants. Additionally, it covers oil contamination, its impact on performance, and key safety calculations for refrigerant storage tanks.