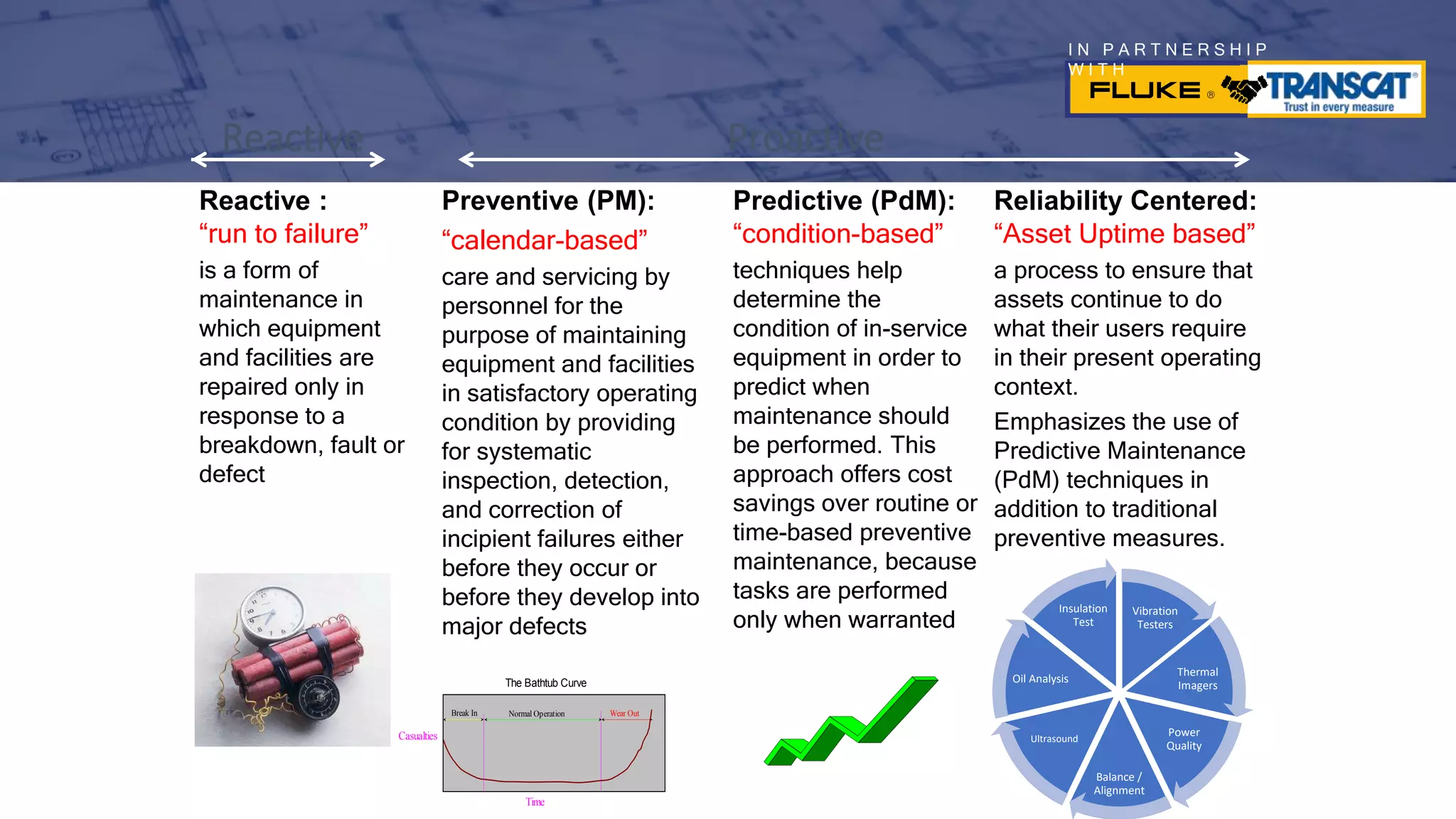

This document outlines a webinar on predictive maintenance hosted by Fluke, covering maintenance practices, trends, and leading technologies for reducing downtime and lost revenue. It compares reactive, preventive, and predictive maintenance strategies, emphasizing the advantages and challenges of each. The presentation also discusses specific technologies such as thermal imaging and vibration analysis, illustrating their role in enhancing efficiency and minimizing maintenance costs.

![I N P A R T N E R S H I P

W I T H

Sample of machine setup fields

• Machine Name: Pump 1

• AC Motor

• No Variable Frequency Drive

• RPM: 1800 (Minimum 200 RPM)

• HP: 40

• Motor Mounting: Horizontal

• Motor Bearing Type: Roller Bearing

• Next Component: Flexible Coupling

• Driven Component: Centrifugal

Pump

• Impeller is supported by: Two

Bearings

• Number of Vanes [optional]: 5

9/7/2023 69](https://image.slidesharecdn.com/transcatpredictivemaintenancewebinar-presentedbyfluke-230907193810-69e47d70/75/Predictive-Maintenance-Best-Practices-Presented-by-Fluke-pptx-64-2048.jpg)