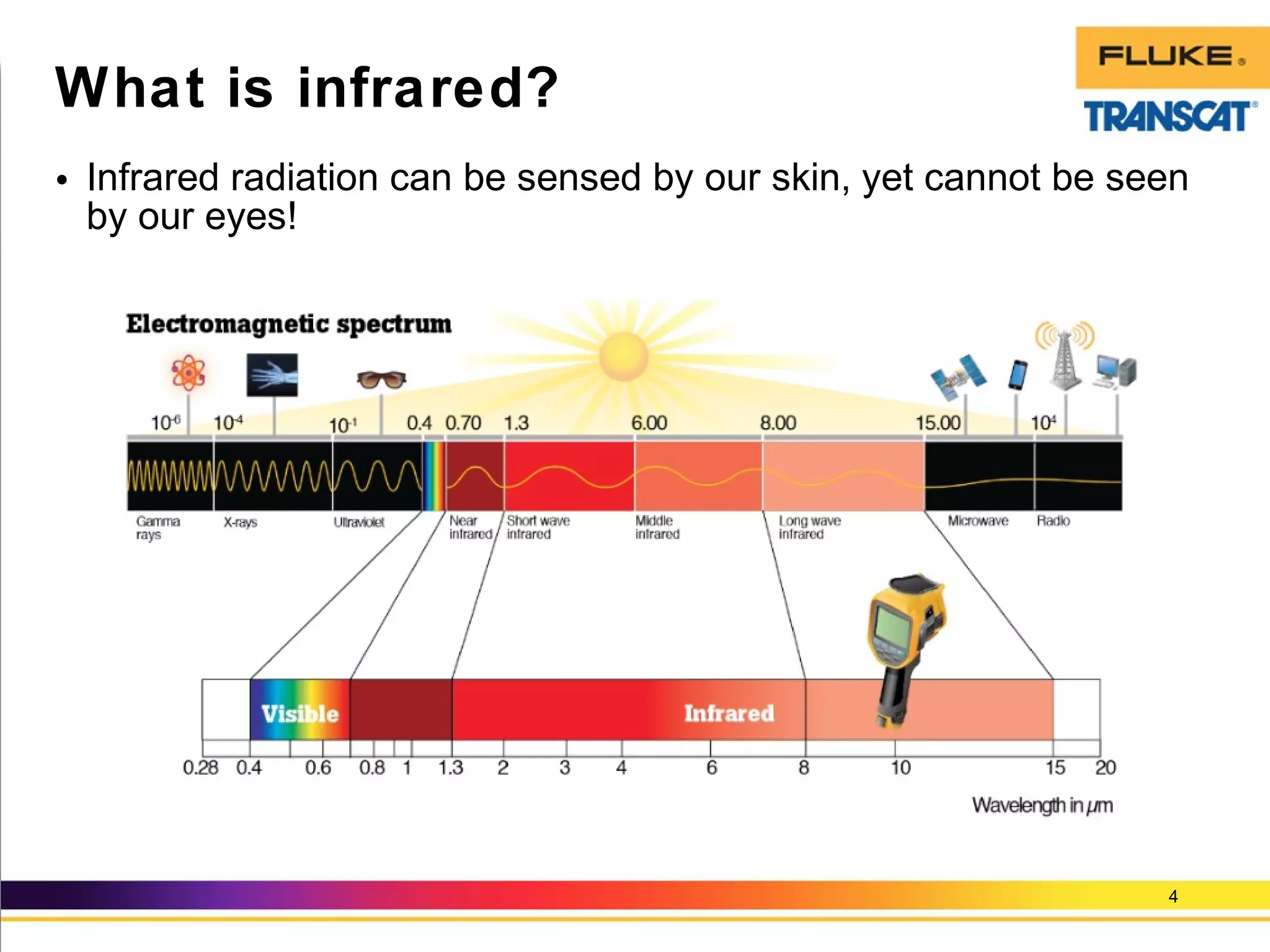

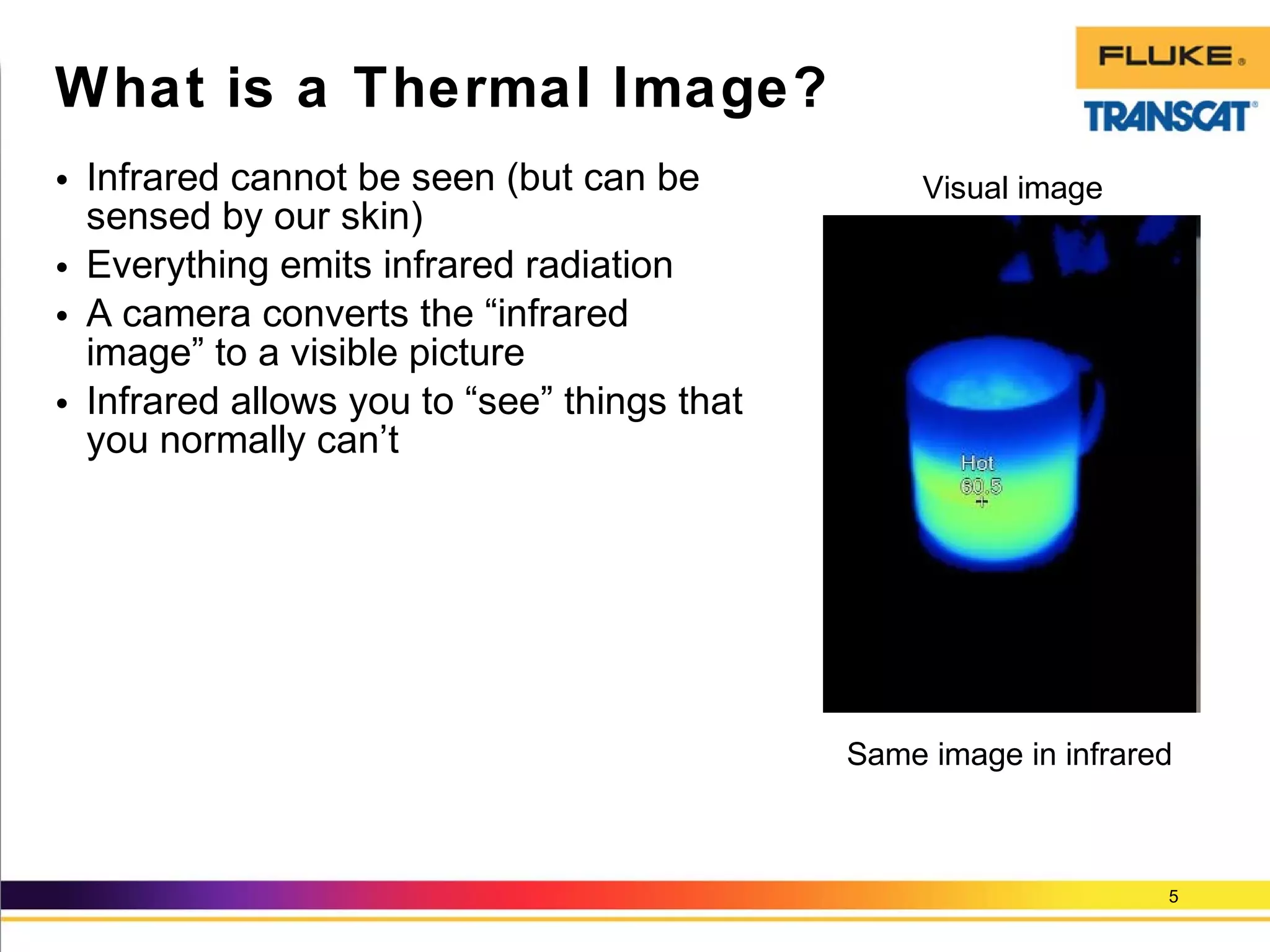

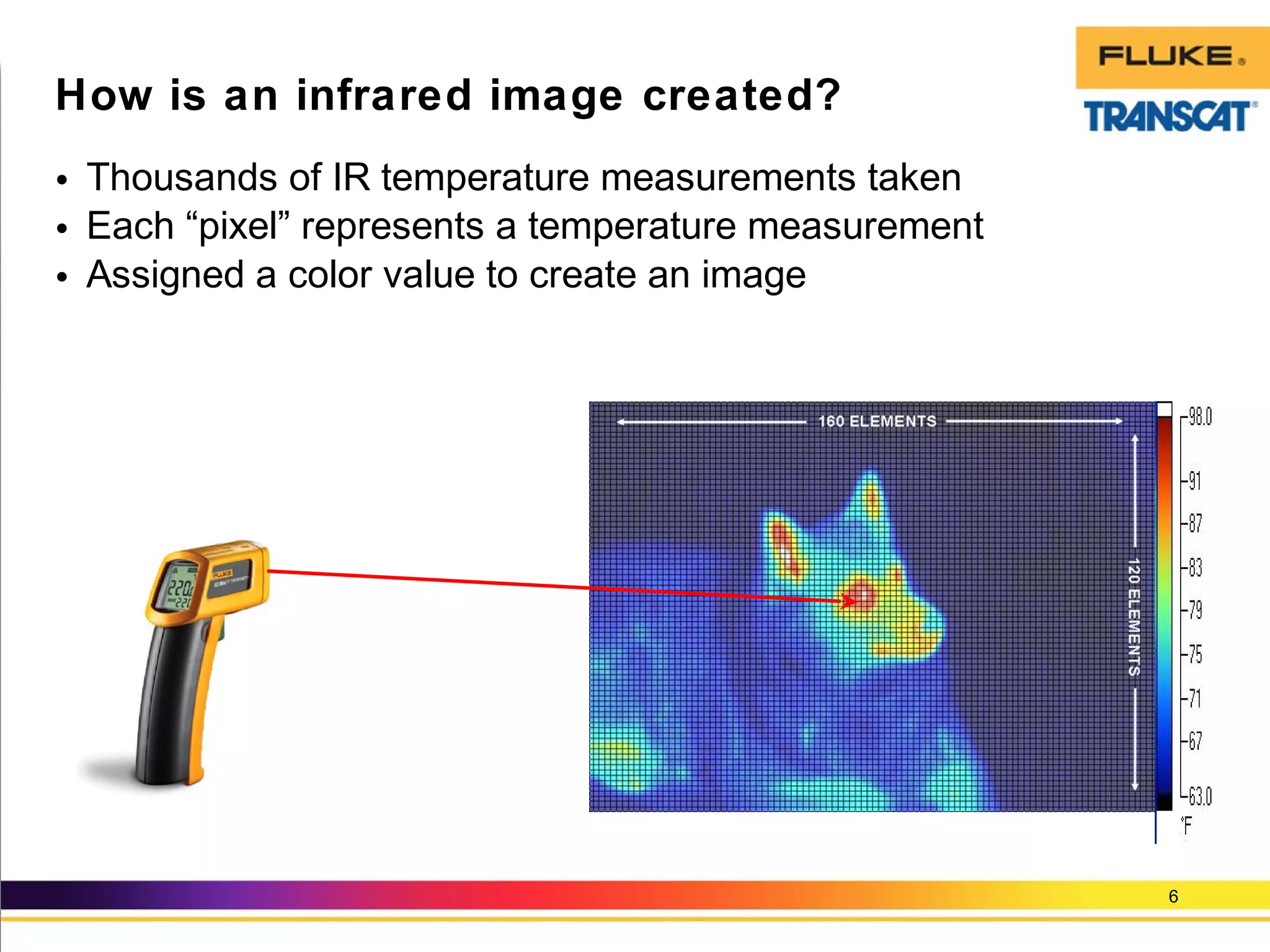

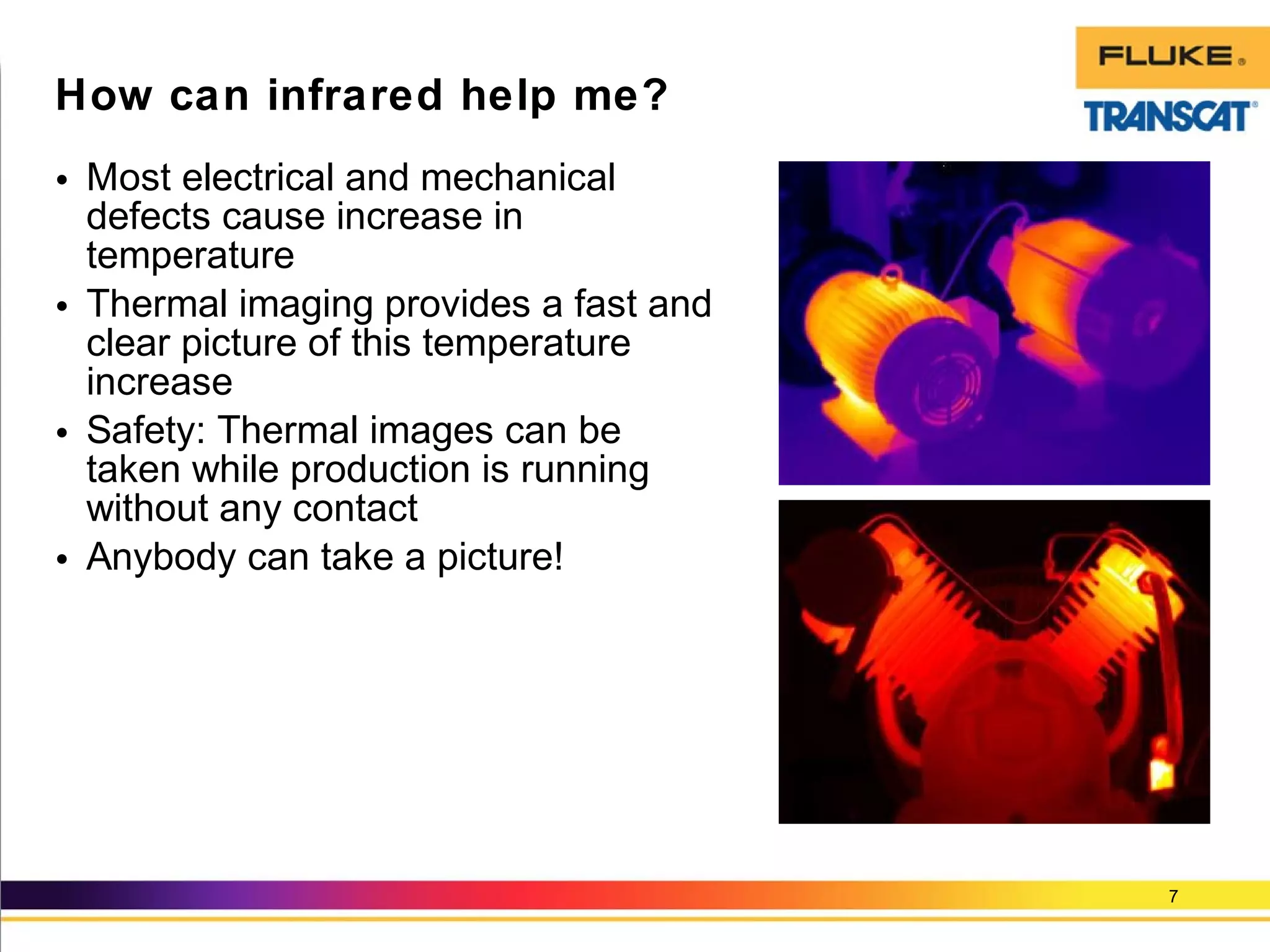

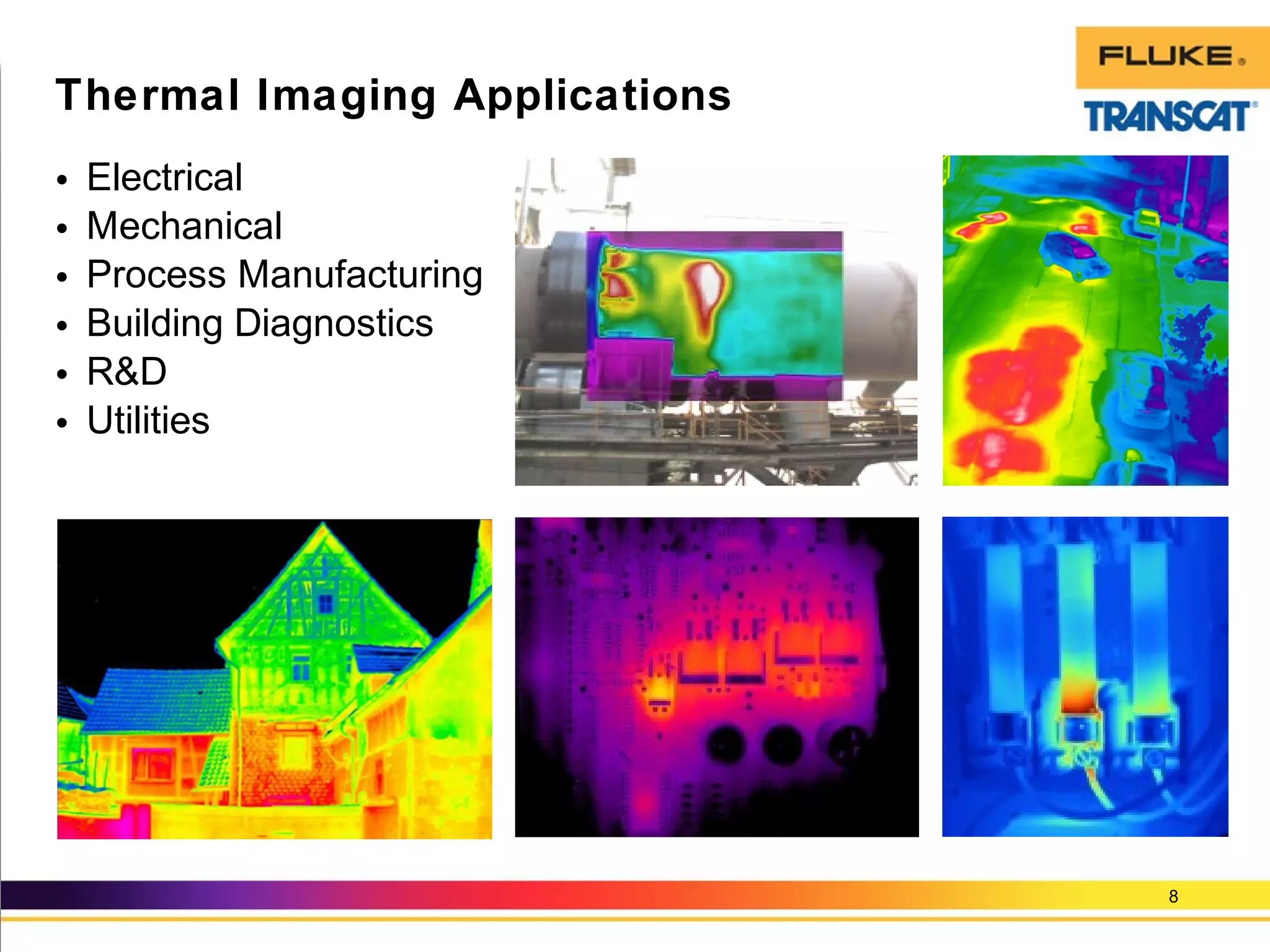

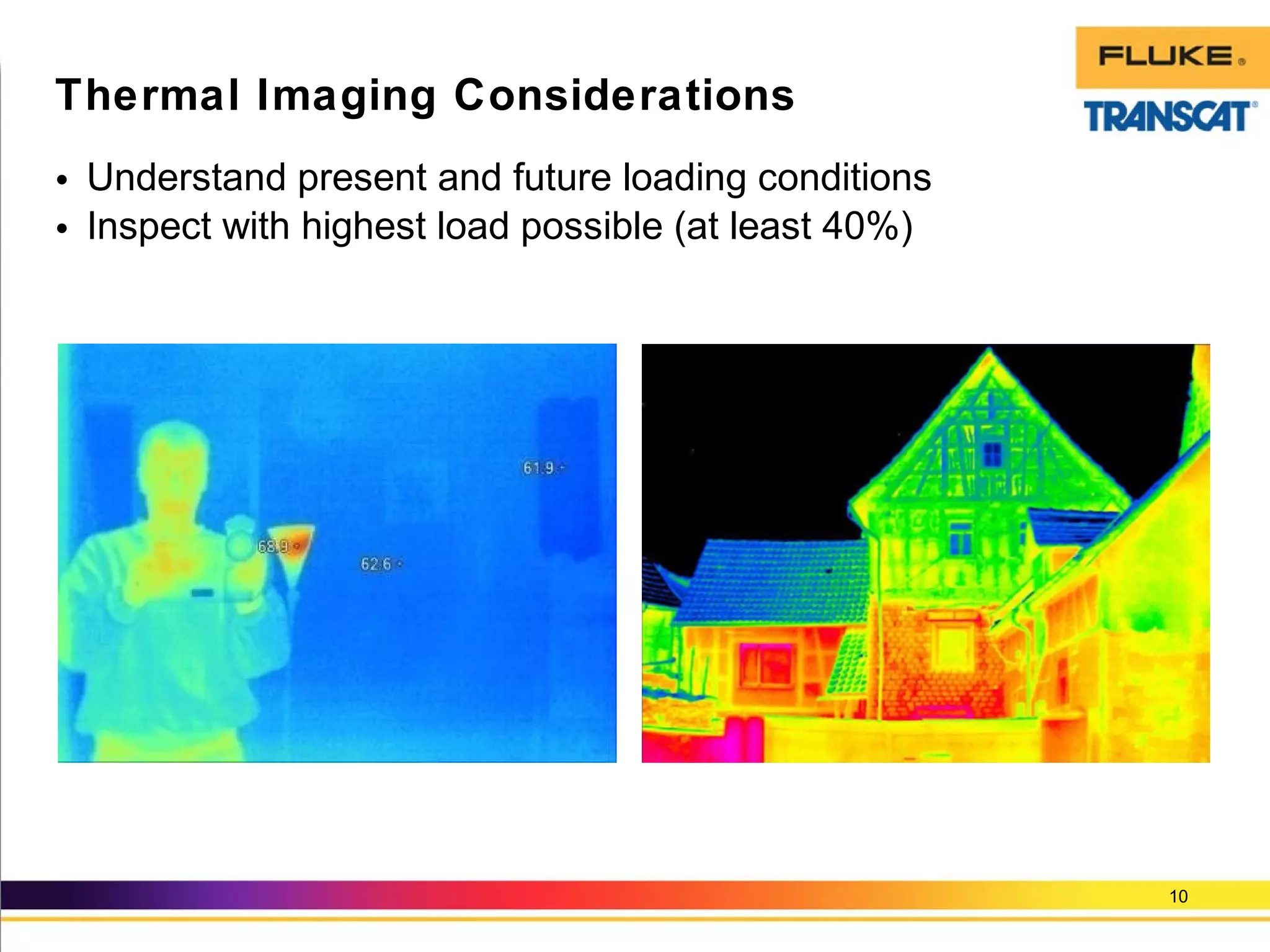

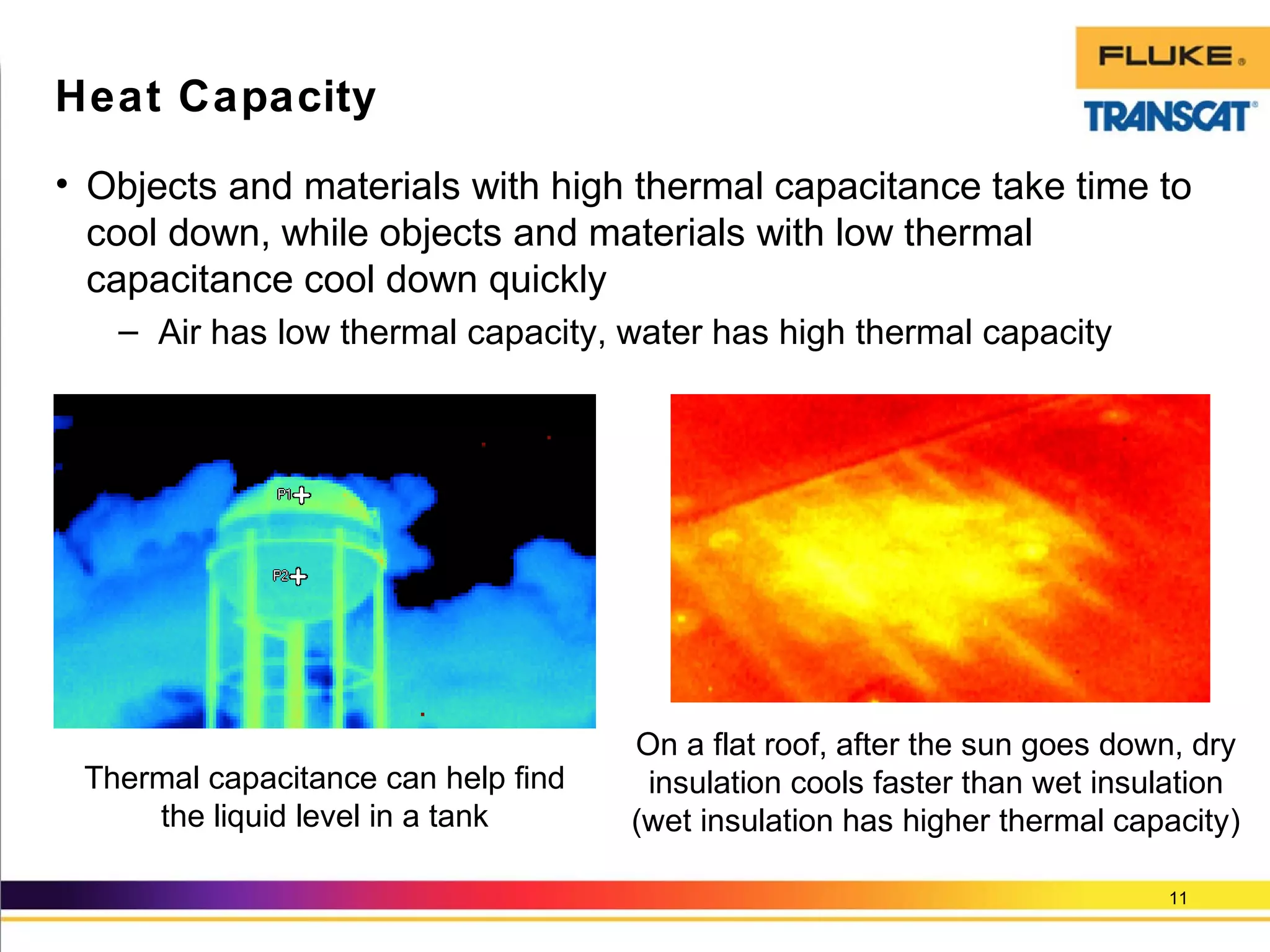

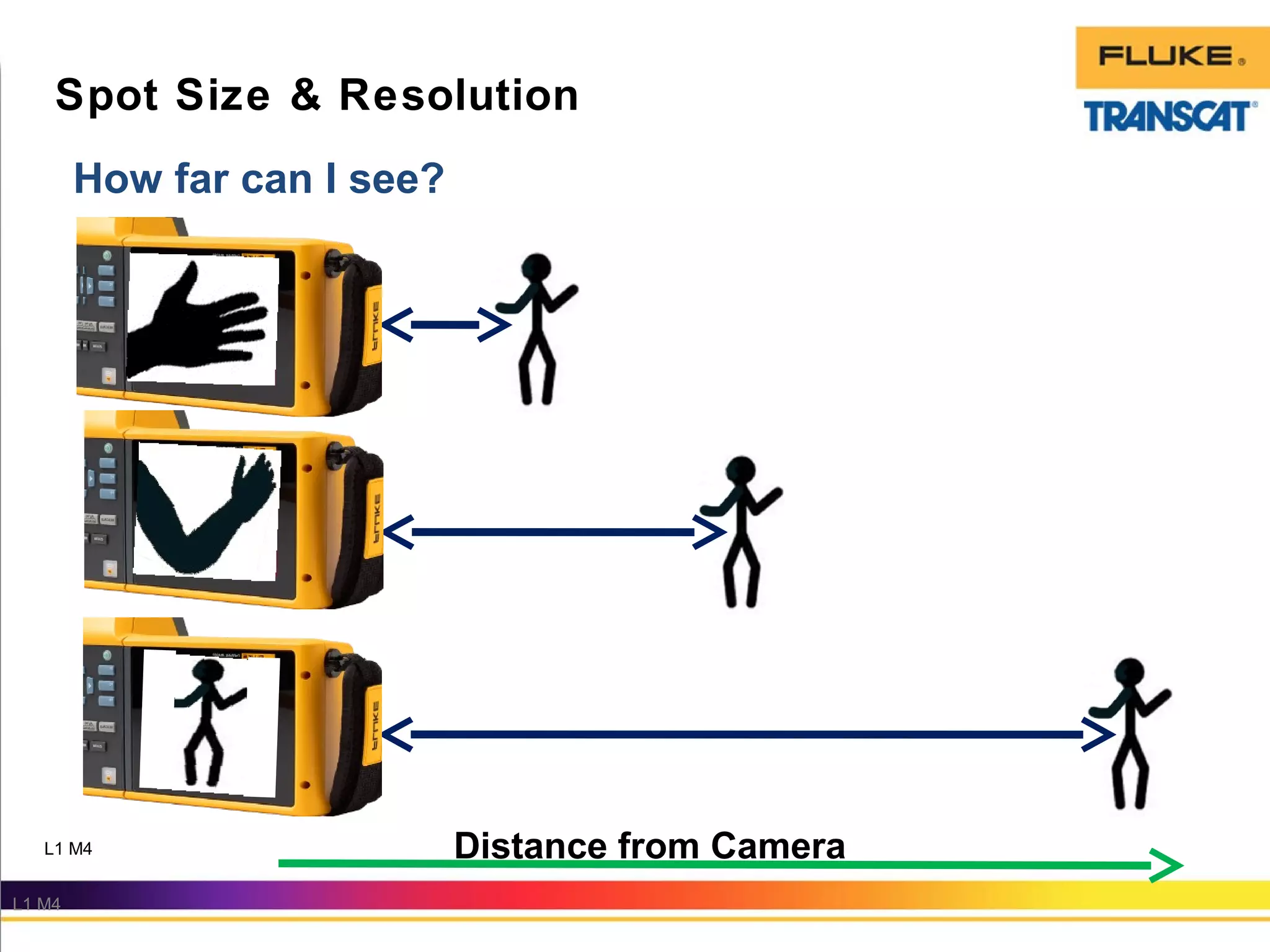

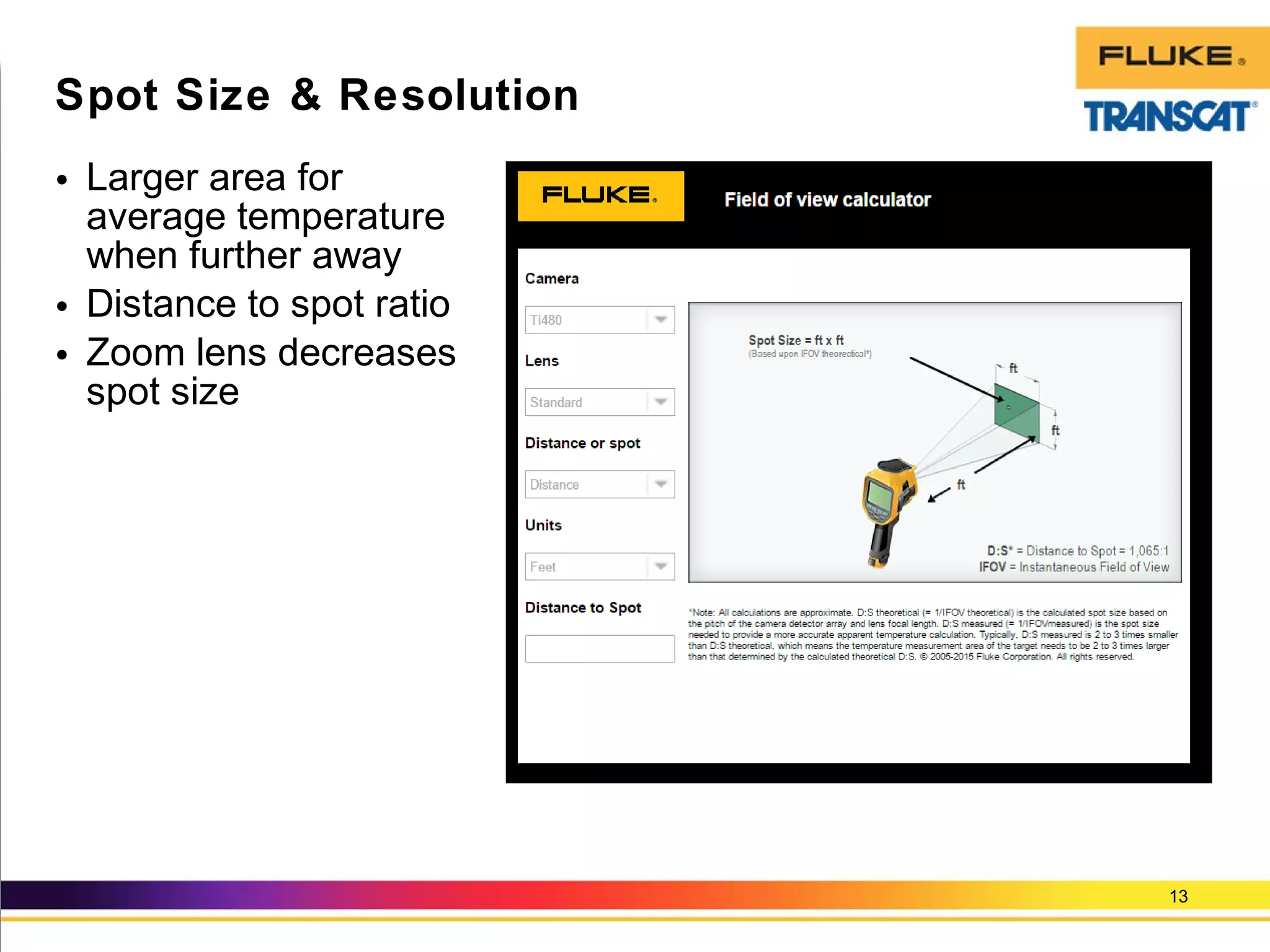

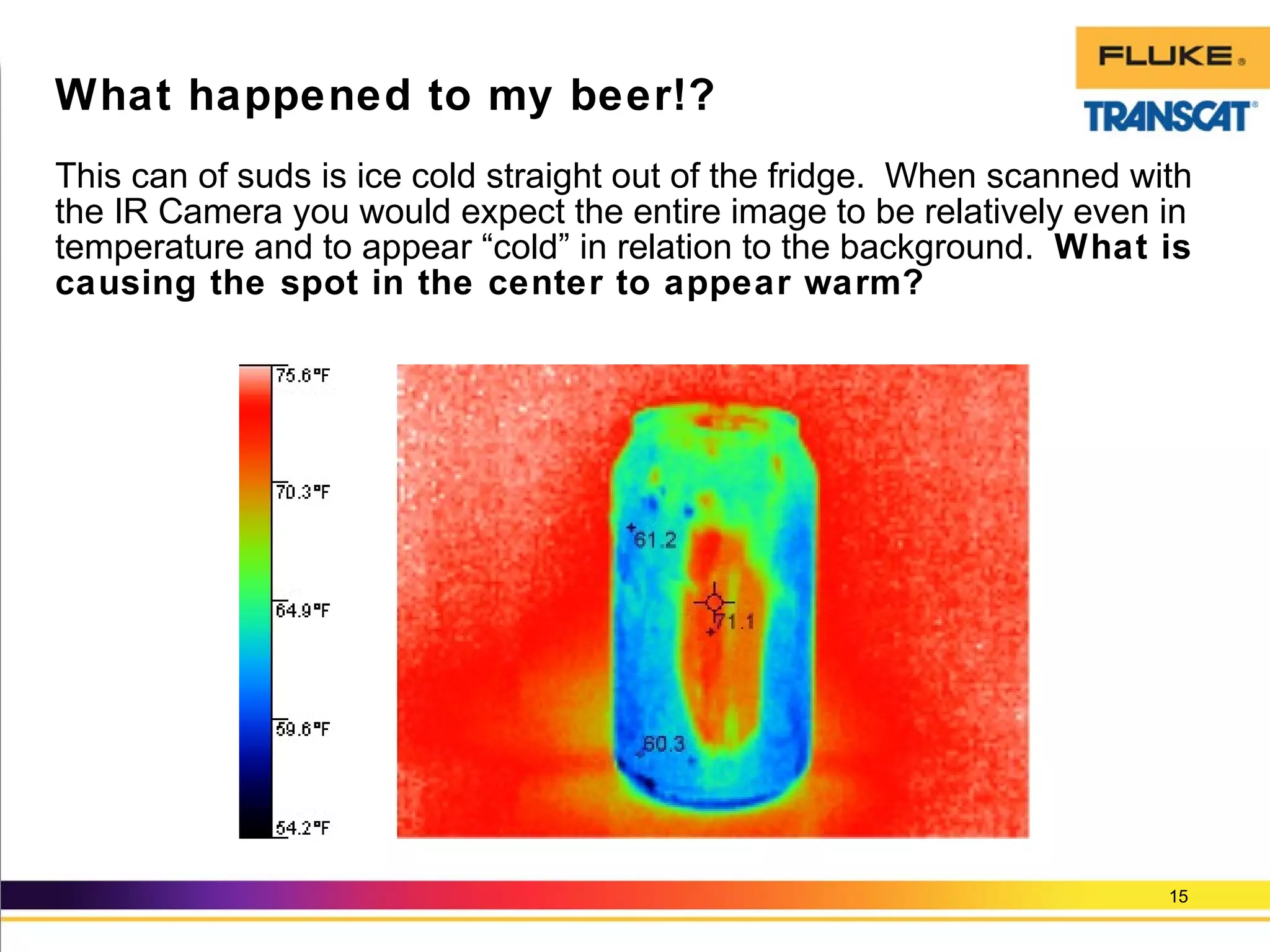

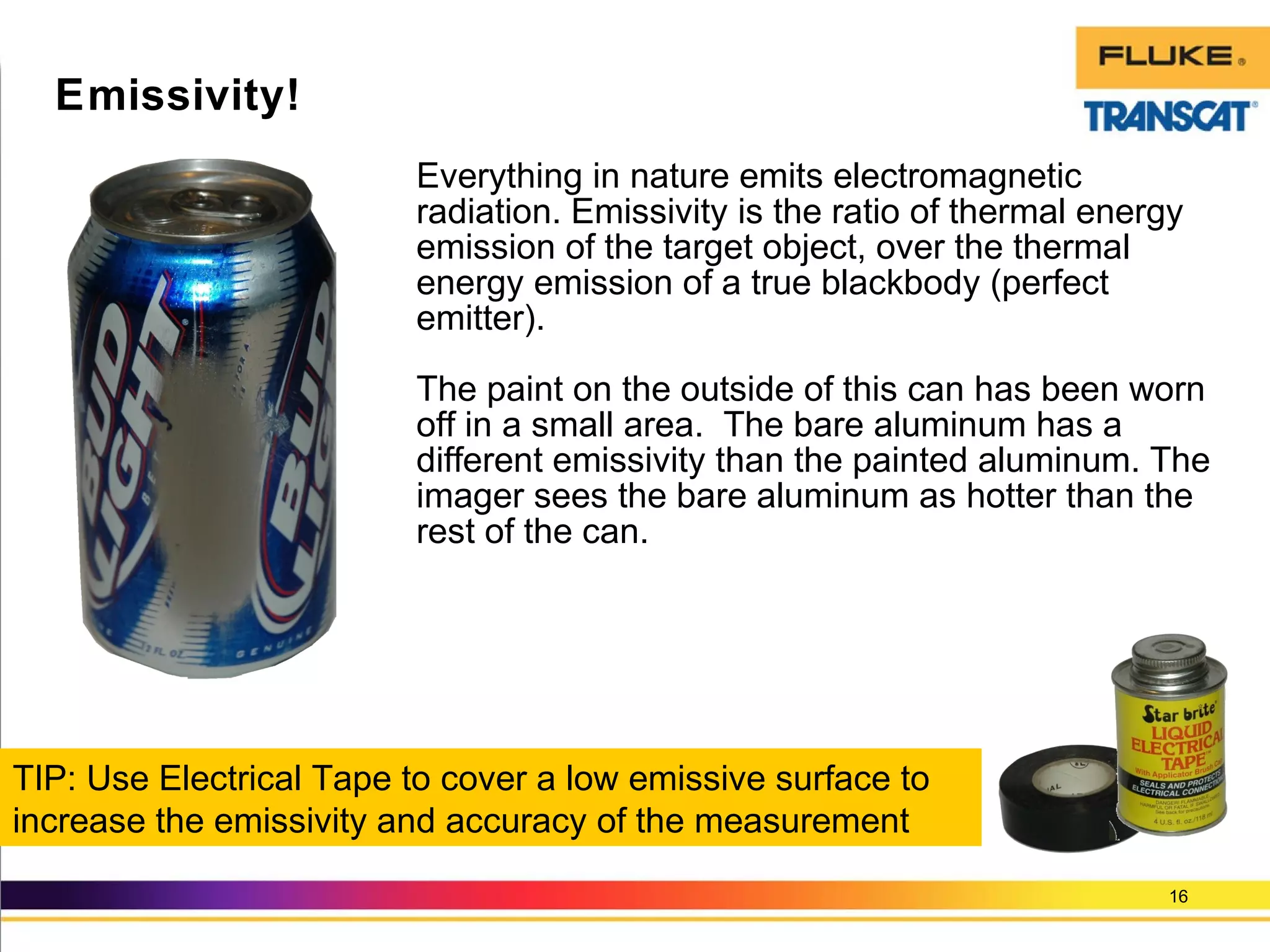

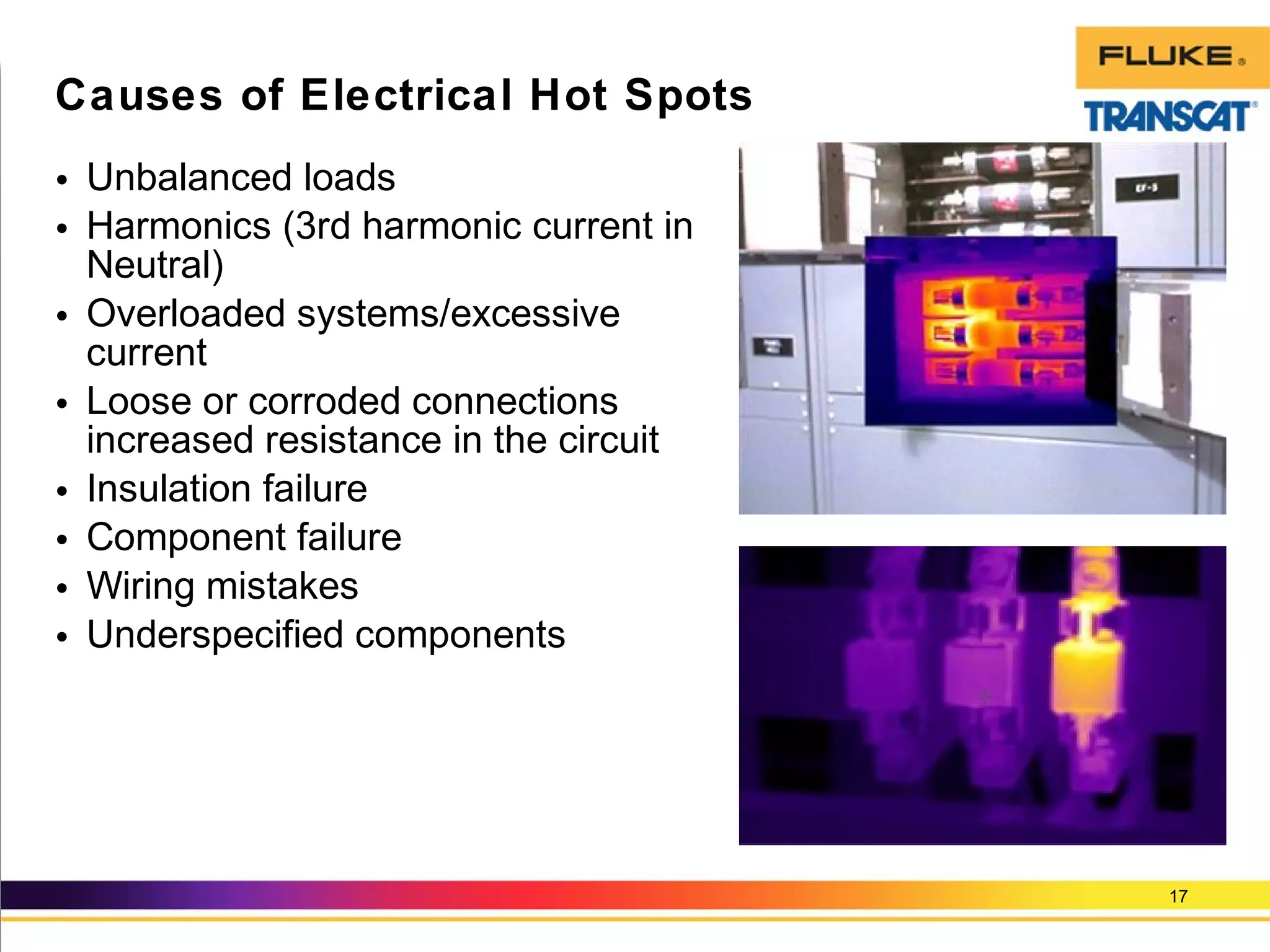

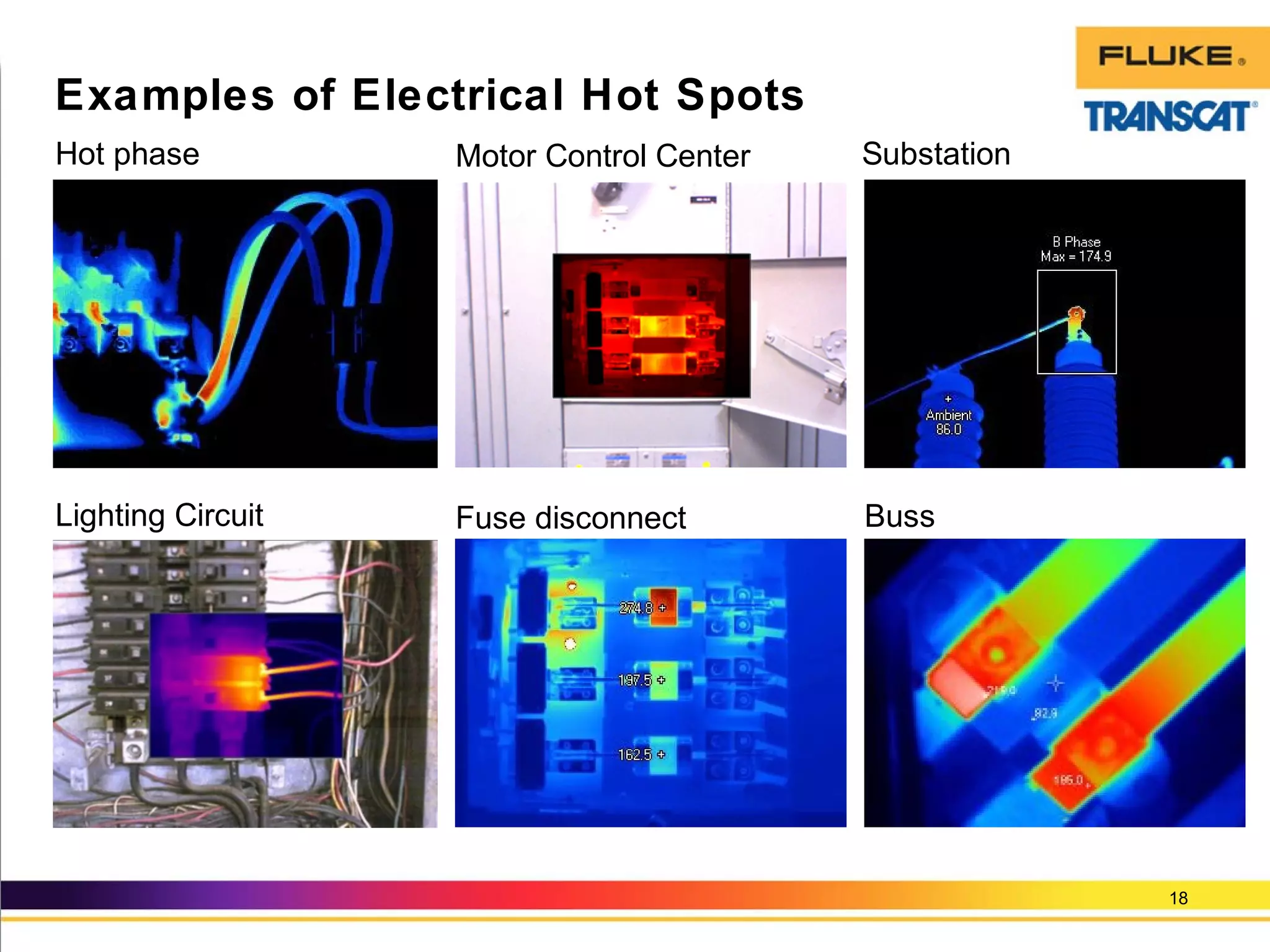

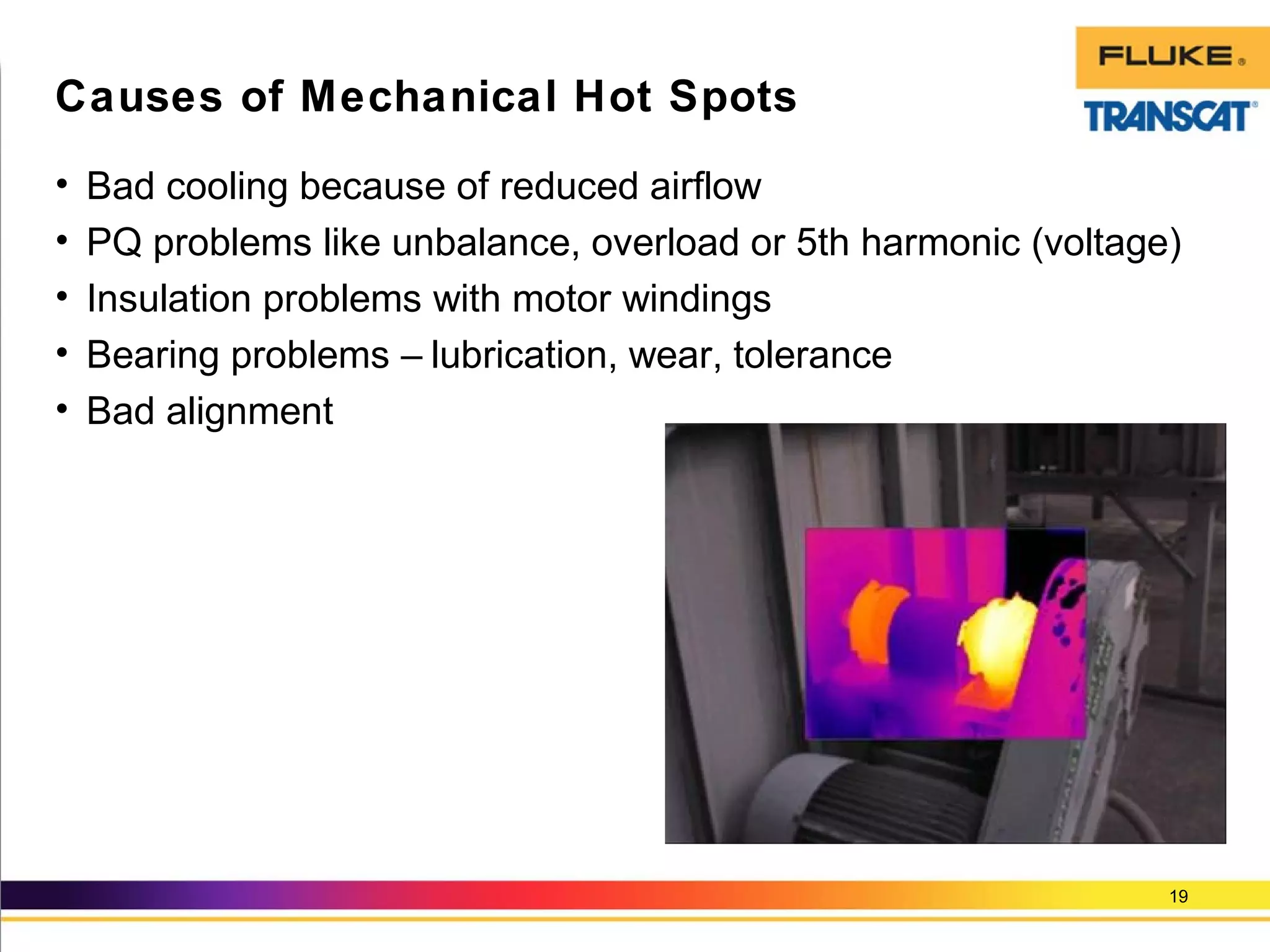

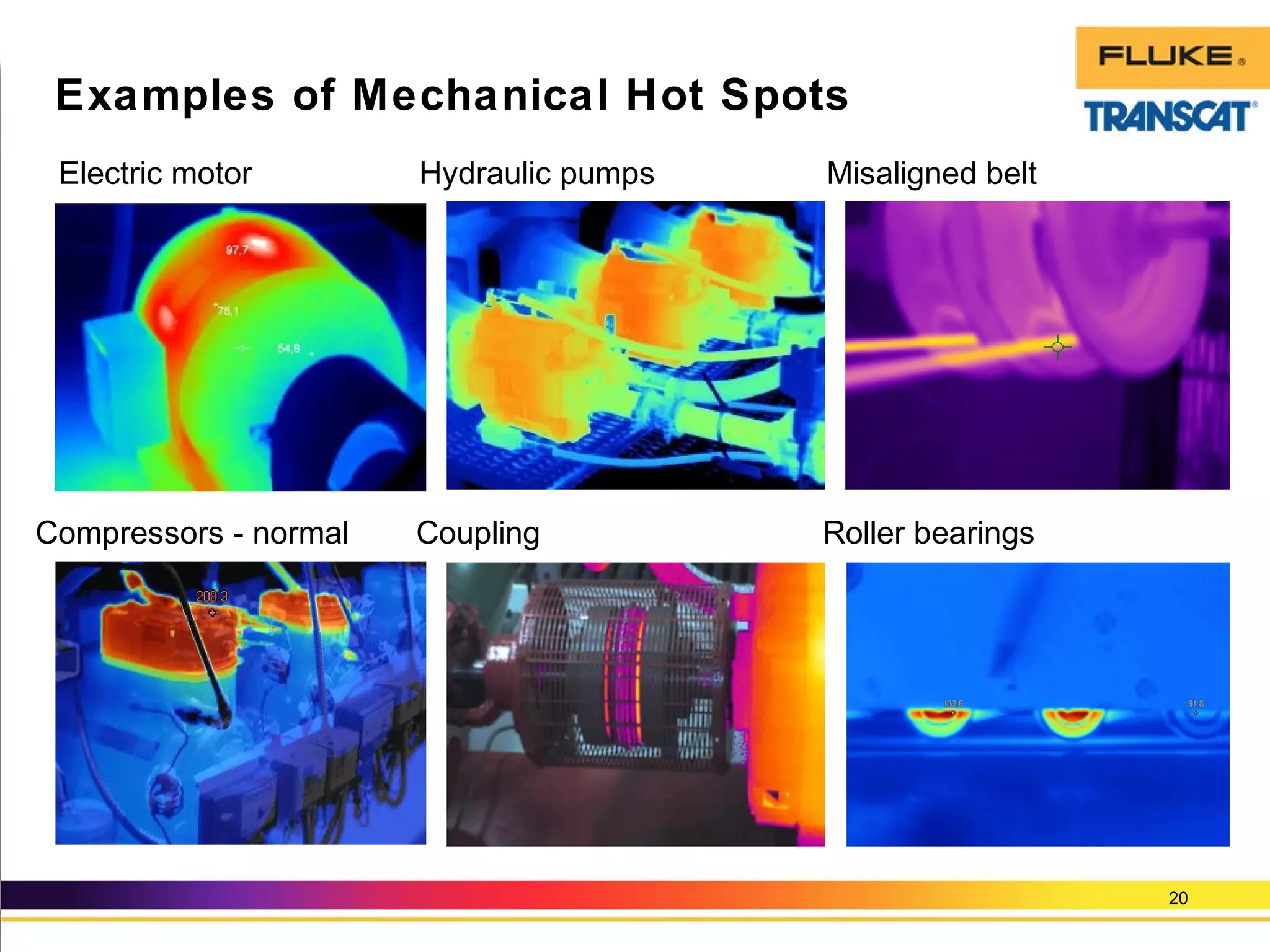

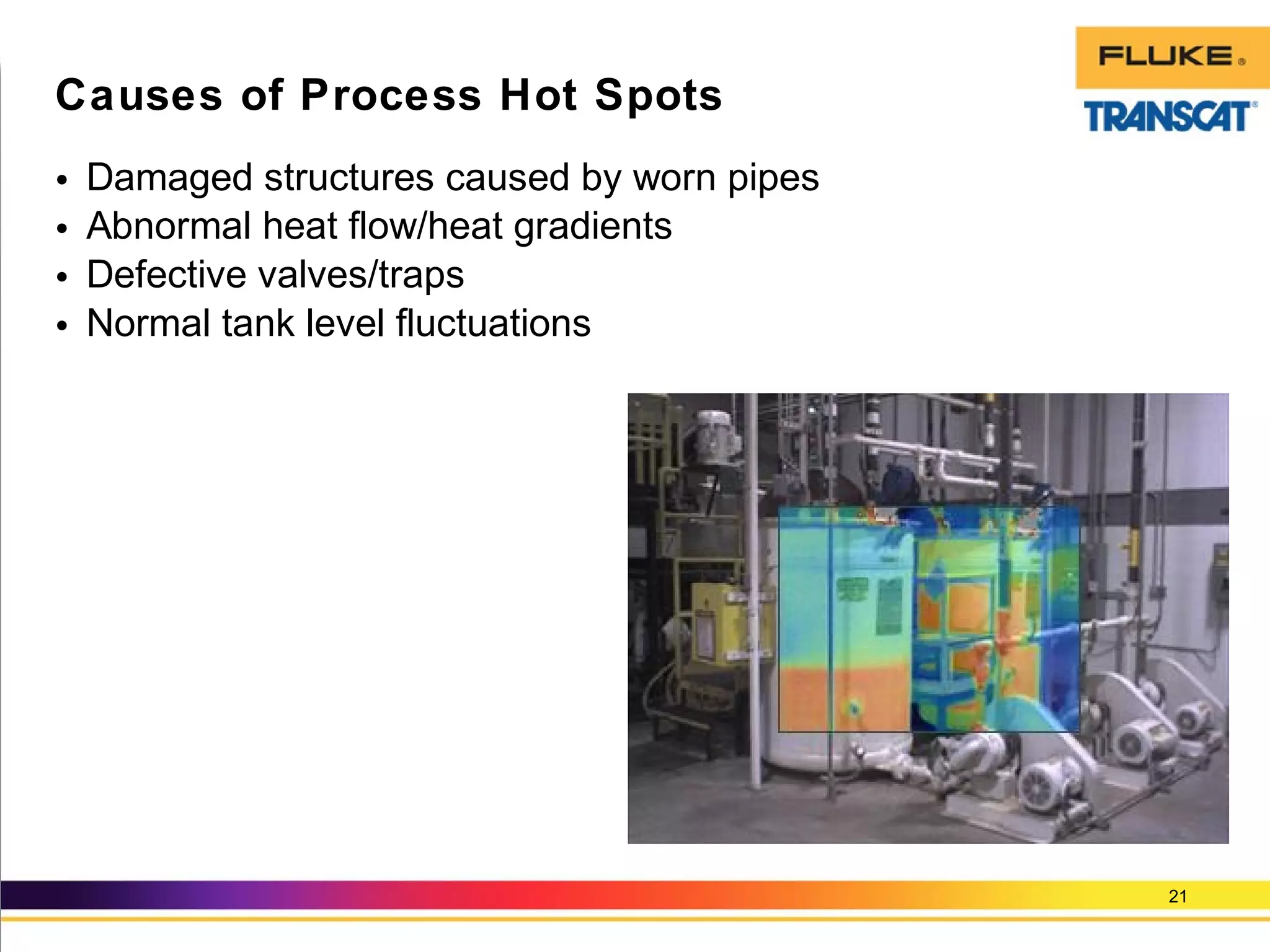

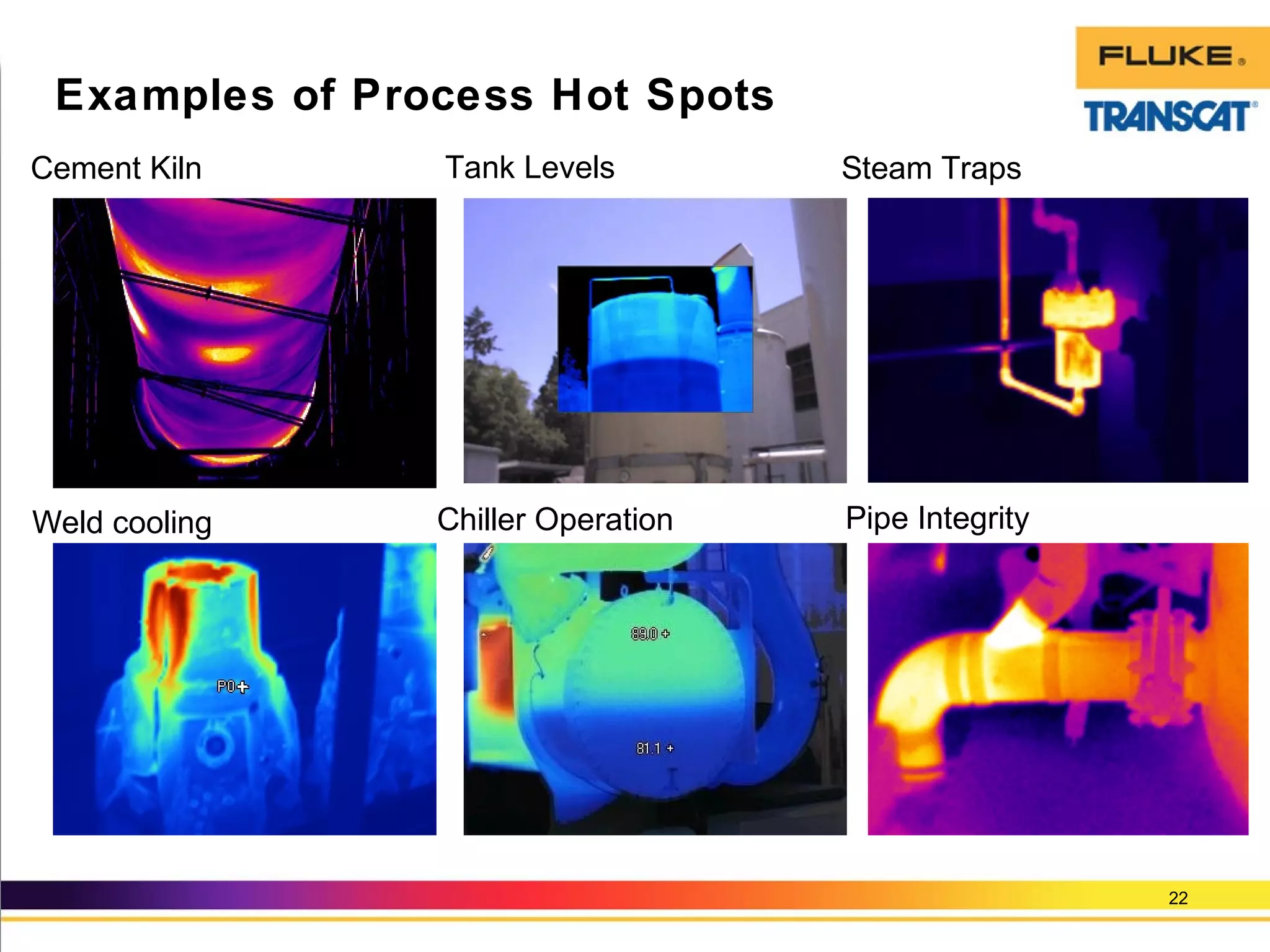

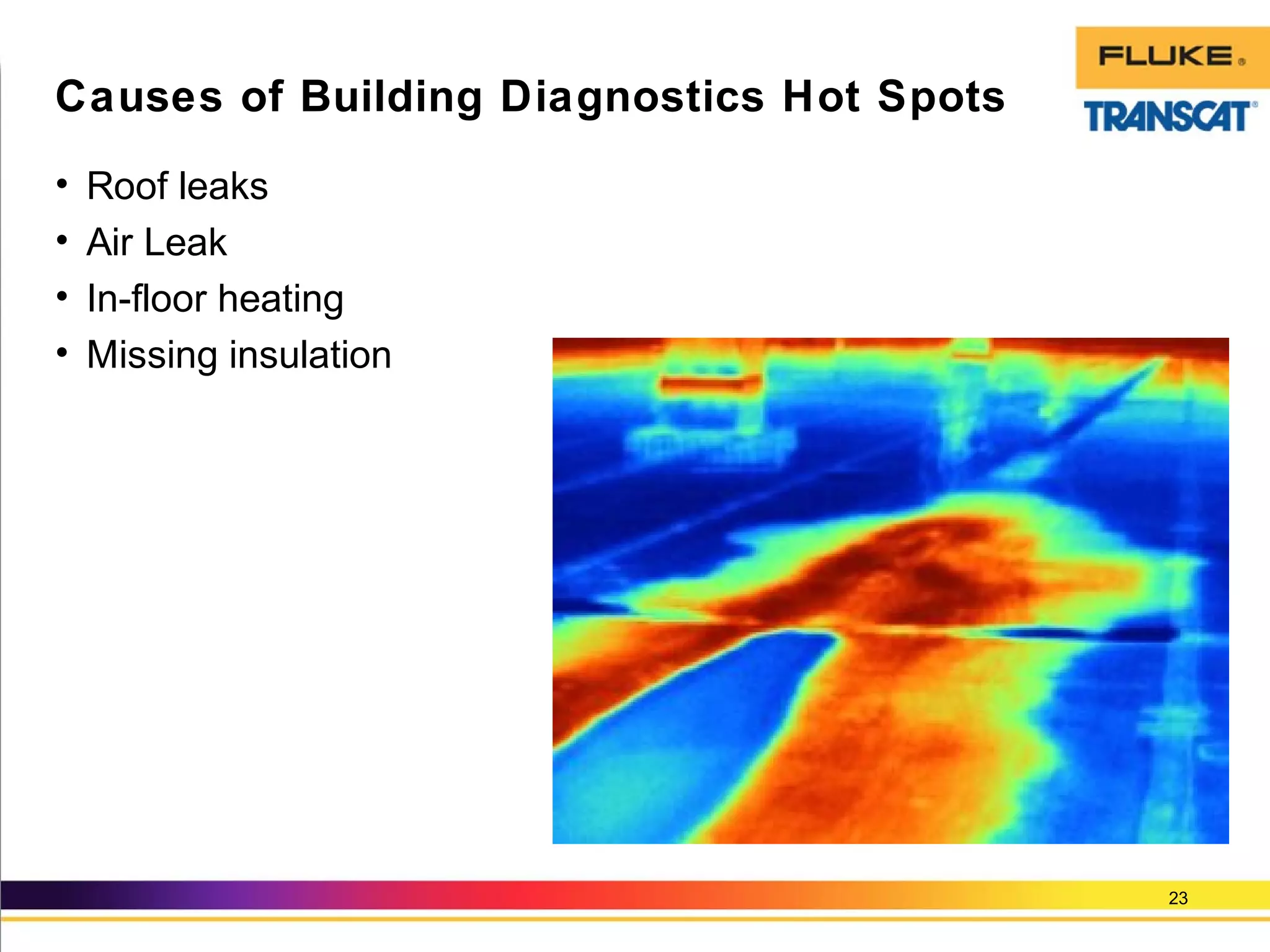

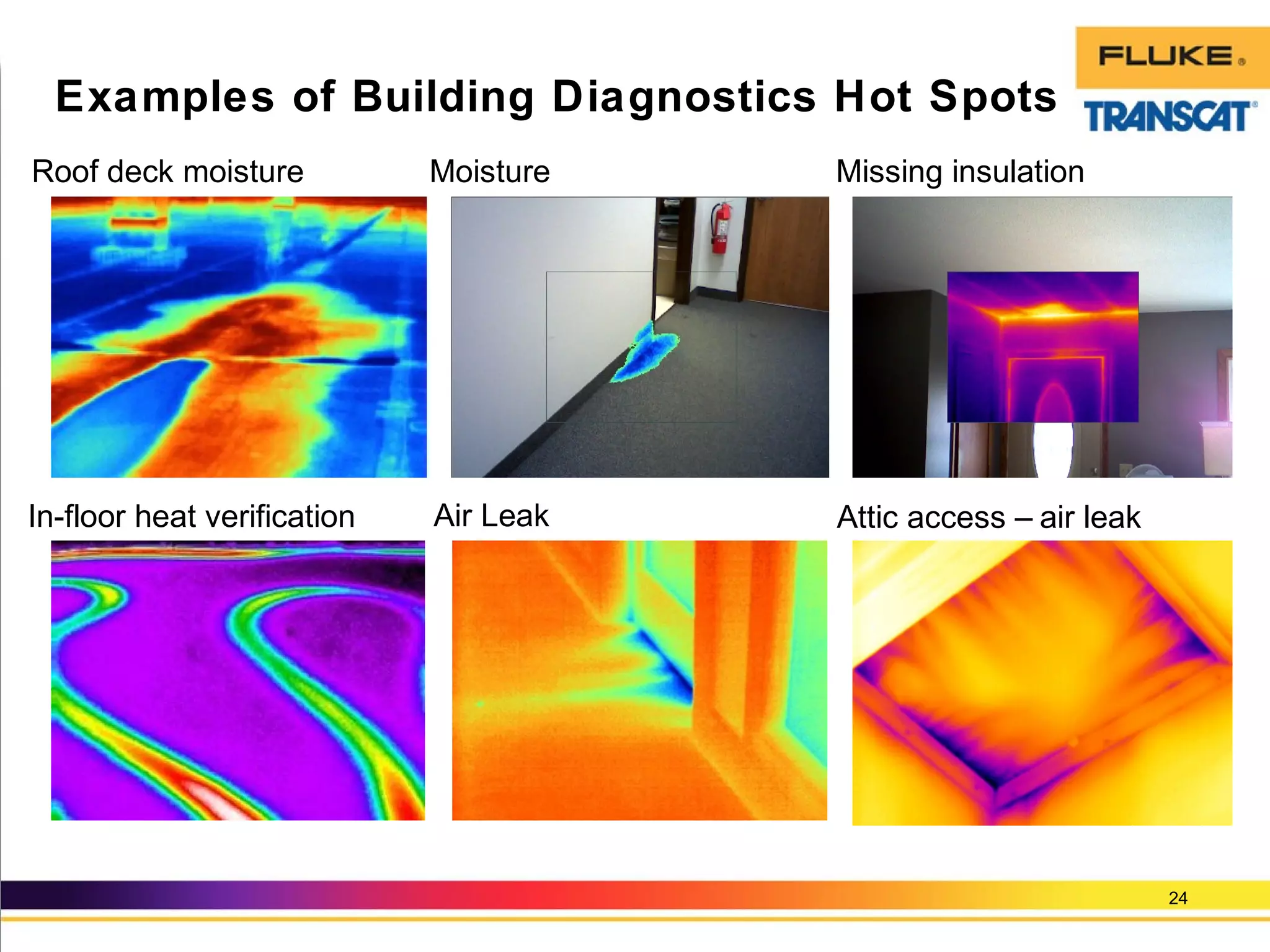

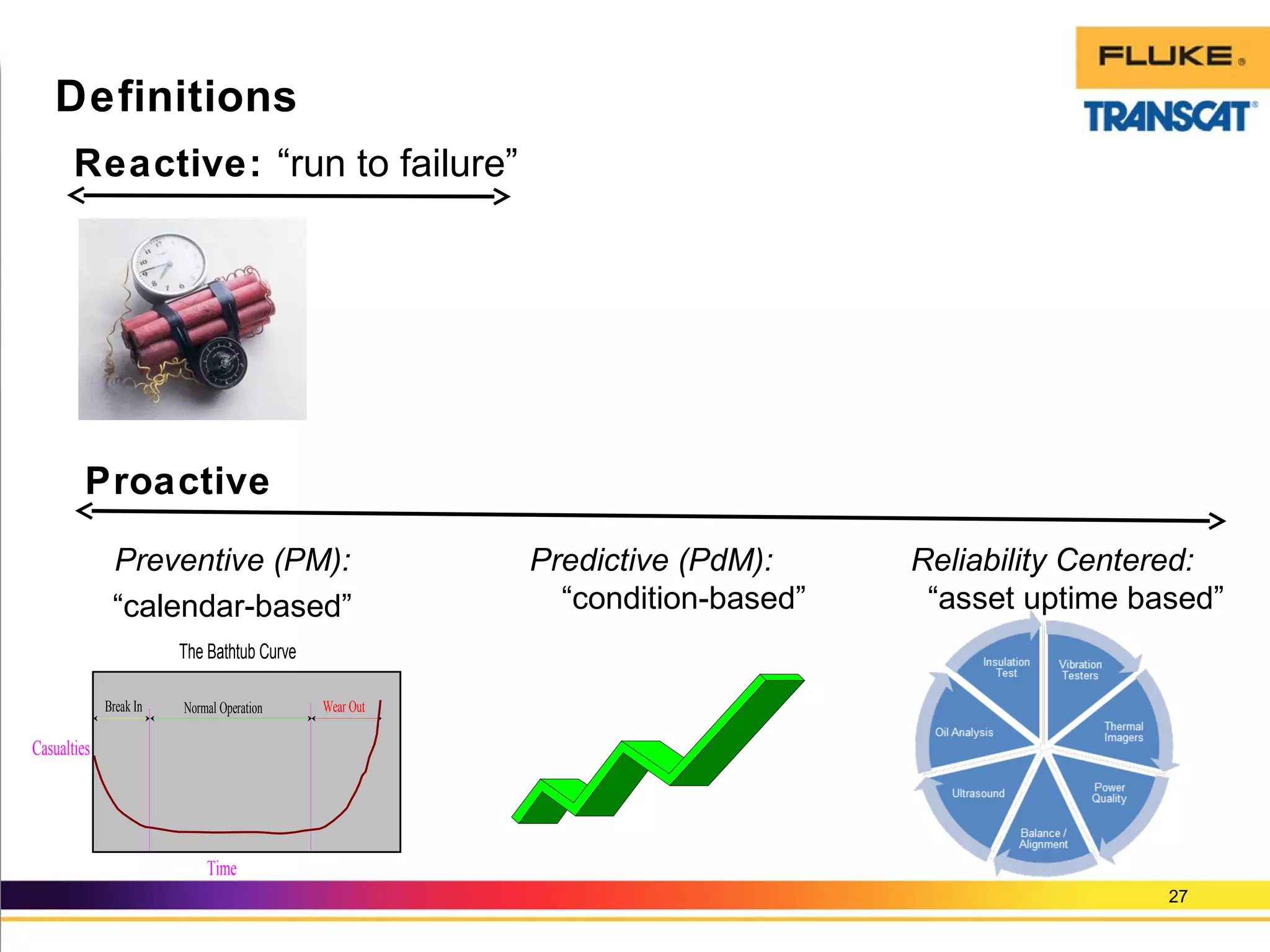

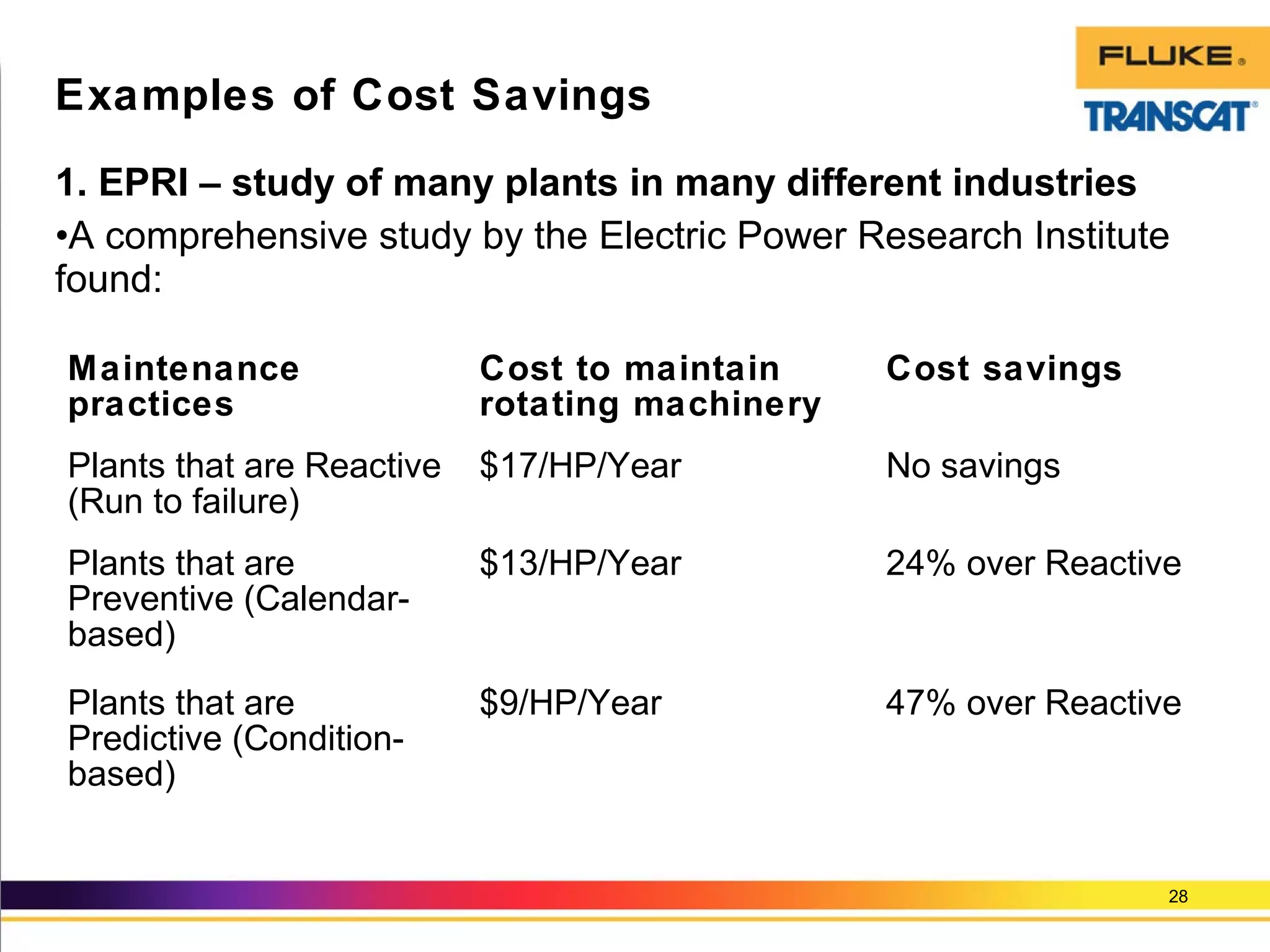

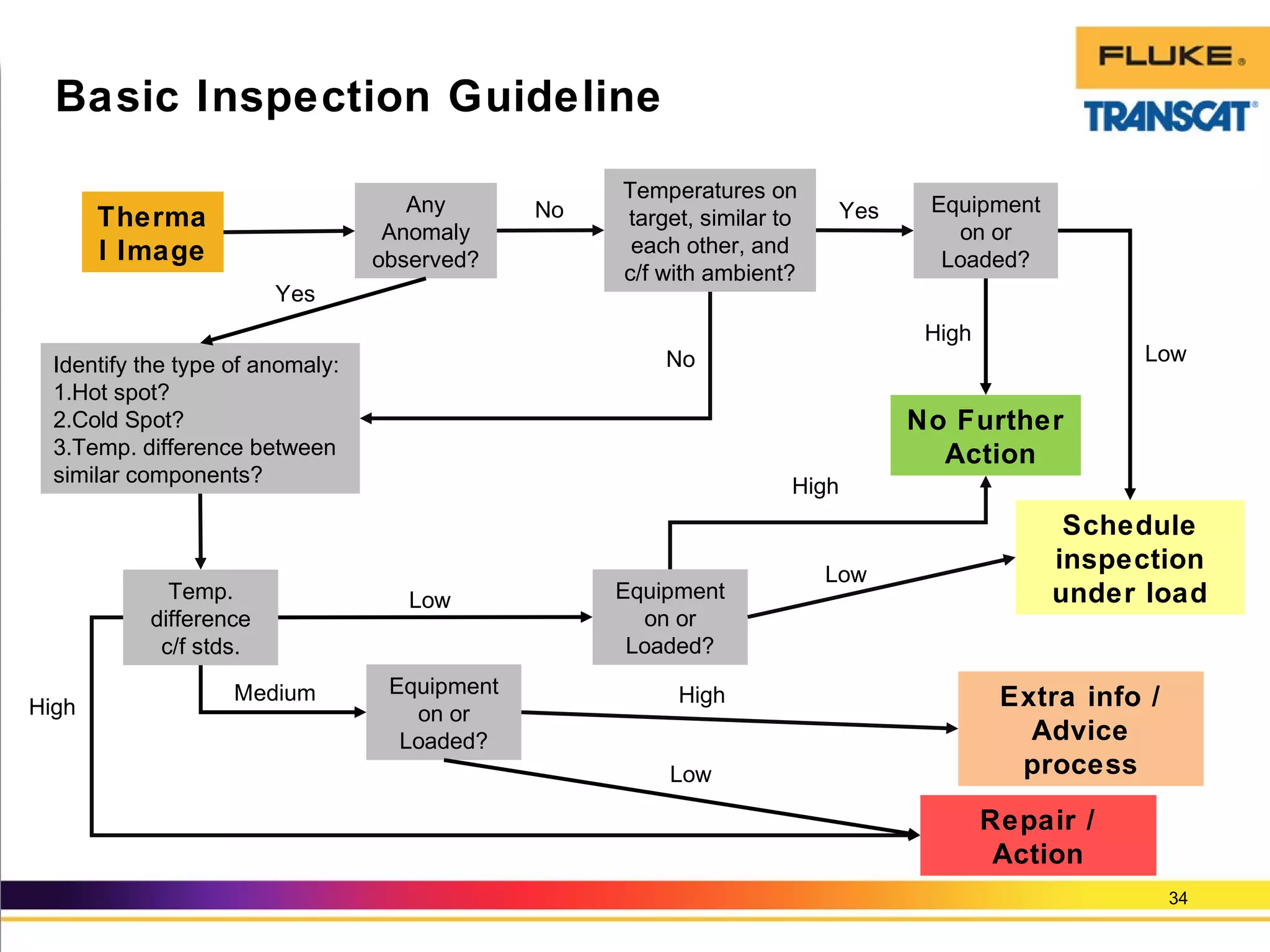

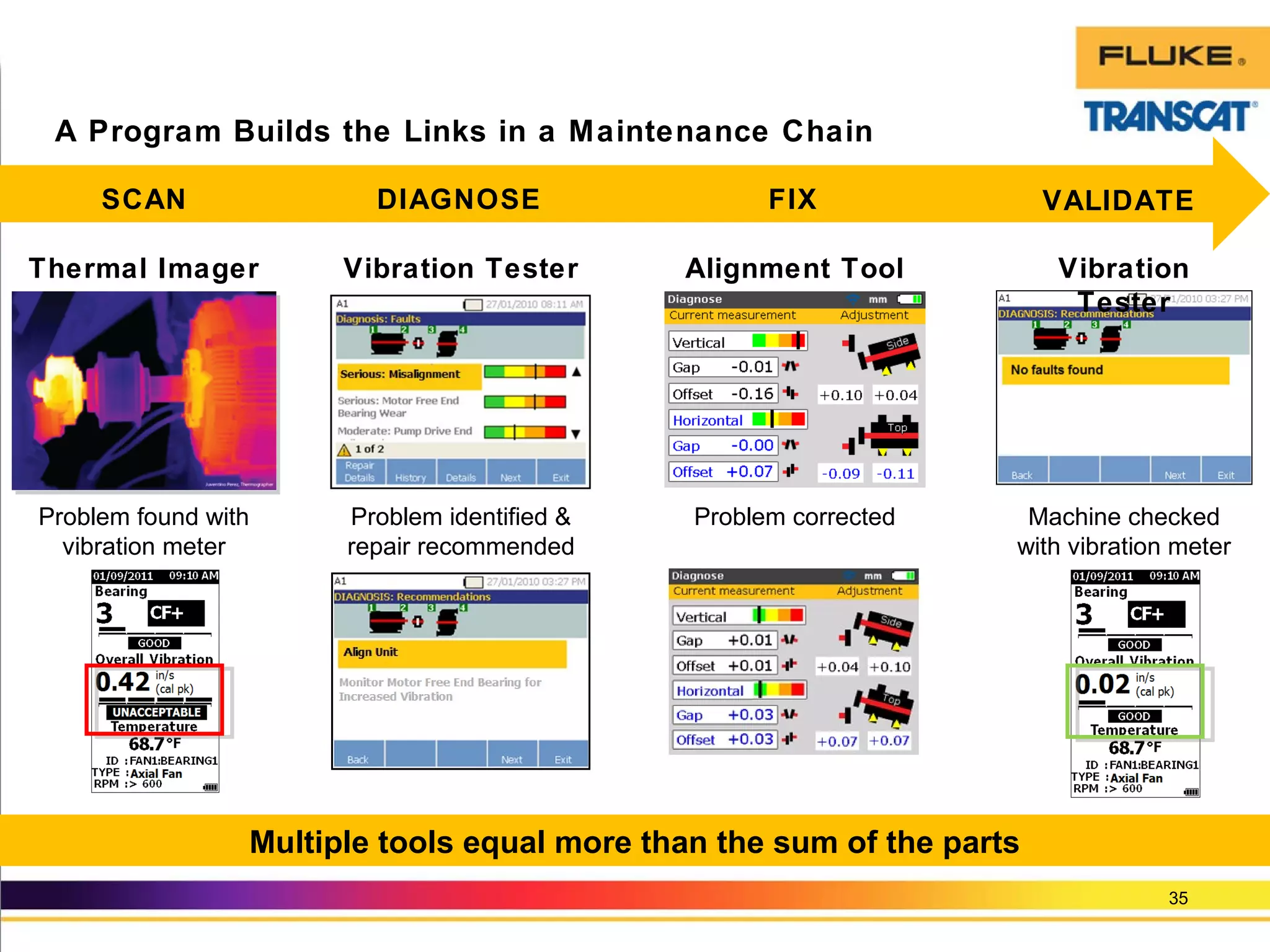

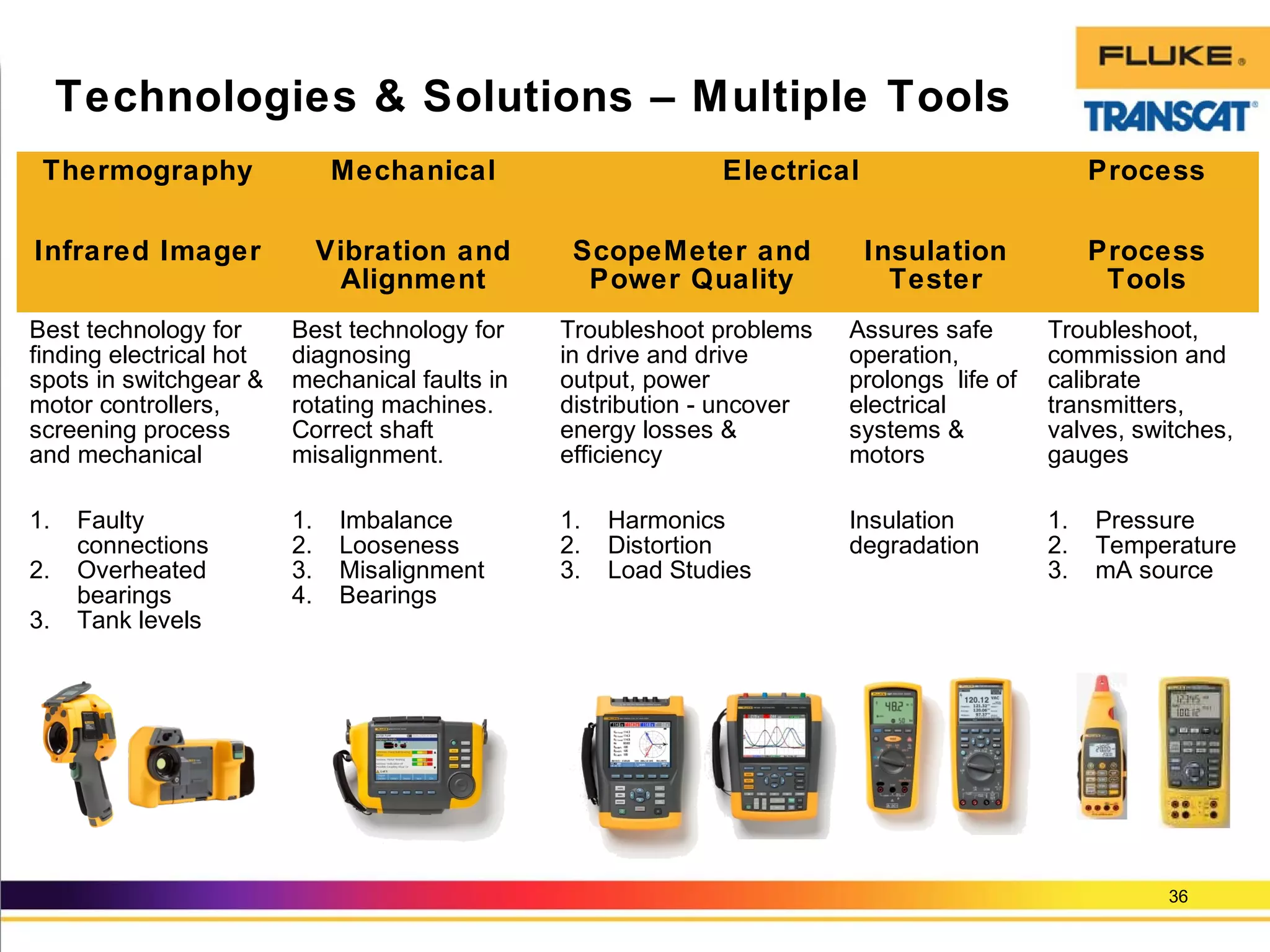

The document provides an overview of thermal imaging techniques and practices for effective maintenance, emphasizing the importance of infrared thermography in identifying electrical, mechanical, process, and building diagnostics issues. It discusses how to integrate infrared inspections into preventative maintenance programs, highlights the benefits of predictive maintenance, and suggests strategies for small maintenance teams to implement efficient proactive practices. Key tips include understanding thermal capacitance, emissivity, and the necessity of regular inspections to enhance equipment reliability and safety.