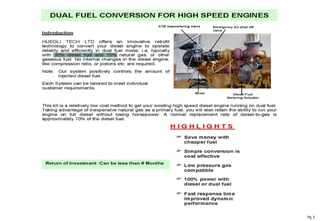

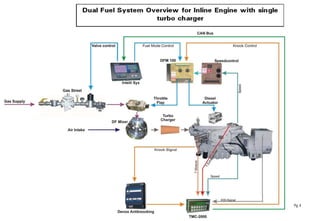

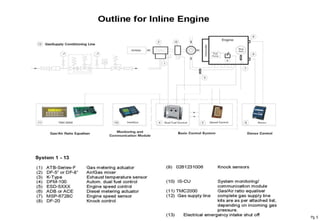

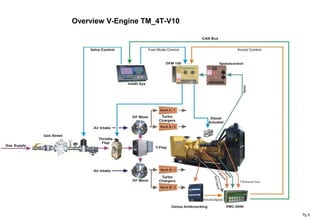

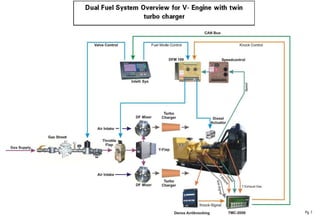

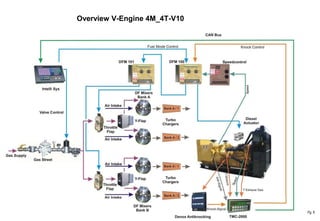

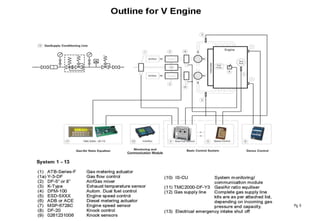

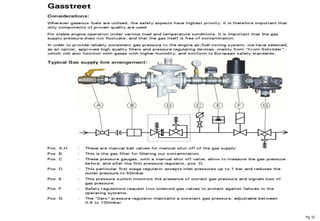

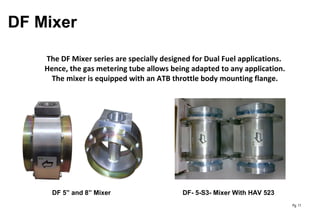

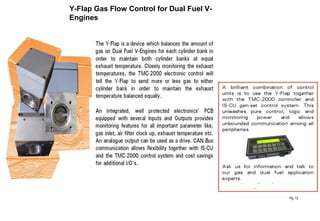

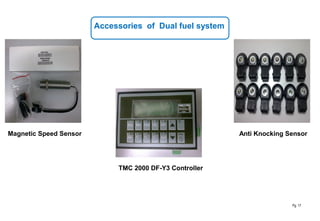

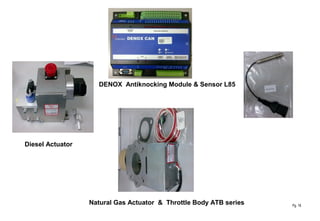

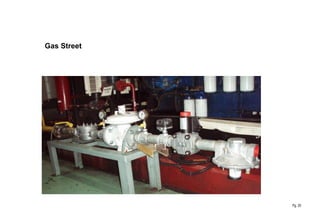

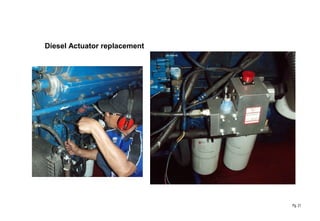

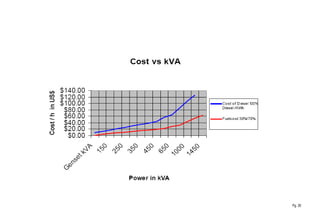

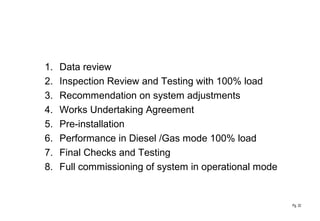

This document discusses various technologies for converting internal combustion engines to operate using alternative fuels. It focuses on dual fuel conversion systems that allow engines to run on both diesel and natural gas. The document provides overviews and specifications for dual fuel mixer components, control modules, sensors and other accessories required for a dual fuel conversion. It also presents case studies on dual fuel conversions conducted in Indonesia and discusses the cost savings and return on investment that can be achieved by converting to lower-cost alternative fuels like natural gas.