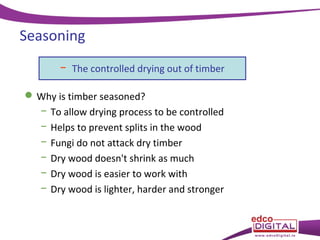

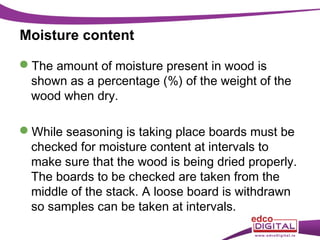

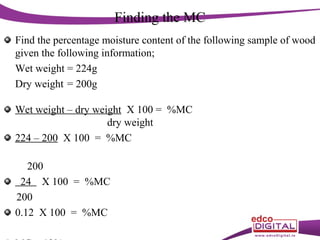

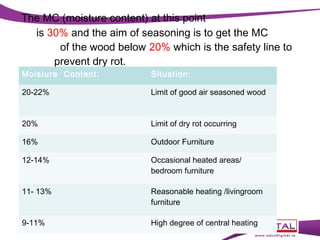

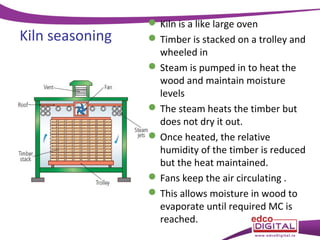

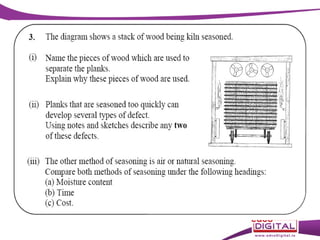

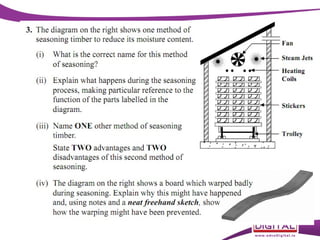

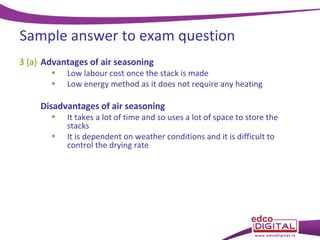

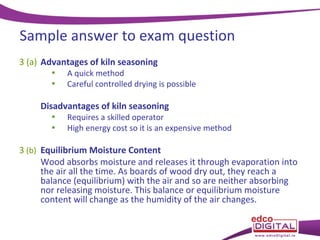

The document discusses seasoning wood. There are two main methods of seasoning timber: natural (air) seasoning and artificial (kiln) drying. Air seasoning is a slower process that relies on outdoor weather conditions, while kiln drying allows for faster, controlled drying in an indoor oven-like chamber. The goal of seasoning is to reduce wood's moisture content below 20% to prevent rot and make it easier to work with.