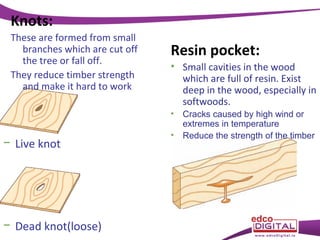

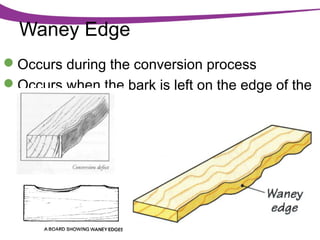

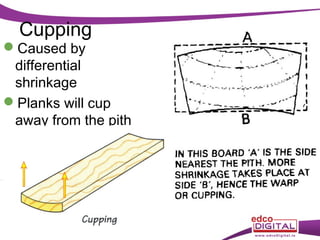

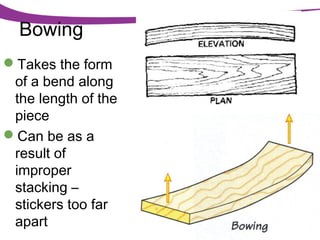

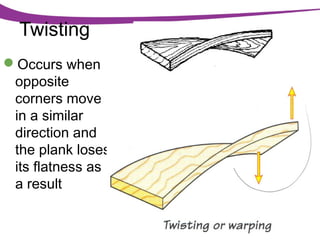

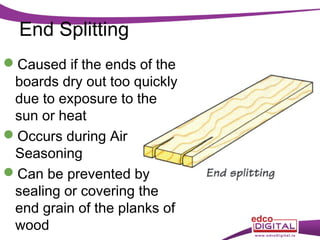

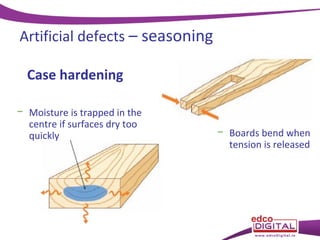

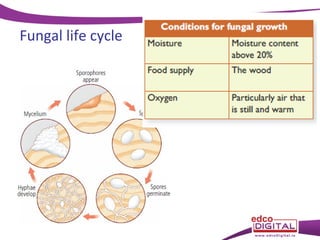

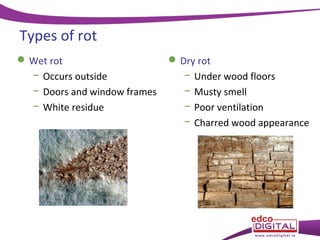

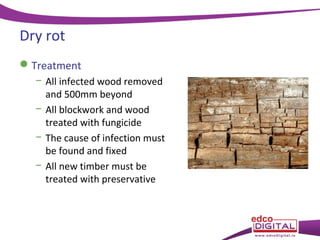

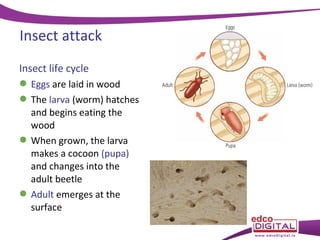

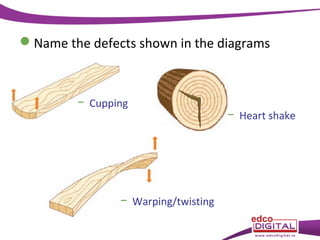

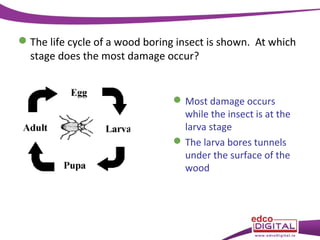

This document discusses defects and diseases that can occur in wood. It describes natural defects like knots, resin pockets, shakes and waney edges that form during tree growth. It also covers artificial defects such as cupping, bowing, twisting and end splitting caused by improper drying. Fungal diseases and insect pests that damage wood are also examined, along with conditions needed for decay. The life cycles of fungi and boring insects are detailed.