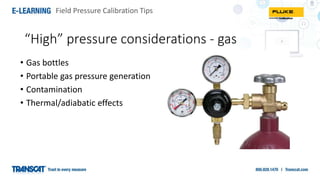

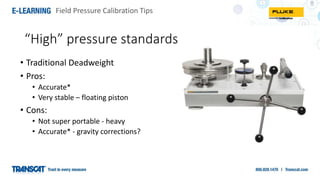

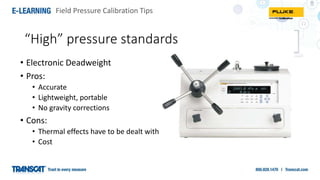

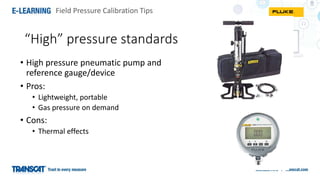

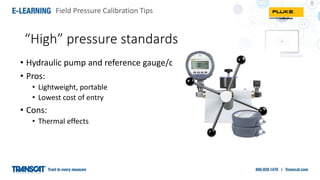

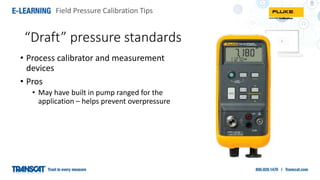

This document provides tips for calibrating pressure measurement devices in the field across various pressure ranges. It discusses considerations and standard options for calibrating at high pressures (>300 PSI) using deadweights, pumps, or hydraulic systems. For low pressures (<few PSI) and vacuums, it recommends using process calibrators or hand pumps. Draft pressure calibration (<1 PSI) requires extra stability and range considerations. Hard vacuum calibration of devices measuring below 1 Torr is challenging due to required large turndowns, and may require using a high-grade vacuum gauge as a standard.