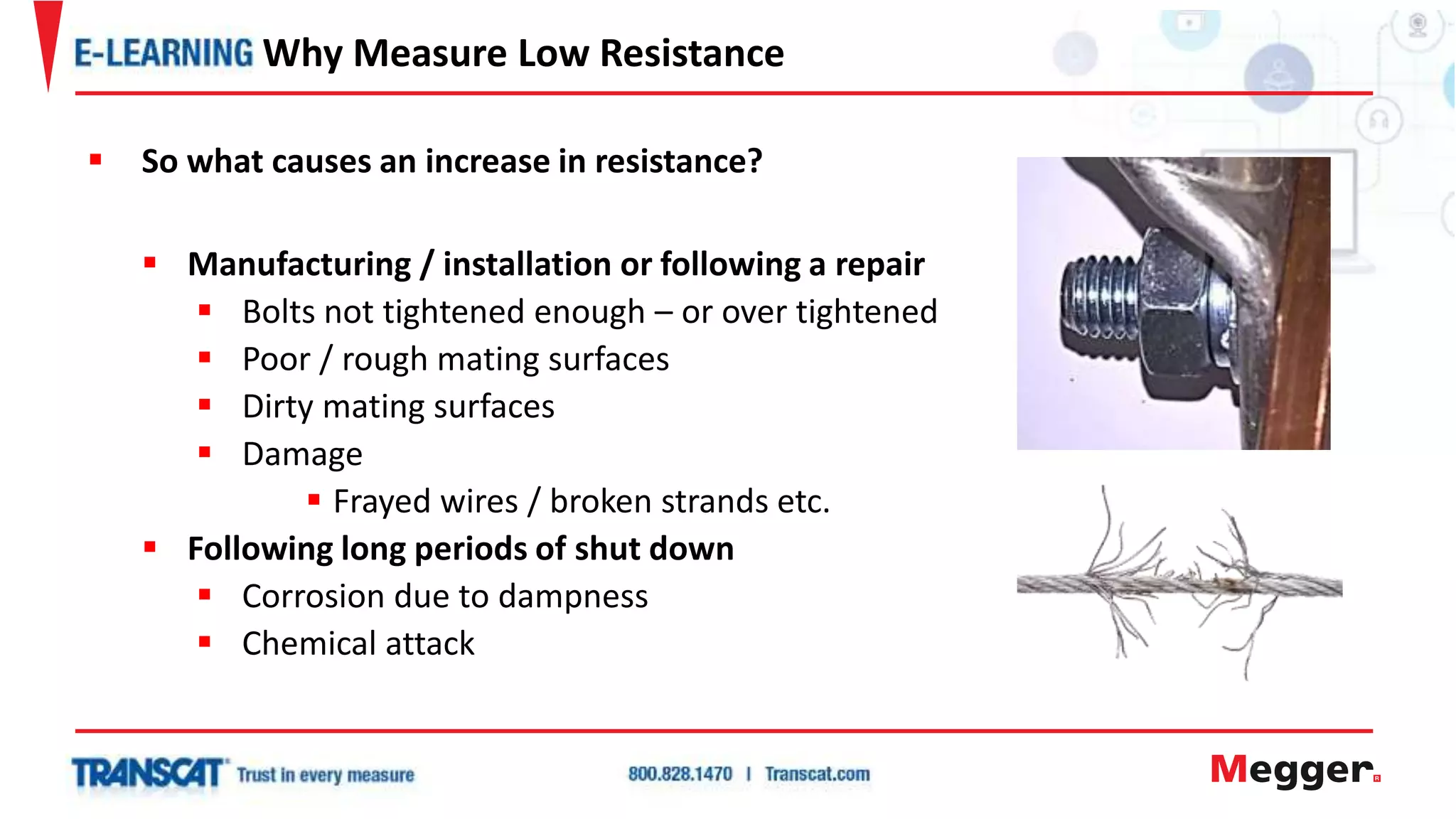

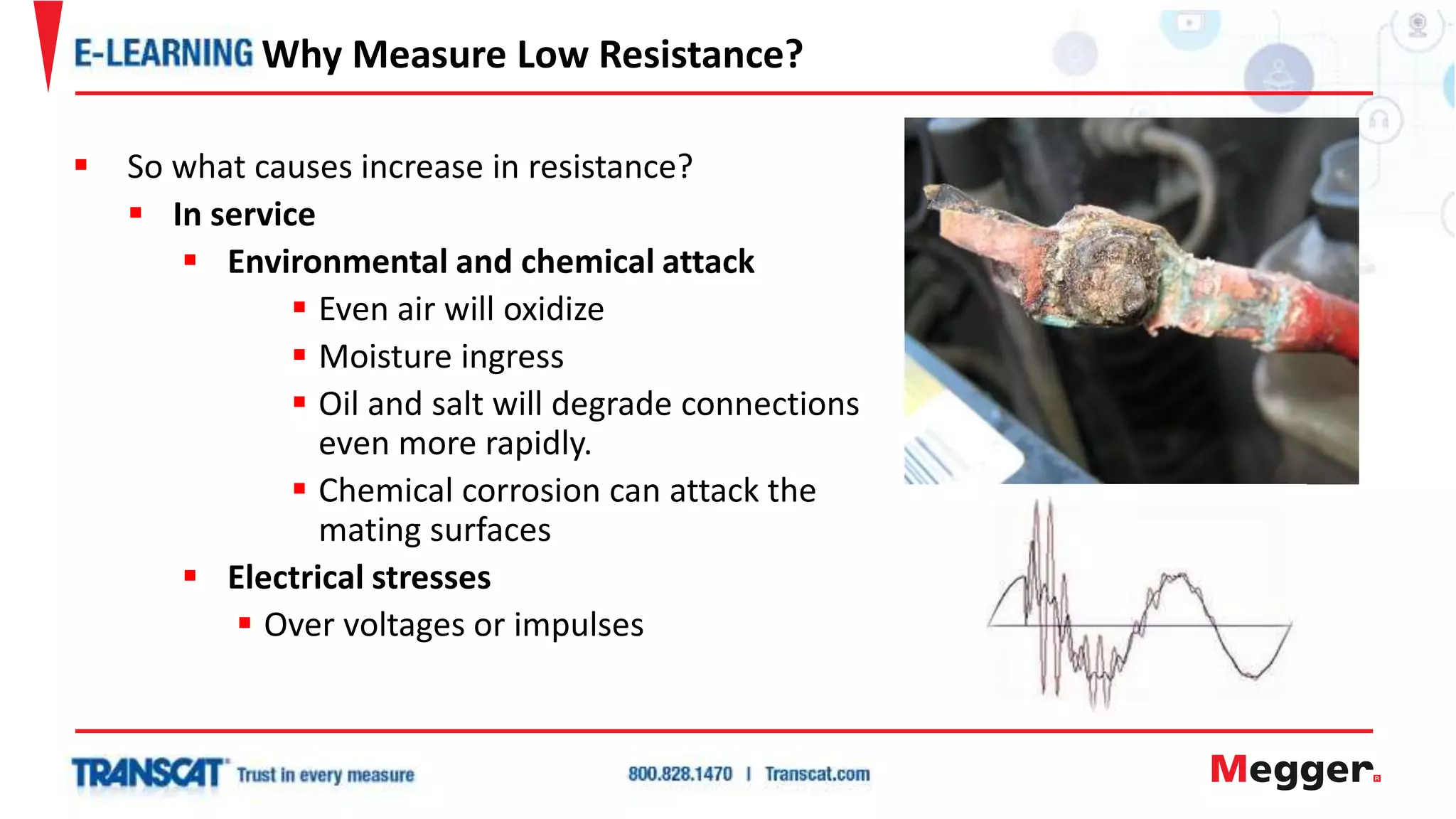

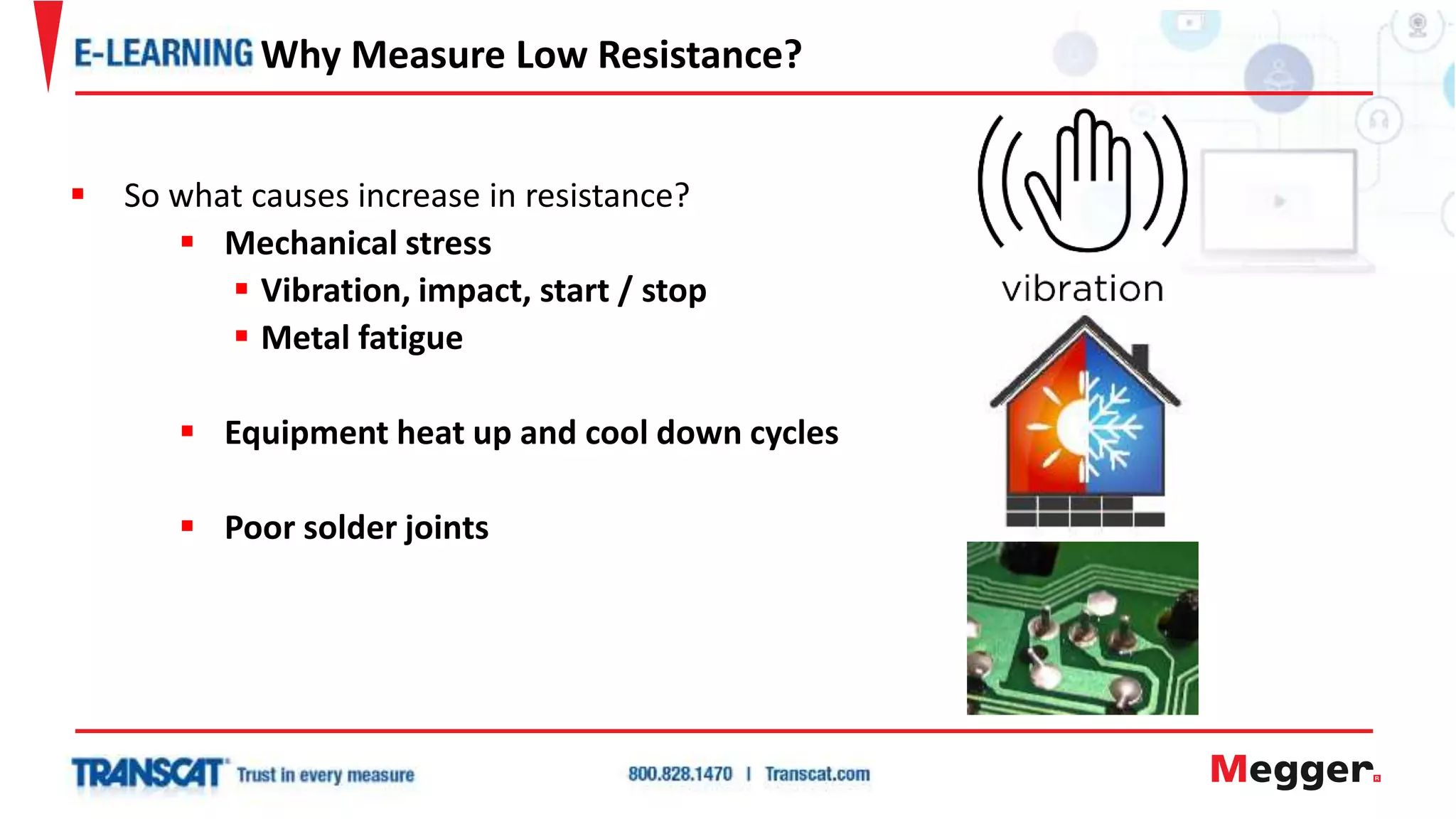

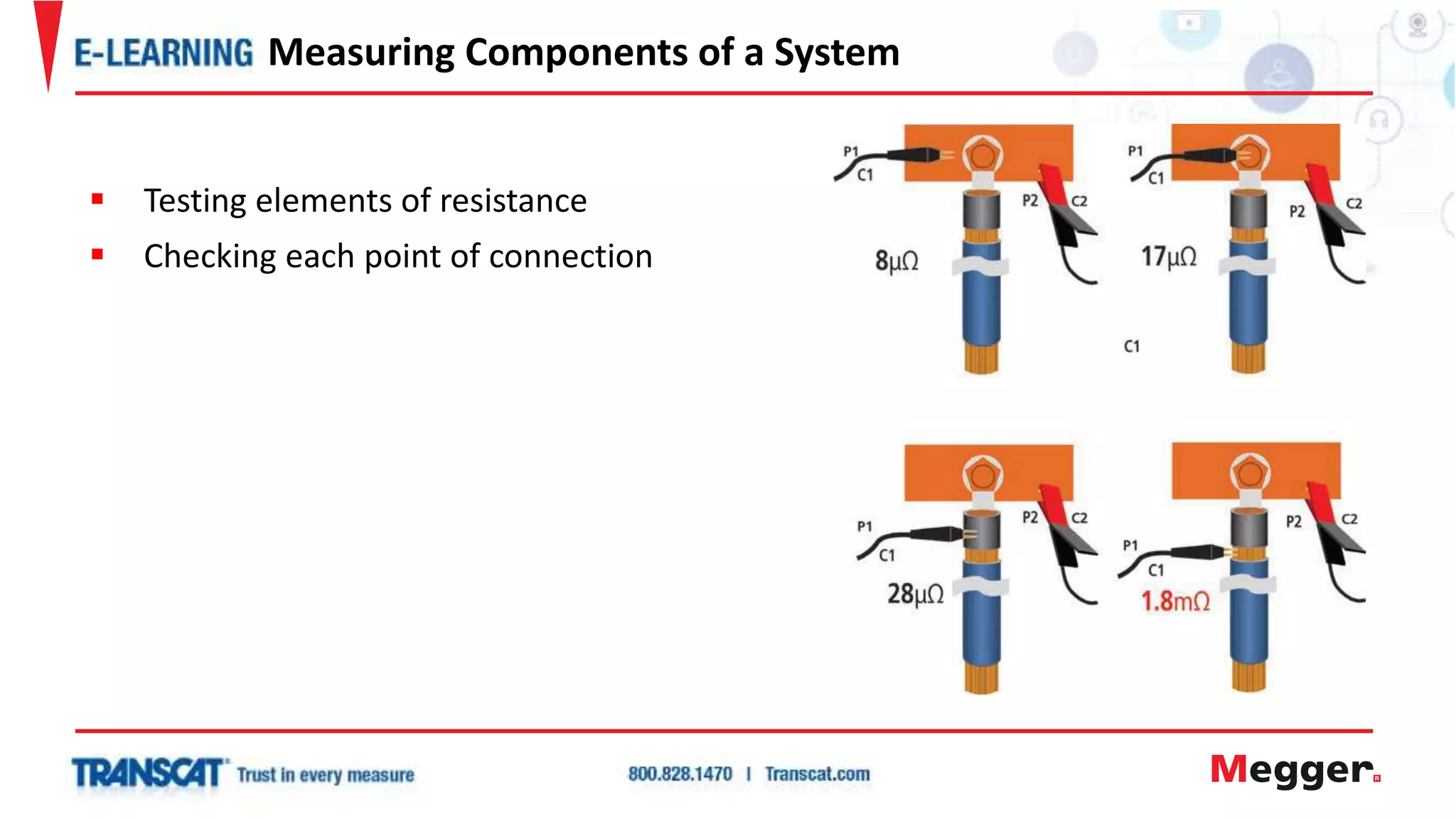

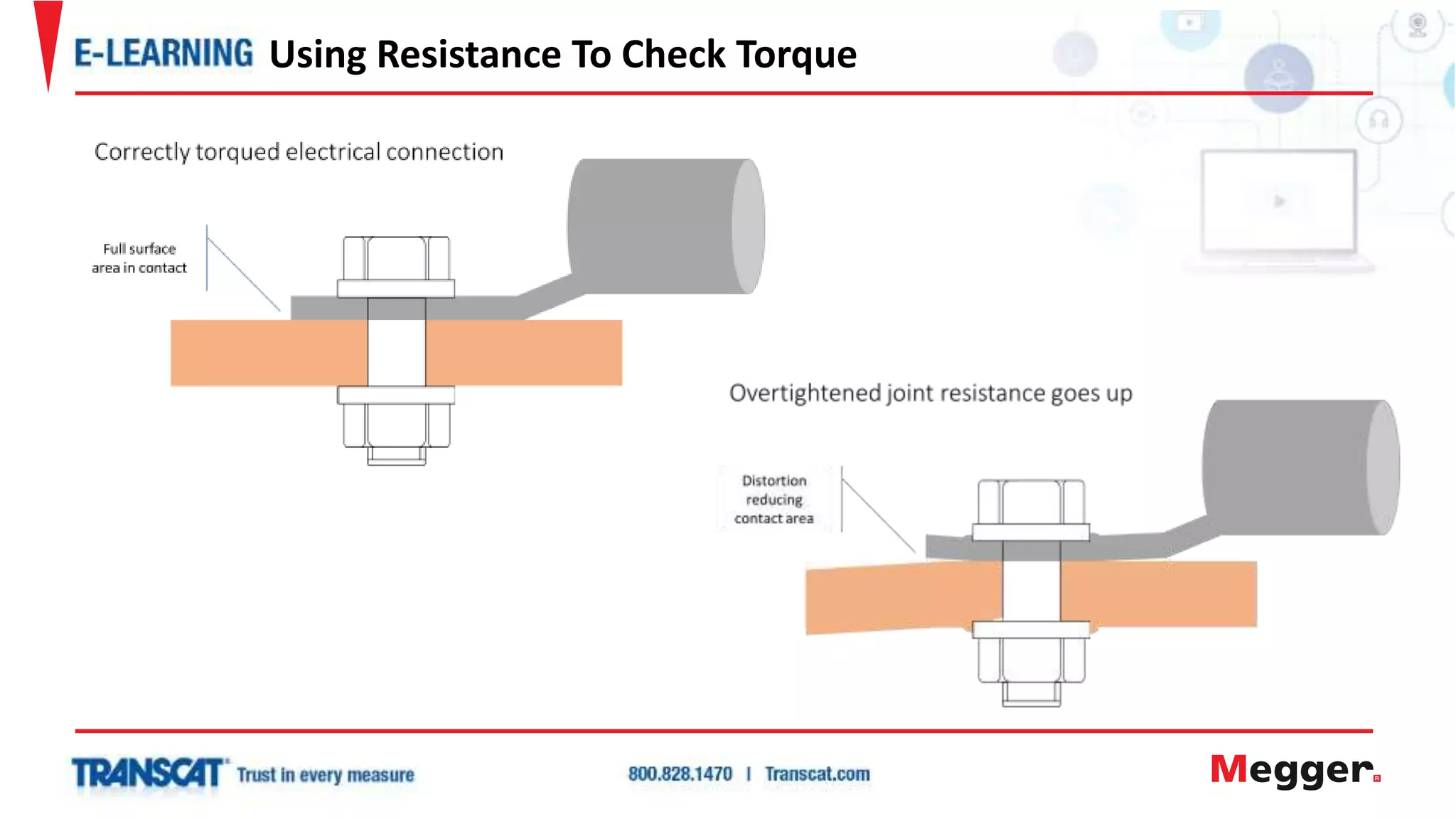

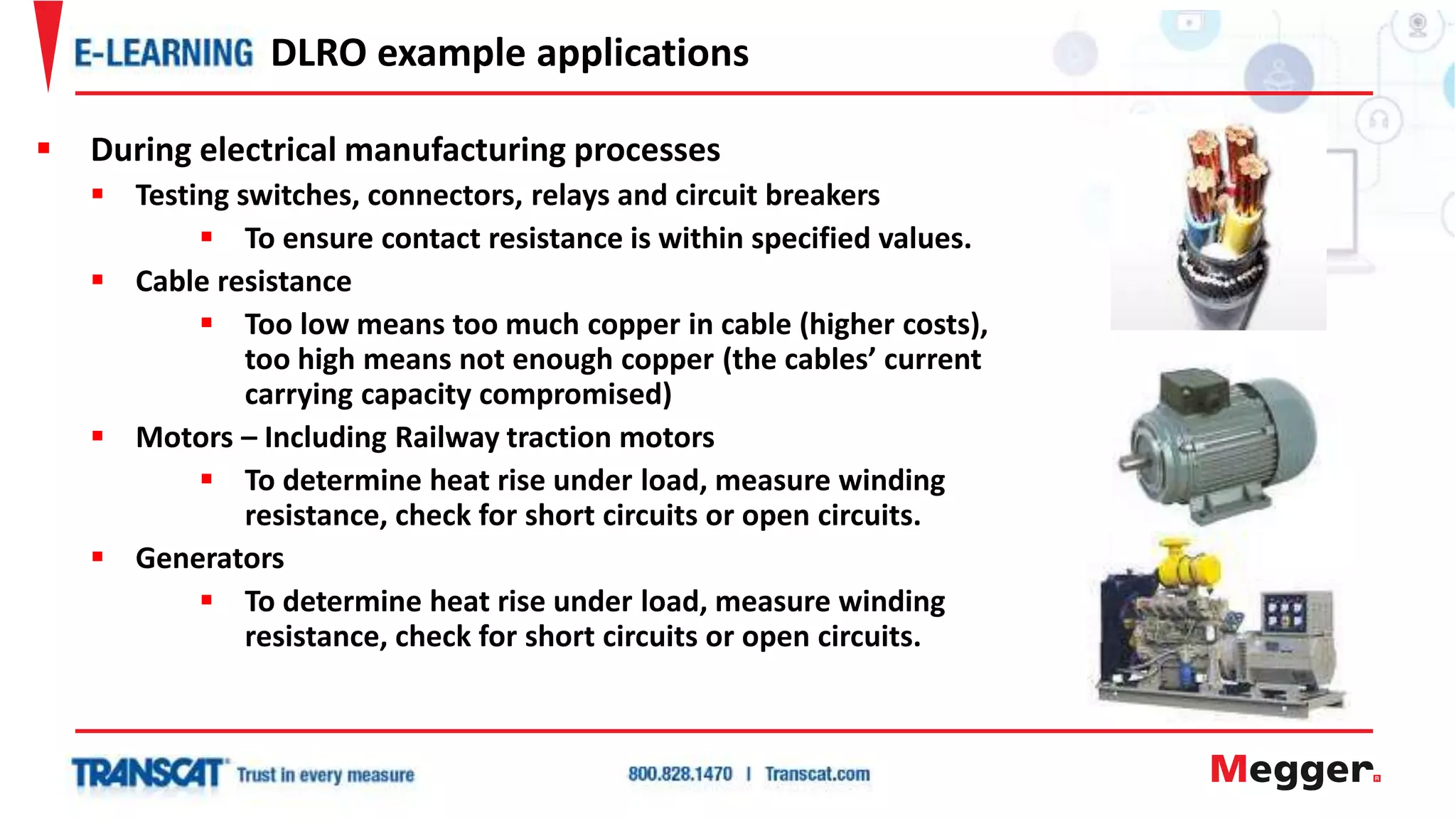

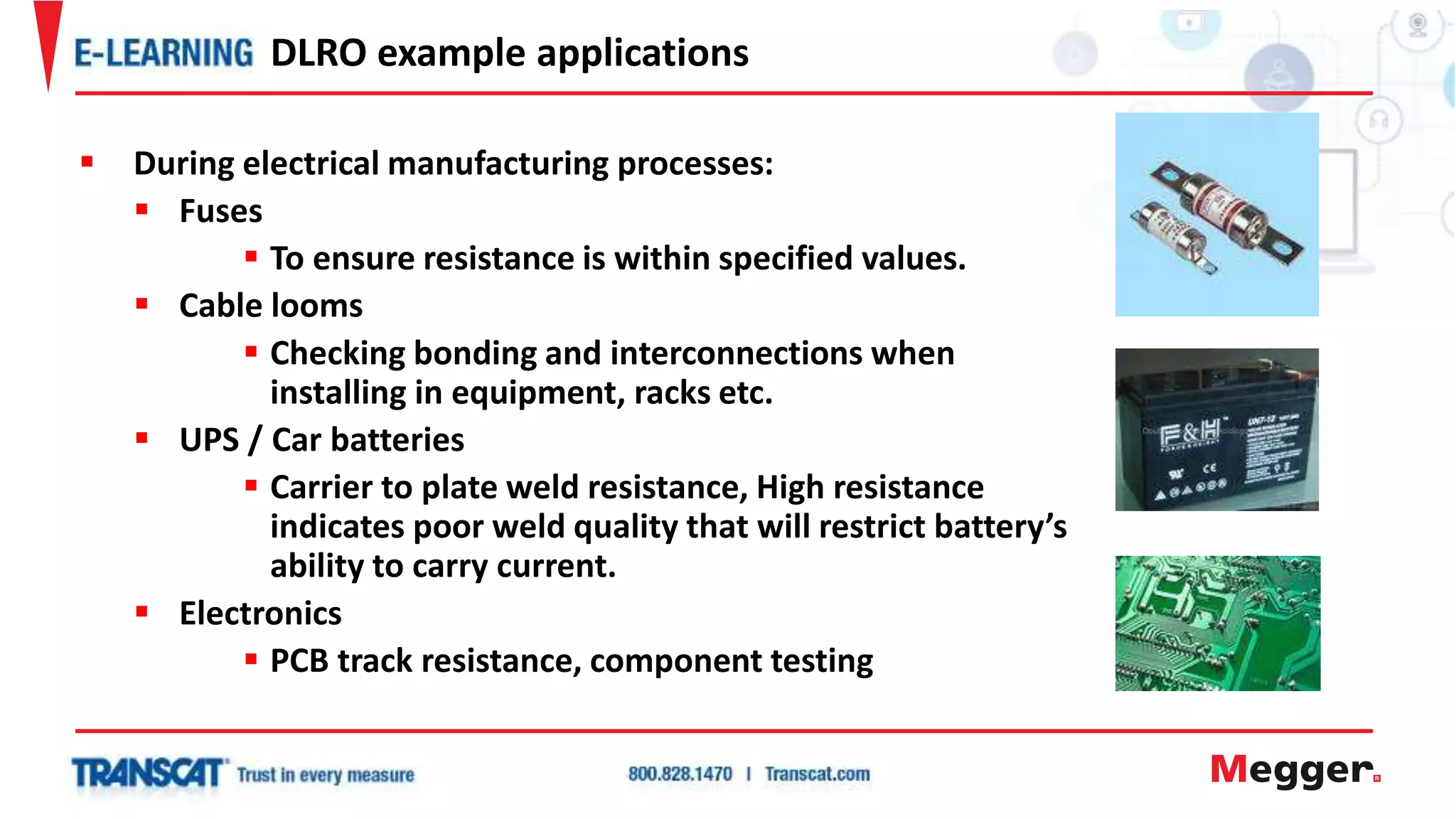

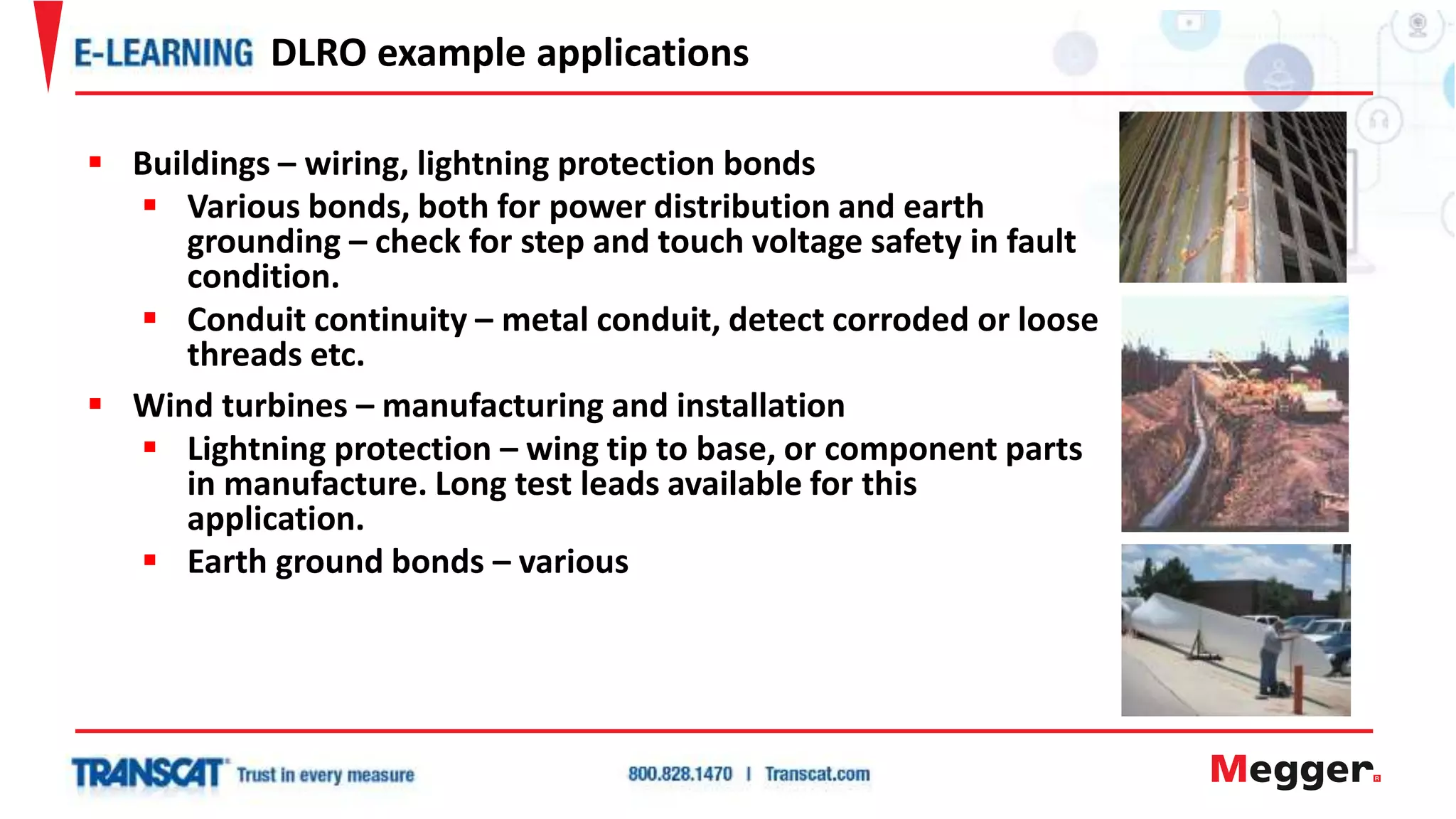

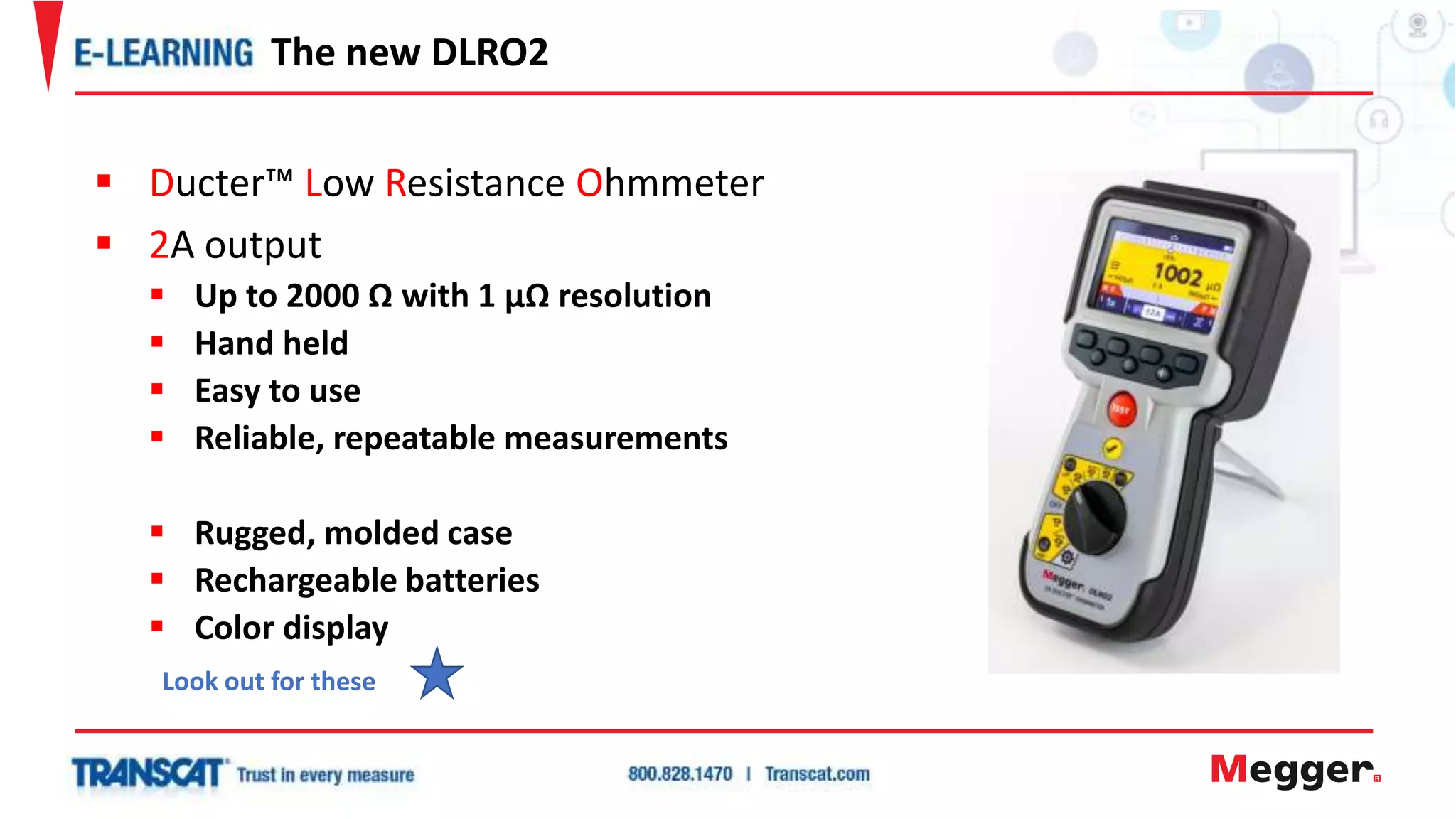

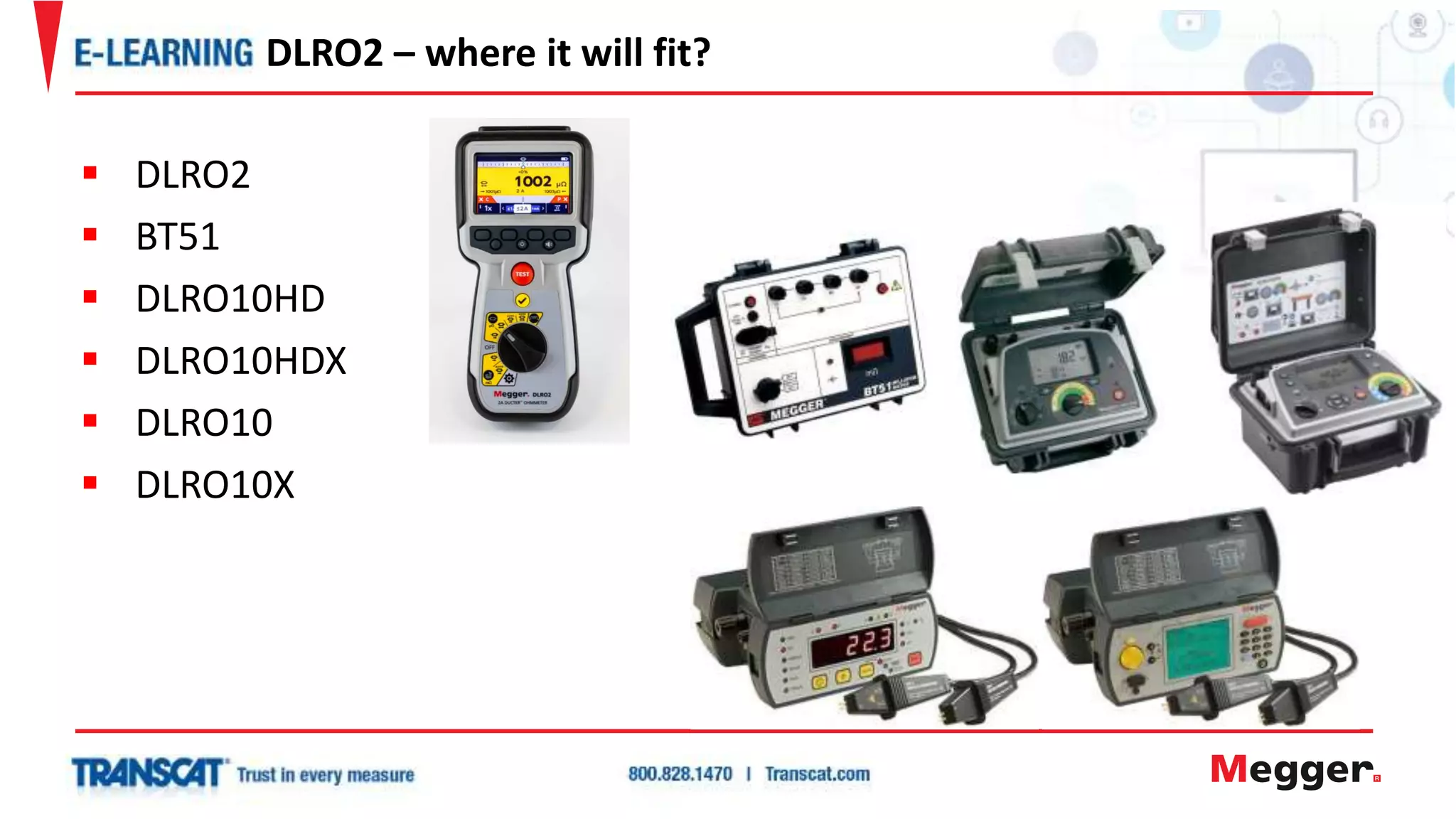

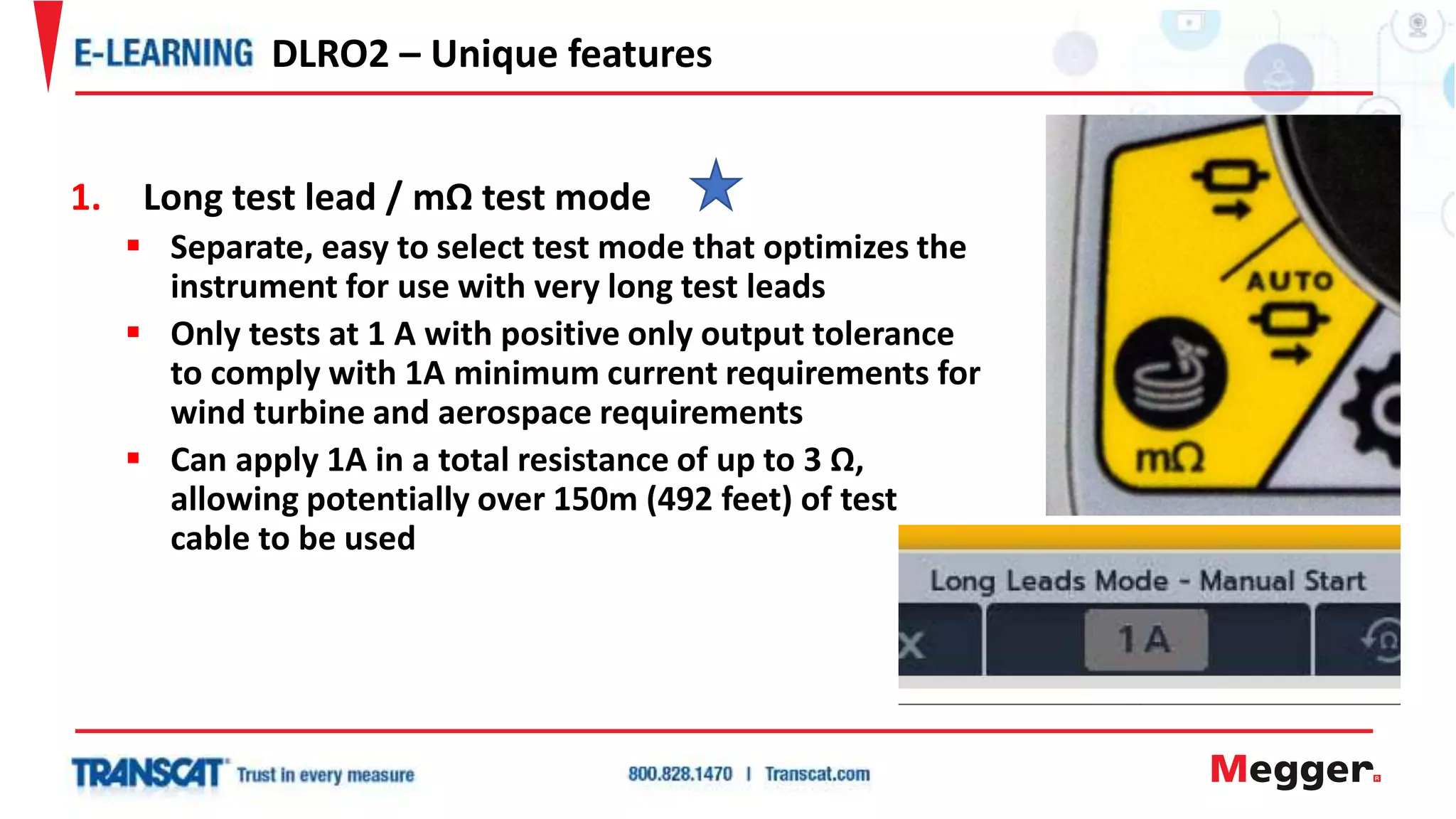

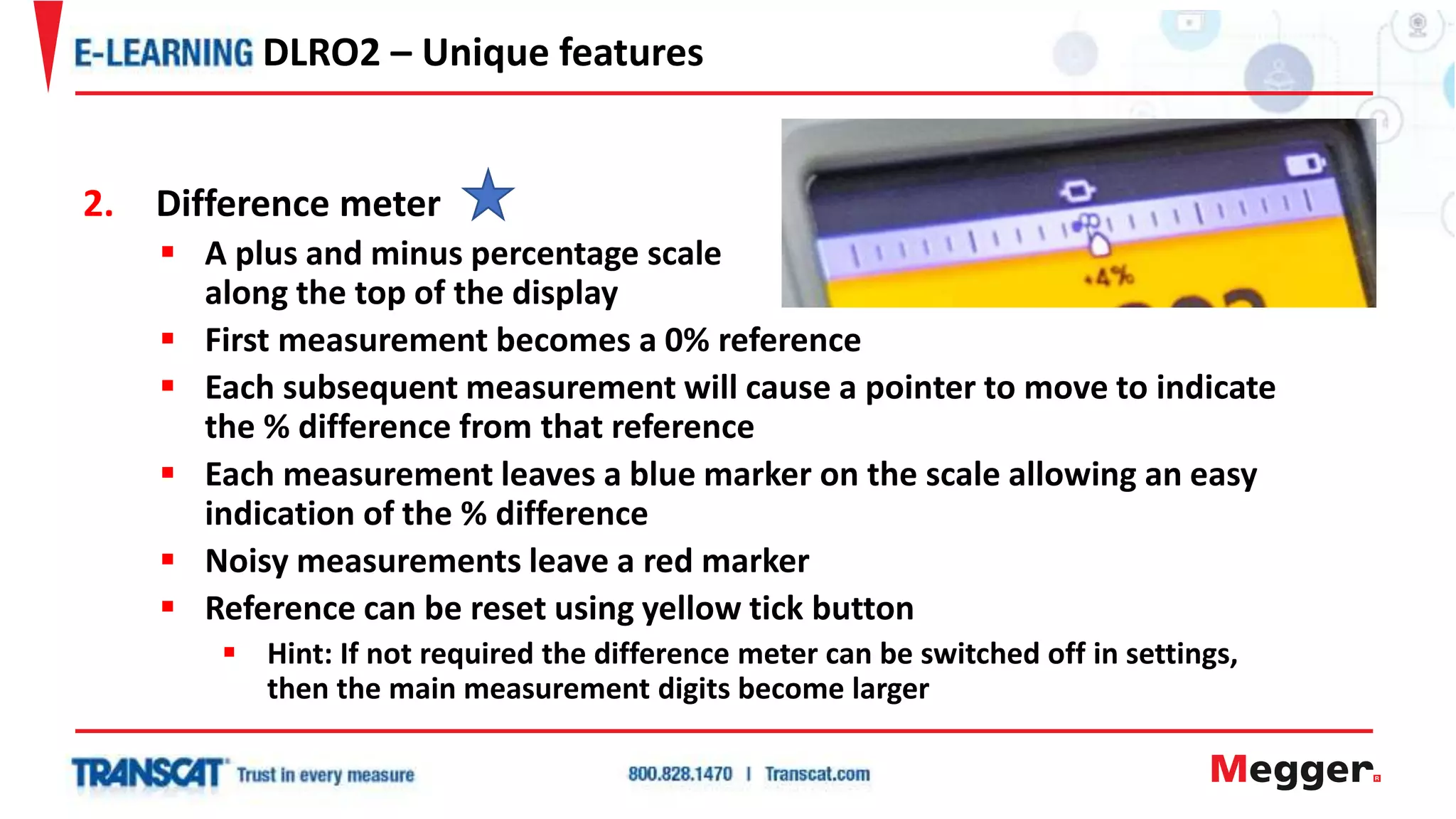

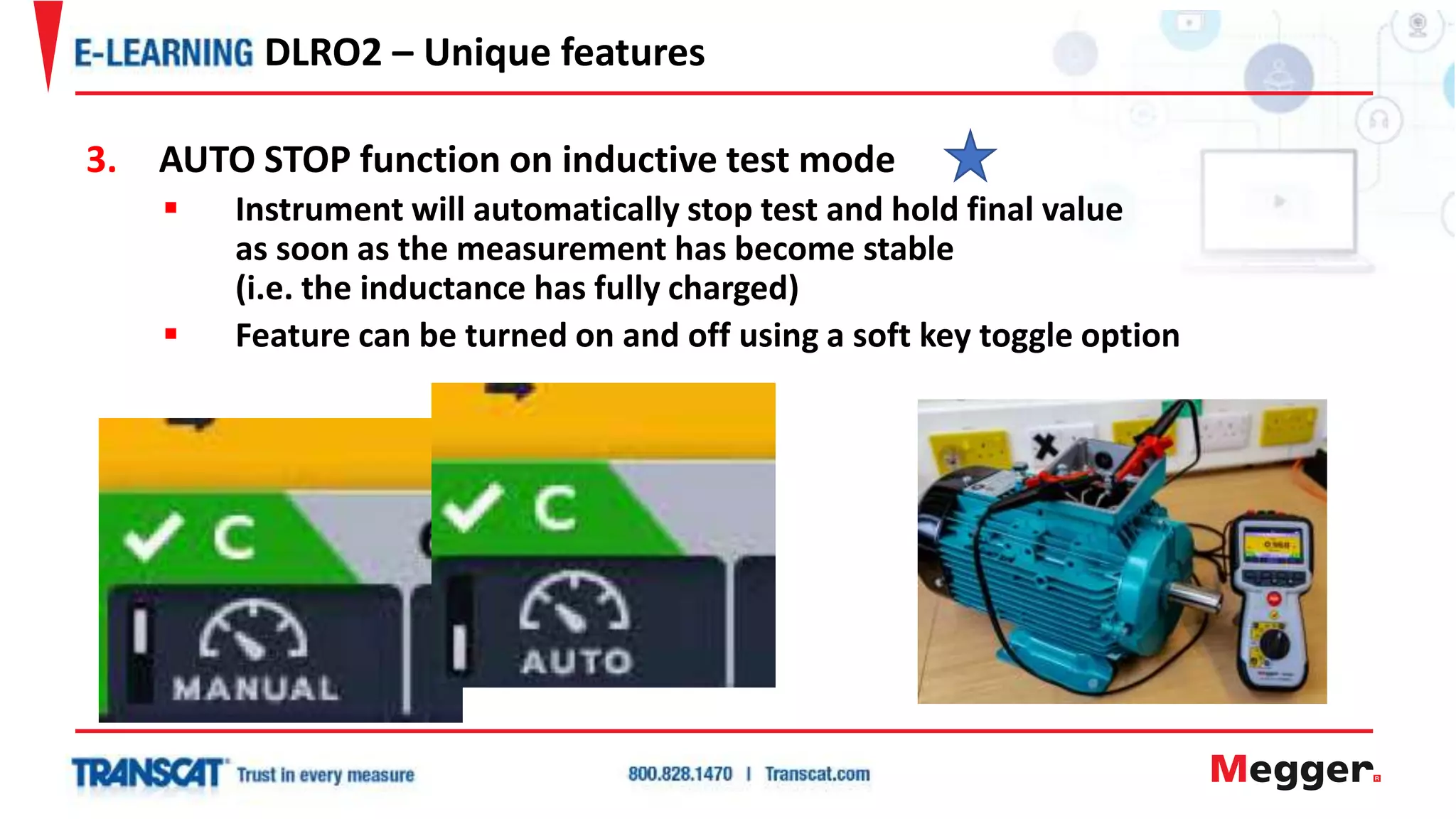

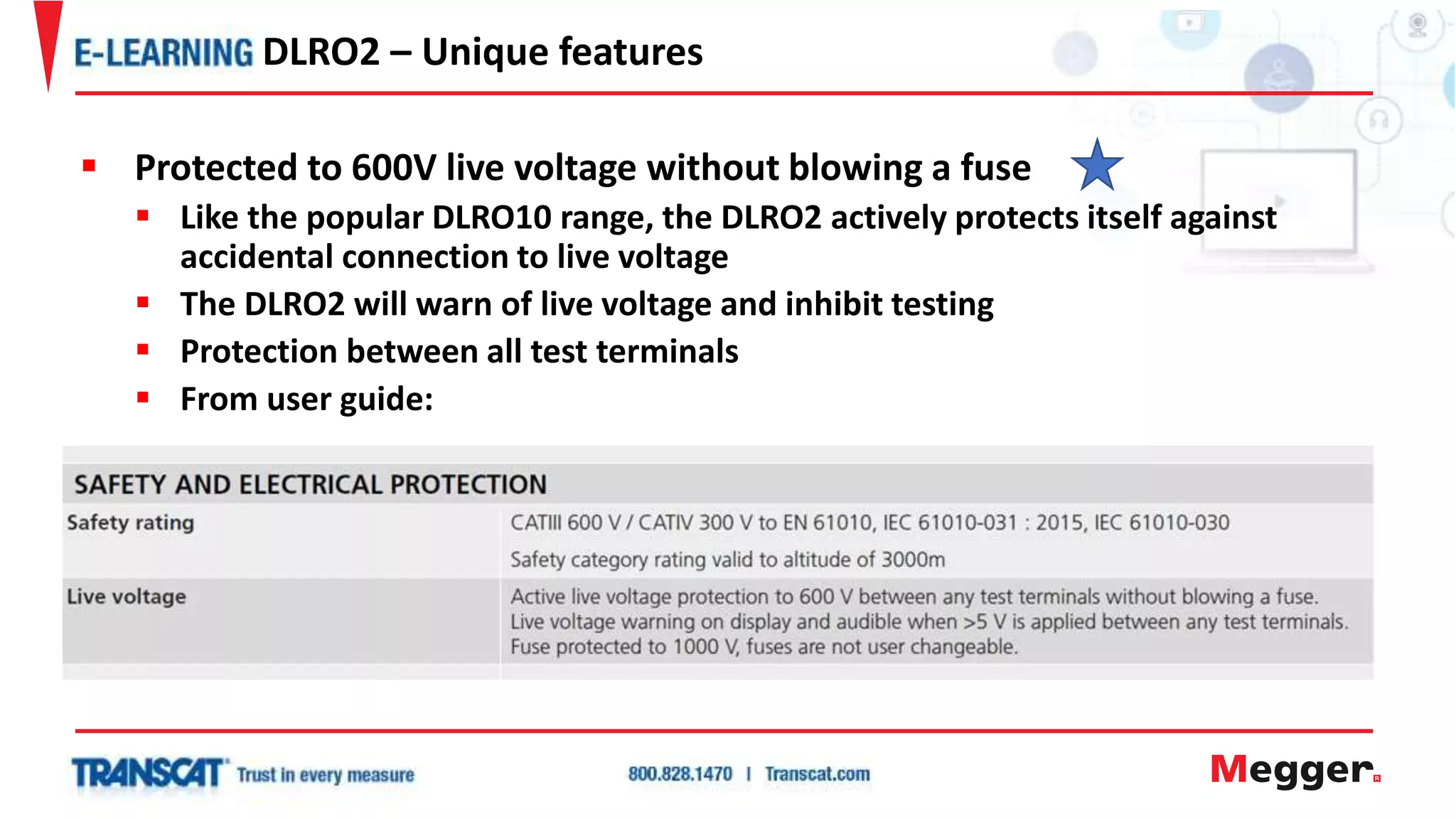

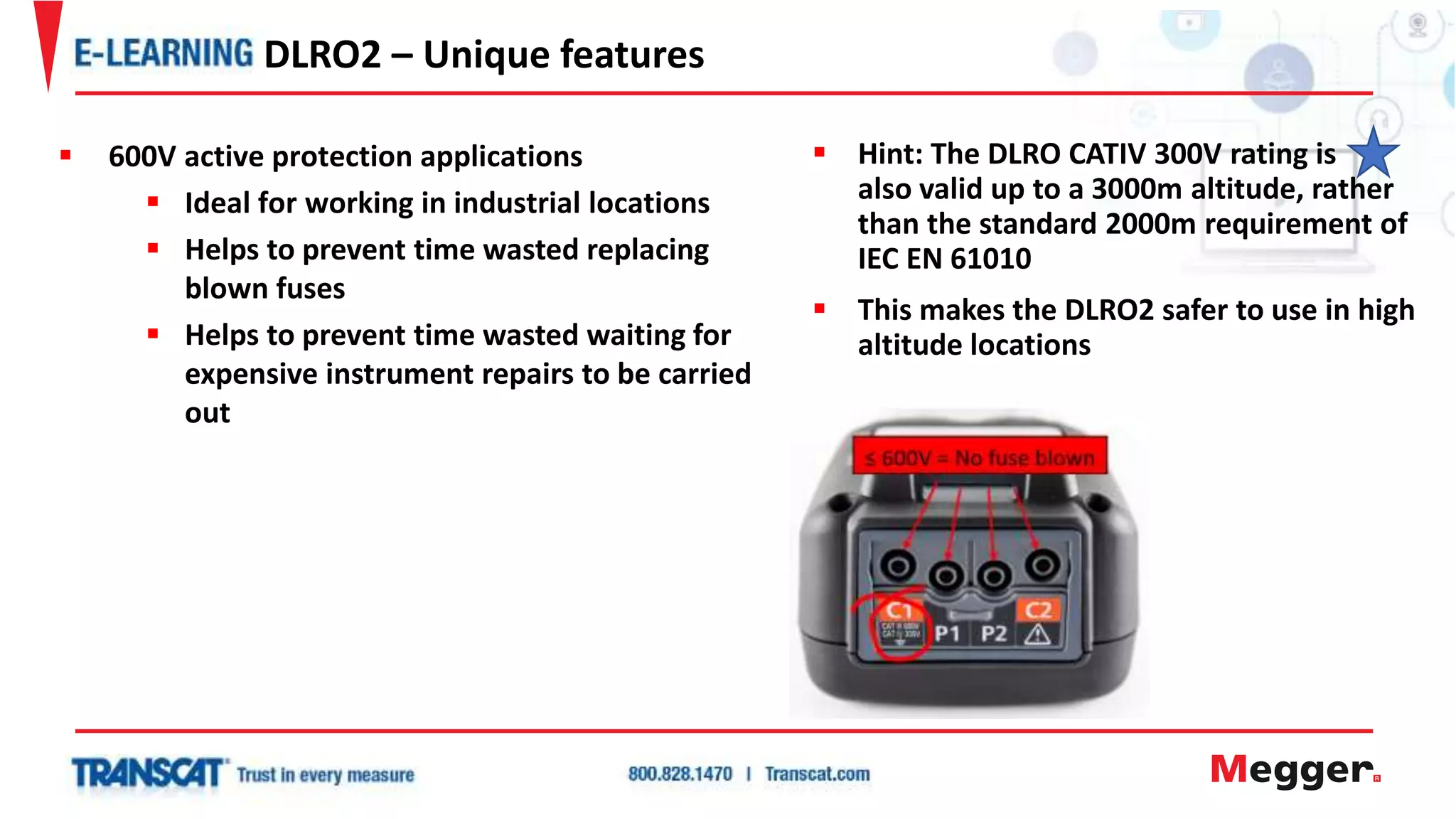

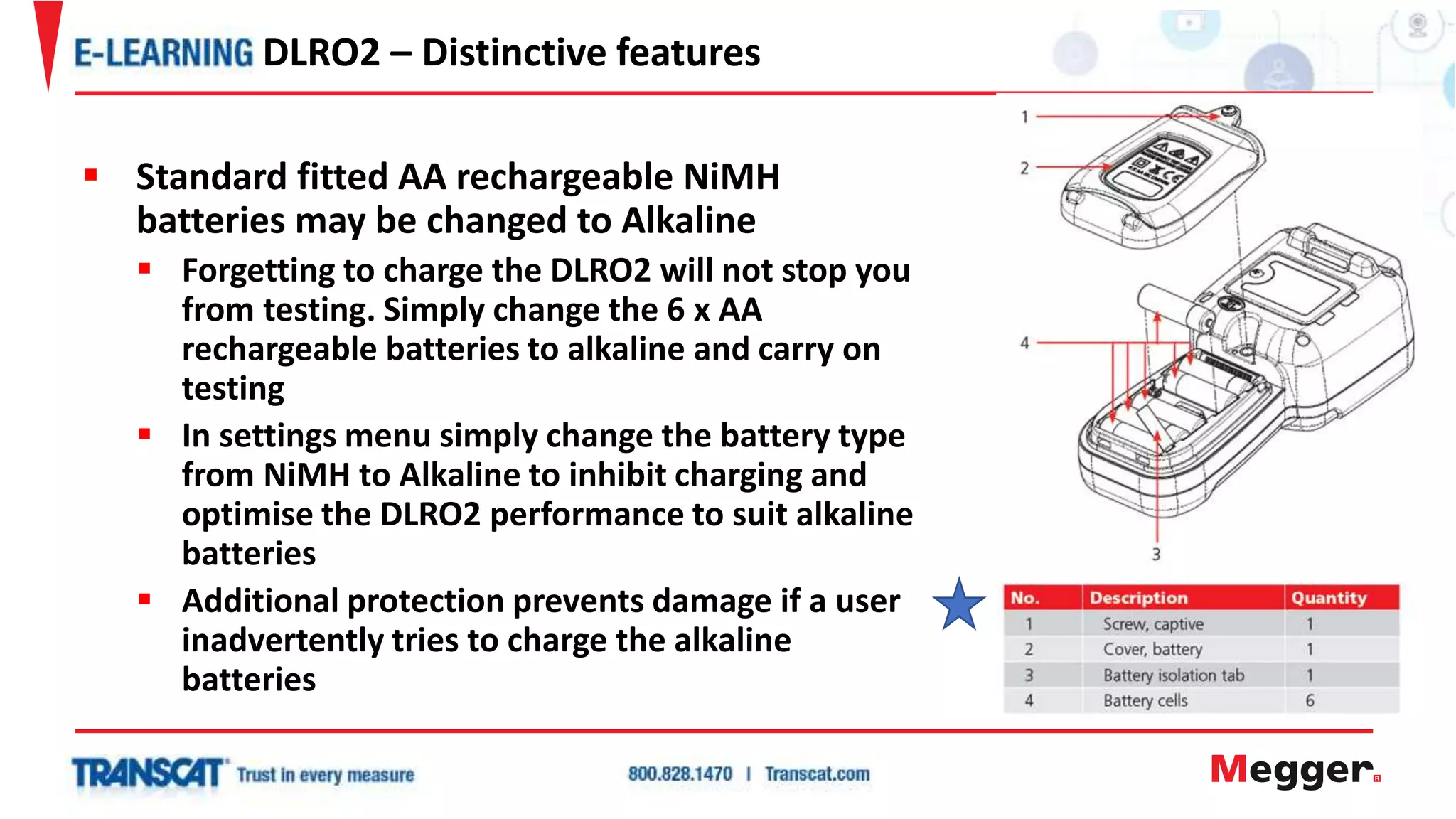

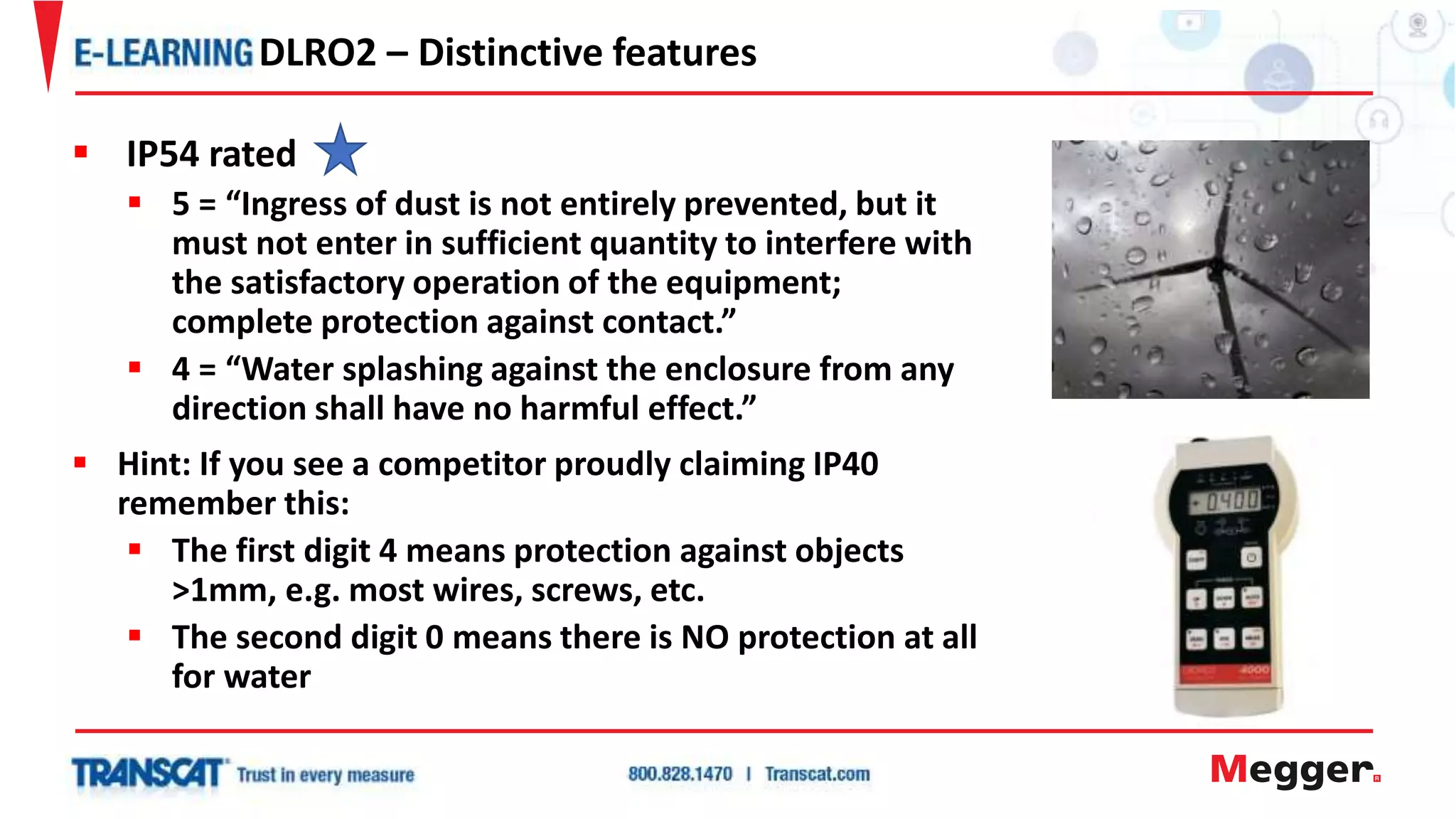

The document discusses the importance and applications of low resistance testing using the DLRO2 digital low resistance ohmmeter. It outlines the benefits of such testing, including preventing equipment damage and ensuring reliable electrical connections, while also highlighting various fields of application like power generation, manufacturing, and aircraft maintenance. Key features of the DLRO2, including its measurement capabilities and safety features, are also presented to demonstrate its effectiveness in identifying and diagnosing issues in electrical systems.