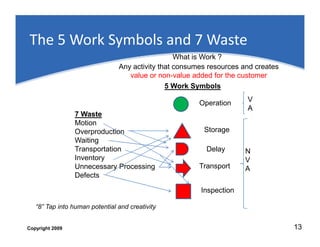

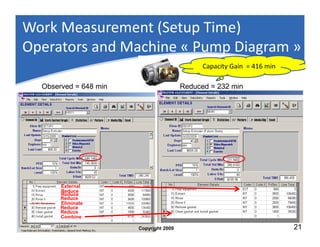

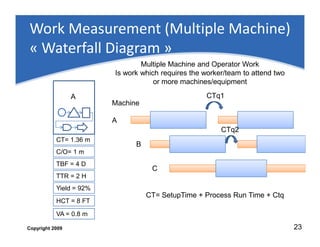

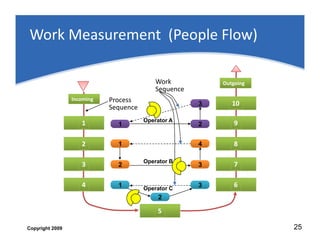

This document discusses work measurement and its applications in lean manufacturing. It provides an overview of the origins and contributors of work measurement. Some key techniques described include predetermined time systems, work method analysis, and video-based work measurement. The document also discusses how work measurement can be applied to understand material flow, labor utilization, setup times, and other processes. The overall aim of work measurement is to analyze work, simplify processes, set performance standards, and improve workflow efficiency in lean applications.