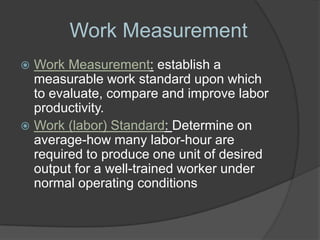

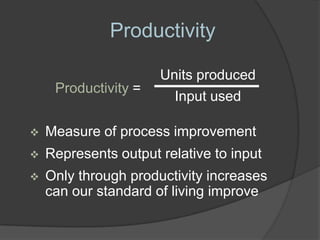

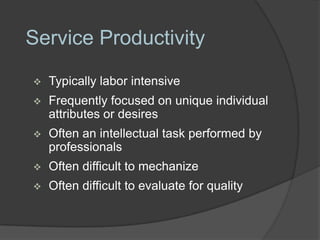

Work measurement and productivity are important concepts for evaluating labor performance and improving efficiency. Key aspects include:

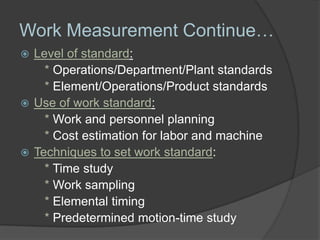

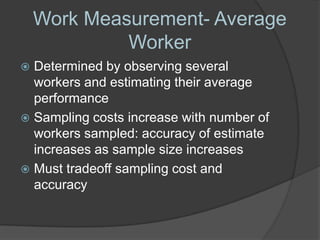

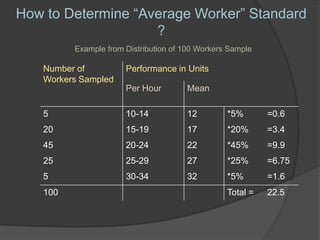

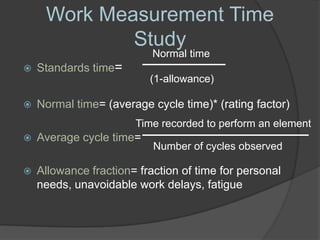

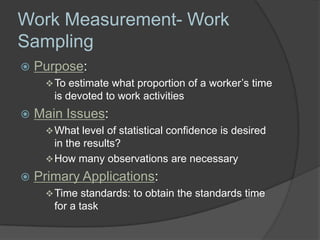

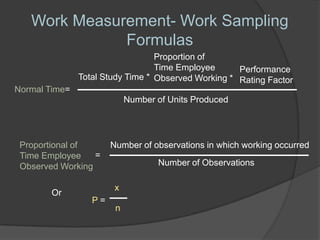

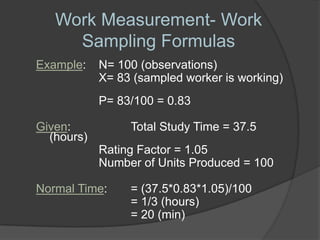

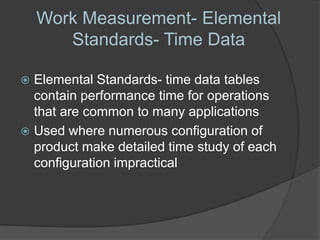

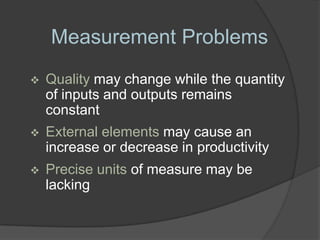

1) Establishing work standards through techniques like time studies and work sampling to measure average worker performance.

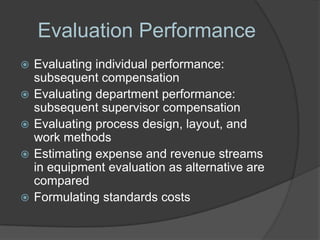

2) Comparing individual, department, and plant performance to standards to evaluate efficiency and compensation.

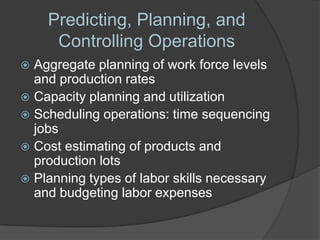

3) Using work standards to estimate costs, schedule operations, and plan workforce needs.

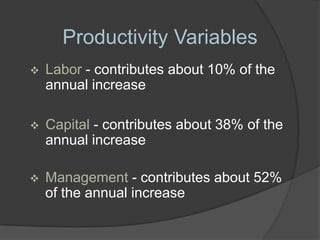

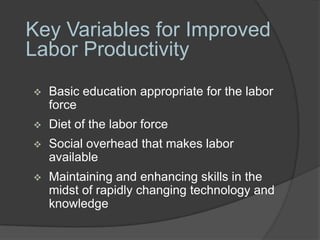

4) Improving productivity over time through factors like capital investment, management practices, worker skills and education.